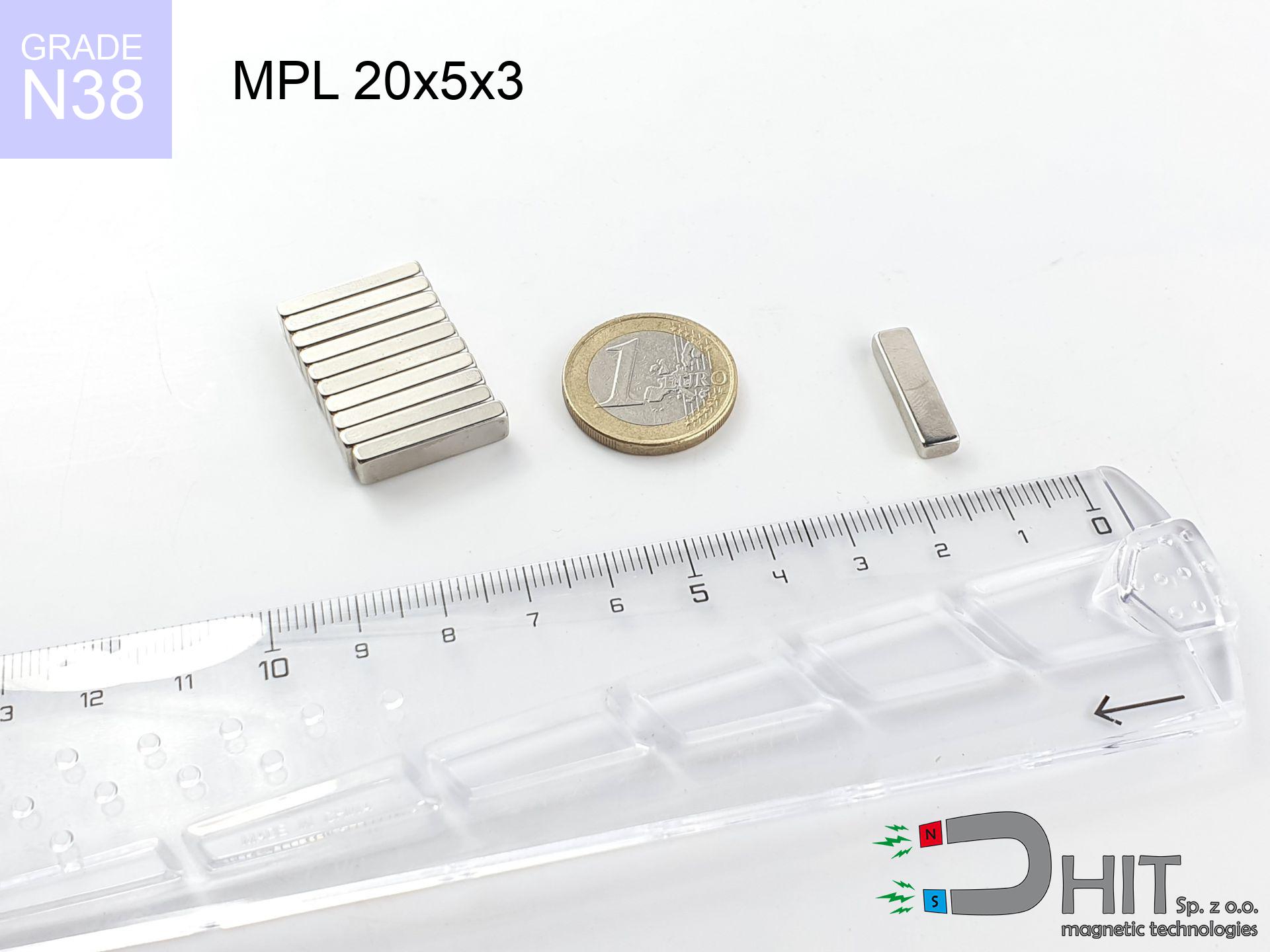

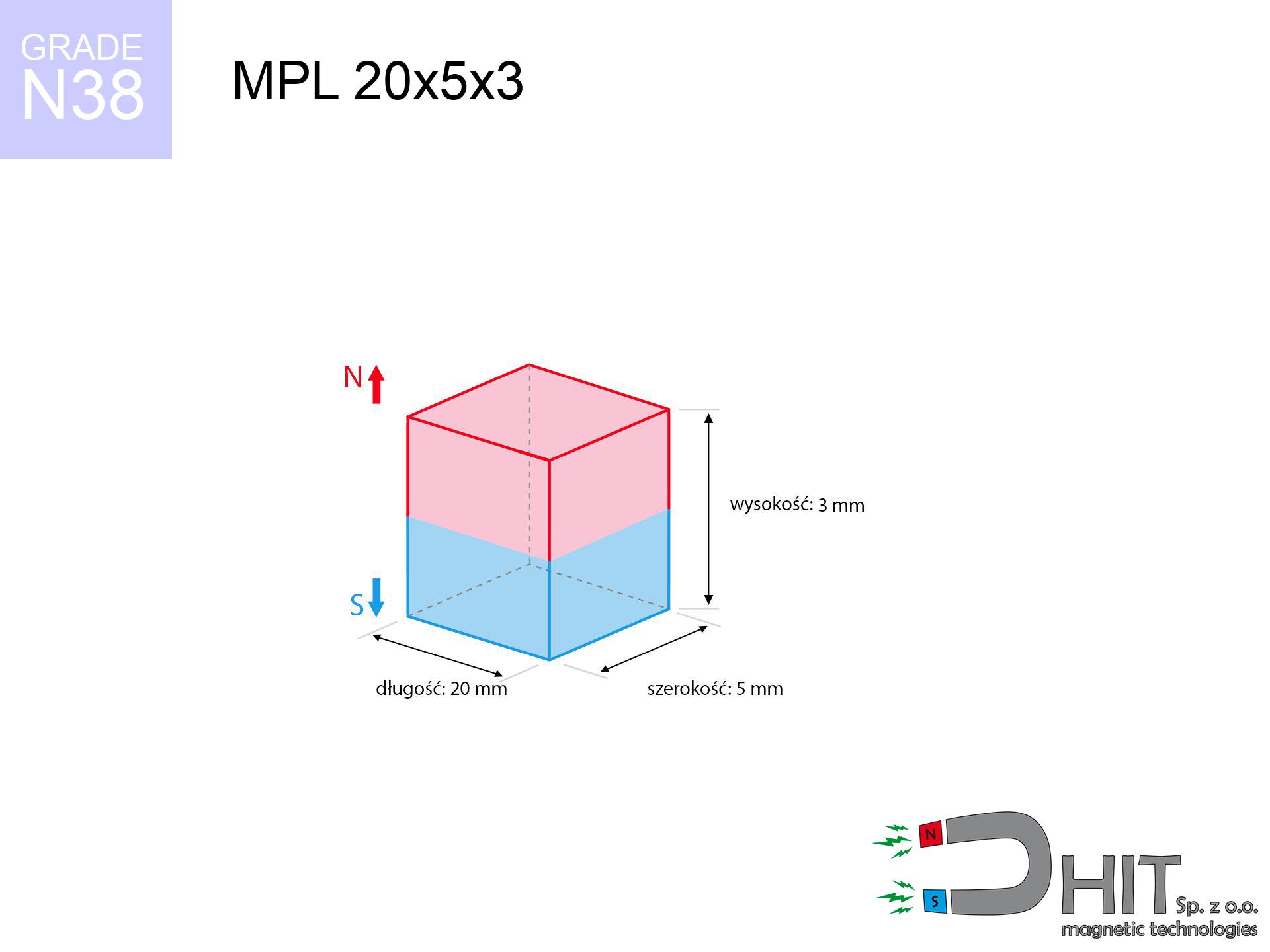

MPL 20x5x3 / N38 - lamellar magnet

lamellar magnet

Catalog no 020131

GTIN/EAN: 5906301811374

length

20 mm [±0,1 mm]

Width

5 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

2.25 g

Magnetization Direction

↑ axial

Load capacity

3.46 kg / 33.96 N

Magnetic Induction

358.88 mT / 3589 Gs

Coating

[NiCuNi] Nickel

1.058 ZŁ with VAT / pcs + price for transport

0.860 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

otherwise let us know using

contact form

the contact page.

Parameters as well as shape of a neodymium magnet can be reviewed with our

power calculator.

Orders submitted before 14:00 will be dispatched today!

Detailed specification - MPL 20x5x3 / N38 - lamellar magnet

Specification / characteristics - MPL 20x5x3 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020131 |

| GTIN/EAN | 5906301811374 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 20 mm [±0,1 mm] |

| Width | 5 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 2.25 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.46 kg / 33.96 N |

| Magnetic Induction ~ ? | 358.88 mT / 3589 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - data

The following values represent the outcome of a engineering simulation. Values were calculated on models for the material Nd2Fe14B. Actual conditions may differ from theoretical values. Use these calculations as a preliminary roadmap when designing systems.

Table 1: Static pull force (pull vs gap) - power drop

MPL 20x5x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3585 Gs

358.5 mT

|

3.46 kg / 7.63 pounds

3460.0 g / 33.9 N

|

strong |

| 1 mm |

2619 Gs

261.9 mT

|

1.85 kg / 4.07 pounds

1846.6 g / 18.1 N

|

low risk |

| 2 mm |

1818 Gs

181.8 mT

|

0.89 kg / 1.96 pounds

889.8 g / 8.7 N

|

low risk |

| 3 mm |

1279 Gs

127.9 mT

|

0.44 kg / 0.97 pounds

440.2 g / 4.3 N

|

low risk |

| 5 mm |

696 Gs

69.6 mT

|

0.13 kg / 0.29 pounds

130.6 g / 1.3 N

|

low risk |

| 10 mm |

225 Gs

22.5 mT

|

0.01 kg / 0.03 pounds

13.6 g / 0.1 N

|

low risk |

| 15 mm |

97 Gs

9.7 mT

|

0.00 kg / 0.01 pounds

2.5 g / 0.0 N

|

low risk |

| 20 mm |

49 Gs

4.9 mT

|

0.00 kg / 0.00 pounds

0.6 g / 0.0 N

|

low risk |

| 30 mm |

17 Gs

1.7 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

low risk |

| 50 mm |

4 Gs

0.4 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

Table 2: Slippage capacity (vertical surface)

MPL 20x5x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.69 kg / 1.53 pounds

692.0 g / 6.8 N

|

| 1 mm | Stal (~0.2) |

0.37 kg / 0.82 pounds

370.0 g / 3.6 N

|

| 2 mm | Stal (~0.2) |

0.18 kg / 0.39 pounds

178.0 g / 1.7 N

|

| 3 mm | Stal (~0.2) |

0.09 kg / 0.19 pounds

88.0 g / 0.9 N

|

| 5 mm | Stal (~0.2) |

0.03 kg / 0.06 pounds

26.0 g / 0.3 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MPL 20x5x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.04 kg / 2.29 pounds

1038.0 g / 10.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.69 kg / 1.53 pounds

692.0 g / 6.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.35 kg / 0.76 pounds

346.0 g / 3.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.73 kg / 3.81 pounds

1730.0 g / 17.0 N

|

Table 4: Steel thickness (substrate influence) - power losses

MPL 20x5x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.35 kg / 0.76 pounds

346.0 g / 3.4 N

|

| 1 mm |

|

0.87 kg / 1.91 pounds

865.0 g / 8.5 N

|

| 2 mm |

|

1.73 kg / 3.81 pounds

1730.0 g / 17.0 N

|

| 3 mm |

|

2.59 kg / 5.72 pounds

2595.0 g / 25.5 N

|

| 5 mm |

|

3.46 kg / 7.63 pounds

3460.0 g / 33.9 N

|

| 10 mm |

|

3.46 kg / 7.63 pounds

3460.0 g / 33.9 N

|

| 11 mm |

|

3.46 kg / 7.63 pounds

3460.0 g / 33.9 N

|

| 12 mm |

|

3.46 kg / 7.63 pounds

3460.0 g / 33.9 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MPL 20x5x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.46 kg / 7.63 pounds

3460.0 g / 33.9 N

|

OK |

| 40 °C | -2.2% |

3.38 kg / 7.46 pounds

3383.9 g / 33.2 N

|

OK |

| 60 °C | -4.4% |

3.31 kg / 7.29 pounds

3307.8 g / 32.4 N

|

|

| 80 °C | -6.6% |

3.23 kg / 7.12 pounds

3231.6 g / 31.7 N

|

|

| 100 °C | -28.8% |

2.46 kg / 5.43 pounds

2463.5 g / 24.2 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MPL 20x5x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

7.92 kg / 17.47 pounds

4 860 Gs

|

1.19 kg / 2.62 pounds

1189 g / 11.7 N

|

N/A |

| 1 mm |

5.94 kg / 13.10 pounds

6 209 Gs

|

0.89 kg / 1.97 pounds

891 g / 8.7 N

|

5.35 kg / 11.79 pounds

~0 Gs

|

| 2 mm |

4.23 kg / 9.32 pounds

5 238 Gs

|

0.63 kg / 1.40 pounds

634 g / 6.2 N

|

3.81 kg / 8.39 pounds

~0 Gs

|

| 3 mm |

2.94 kg / 6.49 pounds

4 369 Gs

|

0.44 kg / 0.97 pounds

441 g / 4.3 N

|

2.65 kg / 5.84 pounds

~0 Gs

|

| 5 mm |

1.42 kg / 3.14 pounds

3 039 Gs

|

0.21 kg / 0.47 pounds

213 g / 2.1 N

|

1.28 kg / 2.82 pounds

~0 Gs

|

| 10 mm |

0.30 kg / 0.66 pounds

1 393 Gs

|

0.04 kg / 0.10 pounds

45 g / 0.4 N

|

0.27 kg / 0.59 pounds

~0 Gs

|

| 20 mm |

0.03 kg / 0.07 pounds

450 Gs

|

0.00 kg / 0.01 pounds

5 g / 0.0 N

|

0.03 kg / 0.06 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

56 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

34 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

23 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

16 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

11 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

8 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MPL 20x5x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MPL 20x5x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

39.65 km/h

(11.01 m/s)

|

0.14 J | |

| 30 mm |

68.50 km/h

(19.03 m/s)

|

0.41 J | |

| 50 mm |

88.43 km/h

(24.56 m/s)

|

0.68 J | |

| 100 mm |

125.06 km/h

(34.74 m/s)

|

1.36 J |

Table 9: Coating parameters (durability)

MPL 20x5x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 20x5x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 197 Mx | 32.0 µWb |

| Pc Coefficient | 0.36 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MPL 20x5x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.46 kg | Standard |

| Water (riverbed) |

3.96 kg

(+0.50 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet holds merely ~20% of its max power.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Power loss vs temp

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.36

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also deals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Benefits

- Their magnetic field is durable, and after approximately ten years it decreases only by ~1% (theoretically),

- They possess excellent resistance to weakening of magnetic properties when exposed to external fields,

- By covering with a lustrous coating of nickel, the element acquires an aesthetic look,

- Magnets are characterized by extremely high magnetic induction on the surface,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- In view of the ability of flexible shaping and customization to specialized requirements, NdFeB magnets can be manufactured in a wide range of geometric configurations, which makes them more universal,

- Universal use in advanced technology sectors – they find application in mass storage devices, drive modules, medical equipment, and multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which allows their use in compact constructions

Cons

- At strong impacts they can break, therefore we recommend placing them in strong housings. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- Due to limitations in realizing nuts and complicated shapes in magnets, we propose using casing - magnetic holder.

- Potential hazard related to microscopic parts of magnets pose a threat, when accidentally swallowed, which gains importance in the context of child safety. It is also worth noting that small elements of these magnets are able to disrupt the diagnostic process medical after entering the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which hinders application in large quantities

Holding force characteristics

Optimal lifting capacity of a neodymium magnet – what it depends on?

- on a base made of structural steel, perfectly concentrating the magnetic flux

- possessing a thickness of minimum 10 mm to ensure full flux closure

- characterized by lack of roughness

- under conditions of gap-free contact (metal-to-metal)

- during detachment in a direction perpendicular to the mounting surface

- at room temperature

Practical aspects of lifting capacity – factors

- Clearance – existence of foreign body (paint, tape, air) acts as an insulator, which reduces power steeply (even by 50% at 0.5 mm).

- Force direction – declared lifting capacity refers to pulling vertically. When slipping, the magnet holds significantly lower power (often approx. 20-30% of nominal force).

- Wall thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of converting into lifting capacity.

- Material composition – not every steel attracts identically. Alloy additives weaken the attraction effect.

- Smoothness – ideal contact is possible only on smooth steel. Rough texture reduce the real contact area, weakening the magnet.

- Thermal factor – hot environment reduces magnetic field. Exceeding the limit temperature can permanently demagnetize the magnet.

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, however under attempts to slide the magnet the load capacity is reduced by as much as fivefold. Moreover, even a slight gap between the magnet’s surface and the plate lowers the load capacity.

Precautions when working with NdFeB magnets

Conscious usage

Be careful. Rare earth magnets attract from a long distance and connect with massive power, often faster than you can react.

Protect data

Equipment safety: Strong magnets can ruin data carriers and sensitive devices (heart implants, hearing aids, timepieces).

ICD Warning

For implant holders: Strong magnetic fields affect electronics. Keep at least 30 cm distance or request help to handle the magnets.

Combustion hazard

Drilling and cutting of neodymium magnets poses a fire risk. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Heat warning

Control the heat. Heating the magnet to high heat will destroy its properties and pulling force.

Product not for children

Only for adults. Tiny parts can be swallowed, leading to severe trauma. Keep away from children and animals.

Bodily injuries

Risk of injury: The pulling power is so immense that it can cause blood blisters, pinching, and broken bones. Use thick gloves.

Protective goggles

Despite metallic appearance, the material is delicate and not impact-resistant. Do not hit, as the magnet may crumble into hazardous fragments.

Precision electronics

Note: rare earth magnets generate a field that confuses sensitive sensors. Keep a safe distance from your mobile, tablet, and GPS.

Skin irritation risks

Studies show that nickel (standard magnet coating) is a potent allergen. For allergy sufferers, refrain from touching magnets with bare hands or select versions in plastic housing.

![SM 32x225 [2xM8] / N42 - magnetic separator SM 32x225 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x225-2xm8-dob.jpg)

![SM 25x300 [2xM8] / N42 - magnetic separator SM 25x300 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x300-2xm8-kud.jpg)

![SM 25x200 [2xM8] / N52 - magnetic separator SM 25x200 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x200-2xm8-jas.jpg)