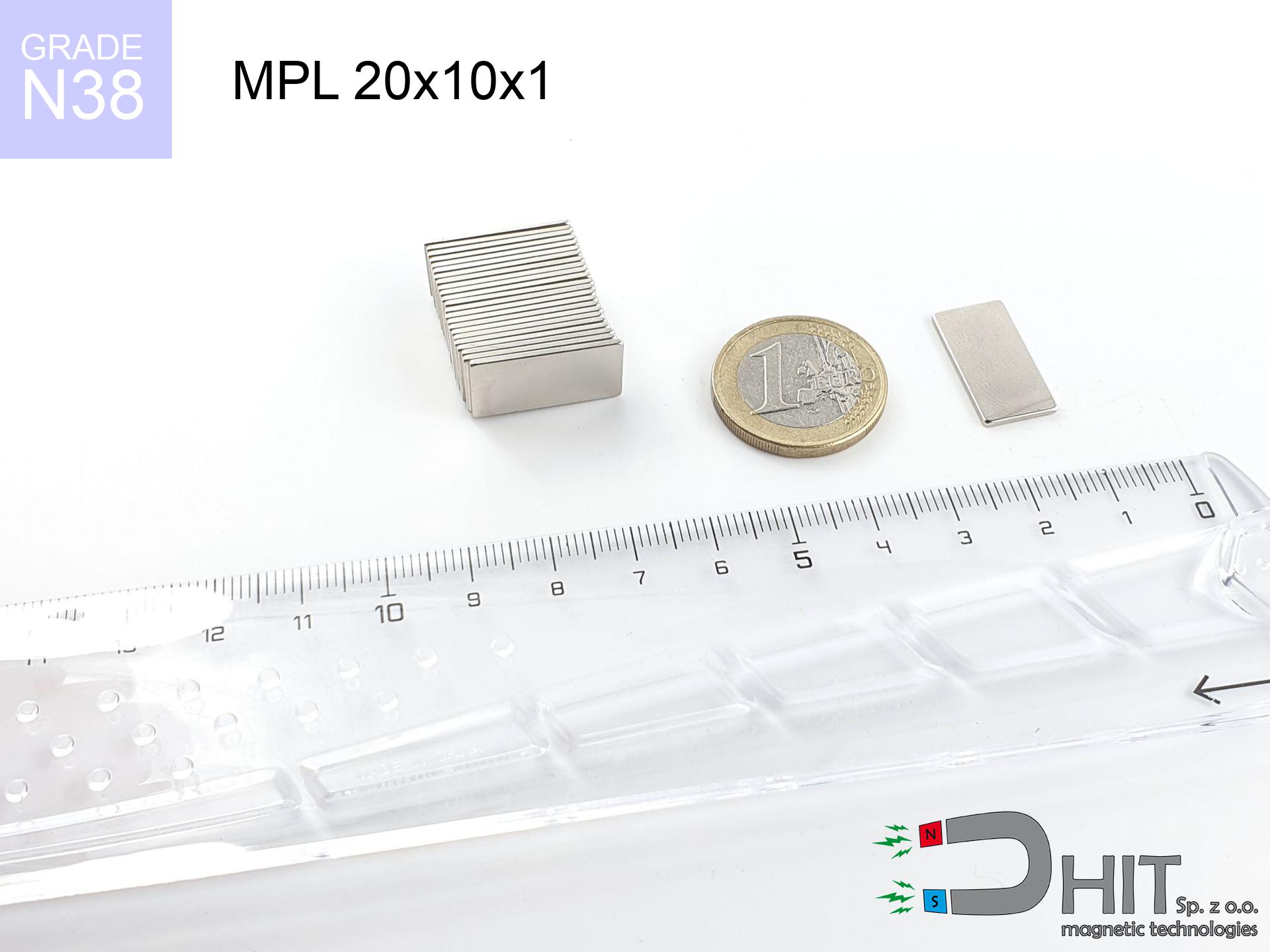

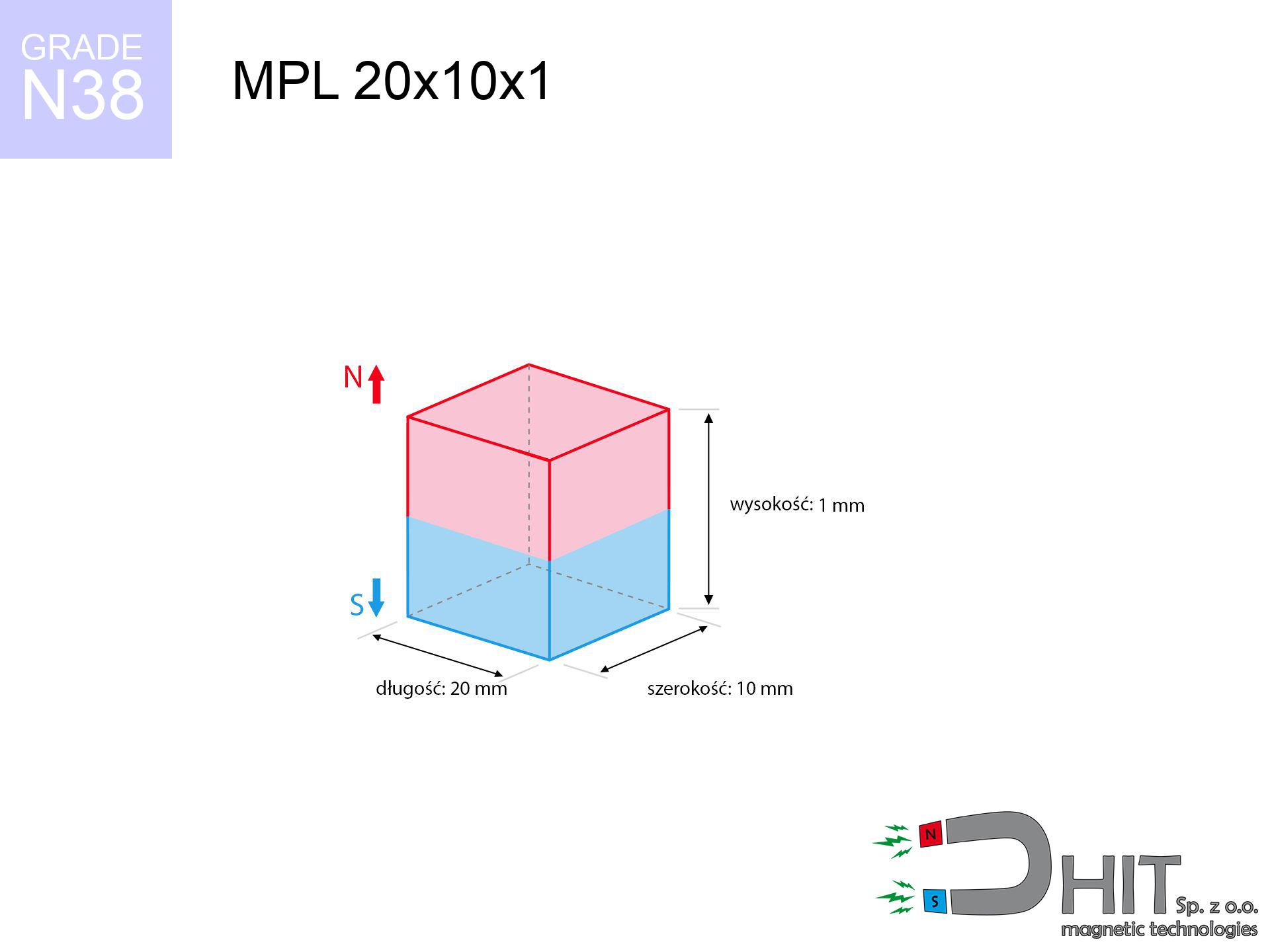

MPL 20x10x1 / N38 - lamellar magnet

lamellar magnet

Catalog no 020126

GTIN/EAN: 5906301811329

length

20 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

1 mm [±0,1 mm]

Weight

1.5 g

Magnetization Direction

↑ axial

Load capacity

0.56 kg / 5.46 N

Magnetic Induction

87.15 mT / 871 Gs

Coating

[NiCuNi] Nickel

0.996 ZŁ with VAT / pcs + price for transport

0.810 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

if you prefer drop us a message via

request form

through our site.

Specifications along with shape of neodymium magnets can be analyzed with our

our magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Technical data - MPL 20x10x1 / N38 - lamellar magnet

Specification / characteristics - MPL 20x10x1 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020126 |

| GTIN/EAN | 5906301811329 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 20 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 1 mm [±0,1 mm] |

| Weight | 1.5 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.56 kg / 5.46 N |

| Magnetic Induction ~ ? | 87.15 mT / 871 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the assembly - technical parameters

These values represent the direct effect of a physical calculation. Results are based on algorithms for the class Nd2Fe14B. Operational conditions might slightly deviate from the simulation results. Please consider these calculations as a reference point when designing systems.

Table 1: Static force (force vs distance) - characteristics

MPL 20x10x1 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

871 Gs

87.1 mT

|

0.56 kg / 1.23 LBS

560.0 g / 5.5 N

|

safe |

| 1 mm |

811 Gs

81.1 mT

|

0.49 kg / 1.07 LBS

485.7 g / 4.8 N

|

safe |

| 2 mm |

713 Gs

71.3 mT

|

0.37 kg / 0.83 LBS

374.9 g / 3.7 N

|

safe |

| 3 mm |

603 Gs

60.3 mT

|

0.27 kg / 0.59 LBS

267.9 g / 2.6 N

|

safe |

| 5 mm |

409 Gs

40.9 mT

|

0.12 kg / 0.27 LBS

123.4 g / 1.2 N

|

safe |

| 10 mm |

157 Gs

15.7 mT

|

0.02 kg / 0.04 LBS

18.1 g / 0.2 N

|

safe |

| 15 mm |

69 Gs

6.9 mT

|

0.00 kg / 0.01 LBS

3.5 g / 0.0 N

|

safe |

| 20 mm |

35 Gs

3.5 mT

|

0.00 kg / 0.00 LBS

0.9 g / 0.0 N

|

safe |

| 30 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

safe |

| 50 mm |

3 Gs

0.3 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Sliding load (wall)

MPL 20x10x1 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.11 kg / 0.25 LBS

112.0 g / 1.1 N

|

| 1 mm | Stal (~0.2) |

0.10 kg / 0.22 LBS

98.0 g / 1.0 N

|

| 2 mm | Stal (~0.2) |

0.07 kg / 0.16 LBS

74.0 g / 0.7 N

|

| 3 mm | Stal (~0.2) |

0.05 kg / 0.12 LBS

54.0 g / 0.5 N

|

| 5 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

24.0 g / 0.2 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 20x10x1 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.17 kg / 0.37 LBS

168.0 g / 1.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.11 kg / 0.25 LBS

112.0 g / 1.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.06 kg / 0.12 LBS

56.0 g / 0.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.28 kg / 0.62 LBS

280.0 g / 2.7 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MPL 20x10x1 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.06 kg / 0.12 LBS

56.0 g / 0.5 N

|

| 1 mm |

|

0.14 kg / 0.31 LBS

140.0 g / 1.4 N

|

| 2 mm |

|

0.28 kg / 0.62 LBS

280.0 g / 2.7 N

|

| 3 mm |

|

0.42 kg / 0.93 LBS

420.0 g / 4.1 N

|

| 5 mm |

|

0.56 kg / 1.23 LBS

560.0 g / 5.5 N

|

| 10 mm |

|

0.56 kg / 1.23 LBS

560.0 g / 5.5 N

|

| 11 mm |

|

0.56 kg / 1.23 LBS

560.0 g / 5.5 N

|

| 12 mm |

|

0.56 kg / 1.23 LBS

560.0 g / 5.5 N

|

Table 5: Working in heat (stability) - thermal limit

MPL 20x10x1 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.56 kg / 1.23 LBS

560.0 g / 5.5 N

|

OK |

| 40 °C | -2.2% |

0.55 kg / 1.21 LBS

547.7 g / 5.4 N

|

OK |

| 60 °C | -4.4% |

0.54 kg / 1.18 LBS

535.4 g / 5.3 N

|

|

| 80 °C | -6.6% |

0.52 kg / 1.15 LBS

523.0 g / 5.1 N

|

|

| 100 °C | -28.8% |

0.40 kg / 0.88 LBS

398.7 g / 3.9 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MPL 20x10x1 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

0.94 kg / 2.06 LBS

1 682 Gs

|

0.14 kg / 0.31 LBS

140 g / 1.4 N

|

N/A |

| 1 mm |

0.89 kg / 1.96 LBS

1 696 Gs

|

0.13 kg / 0.29 LBS

133 g / 1.3 N

|

0.80 kg / 1.76 LBS

~0 Gs

|

| 2 mm |

0.81 kg / 1.79 LBS

1 623 Gs

|

0.12 kg / 0.27 LBS

122 g / 1.2 N

|

0.73 kg / 1.61 LBS

~0 Gs

|

| 3 mm |

0.72 kg / 1.59 LBS

1 530 Gs

|

0.11 kg / 0.24 LBS

108 g / 1.1 N

|

0.65 kg / 1.43 LBS

~0 Gs

|

| 5 mm |

0.53 kg / 1.18 LBS

1 316 Gs

|

0.08 kg / 0.18 LBS

80 g / 0.8 N

|

0.48 kg / 1.06 LBS

~0 Gs

|

| 10 mm |

0.21 kg / 0.45 LBS

818 Gs

|

0.03 kg / 0.07 LBS

31 g / 0.3 N

|

0.19 kg / 0.41 LBS

~0 Gs

|

| 20 mm |

0.03 kg / 0.07 LBS

313 Gs

|

0.00 kg / 0.01 LBS

5 g / 0.0 N

|

0.03 kg / 0.06 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

40 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

25 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

16 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

11 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

8 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

6 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MPL 20x10x1 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MPL 20x10x1 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

19.88 km/h

(5.52 m/s)

|

0.02 J | |

| 30 mm |

33.76 km/h

(9.38 m/s)

|

0.07 J | |

| 50 mm |

43.57 km/h

(12.10 m/s)

|

0.11 J | |

| 100 mm |

61.62 km/h

(17.12 m/s)

|

0.22 J |

Table 9: Corrosion resistance

MPL 20x10x1 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MPL 20x10x1 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 2 173 Mx | 21.7 µWb |

| Pc Coefficient | 0.10 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MPL 20x10x1 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.56 kg | Standard |

| Water (riverbed) |

0.64 kg

(+0.08 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical wall, the magnet holds merely ~20% of its perpendicular strength.

2. Efficiency vs thickness

*Thin metal sheet (e.g. computer case) drastically weakens the holding force.

3. Thermal stability

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.10

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also products

Pros as well as cons of rare earth magnets.

Strengths

- They have unchanged lifting capacity, and over around 10 years their attraction force decreases symbolically – ~1% (in testing),

- They feature excellent resistance to magnetic field loss as a result of external magnetic sources,

- In other words, due to the aesthetic finish of nickel, the element becomes visually attractive,

- Magnets are distinguished by excellent magnetic induction on the outer layer,

- Thanks to resistance to high temperature, they are able to function (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of individual forming and optimizing to atypical applications,

- Key role in advanced technology sectors – they find application in hard drives, electric drive systems, medical devices, and modern systems.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Cons

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only protects the magnet but also improves its resistance to damage

- Neodymium magnets lose power when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- We recommend casing - magnetic holder, due to difficulties in realizing nuts inside the magnet and complex shapes.

- Potential hazard to health – tiny shards of magnets can be dangerous, in case of ingestion, which is particularly important in the context of child health protection. Furthermore, small elements of these devices are able to complicate diagnosis medical in case of swallowing.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Best holding force of the magnet in ideal parameters – what it depends on?

- with the contact of a yoke made of special test steel, guaranteeing full magnetic saturation

- with a cross-section of at least 10 mm

- characterized by lack of roughness

- without any air gap between the magnet and steel

- for force acting at a right angle (in the magnet axis)

- at standard ambient temperature

Key elements affecting lifting force

- Air gap (between the magnet and the metal), as even a tiny clearance (e.g. 0.5 mm) can cause a reduction in force by up to 50% (this also applies to paint, rust or dirt).

- Loading method – catalog parameter refers to detachment vertically. When applying parallel force, the magnet holds much less (typically approx. 20-30% of maximum force).

- Element thickness – for full efficiency, the steel must be adequately massive. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Steel grade – ideal substrate is high-permeability steel. Hardened steels may attract less.

- Surface finish – ideal contact is possible only on smooth steel. Rough texture create air cushions, reducing force.

- Operating temperature – NdFeB sinters have a sensitivity to temperature. When it is hot they lose power, and in frost gain strength (up to a certain limit).

Holding force was checked on the plate surface of 20 mm thickness, when the force acted perpendicularly, in contrast under attempts to slide the magnet the holding force is lower. Moreover, even a minimal clearance between the magnet and the plate lowers the holding force.

Safety rules for work with neodymium magnets

No play value

Always keep magnets away from children. Risk of swallowing is high, and the effects of magnets clamping inside the body are very dangerous.

Machining danger

Combustion risk: Rare earth powder is explosive. Avoid machining magnets without safety gear as this risks ignition.

Thermal limits

Standard neodymium magnets (grade N) lose power when the temperature surpasses 80°C. This process is irreversible.

Magnetic media

Do not bring magnets close to a wallet, laptop, or screen. The magnetic field can destroy these devices and wipe information from cards.

Fragile material

NdFeB magnets are ceramic materials, which means they are very brittle. Clashing of two magnets leads to them shattering into small pieces.

Bone fractures

Large magnets can crush fingers instantly. Do not put your hand between two strong magnets.

Allergy Warning

Certain individuals suffer from a hypersensitivity to nickel, which is the standard coating for NdFeB magnets. Prolonged contact can result in an allergic reaction. We recommend use protective gloves.

Medical implants

People with a ICD must keep an large gap from magnets. The magnetism can interfere with the functioning of the life-saving device.

Handling guide

Before starting, read the rules. Sudden snapping can destroy the magnet or injure your hand. Be predictive.

Keep away from electronics

A strong magnetic field negatively affects the operation of compasses in phones and GPS navigation. Keep magnets close to a smartphone to prevent breaking the sensors.