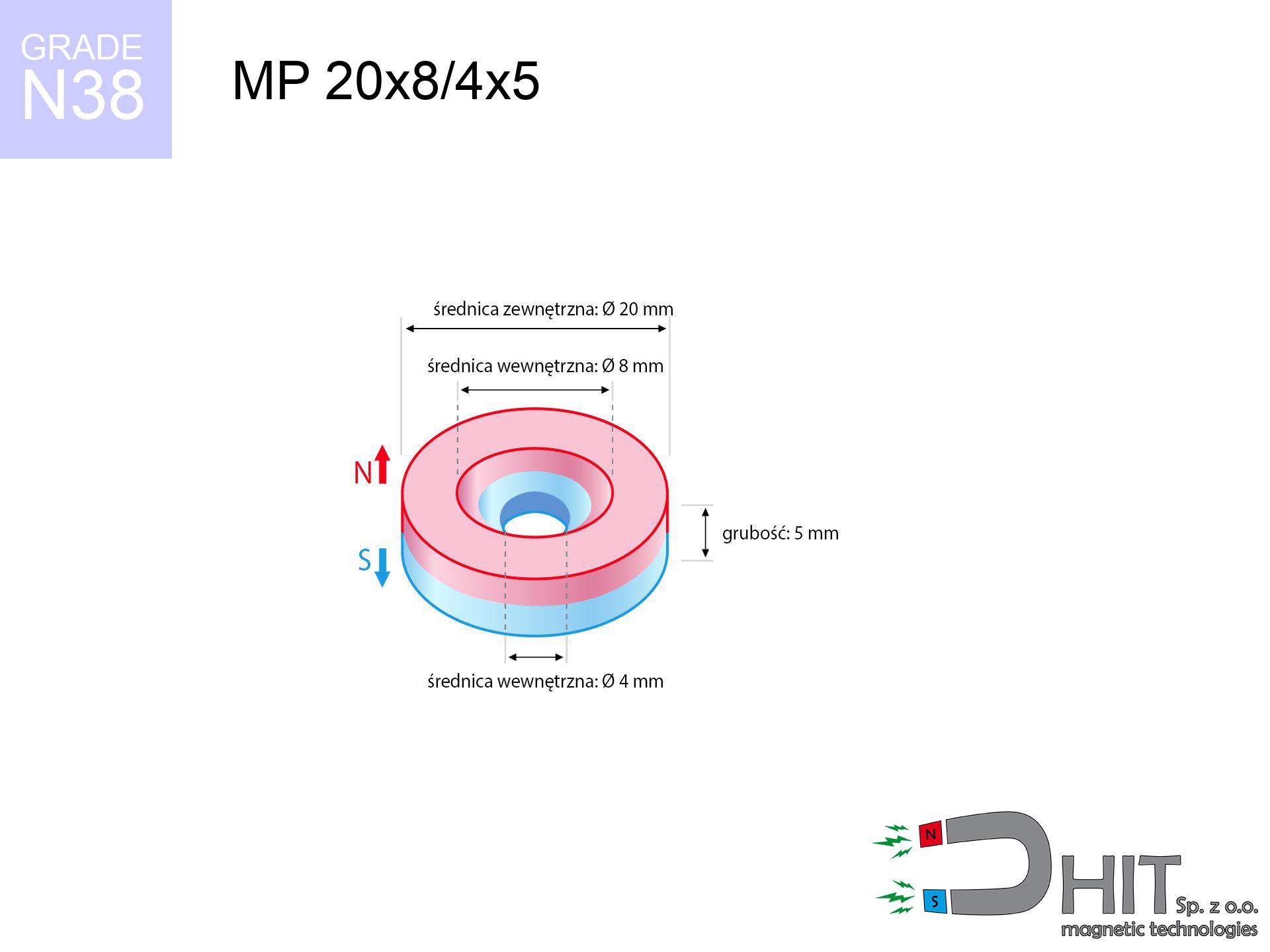

MP 20x8/4x5 / N38 - ring magnet

ring magnet

Catalog no 030333

GTIN/EAN: 5906301812272

Diameter

20 mm [±0,1 mm]

internal diameter Ø

8/4 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

11.31 g

Magnetization Direction

↑ axial

Load capacity

6.65 kg / 65.21 N

Magnetic Induction

277.16 mT / 2772 Gs

Coating

[NiCuNi] Nickel

7.75 ZŁ with VAT / pcs + price for transport

6.30 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

otherwise contact us by means of

our online form

our website.

Strength as well as form of a magnet can be analyzed using our

power calculator.

Orders submitted before 14:00 will be dispatched today!

Product card - MP 20x8/4x5 / N38 - ring magnet

Specification / characteristics - MP 20x8/4x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030333 |

| GTIN/EAN | 5906301812272 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 20 mm [±0,1 mm] |

| internal diameter Ø | 8/4 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 11.31 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 6.65 kg / 65.21 N |

| Magnetic Induction ~ ? | 277.16 mT / 2772 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - report

The following values constitute the outcome of a engineering simulation. Results rely on algorithms for the material Nd2Fe14B. Real-world performance may deviate from the simulation results. Use these calculations as a preliminary roadmap when designing systems.

Table 1: Static force (force vs gap) - characteristics

MP 20x8/4x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2424 Gs

242.4 mT

|

6.65 kg / 14.66 LBS

6650.0 g / 65.2 N

|

medium risk |

| 1 mm |

2265 Gs

226.5 mT

|

5.81 kg / 12.80 LBS

5807.9 g / 57.0 N

|

medium risk |

| 2 mm |

2070 Gs

207.0 mT

|

4.85 kg / 10.69 LBS

4851.0 g / 47.6 N

|

medium risk |

| 3 mm |

1858 Gs

185.8 mT

|

3.91 kg / 8.61 LBS

3906.5 g / 38.3 N

|

medium risk |

| 5 mm |

1437 Gs

143.7 mT

|

2.34 kg / 5.16 LBS

2338.7 g / 22.9 N

|

medium risk |

| 10 mm |

691 Gs

69.1 mT

|

0.54 kg / 1.19 LBS

540.5 g / 5.3 N

|

weak grip |

| 15 mm |

343 Gs

34.3 mT

|

0.13 kg / 0.29 LBS

133.3 g / 1.3 N

|

weak grip |

| 20 mm |

186 Gs

18.6 mT

|

0.04 kg / 0.09 LBS

39.3 g / 0.4 N

|

weak grip |

| 30 mm |

70 Gs

7.0 mT

|

0.01 kg / 0.01 LBS

5.5 g / 0.1 N

|

weak grip |

| 50 mm |

18 Gs

1.8 mT

|

0.00 kg / 0.00 LBS

0.4 g / 0.0 N

|

weak grip |

Table 2: Sliding capacity (wall)

MP 20x8/4x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.33 kg / 2.93 LBS

1330.0 g / 13.0 N

|

| 1 mm | Stal (~0.2) |

1.16 kg / 2.56 LBS

1162.0 g / 11.4 N

|

| 2 mm | Stal (~0.2) |

0.97 kg / 2.14 LBS

970.0 g / 9.5 N

|

| 3 mm | Stal (~0.2) |

0.78 kg / 1.72 LBS

782.0 g / 7.7 N

|

| 5 mm | Stal (~0.2) |

0.47 kg / 1.03 LBS

468.0 g / 4.6 N

|

| 10 mm | Stal (~0.2) |

0.11 kg / 0.24 LBS

108.0 g / 1.1 N

|

| 15 mm | Stal (~0.2) |

0.03 kg / 0.06 LBS

26.0 g / 0.3 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.02 LBS

8.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MP 20x8/4x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.00 kg / 4.40 LBS

1995.0 g / 19.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.33 kg / 2.93 LBS

1330.0 g / 13.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.67 kg / 1.47 LBS

665.0 g / 6.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.33 kg / 7.33 LBS

3325.0 g / 32.6 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MP 20x8/4x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.67 kg / 1.47 LBS

665.0 g / 6.5 N

|

| 1 mm |

|

1.66 kg / 3.67 LBS

1662.5 g / 16.3 N

|

| 2 mm |

|

3.33 kg / 7.33 LBS

3325.0 g / 32.6 N

|

| 3 mm |

|

4.99 kg / 11.00 LBS

4987.5 g / 48.9 N

|

| 5 mm |

|

6.65 kg / 14.66 LBS

6650.0 g / 65.2 N

|

| 10 mm |

|

6.65 kg / 14.66 LBS

6650.0 g / 65.2 N

|

| 11 mm |

|

6.65 kg / 14.66 LBS

6650.0 g / 65.2 N

|

| 12 mm |

|

6.65 kg / 14.66 LBS

6650.0 g / 65.2 N

|

Table 5: Thermal stability (material behavior) - resistance threshold

MP 20x8/4x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

6.65 kg / 14.66 LBS

6650.0 g / 65.2 N

|

OK |

| 40 °C | -2.2% |

6.50 kg / 14.34 LBS

6503.7 g / 63.8 N

|

OK |

| 60 °C | -4.4% |

6.36 kg / 14.02 LBS

6357.4 g / 62.4 N

|

|

| 80 °C | -6.6% |

6.21 kg / 13.69 LBS

6211.1 g / 60.9 N

|

|

| 100 °C | -28.8% |

4.73 kg / 10.44 LBS

4734.8 g / 46.4 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MP 20x8/4x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

9.28 kg / 20.47 LBS

4 012 Gs

|

1.39 kg / 3.07 LBS

1393 g / 13.7 N

|

N/A |

| 1 mm |

8.73 kg / 19.25 LBS

4 701 Gs

|

1.31 kg / 2.89 LBS

1310 g / 12.8 N

|

7.86 kg / 17.33 LBS

~0 Gs

|

| 2 mm |

8.11 kg / 17.88 LBS

4 530 Gs

|

1.22 kg / 2.68 LBS

1216 g / 11.9 N

|

7.30 kg / 16.09 LBS

~0 Gs

|

| 3 mm |

7.45 kg / 16.42 LBS

4 342 Gs

|

1.12 kg / 2.46 LBS

1117 g / 11.0 N

|

6.70 kg / 14.78 LBS

~0 Gs

|

| 5 mm |

6.10 kg / 13.45 LBS

3 930 Gs

|

0.92 kg / 2.02 LBS

915 g / 9.0 N

|

5.49 kg / 12.11 LBS

~0 Gs

|

| 10 mm |

3.27 kg / 7.20 LBS

2 875 Gs

|

0.49 kg / 1.08 LBS

490 g / 4.8 N

|

2.94 kg / 6.48 LBS

~0 Gs

|

| 20 mm |

0.75 kg / 1.66 LBS

1 382 Gs

|

0.11 kg / 0.25 LBS

113 g / 1.1 N

|

0.68 kg / 1.50 LBS

~0 Gs

|

| 50 mm |

0.02 kg / 0.04 LBS

220 Gs

|

0.00 kg / 0.01 LBS

3 g / 0.0 N

|

0.02 kg / 0.04 LBS

~0 Gs

|

| 60 mm |

0.01 kg / 0.02 LBS

139 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.01 LBS

93 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

65 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

47 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

35 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (implants) - warnings

MP 20x8/4x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 8.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 5.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 4.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (cracking risk) - collision effects

MP 20x8/4x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

25.67 km/h

(7.13 m/s)

|

0.29 J | |

| 30 mm |

42.38 km/h

(11.77 m/s)

|

0.78 J | |

| 50 mm |

54.68 km/h

(15.19 m/s)

|

1.30 J | |

| 100 mm |

77.33 km/h

(21.48 m/s)

|

2.61 J |

Table 9: Corrosion resistance

MP 20x8/4x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MP 20x8/4x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 7 218 Mx | 72.2 µWb |

| Pc Coefficient | 0.31 | Low (Flat) |

Table 11: Submerged application

MP 20x8/4x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 6.65 kg | Standard |

| Water (riverbed) |

7.61 kg

(+0.96 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical wall, the magnet holds just approx. 20-30% of its max power.

2. Efficiency vs thickness

*Thin metal sheet (e.g. 0.5mm PC case) severely reduces the holding force.

3. Power loss vs temp

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.31

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more offers

Strengths as well as weaknesses of rare earth magnets.

Advantages

- They retain attractive force for nearly ten years – the loss is just ~1% (based on simulations),

- They do not lose their magnetic properties even under external field action,

- A magnet with a shiny gold surface is more attractive,

- Magnets possess maximum magnetic induction on the working surface,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of individual forming and adjusting to complex conditions,

- Versatile presence in high-tech industry – they find application in magnetic memories, brushless drives, medical equipment, also other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in tiny dimensions, which allows their use in compact constructions

Limitations

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We advise keeping them in a strong case, which not only protects them against impacts but also raises their durability

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation and corrosion.

- Due to limitations in realizing threads and complicated shapes in magnets, we recommend using cover - magnetic mount.

- Possible danger resulting from small fragments of magnets are risky, when accidentally swallowed, which is particularly important in the context of child safety. It is also worth noting that tiny parts of these products can be problematic in diagnostics medical after entering the body.

- With mass production the cost of neodymium magnets is a challenge,

Holding force characteristics

Best holding force of the magnet in ideal parameters – what contributes to it?

- on a plate made of mild steel, effectively closing the magnetic field

- whose transverse dimension is min. 10 mm

- characterized by lack of roughness

- with direct contact (without paint)

- under vertical force vector (90-degree angle)

- at ambient temperature room level

Determinants of lifting force in real conditions

- Distance – existence of foreign body (rust, dirt, gap) interrupts the magnetic circuit, which lowers power rapidly (even by 50% at 0.5 mm).

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Wall thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of generating force.

- Material type – ideal substrate is high-permeability steel. Cast iron may attract less.

- Surface condition – smooth surfaces ensure maximum contact, which increases field saturation. Rough surfaces weaken the grip.

- Thermal conditions – NdFeB sinters have a sensitivity to temperature. When it is hot they are weaker, and at low temperatures they can be stronger (up to a certain limit).

Holding force was tested on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, whereas under shearing force the holding force is lower. In addition, even a slight gap between the magnet and the plate decreases the holding force.

Safe handling of neodymium magnets

Magnets are brittle

Beware of splinters. Magnets can fracture upon violent connection, launching sharp fragments into the air. Wear goggles.

Compass and GPS

Be aware: neodymium magnets produce a field that confuses precision electronics. Maintain a separation from your mobile, tablet, and GPS.

Safe operation

Before use, read the rules. Sudden snapping can break the magnet or hurt your hand. Be predictive.

Bodily injuries

Mind your fingers. Two large magnets will snap together immediately with a force of several hundred kilograms, destroying anything in their path. Be careful!

Threat to electronics

Avoid bringing magnets close to a wallet, laptop, or TV. The magnetism can permanently damage these devices and wipe information from cards.

Mechanical processing

Drilling and cutting of NdFeB material poses a fire hazard. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Demagnetization risk

Regular neodymium magnets (N-type) undergo demagnetization when the temperature exceeds 80°C. This process is irreversible.

Medical implants

For implant holders: Strong magnetic fields disrupt electronics. Keep minimum 30 cm distance or request help to handle the magnets.

Danger to the youngest

Product intended for adults. Tiny parts can be swallowed, causing intestinal necrosis. Keep out of reach of kids and pets.

Allergic reactions

A percentage of the population have a hypersensitivity to nickel, which is the typical protective layer for NdFeB magnets. Prolonged contact may cause a rash. We suggest use safety gloves.