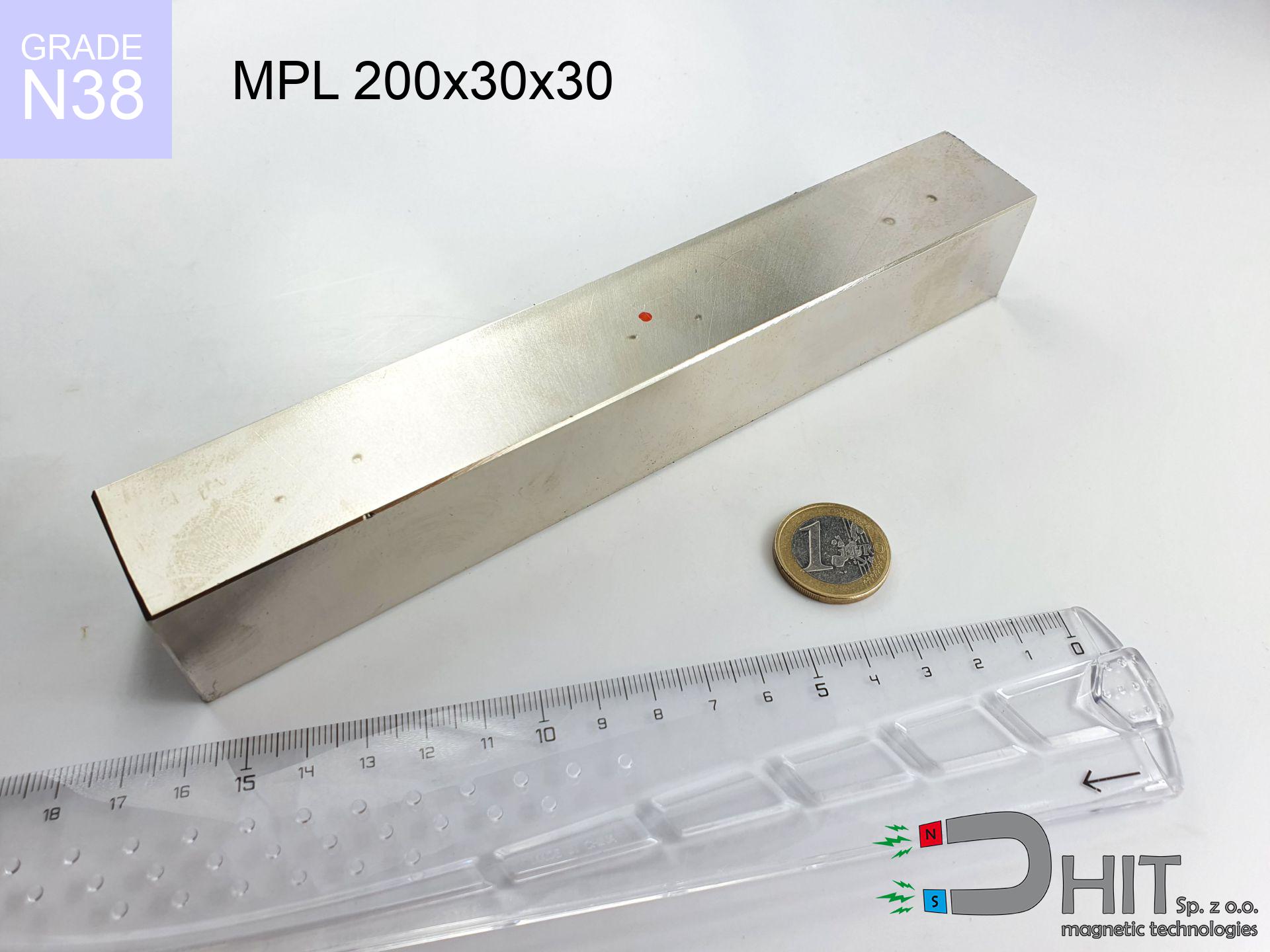

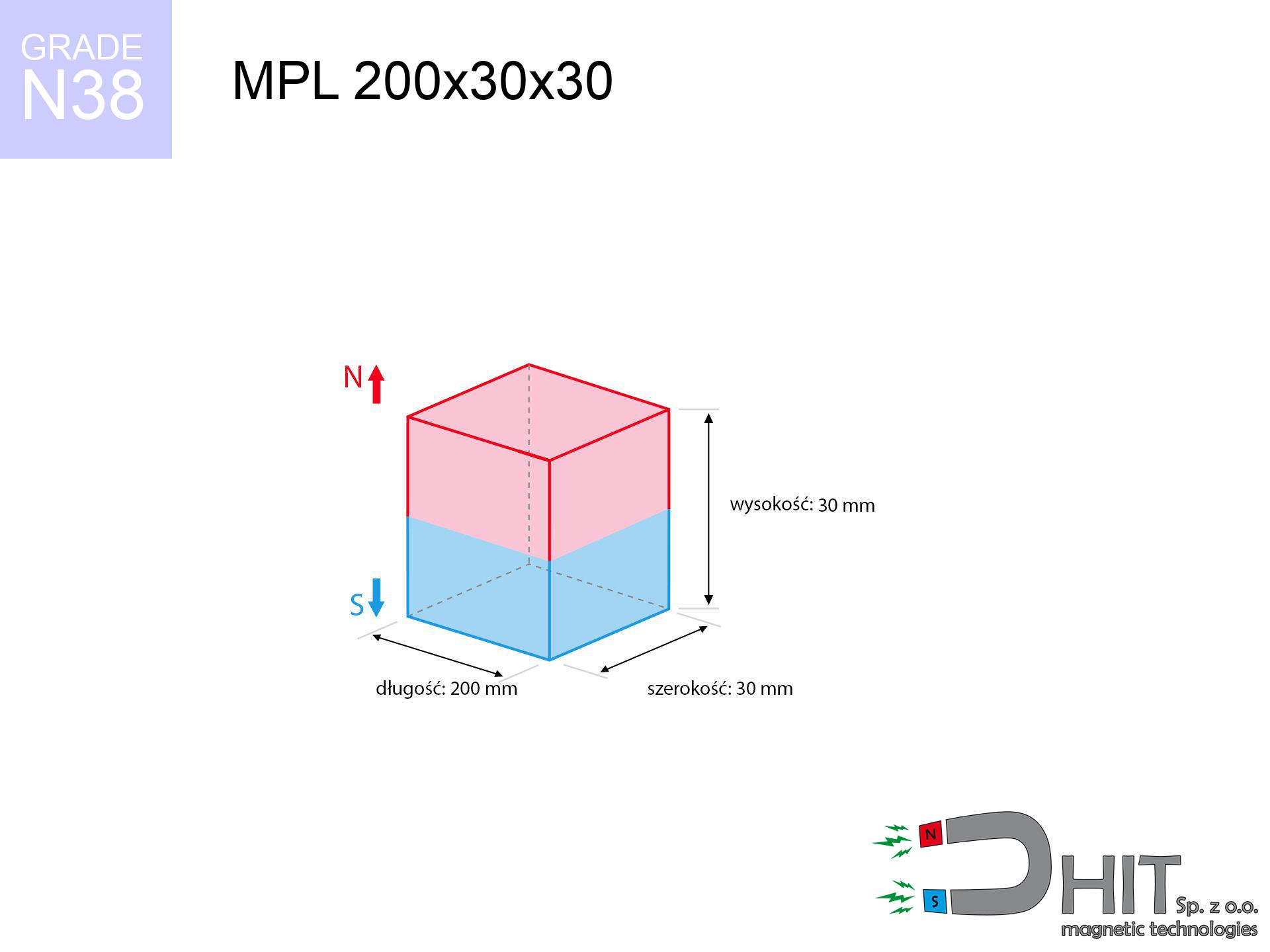

MPL 200x30x30 / N38 - lamellar magnet

lamellar magnet

Catalog no 020125

GTIN/EAN: 5906301811312

length

200 mm [±0,1 mm]

Width

30 mm [±0,1 mm]

Height

30 mm [±0,1 mm]

Weight

1350 g

Magnetization Direction

↑ axial

Load capacity

287.38 kg / 2819.19 N

Magnetic Induction

445.15 mT / 4451 Gs

Coating

[NiCuNi] Nickel

563.28 ZŁ with VAT / pcs + price for transport

457.95 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

otherwise drop us a message via

our online form

the contact section.

Strength along with shape of a neodymium magnet can be tested using our

online calculation tool.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - MPL 200x30x30 / N38 - lamellar magnet

Specification / characteristics - MPL 200x30x30 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020125 |

| GTIN/EAN | 5906301811312 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

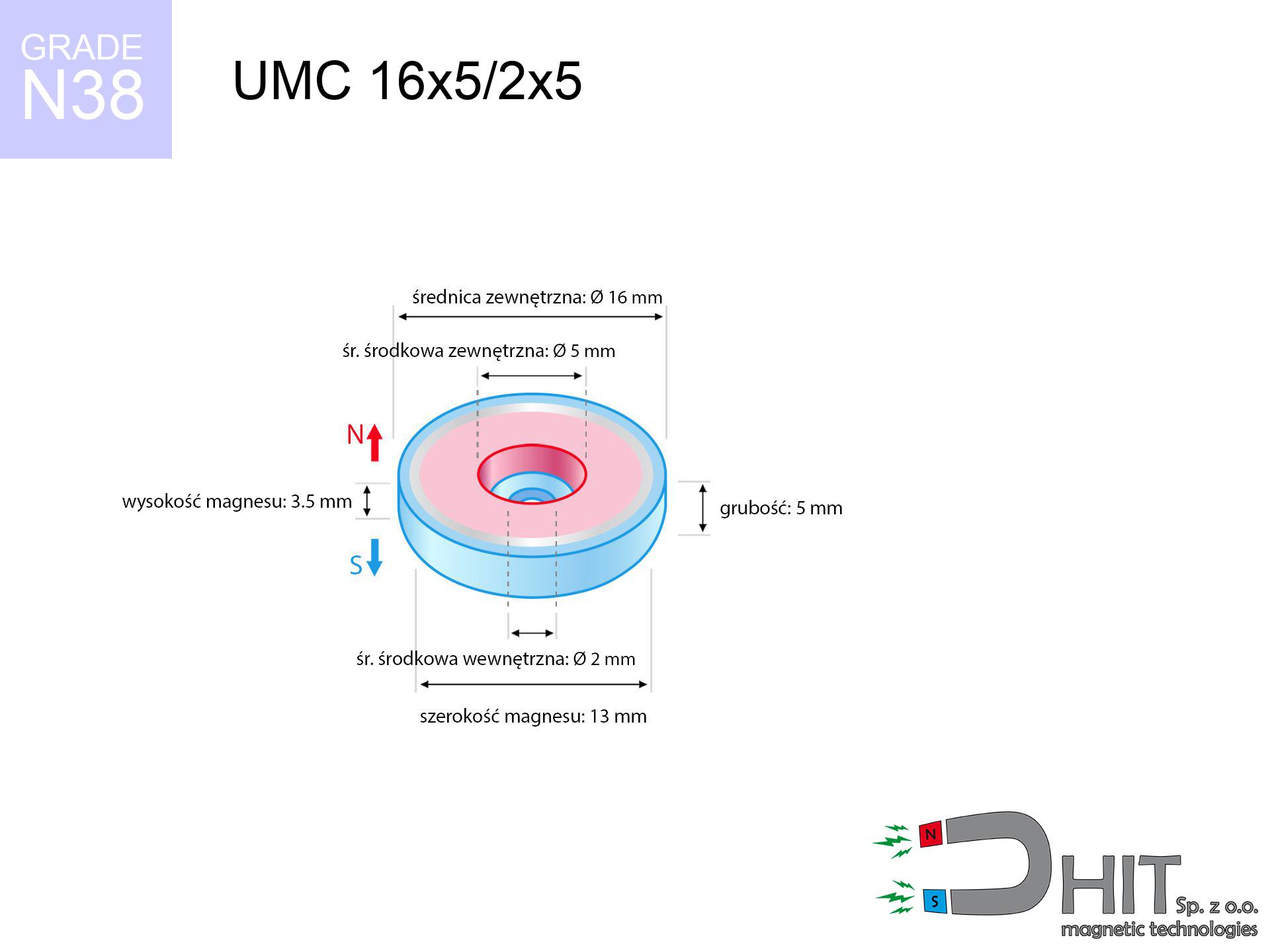

| length | 200 mm [±0,1 mm] |

| Width | 30 mm [±0,1 mm] |

| Height | 30 mm [±0,1 mm] |

| Weight | 1350 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 287.38 kg / 2819.19 N |

| Magnetic Induction ~ ? | 445.15 mT / 4451 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical modeling of the product - report

These data are the outcome of a engineering calculation. Values were calculated on models for the class Nd2Fe14B. Actual parameters might slightly differ from theoretical values. Use these calculations as a supplementary guide for designers.

Table 1: Static pull force (force vs distance) - power drop

MPL 200x30x30 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4451 Gs

445.1 mT

|

287.38 kg / 633.56 lbs

287380.0 g / 2819.2 N

|

crushing |

| 1 mm |

4241 Gs

424.1 mT

|

260.91 kg / 575.21 lbs

260910.0 g / 2559.5 N

|

crushing |

| 2 mm |

4028 Gs

402.8 mT

|

235.43 kg / 519.04 lbs

235433.0 g / 2309.6 N

|

crushing |

| 3 mm |

3818 Gs

381.8 mT

|

211.49 kg / 466.26 lbs

211490.2 g / 2074.7 N

|

crushing |

| 5 mm |

3412 Gs

341.2 mT

|

168.87 kg / 372.30 lbs

168870.4 g / 1656.6 N

|

crushing |

| 10 mm |

2539 Gs

253.9 mT

|

93.54 kg / 206.22 lbs

93539.2 g / 917.6 N

|

crushing |

| 15 mm |

1902 Gs

190.2 mT

|

52.48 kg / 115.70 lbs

52481.2 g / 514.8 N

|

crushing |

| 20 mm |

1457 Gs

145.7 mT

|

30.79 kg / 67.88 lbs

30789.8 g / 302.0 N

|

crushing |

| 30 mm |

920 Gs

92.0 mT

|

12.29 kg / 27.09 lbs

12288.2 g / 120.5 N

|

crushing |

| 50 mm |

456 Gs

45.6 mT

|

3.02 kg / 6.65 lbs

3016.4 g / 29.6 N

|

warning |

Table 2: Slippage capacity (wall)

MPL 200x30x30 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

57.48 kg / 126.71 lbs

57476.0 g / 563.8 N

|

| 1 mm | Stal (~0.2) |

52.18 kg / 115.04 lbs

52182.0 g / 511.9 N

|

| 2 mm | Stal (~0.2) |

47.09 kg / 103.81 lbs

47086.0 g / 461.9 N

|

| 3 mm | Stal (~0.2) |

42.30 kg / 93.25 lbs

42298.0 g / 414.9 N

|

| 5 mm | Stal (~0.2) |

33.77 kg / 74.46 lbs

33774.0 g / 331.3 N

|

| 10 mm | Stal (~0.2) |

18.71 kg / 41.24 lbs

18708.0 g / 183.5 N

|

| 15 mm | Stal (~0.2) |

10.50 kg / 23.14 lbs

10496.0 g / 103.0 N

|

| 20 mm | Stal (~0.2) |

6.16 kg / 13.58 lbs

6158.0 g / 60.4 N

|

| 30 mm | Stal (~0.2) |

2.46 kg / 5.42 lbs

2458.0 g / 24.1 N

|

| 50 mm | Stal (~0.2) |

0.60 kg / 1.33 lbs

604.0 g / 5.9 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 200x30x30 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

86.21 kg / 190.07 lbs

86214.0 g / 845.8 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

57.48 kg / 126.71 lbs

57476.0 g / 563.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

28.74 kg / 63.36 lbs

28738.0 g / 281.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

143.69 kg / 316.78 lbs

143690.0 g / 1409.6 N

|

Table 4: Steel thickness (saturation) - power losses

MPL 200x30x30 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

9.58 kg / 21.12 lbs

9579.3 g / 94.0 N

|

| 1 mm |

|

23.95 kg / 52.80 lbs

23948.3 g / 234.9 N

|

| 2 mm |

|

47.90 kg / 105.59 lbs

47896.7 g / 469.9 N

|

| 3 mm |

|

71.85 kg / 158.39 lbs

71845.0 g / 704.8 N

|

| 5 mm |

|

119.74 kg / 263.98 lbs

119741.7 g / 1174.7 N

|

| 10 mm |

|

239.48 kg / 527.97 lbs

239483.3 g / 2349.3 N

|

| 11 mm |

|

263.43 kg / 580.77 lbs

263431.7 g / 2584.3 N

|

| 12 mm |

|

287.38 kg / 633.56 lbs

287380.0 g / 2819.2 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MPL 200x30x30 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

287.38 kg / 633.56 lbs

287380.0 g / 2819.2 N

|

OK |

| 40 °C | -2.2% |

281.06 kg / 619.63 lbs

281057.6 g / 2757.2 N

|

OK |

| 60 °C | -4.4% |

274.74 kg / 605.69 lbs

274735.3 g / 2695.2 N

|

|

| 80 °C | -6.6% |

268.41 kg / 591.75 lbs

268412.9 g / 2633.1 N

|

|

| 100 °C | -28.8% |

204.61 kg / 451.10 lbs

204614.6 g / 2007.3 N

|

Table 6: Two magnets (attraction) - field range

MPL 200x30x30 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

732.71 kg / 1615.35 lbs

5 371 Gs

|

109.91 kg / 242.30 lbs

109907 g / 1078.2 N

|

N/A |

| 1 mm |

698.96 kg / 1540.95 lbs

8 694 Gs

|

104.84 kg / 231.14 lbs

104845 g / 1028.5 N

|

629.07 kg / 1386.85 lbs

~0 Gs

|

| 2 mm |

665.22 kg / 1466.57 lbs

8 481 Gs

|

99.78 kg / 219.99 lbs

99784 g / 978.9 N

|

598.70 kg / 1319.91 lbs

~0 Gs

|

| 3 mm |

632.29 kg / 1393.97 lbs

8 269 Gs

|

94.84 kg / 209.10 lbs

94844 g / 930.4 N

|

569.07 kg / 1254.57 lbs

~0 Gs

|

| 5 mm |

569.22 kg / 1254.92 lbs

7 846 Gs

|

85.38 kg / 188.24 lbs

85383 g / 837.6 N

|

512.30 kg / 1129.42 lbs

~0 Gs

|

| 10 mm |

430.56 kg / 949.22 lbs

6 823 Gs

|

64.58 kg / 142.38 lbs

64584 g / 633.6 N

|

387.50 kg / 854.29 lbs

~0 Gs

|

| 20 mm |

238.49 kg / 525.78 lbs

5 078 Gs

|

35.77 kg / 78.87 lbs

35774 g / 350.9 N

|

214.64 kg / 473.20 lbs

~0 Gs

|

| 50 mm |

48.45 kg / 106.82 lbs

2 289 Gs

|

7.27 kg / 16.02 lbs

7268 g / 71.3 N

|

43.61 kg / 96.13 lbs

~0 Gs

|

| 60 mm |

31.33 kg / 69.07 lbs

1 841 Gs

|

4.70 kg / 10.36 lbs

4700 g / 46.1 N

|

28.20 kg / 62.16 lbs

~0 Gs

|

| 70 mm |

21.09 kg / 46.49 lbs

1 510 Gs

|

3.16 kg / 6.97 lbs

3163 g / 31.0 N

|

18.98 kg / 41.84 lbs

~0 Gs

|

| 80 mm |

14.67 kg / 32.35 lbs

1 260 Gs

|

2.20 kg / 4.85 lbs

2201 g / 21.6 N

|

13.21 kg / 29.12 lbs

~0 Gs

|

| 90 mm |

10.50 kg / 23.15 lbs

1 066 Gs

|

1.58 kg / 3.47 lbs

1575 g / 15.5 N

|

9.45 kg / 20.83 lbs

~0 Gs

|

| 100 mm |

7.69 kg / 16.95 lbs

912 Gs

|

1.15 kg / 2.54 lbs

1154 g / 11.3 N

|

6.92 kg / 15.26 lbs

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MPL 200x30x30 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 39.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 30.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 23.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 18.0 cm |

| Car key | 50 Gs (5.0 mT) | 16.5 cm |

| Payment card | 400 Gs (40.0 mT) | 5.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 4.5 cm |

Table 8: Collisions (cracking risk) - collision effects

MPL 200x30x30 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.45 km/h

(4.85 m/s)

|

15.86 J | |

| 30 mm |

26.16 km/h

(7.27 m/s)

|

35.64 J | |

| 50 mm |

33.12 km/h

(9.20 m/s)

|

57.12 J | |

| 100 mm |

46.56 km/h

(12.93 m/s)

|

112.90 J |

Table 9: Surface protection spec

MPL 200x30x30 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 200x30x30 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 221 734 Mx | 2217.3 µWb |

| Pc Coefficient | 0.45 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MPL 200x30x30 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 287.38 kg | Standard |

| Water (riverbed) |

329.05 kg

(+41.67 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical surface, the magnet retains merely approx. 20-30% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) significantly weakens the holding force.

3. Temperature resistance

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.45

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also offers

Pros as well as cons of neodymium magnets.

Strengths

- They retain full power for nearly ten years – the loss is just ~1% (according to analyses),

- They show high resistance to demagnetization induced by presence of other magnetic fields,

- The use of an aesthetic layer of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- The surface of neodymium magnets generates a strong magnetic field – this is one of their assets,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Considering the option of precise shaping and customization to unique projects, neodymium magnets can be created in a broad palette of shapes and sizes, which makes them more universal,

- Wide application in electronics industry – they are used in magnetic memories, electromotive mechanisms, precision medical tools, also multitasking production systems.

- Thanks to efficiency per cm³, small magnets offer high operating force, with minimal size,

Disadvantages

- At strong impacts they can crack, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets lose strength when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation and corrosion.

- Due to limitations in creating threads and complex forms in magnets, we propose using casing - magnetic mechanism.

- Possible danger related to microscopic parts of magnets can be dangerous, when accidentally swallowed, which becomes key in the aspect of protecting the youngest. Furthermore, tiny parts of these products can complicate diagnosis medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Maximum lifting force for a neodymium magnet – what contributes to it?

- on a block made of mild steel, perfectly concentrating the magnetic flux

- whose thickness equals approx. 10 mm

- with a plane perfectly flat

- under conditions of ideal adhesion (surface-to-surface)

- during pulling in a direction perpendicular to the plane

- in stable room temperature

Determinants of practical lifting force of a magnet

- Distance (between the magnet and the metal), as even a microscopic distance (e.g. 0.5 mm) can cause a reduction in force by up to 50% (this also applies to paint, corrosion or dirt).

- Loading method – catalog parameter refers to pulling vertically. When applying parallel force, the magnet exhibits significantly lower power (often approx. 20-30% of maximum force).

- Metal thickness – the thinner the sheet, the weaker the hold. Magnetic flux penetrates through instead of converting into lifting capacity.

- Material composition – different alloys reacts the same. High carbon content worsen the attraction effect.

- Surface finish – ideal contact is possible only on smooth steel. Rough texture reduce the real contact area, reducing force.

- Thermal environment – heating the magnet causes a temporary drop of induction. Check the maximum operating temperature for a given model.

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under perpendicular forces, whereas under attempts to slide the magnet the lifting capacity is smaller. In addition, even a slight gap between the magnet’s surface and the plate decreases the holding force.

Warnings

Health Danger

Warning for patients: Powerful magnets affect medical devices. Keep minimum 30 cm distance or ask another person to handle the magnets.

Nickel allergy

Medical facts indicate that nickel (standard magnet coating) is a strong allergen. For allergy sufferers, refrain from touching magnets with bare hands and choose encased magnets.

Handling rules

Use magnets with awareness. Their immense force can shock even professionals. Be vigilant and do not underestimate their power.

Operating temperature

Keep cool. NdFeB magnets are sensitive to heat. If you require resistance above 80°C, inquire about special high-temperature series (H, SH, UH).

This is not a toy

Only for adults. Small elements pose a choking risk, leading to intestinal necrosis. Store away from children and animals.

Beware of splinters

NdFeB magnets are sintered ceramics, which means they are prone to chipping. Collision of two magnets will cause them breaking into small pieces.

Fire warning

Mechanical processing of neodymium magnets poses a fire risk. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

Electronic devices

Equipment safety: Neodymium magnets can ruin payment cards and sensitive devices (pacemakers, medical aids, timepieces).

Bone fractures

Large magnets can crush fingers in a fraction of a second. Do not put your hand betwixt two strong magnets.

Compass and GPS

A powerful magnetic field disrupts the operation of compasses in phones and navigation systems. Keep magnets close to a smartphone to prevent breaking the sensors.

![SM 25x325 [2xM8] / N52 - magnetic separator SM 25x325 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x325-2xm8-bit.jpg)