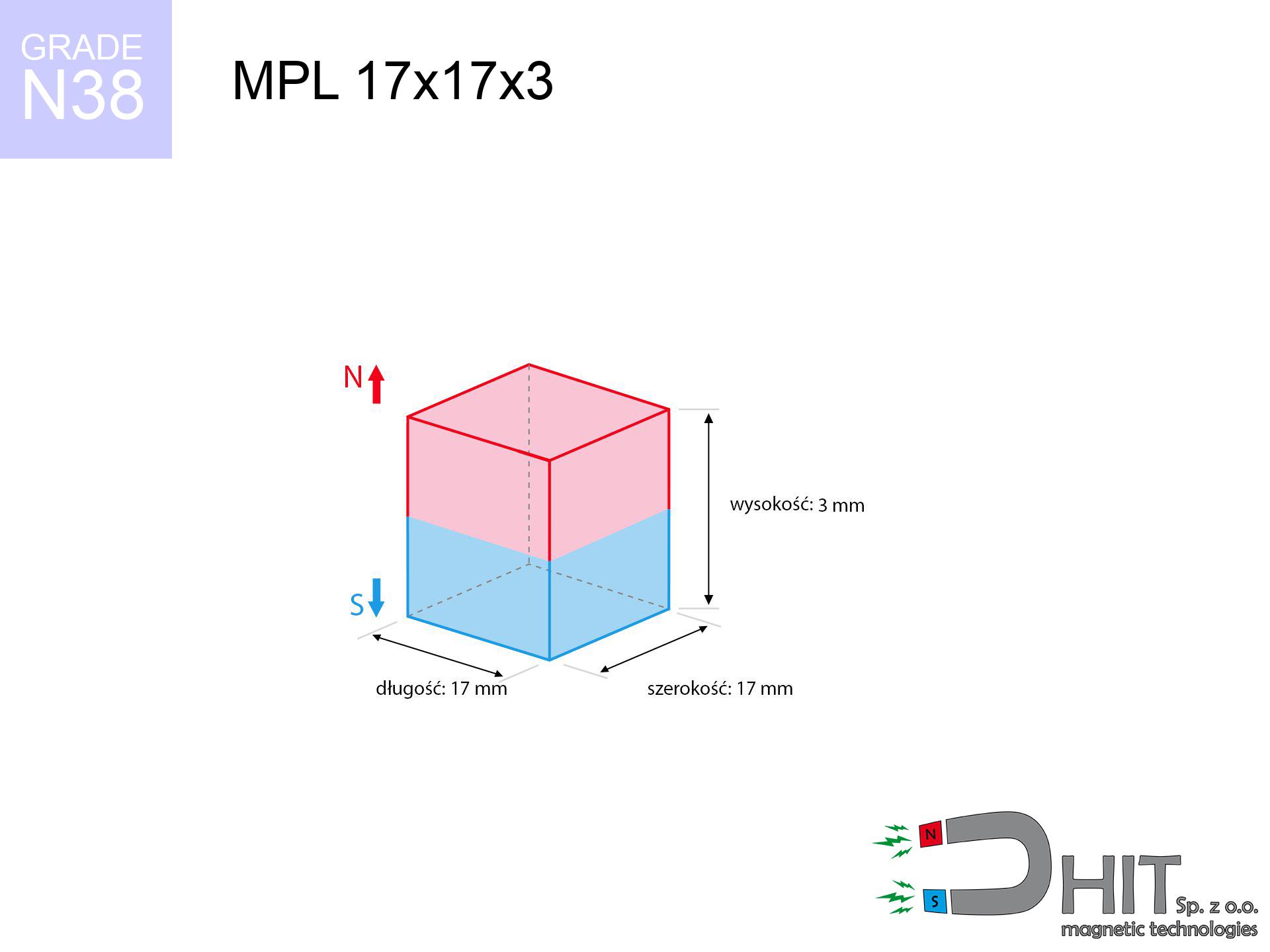

MPL 17x17x3 / N38 - lamellar magnet

lamellar magnet

Catalog no 020124

GTIN/EAN: 5906301811305

length

17 mm [±0,1 mm]

Width

17 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

6.5 g

Magnetization Direction

↑ axial

Load capacity

3.22 kg / 31.54 N

Magnetic Induction

187.48 mT / 1875 Gs

Coating

[NiCuNi] Nickel

4.71 ZŁ with VAT / pcs + price for transport

3.83 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

if you prefer drop us a message by means of

inquiry form

the contact section.

Force along with form of magnetic components can be checked using our

online calculation tool.

Orders submitted before 14:00 will be dispatched today!

Detailed specification - MPL 17x17x3 / N38 - lamellar magnet

Specification / characteristics - MPL 17x17x3 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020124 |

| GTIN/EAN | 5906301811305 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 17 mm [±0,1 mm] |

| Width | 17 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 6.5 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.22 kg / 31.54 N |

| Magnetic Induction ~ ? | 187.48 mT / 1875 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the product - report

The following values constitute the outcome of a physical simulation. Results were calculated on algorithms for the class Nd2Fe14B. Actual parameters may differ from theoretical values. Please consider these data as a reference point for designers.

Table 1: Static pull force (pull vs distance) - power drop

MPL 17x17x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1874 Gs

187.4 mT

|

3.22 kg / 7.10 lbs

3220.0 g / 31.6 N

|

strong |

| 1 mm |

1761 Gs

176.1 mT

|

2.84 kg / 6.27 lbs

2842.9 g / 27.9 N

|

strong |

| 2 mm |

1610 Gs

161.0 mT

|

2.38 kg / 5.24 lbs

2376.8 g / 23.3 N

|

strong |

| 3 mm |

1440 Gs

144.0 mT

|

1.90 kg / 4.19 lbs

1901.0 g / 18.6 N

|

safe |

| 5 mm |

1099 Gs

109.9 mT

|

1.11 kg / 2.44 lbs

1107.5 g / 10.9 N

|

safe |

| 10 mm |

508 Gs

50.8 mT

|

0.24 kg / 0.52 lbs

236.4 g / 2.3 N

|

safe |

| 15 mm |

245 Gs

24.5 mT

|

0.06 kg / 0.12 lbs

55.2 g / 0.5 N

|

safe |

| 20 mm |

131 Gs

13.1 mT

|

0.02 kg / 0.03 lbs

15.7 g / 0.2 N

|

safe |

| 30 mm |

48 Gs

4.8 mT

|

0.00 kg / 0.00 lbs

2.1 g / 0.0 N

|

safe |

| 50 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

safe |

Table 2: Slippage hold (wall)

MPL 17x17x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.64 kg / 1.42 lbs

644.0 g / 6.3 N

|

| 1 mm | Stal (~0.2) |

0.57 kg / 1.25 lbs

568.0 g / 5.6 N

|

| 2 mm | Stal (~0.2) |

0.48 kg / 1.05 lbs

476.0 g / 4.7 N

|

| 3 mm | Stal (~0.2) |

0.38 kg / 0.84 lbs

380.0 g / 3.7 N

|

| 5 mm | Stal (~0.2) |

0.22 kg / 0.49 lbs

222.0 g / 2.2 N

|

| 10 mm | Stal (~0.2) |

0.05 kg / 0.11 lbs

48.0 g / 0.5 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.03 lbs

12.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MPL 17x17x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.97 kg / 2.13 lbs

966.0 g / 9.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.64 kg / 1.42 lbs

644.0 g / 6.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.32 kg / 0.71 lbs

322.0 g / 3.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.61 kg / 3.55 lbs

1610.0 g / 15.8 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 17x17x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.32 kg / 0.71 lbs

322.0 g / 3.2 N

|

| 1 mm |

|

0.81 kg / 1.77 lbs

805.0 g / 7.9 N

|

| 2 mm |

|

1.61 kg / 3.55 lbs

1610.0 g / 15.8 N

|

| 3 mm |

|

2.42 kg / 5.32 lbs

2415.0 g / 23.7 N

|

| 5 mm |

|

3.22 kg / 7.10 lbs

3220.0 g / 31.6 N

|

| 10 mm |

|

3.22 kg / 7.10 lbs

3220.0 g / 31.6 N

|

| 11 mm |

|

3.22 kg / 7.10 lbs

3220.0 g / 31.6 N

|

| 12 mm |

|

3.22 kg / 7.10 lbs

3220.0 g / 31.6 N

|

Table 5: Working in heat (material behavior) - thermal limit

MPL 17x17x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.22 kg / 7.10 lbs

3220.0 g / 31.6 N

|

OK |

| 40 °C | -2.2% |

3.15 kg / 6.94 lbs

3149.2 g / 30.9 N

|

OK |

| 60 °C | -4.4% |

3.08 kg / 6.79 lbs

3078.3 g / 30.2 N

|

|

| 80 °C | -6.6% |

3.01 kg / 6.63 lbs

3007.5 g / 29.5 N

|

|

| 100 °C | -28.8% |

2.29 kg / 5.05 lbs

2292.6 g / 22.5 N

|

Table 6: Two magnets (repulsion) - field collision

MPL 17x17x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

6.26 kg / 13.80 lbs

3 313 Gs

|

0.94 kg / 2.07 lbs

939 g / 9.2 N

|

N/A |

| 1 mm |

5.93 kg / 13.07 lbs

3 648 Gs

|

0.89 kg / 1.96 lbs

889 g / 8.7 N

|

5.33 kg / 11.76 lbs

~0 Gs

|

| 2 mm |

5.53 kg / 12.19 lbs

3 523 Gs

|

0.83 kg / 1.83 lbs

829 g / 8.1 N

|

4.97 kg / 10.97 lbs

~0 Gs

|

| 3 mm |

5.08 kg / 11.21 lbs

3 379 Gs

|

0.76 kg / 1.68 lbs

763 g / 7.5 N

|

4.58 kg / 10.09 lbs

~0 Gs

|

| 5 mm |

4.15 kg / 9.16 lbs

3 053 Gs

|

0.62 kg / 1.37 lbs

623 g / 6.1 N

|

3.74 kg / 8.24 lbs

~0 Gs

|

| 10 mm |

2.15 kg / 4.75 lbs

2 199 Gs

|

0.32 kg / 0.71 lbs

323 g / 3.2 N

|

1.94 kg / 4.27 lbs

~0 Gs

|

| 20 mm |

0.46 kg / 1.01 lbs

1 016 Gs

|

0.07 kg / 0.15 lbs

69 g / 0.7 N

|

0.41 kg / 0.91 lbs

~0 Gs

|

| 50 mm |

0.01 kg / 0.02 lbs

153 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.02 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.01 lbs

96 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

64 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

44 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

32 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

24 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MPL 17x17x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.5 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MPL 17x17x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

23.45 km/h

(6.52 m/s)

|

0.14 J | |

| 30 mm |

38.89 km/h

(10.80 m/s)

|

0.38 J | |

| 50 mm |

50.19 km/h

(13.94 m/s)

|

0.63 J | |

| 100 mm |

70.98 km/h

(19.72 m/s)

|

1.26 J |

Table 9: Anti-corrosion coating durability

MPL 17x17x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 17x17x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 6 509 Mx | 65.1 µWb |

| Pc Coefficient | 0.23 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 17x17x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.22 kg | Standard |

| Water (riverbed) |

3.69 kg

(+0.47 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet holds just a fraction of its nominal pull.

2. Efficiency vs thickness

*Thin metal sheet (e.g. 0.5mm PC case) drastically reduces the holding force.

3. Thermal stability

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.23

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Advantages

- Their magnetic field remains stable, and after approximately 10 years it decreases only by ~1% (theoretically),

- They are noted for resistance to demagnetization induced by external magnetic fields,

- The use of an metallic finish of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- Magnetic induction on the working part of the magnet remains very high,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Thanks to versatility in forming and the ability to modify to complex applications,

- Key role in future technologies – they serve a role in hard drives, brushless drives, medical devices, and other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which allows their use in small systems

Disadvantages

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth securing magnets using a steel holder. Such protection not only shields the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- Due to limitations in producing nuts and complex forms in magnets, we propose using casing - magnetic mount.

- Health risk related to microscopic parts of magnets can be dangerous, if swallowed, which is particularly important in the context of child health protection. Furthermore, small components of these devices can be problematic in diagnostics medical when they are in the body.

- Due to complex production process, their price is higher than average,

Pull force analysis

Maximum holding power of the magnet – what it depends on?

- with the application of a sheet made of special test steel, ensuring full magnetic saturation

- whose transverse dimension is min. 10 mm

- with an ground touching surface

- with direct contact (without impurities)

- during pulling in a direction vertical to the mounting surface

- at standard ambient temperature

Determinants of lifting force in real conditions

- Gap between magnet and steel – every millimeter of separation (caused e.g. by veneer or unevenness) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Force direction – catalog parameter refers to pulling vertically. When slipping, the magnet holds significantly lower power (often approx. 20-30% of nominal force).

- Element thickness – for full efficiency, the steel must be sufficiently thick. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Steel grade – the best choice is pure iron steel. Cast iron may generate lower lifting capacity.

- Base smoothness – the smoother and more polished the plate, the better the adhesion and higher the lifting capacity. Unevenness creates an air distance.

- Temperature influence – high temperature weakens pulling force. Exceeding the limit temperature can permanently demagnetize the magnet.

Holding force was tested on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under shearing force the load capacity is reduced by as much as fivefold. Additionally, even a minimal clearance between the magnet and the plate lowers the holding force.

Safe handling of NdFeB magnets

Allergic reactions

Medical facts indicate that nickel (standard magnet coating) is a potent allergen. If you have an allergy, prevent touching magnets with bare hands or opt for versions in plastic housing.

Protective goggles

Despite the nickel coating, the material is brittle and not impact-resistant. Avoid impacts, as the magnet may crumble into hazardous fragments.

Keep away from computers

Data protection: Neodymium magnets can damage payment cards and delicate electronics (pacemakers, hearing aids, mechanical watches).

Phone sensors

A powerful magnetic field disrupts the operation of compasses in smartphones and navigation systems. Do not bring magnets close to a device to avoid breaking the sensors.

Do not give to children

Strictly keep magnets out of reach of children. Risk of swallowing is high, and the effects of magnets connecting inside the body are life-threatening.

Pinching danger

Large magnets can smash fingers in a fraction of a second. Do not put your hand betwixt two strong magnets.

Caution required

Before use, check safety instructions. Uncontrolled attraction can break the magnet or injure your hand. Think ahead.

Dust explosion hazard

Dust produced during cutting of magnets is flammable. Do not drill into magnets without proper cooling and knowledge.

Health Danger

Warning for patients: Strong magnetic fields affect medical devices. Maintain at least 30 cm distance or ask another person to handle the magnets.

Power loss in heat

Standard neodymium magnets (N-type) lose power when the temperature goes above 80°C. This process is irreversible.

![SM 18x200 [2xM5] / N42 - magnetic separator SM 18x200 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x200-2xm5-gig.jpg)