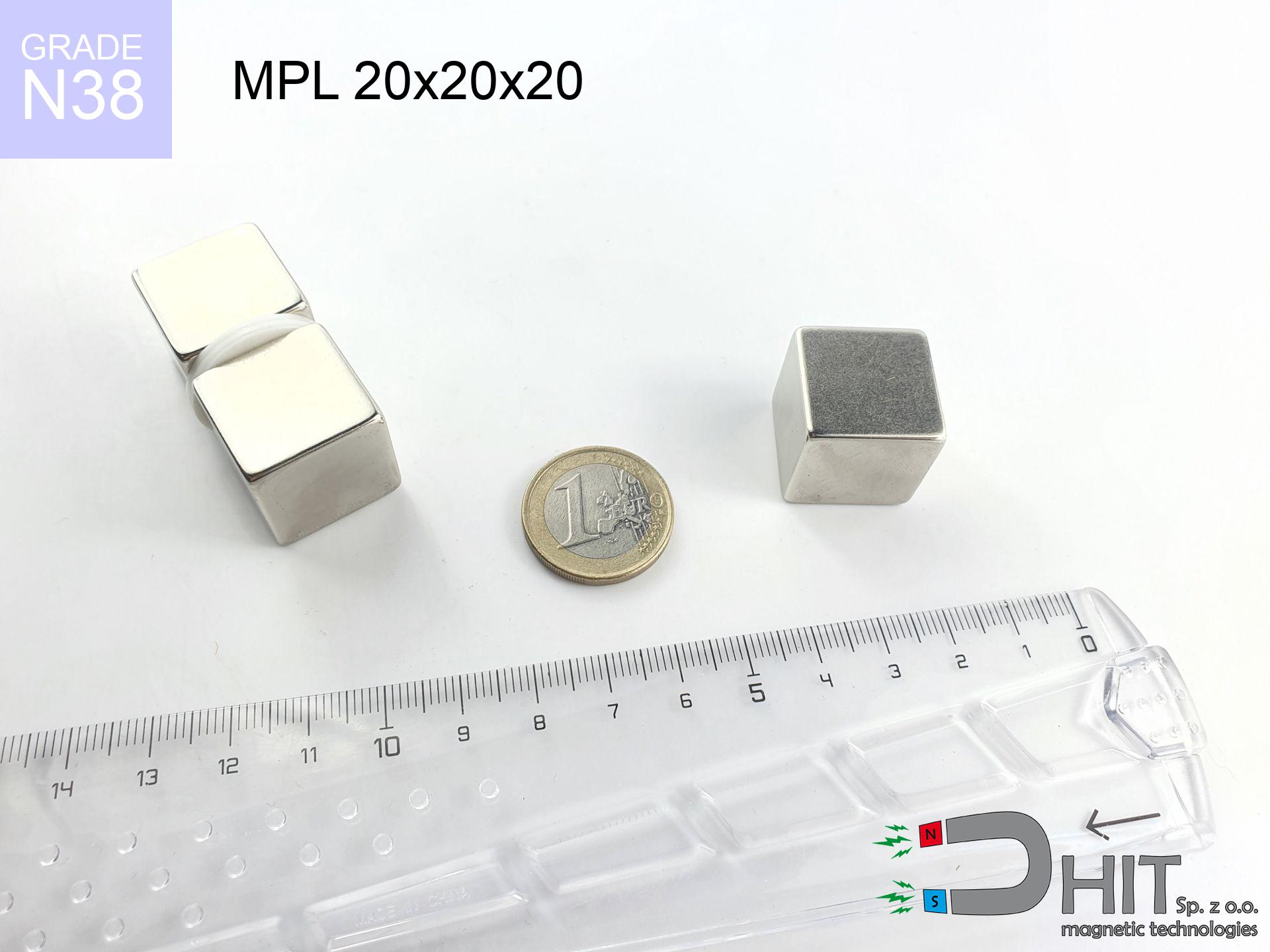

MPL 20x20x20 / N38 - lamellar magnet

lamellar magnet

Catalog no 020129

GTIN/EAN: 5906301811350

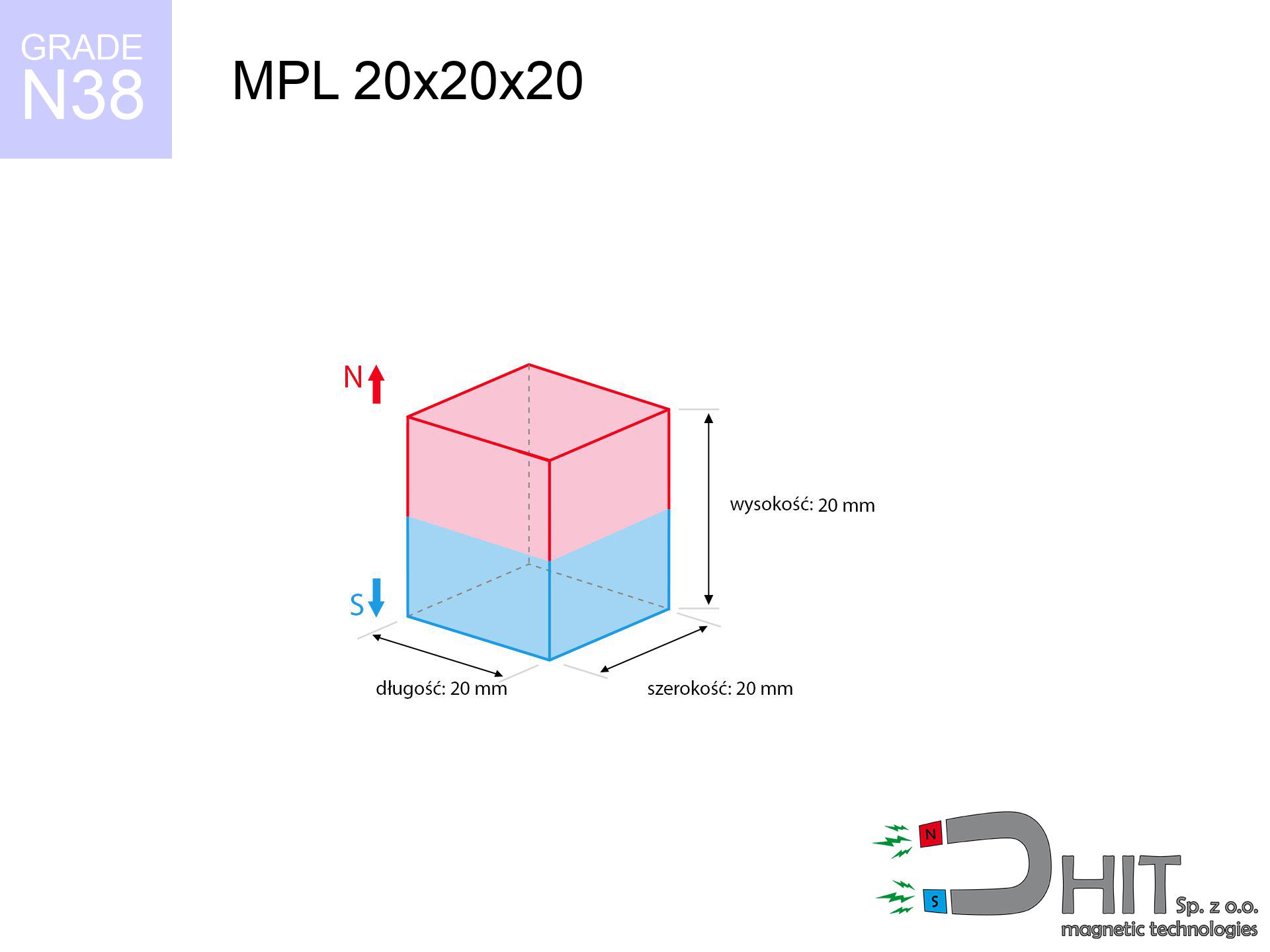

length

20 mm [±0,1 mm]

Width

20 mm [±0,1 mm]

Height

20 mm [±0,1 mm]

Weight

60 g

Magnetization Direction

↑ axial

Load capacity

15.40 kg / 151.12 N

Magnetic Induction

540.22 mT / 5402 Gs

Coating

[NiCuNi] Nickel

33.21 ZŁ with VAT / pcs + price for transport

27.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

otherwise contact us by means of

form

our website.

Parameters and shape of a neodymium magnet can be reviewed with our

force calculator.

Same-day shipping for orders placed before 14:00.

Technical specification - MPL 20x20x20 / N38 - lamellar magnet

Specification / characteristics - MPL 20x20x20 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020129 |

| GTIN/EAN | 5906301811350 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 20 mm [±0,1 mm] |

| Width | 20 mm [±0,1 mm] |

| Height | 20 mm [±0,1 mm] |

| Weight | 60 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 15.40 kg / 151.12 N |

| Magnetic Induction ~ ? | 540.22 mT / 5402 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the magnet - data

The following data represent the result of a mathematical simulation. Results are based on models for the class Nd2Fe14B. Actual parameters might slightly deviate from the simulation results. Use these data as a reference point during assembly planning.

Table 1: Static force (force vs distance) - characteristics

MPL 20x20x20 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5400 Gs

540.0 mT

|

15.40 kg / 33.95 pounds

15400.0 g / 151.1 N

|

critical level |

| 1 mm |

4910 Gs

491.0 mT

|

12.73 kg / 28.07 pounds

12732.2 g / 124.9 N

|

critical level |

| 2 mm |

4423 Gs

442.3 mT

|

10.33 kg / 22.77 pounds

10328.3 g / 101.3 N

|

critical level |

| 3 mm |

3955 Gs

395.5 mT

|

8.26 kg / 18.21 pounds

8258.3 g / 81.0 N

|

warning |

| 5 mm |

3114 Gs

311.4 mT

|

5.12 kg / 11.29 pounds

5120.3 g / 50.2 N

|

warning |

| 10 mm |

1671 Gs

167.1 mT

|

1.48 kg / 3.25 pounds

1475.0 g / 14.5 N

|

low risk |

| 15 mm |

936 Gs

93.6 mT

|

0.46 kg / 1.02 pounds

463.0 g / 4.5 N

|

low risk |

| 20 mm |

562 Gs

56.2 mT

|

0.17 kg / 0.37 pounds

167.1 g / 1.6 N

|

low risk |

| 30 mm |

244 Gs

24.4 mT

|

0.03 kg / 0.07 pounds

31.3 g / 0.3 N

|

low risk |

| 50 mm |

73 Gs

7.3 mT

|

0.00 kg / 0.01 pounds

2.8 g / 0.0 N

|

low risk |

Table 2: Slippage hold (wall)

MPL 20x20x20 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

3.08 kg / 6.79 pounds

3080.0 g / 30.2 N

|

| 1 mm | Stal (~0.2) |

2.55 kg / 5.61 pounds

2546.0 g / 25.0 N

|

| 2 mm | Stal (~0.2) |

2.07 kg / 4.55 pounds

2066.0 g / 20.3 N

|

| 3 mm | Stal (~0.2) |

1.65 kg / 3.64 pounds

1652.0 g / 16.2 N

|

| 5 mm | Stal (~0.2) |

1.02 kg / 2.26 pounds

1024.0 g / 10.0 N

|

| 10 mm | Stal (~0.2) |

0.30 kg / 0.65 pounds

296.0 g / 2.9 N

|

| 15 mm | Stal (~0.2) |

0.09 kg / 0.20 pounds

92.0 g / 0.9 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.07 pounds

34.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 20x20x20 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

4.62 kg / 10.19 pounds

4620.0 g / 45.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

3.08 kg / 6.79 pounds

3080.0 g / 30.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.54 kg / 3.40 pounds

1540.0 g / 15.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

7.70 kg / 16.98 pounds

7700.0 g / 75.5 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 20x20x20 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.77 kg / 1.70 pounds

770.0 g / 7.6 N

|

| 1 mm |

|

1.93 kg / 4.24 pounds

1925.0 g / 18.9 N

|

| 2 mm |

|

3.85 kg / 8.49 pounds

3850.0 g / 37.8 N

|

| 3 mm |

|

5.78 kg / 12.73 pounds

5775.0 g / 56.7 N

|

| 5 mm |

|

9.63 kg / 21.22 pounds

9625.0 g / 94.4 N

|

| 10 mm |

|

15.40 kg / 33.95 pounds

15400.0 g / 151.1 N

|

| 11 mm |

|

15.40 kg / 33.95 pounds

15400.0 g / 151.1 N

|

| 12 mm |

|

15.40 kg / 33.95 pounds

15400.0 g / 151.1 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MPL 20x20x20 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

15.40 kg / 33.95 pounds

15400.0 g / 151.1 N

|

OK |

| 40 °C | -2.2% |

15.06 kg / 33.20 pounds

15061.2 g / 147.8 N

|

OK |

| 60 °C | -4.4% |

14.72 kg / 32.46 pounds

14722.4 g / 144.4 N

|

OK |

| 80 °C | -6.6% |

14.38 kg / 31.71 pounds

14383.6 g / 141.1 N

|

|

| 100 °C | -28.8% |

10.96 kg / 24.17 pounds

10964.8 g / 107.6 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MPL 20x20x20 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

71.92 kg / 158.55 pounds

5 962 Gs

|

10.79 kg / 23.78 pounds

10787 g / 105.8 N

|

N/A |

| 1 mm |

65.60 kg / 144.63 pounds

10 316 Gs

|

9.84 kg / 21.69 pounds

9840 g / 96.5 N

|

59.04 kg / 130.16 pounds

~0 Gs

|

| 2 mm |

59.46 kg / 131.08 pounds

9 821 Gs

|

8.92 kg / 19.66 pounds

8919 g / 87.5 N

|

53.51 kg / 117.97 pounds

~0 Gs

|

| 3 mm |

53.66 kg / 118.30 pounds

9 329 Gs

|

8.05 kg / 17.74 pounds

8049 g / 79.0 N

|

48.29 kg / 106.47 pounds

~0 Gs

|

| 5 mm |

43.20 kg / 95.24 pounds

8 371 Gs

|

6.48 kg / 14.29 pounds

6480 g / 63.6 N

|

38.88 kg / 85.71 pounds

~0 Gs

|

| 10 mm |

23.91 kg / 52.72 pounds

6 228 Gs

|

3.59 kg / 7.91 pounds

3587 g / 35.2 N

|

21.52 kg / 47.44 pounds

~0 Gs

|

| 20 mm |

6.89 kg / 15.19 pounds

3 343 Gs

|

1.03 kg / 2.28 pounds

1033 g / 10.1 N

|

6.20 kg / 13.67 pounds

~0 Gs

|

| 50 mm |

0.32 kg / 0.71 pounds

721 Gs

|

0.05 kg / 0.11 pounds

48 g / 0.5 N

|

0.29 kg / 0.64 pounds

~0 Gs

|

| 60 mm |

0.15 kg / 0.32 pounds

487 Gs

|

0.02 kg / 0.05 pounds

22 g / 0.2 N

|

0.13 kg / 0.29 pounds

~0 Gs

|

| 70 mm |

0.07 kg / 0.16 pounds

344 Gs

|

0.01 kg / 0.02 pounds

11 g / 0.1 N

|

0.07 kg / 0.14 pounds

~0 Gs

|

| 80 mm |

0.04 kg / 0.09 pounds

251 Gs

|

0.01 kg / 0.01 pounds

6 g / 0.1 N

|

0.04 kg / 0.08 pounds

~0 Gs

|

| 90 mm |

0.02 kg / 0.05 pounds

189 Gs

|

0.00 kg / 0.01 pounds

3 g / 0.0 N

|

0.02 kg / 0.04 pounds

~0 Gs

|

| 100 mm |

0.01 kg / 0.03 pounds

146 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.03 pounds

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MPL 20x20x20 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 14.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 11.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 8.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 6.5 cm |

| Car key | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MPL 20x20x20 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.10 km/h

(4.75 m/s)

|

0.68 J | |

| 30 mm |

28.02 km/h

(7.78 m/s)

|

1.82 J | |

| 50 mm |

36.13 km/h

(10.04 m/s)

|

3.02 J | |

| 100 mm |

51.09 km/h

(14.19 m/s)

|

6.04 J |

Table 9: Coating parameters (durability)

MPL 20x20x20 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 20x20x20 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 22 017 Mx | 220.2 µWb |

| Pc Coefficient | 0.84 | High (Stable) |

Table 11: Physics of underwater searching

MPL 20x20x20 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 15.40 kg | Standard |

| Water (riverbed) |

17.63 kg

(+2.23 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical wall, the magnet holds only ~20% of its perpendicular strength.

2. Plate thickness effect

*Thin steel (e.g. computer case) significantly limits the holding force.

3. Thermal stability

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.84

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more deals

Advantages and disadvantages of Nd2Fe14B magnets.

Pros

- Their strength is durable, and after around ten years it decreases only by ~1% (according to research),

- They are noted for resistance to demagnetization induced by external magnetic fields,

- A magnet with a smooth nickel surface has an effective appearance,

- They are known for high magnetic induction at the operating surface, which affects their effectiveness,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, allowing for operation at temperatures reaching 230°C and above...

- Thanks to flexibility in shaping and the ability to modify to specific needs,

- Versatile presence in innovative solutions – they serve a role in magnetic memories, drive modules, medical devices, as well as technologically advanced constructions.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Weaknesses

- To avoid cracks under impact, we recommend using special steel holders. Such a solution secures the magnet and simultaneously increases its durability.

- Neodymium magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Magnets exposed to a humid environment can rust. Therefore during using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Limited ability of creating threads in the magnet and complicated forms - recommended is a housing - mounting mechanism.

- Health risk resulting from small fragments of magnets pose a threat, when accidentally swallowed, which becomes key in the aspect of protecting the youngest. It is also worth noting that small elements of these devices are able to be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Maximum lifting force for a neodymium magnet – what it depends on?

- with the application of a sheet made of special test steel, ensuring maximum field concentration

- whose thickness is min. 10 mm

- with an ideally smooth touching surface

- without the slightest clearance between the magnet and steel

- for force acting at a right angle (pull-off, not shear)

- in stable room temperature

Impact of factors on magnetic holding capacity in practice

- Distance (between the magnet and the metal), since even a microscopic clearance (e.g. 0.5 mm) leads to a reduction in force by up to 50% (this also applies to varnish, rust or dirt).

- Force direction – declared lifting capacity refers to pulling vertically. When applying parallel force, the magnet holds much less (typically approx. 20-30% of nominal force).

- Base massiveness – insufficiently thick sheet causes magnetic saturation, causing part of the power to be escaped into the air.

- Steel type – low-carbon steel attracts best. Alloy steels lower magnetic properties and lifting capacity.

- Smoothness – full contact is obtained only on smooth steel. Rough texture create air cushions, reducing force.

- Thermal environment – temperature increase causes a temporary drop of induction. Check the thermal limit for a given model.

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under a perpendicular pulling force, whereas under parallel forces the lifting capacity is smaller. Moreover, even a small distance between the magnet’s surface and the plate decreases the lifting capacity.

Warnings

Bone fractures

Pinching hazard: The pulling power is so great that it can cause blood blisters, pinching, and even bone fractures. Protective gloves are recommended.

Fragile material

Despite metallic appearance, neodymium is delicate and cannot withstand shocks. Avoid impacts, as the magnet may shatter into hazardous fragments.

Data carriers

Avoid bringing magnets close to a purse, laptop, or TV. The magnetic field can permanently damage these devices and erase data from cards.

Power loss in heat

Standard neodymium magnets (N-type) lose magnetization when the temperature exceeds 80°C. The loss of strength is permanent.

Fire risk

Powder created during grinding of magnets is combustible. Do not drill into magnets unless you are an expert.

Life threat

Individuals with a ICD have to keep an safe separation from magnets. The magnetism can interfere with the operation of the life-saving device.

GPS Danger

A powerful magnetic field disrupts the operation of compasses in smartphones and GPS navigation. Do not bring magnets close to a device to avoid breaking the sensors.

Conscious usage

Before use, check safety instructions. Sudden snapping can break the magnet or injure your hand. Think ahead.

Nickel coating and allergies

A percentage of the population suffer from a sensitization to Ni, which is the standard coating for NdFeB magnets. Frequent touching might lead to dermatitis. It is best to wear protective gloves.

Choking Hazard

Always keep magnets away from children. Choking hazard is significant, and the effects of magnets clamping inside the body are very dangerous.