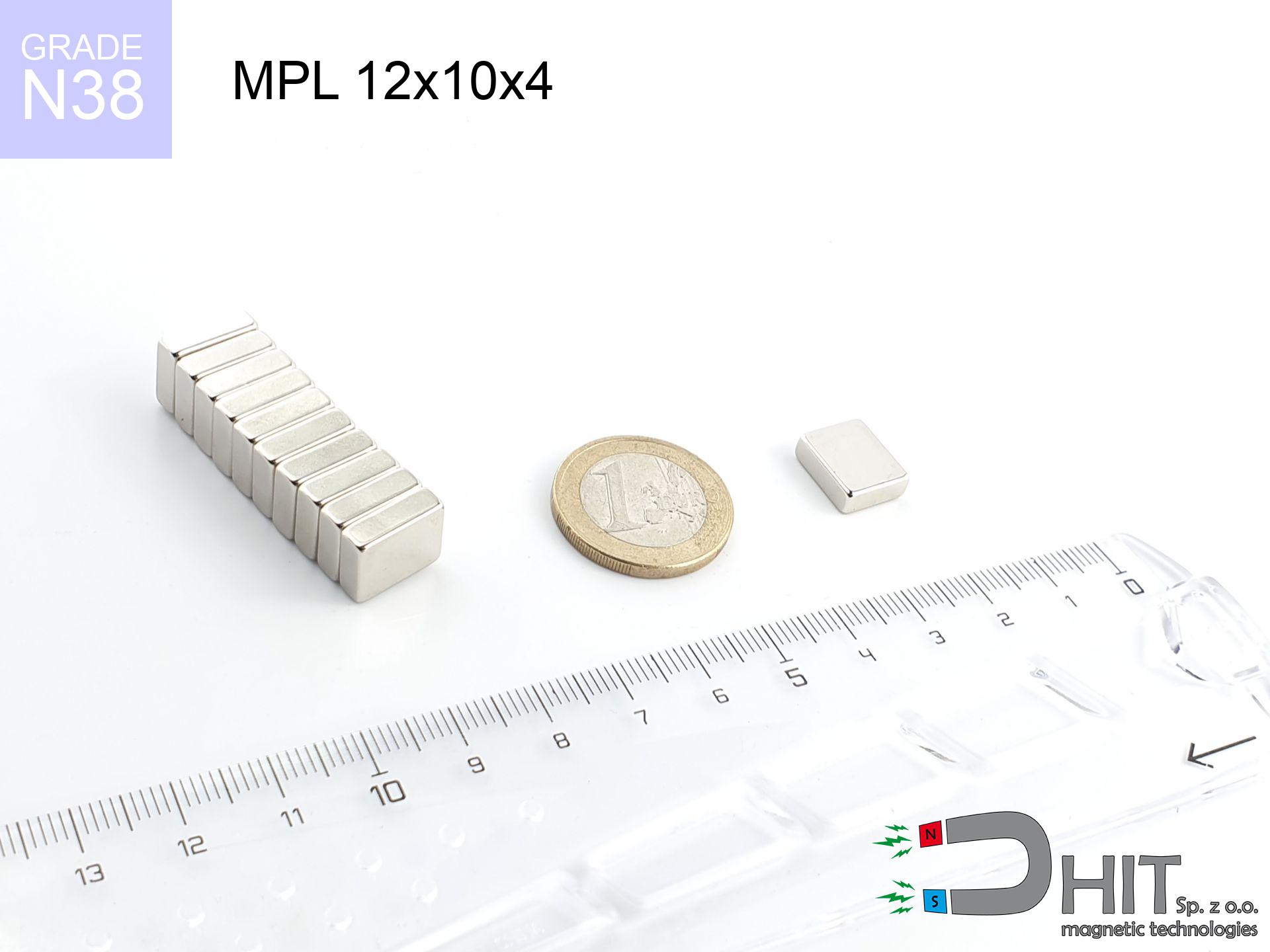

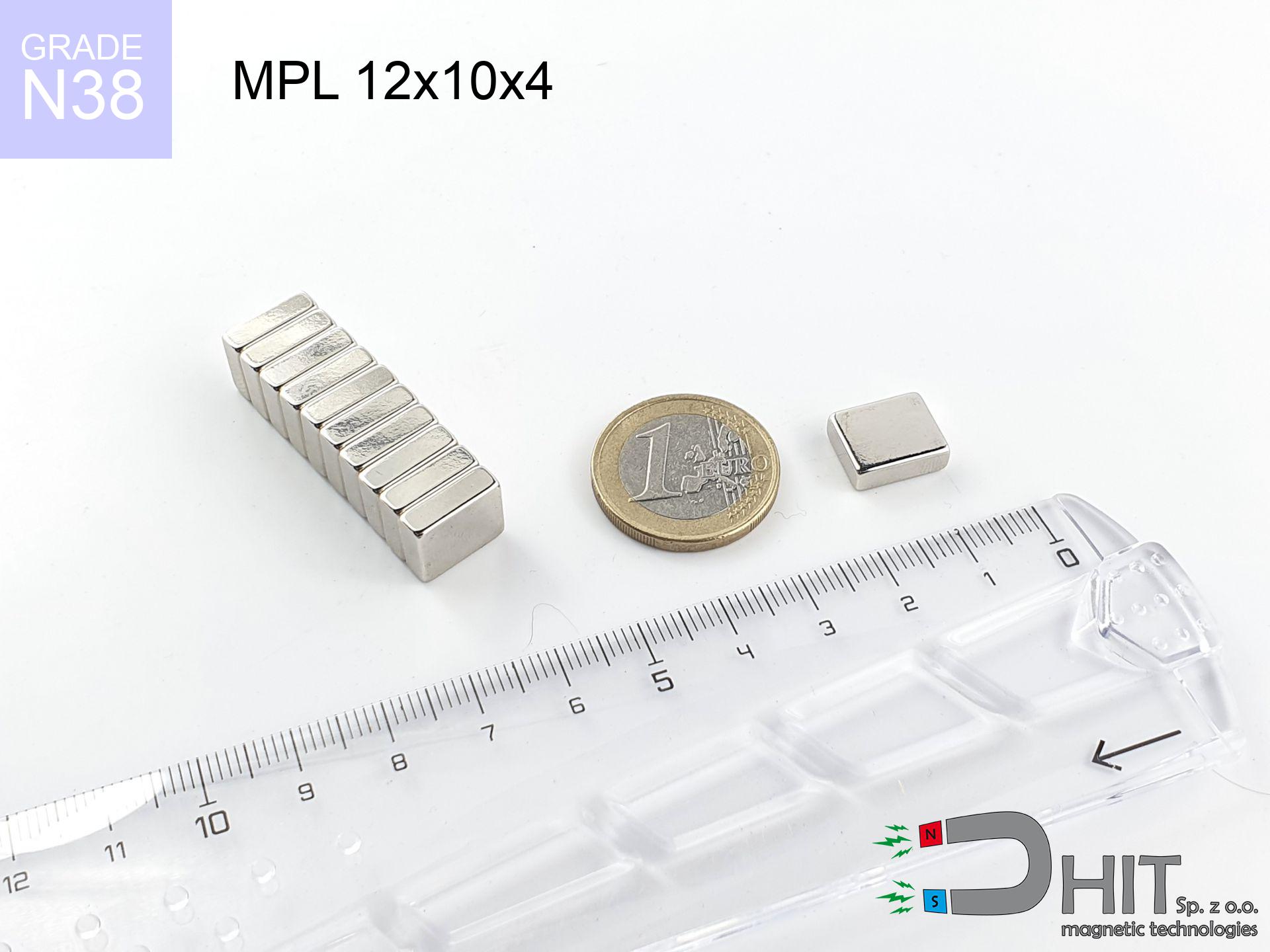

MPL 12x10x4 / N38 - lamellar magnet

lamellar magnet

Catalog no 020118

GTIN/EAN: 5906301811244

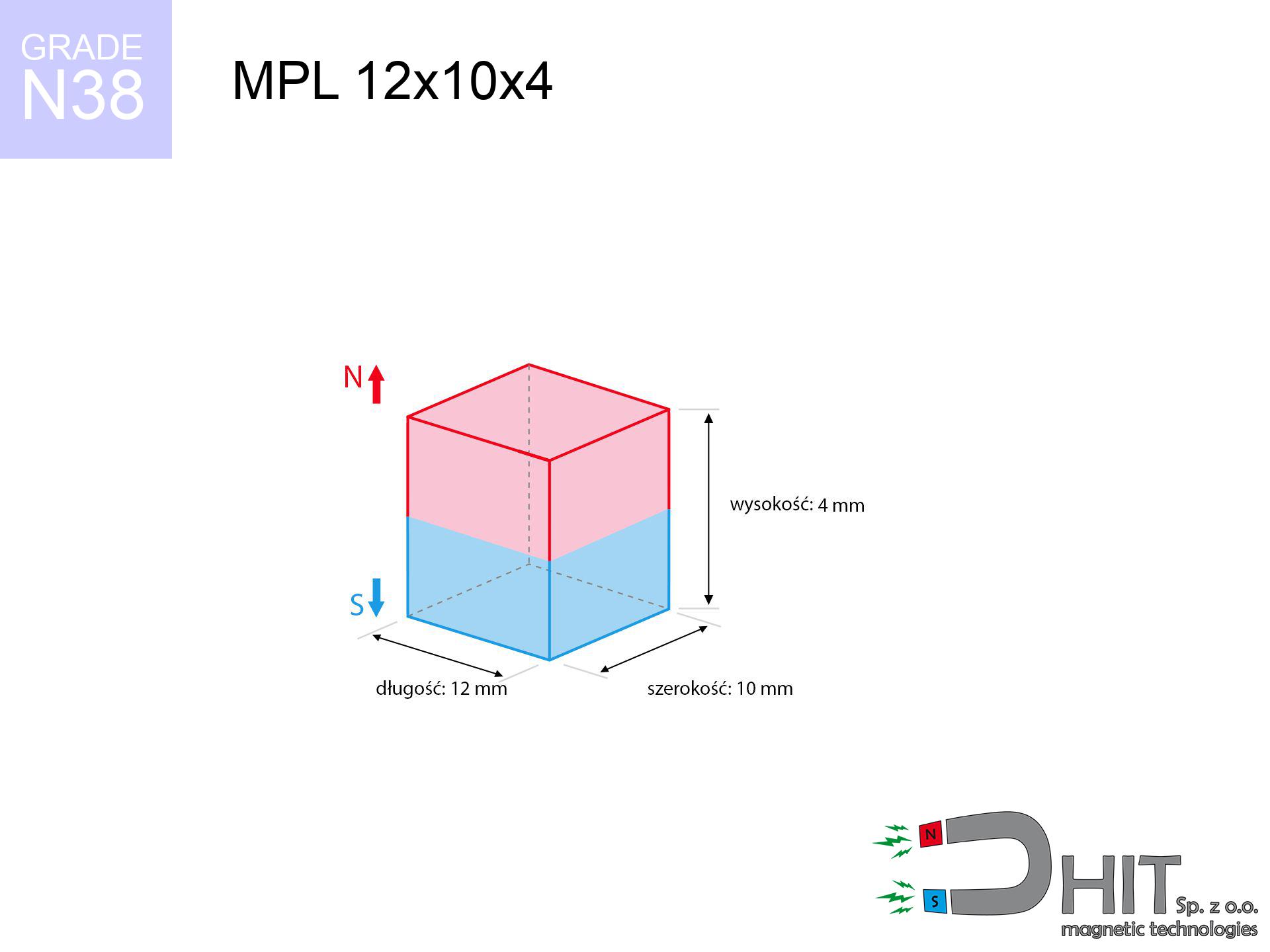

length

12 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

3.6 g

Magnetization Direction

↑ axial

Load capacity

3.45 kg / 33.88 N

Magnetic Induction

340.59 mT / 3406 Gs

Coating

[NiCuNi] Nickel

1.697 ZŁ with VAT / pcs + price for transport

1.380 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

if you prefer let us know using

inquiry form

the contact page.

Lifting power along with form of magnetic components can be checked with our

magnetic mass calculator.

Same-day shipping for orders placed before 14:00.

Technical - MPL 12x10x4 / N38 - lamellar magnet

Specification / characteristics - MPL 12x10x4 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020118 |

| GTIN/EAN | 5906301811244 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 12 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 3.6 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.45 kg / 33.88 N |

| Magnetic Induction ~ ? | 340.59 mT / 3406 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the assembly - technical parameters

The following information constitute the direct effect of a engineering simulation. Results were calculated on models for the material Nd2Fe14B. Real-world performance may differ. Use these data as a reference point during assembly planning.

Table 1: Static pull force (pull vs distance) - characteristics

MPL 12x10x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3404 Gs

340.4 mT

|

3.45 kg / 7.61 lbs

3450.0 g / 33.8 N

|

strong |

| 1 mm |

2920 Gs

292.0 mT

|

2.54 kg / 5.60 lbs

2538.8 g / 24.9 N

|

strong |

| 2 mm |

2399 Gs

239.9 mT

|

1.71 kg / 3.78 lbs

1713.7 g / 16.8 N

|

low risk |

| 3 mm |

1919 Gs

191.9 mT

|

1.10 kg / 2.42 lbs

1096.3 g / 10.8 N

|

low risk |

| 5 mm |

1190 Gs

119.0 mT

|

0.42 kg / 0.93 lbs

421.6 g / 4.1 N

|

low risk |

| 10 mm |

392 Gs

39.2 mT

|

0.05 kg / 0.10 lbs

45.7 g / 0.4 N

|

low risk |

| 15 mm |

162 Gs

16.2 mT

|

0.01 kg / 0.02 lbs

7.8 g / 0.1 N

|

low risk |

| 20 mm |

80 Gs

8.0 mT

|

0.00 kg / 0.00 lbs

1.9 g / 0.0 N

|

low risk |

| 30 mm |

27 Gs

2.7 mT

|

0.00 kg / 0.00 lbs

0.2 g / 0.0 N

|

low risk |

| 50 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

low risk |

Table 2: Sliding hold (wall)

MPL 12x10x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.69 kg / 1.52 lbs

690.0 g / 6.8 N

|

| 1 mm | Stal (~0.2) |

0.51 kg / 1.12 lbs

508.0 g / 5.0 N

|

| 2 mm | Stal (~0.2) |

0.34 kg / 0.75 lbs

342.0 g / 3.4 N

|

| 3 mm | Stal (~0.2) |

0.22 kg / 0.49 lbs

220.0 g / 2.2 N

|

| 5 mm | Stal (~0.2) |

0.08 kg / 0.19 lbs

84.0 g / 0.8 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

10.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MPL 12x10x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.04 kg / 2.28 lbs

1035.0 g / 10.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.69 kg / 1.52 lbs

690.0 g / 6.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.35 kg / 0.76 lbs

345.0 g / 3.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.73 kg / 3.80 lbs

1725.0 g / 16.9 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 12x10x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.35 kg / 0.76 lbs

345.0 g / 3.4 N

|

| 1 mm |

|

0.86 kg / 1.90 lbs

862.5 g / 8.5 N

|

| 2 mm |

|

1.73 kg / 3.80 lbs

1725.0 g / 16.9 N

|

| 3 mm |

|

2.59 kg / 5.70 lbs

2587.5 g / 25.4 N

|

| 5 mm |

|

3.45 kg / 7.61 lbs

3450.0 g / 33.8 N

|

| 10 mm |

|

3.45 kg / 7.61 lbs

3450.0 g / 33.8 N

|

| 11 mm |

|

3.45 kg / 7.61 lbs

3450.0 g / 33.8 N

|

| 12 mm |

|

3.45 kg / 7.61 lbs

3450.0 g / 33.8 N

|

Table 5: Thermal stability (stability) - power drop

MPL 12x10x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.45 kg / 7.61 lbs

3450.0 g / 33.8 N

|

OK |

| 40 °C | -2.2% |

3.37 kg / 7.44 lbs

3374.1 g / 33.1 N

|

OK |

| 60 °C | -4.4% |

3.30 kg / 7.27 lbs

3298.2 g / 32.4 N

|

|

| 80 °C | -6.6% |

3.22 kg / 7.10 lbs

3222.3 g / 31.6 N

|

|

| 100 °C | -28.8% |

2.46 kg / 5.42 lbs

2456.4 g / 24.1 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MPL 12x10x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

8.57 kg / 18.90 lbs

4 915 Gs

|

1.29 kg / 2.84 lbs

1286 g / 12.6 N

|

N/A |

| 1 mm |

7.46 kg / 16.44 lbs

6 349 Gs

|

1.12 kg / 2.47 lbs

1118 g / 11.0 N

|

6.71 kg / 14.79 lbs

~0 Gs

|

| 2 mm |

6.31 kg / 13.91 lbs

5 841 Gs

|

0.95 kg / 2.09 lbs

946 g / 9.3 N

|

5.68 kg / 12.52 lbs

~0 Gs

|

| 3 mm |

5.23 kg / 11.53 lbs

5 317 Gs

|

0.78 kg / 1.73 lbs

784 g / 7.7 N

|

4.71 kg / 10.37 lbs

~0 Gs

|

| 5 mm |

3.42 kg / 7.55 lbs

4 302 Gs

|

0.51 kg / 1.13 lbs

513 g / 5.0 N

|

3.08 kg / 6.79 lbs

~0 Gs

|

| 10 mm |

1.05 kg / 2.31 lbs

2 380 Gs

|

0.16 kg / 0.35 lbs

157 g / 1.5 N

|

0.94 kg / 2.08 lbs

~0 Gs

|

| 20 mm |

0.11 kg / 0.25 lbs

784 Gs

|

0.02 kg / 0.04 lbs

17 g / 0.2 N

|

0.10 kg / 0.23 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

90 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

55 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

36 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

25 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

18 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

13 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MPL 12x10x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - collision effects

MPL 12x10x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

31.48 km/h

(8.74 m/s)

|

0.14 J | |

| 30 mm |

54.08 km/h

(15.02 m/s)

|

0.41 J | |

| 50 mm |

69.81 km/h

(19.39 m/s)

|

0.68 J | |

| 100 mm |

98.73 km/h

(27.42 m/s)

|

1.35 J |

Table 9: Corrosion resistance

MPL 12x10x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 12x10x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 4 295 Mx | 42.9 µWb |

| Pc Coefficient | 0.43 | Low (Flat) |

Table 11: Submerged application

MPL 12x10x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.45 kg | Standard |

| Water (riverbed) |

3.95 kg

(+0.50 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical surface, the magnet holds only a fraction of its perpendicular strength.

2. Steel thickness impact

*Thin metal sheet (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Power loss vs temp

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.43

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also products

Pros as well as cons of Nd2Fe14B magnets.

Advantages

- They have stable power, and over more than 10 years their performance decreases symbolically – ~1% (in testing),

- They do not lose their magnetic properties even under close interference source,

- A magnet with a smooth gold surface is more attractive,

- Neodymium magnets ensure maximum magnetic induction on a small surface, which ensures high operational effectiveness,

- Thanks to resistance to high temperature, they are capable of working (depending on the shape) even at temperatures up to 230°C and higher...

- Due to the possibility of flexible molding and customization to individualized projects, neodymium magnets can be manufactured in a variety of shapes and sizes, which amplifies use scope,

- Significant place in advanced technology sectors – they are utilized in mass storage devices, electric drive systems, advanced medical instruments, as well as technologically advanced constructions.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Cons

- Susceptibility to cracking is one of their disadvantages. Upon strong impact they can fracture. We advise keeping them in a strong case, which not only secures them against impacts but also raises their durability

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They rust in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- Limited ability of creating nuts in the magnet and complicated forms - recommended is a housing - magnet mounting.

- Potential hazard to health – tiny shards of magnets pose a threat, when accidentally swallowed, which becomes key in the aspect of protecting the youngest. It is also worth noting that small elements of these devices are able to disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Magnetic strength at its maximum – what contributes to it?

- on a block made of mild steel, optimally conducting the magnetic flux

- with a cross-section of at least 10 mm

- characterized by lack of roughness

- without any clearance between the magnet and steel

- under axial application of breakaway force (90-degree angle)

- in stable room temperature

Key elements affecting lifting force

- Distance – the presence of foreign body (rust, dirt, gap) interrupts the magnetic circuit, which reduces power rapidly (even by 50% at 0.5 mm).

- Force direction – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Steel thickness – too thin plate does not close the flux, causing part of the flux to be escaped into the air.

- Steel grade – the best choice is high-permeability steel. Cast iron may generate lower lifting capacity.

- Smoothness – ideal contact is obtained only on polished steel. Any scratches and bumps create air cushions, weakening the magnet.

- Heat – neodymium magnets have a negative temperature coefficient. When it is hot they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Lifting capacity was assessed using a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular pulling force, whereas under parallel forces the holding force is lower. In addition, even a minimal clearance between the magnet and the plate decreases the lifting capacity.

Safe handling of NdFeB magnets

Avoid contact if allergic

Medical facts indicate that the nickel plating (the usual finish) is a common allergen. If your skin reacts to metals, avoid direct skin contact and select coated magnets.

Impact on smartphones

GPS units and smartphones are extremely sensitive to magnetism. Close proximity with a strong magnet can decalibrate the sensors in your phone.

This is not a toy

Absolutely keep magnets out of reach of children. Risk of swallowing is high, and the consequences of magnets clamping inside the body are life-threatening.

Heat sensitivity

Keep cool. NdFeB magnets are susceptible to heat. If you require operation above 80°C, inquire about special high-temperature series (H, SH, UH).

Handling guide

Handle magnets with awareness. Their huge power can shock even experienced users. Stay alert and do not underestimate their power.

Mechanical processing

Powder generated during grinding of magnets is flammable. Do not drill into magnets without proper cooling and knowledge.

Data carriers

Avoid bringing magnets close to a wallet, laptop, or screen. The magnetism can destroy these devices and wipe information from cards.

Physical harm

Protect your hands. Two powerful magnets will join instantly with a force of several hundred kilograms, destroying anything in their path. Exercise extreme caution!

ICD Warning

People with a pacemaker have to keep an safe separation from magnets. The magnetism can stop the functioning of the life-saving device.

Beware of splinters

NdFeB magnets are ceramic materials, which means they are fragile like glass. Clashing of two magnets will cause them breaking into shards.

![UMGW 48x24x11.5 [M8] GW / N38 - magnetic holder internal thread UMGW 48x24x11.5 [M8] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/umgw-48x24x11.5-m8-gw-val.jpg)

![UI 45x13x6 [Z323] / N38 - badge holder UI 45x13x6 [Z323] / N38 - badge holder](https://cdn3.dhit.pl/graphics/products/ui45x13x6-z323-fap.jpg)

![HH 42x8.8 [M6] / N38 - through hole magnetic holder HH 42x8.8 [M6] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-42x8.8-m6-hin.jpg)