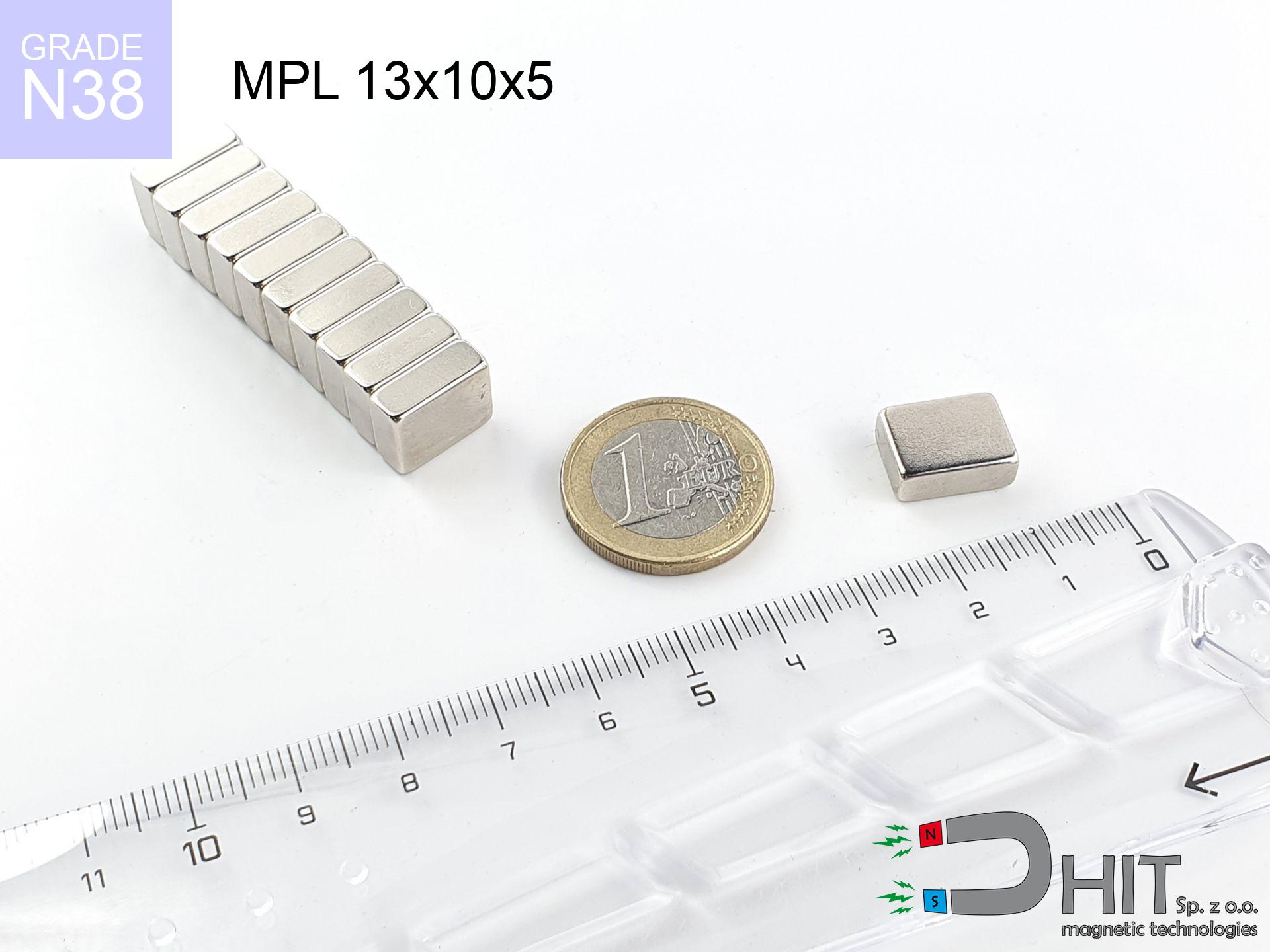

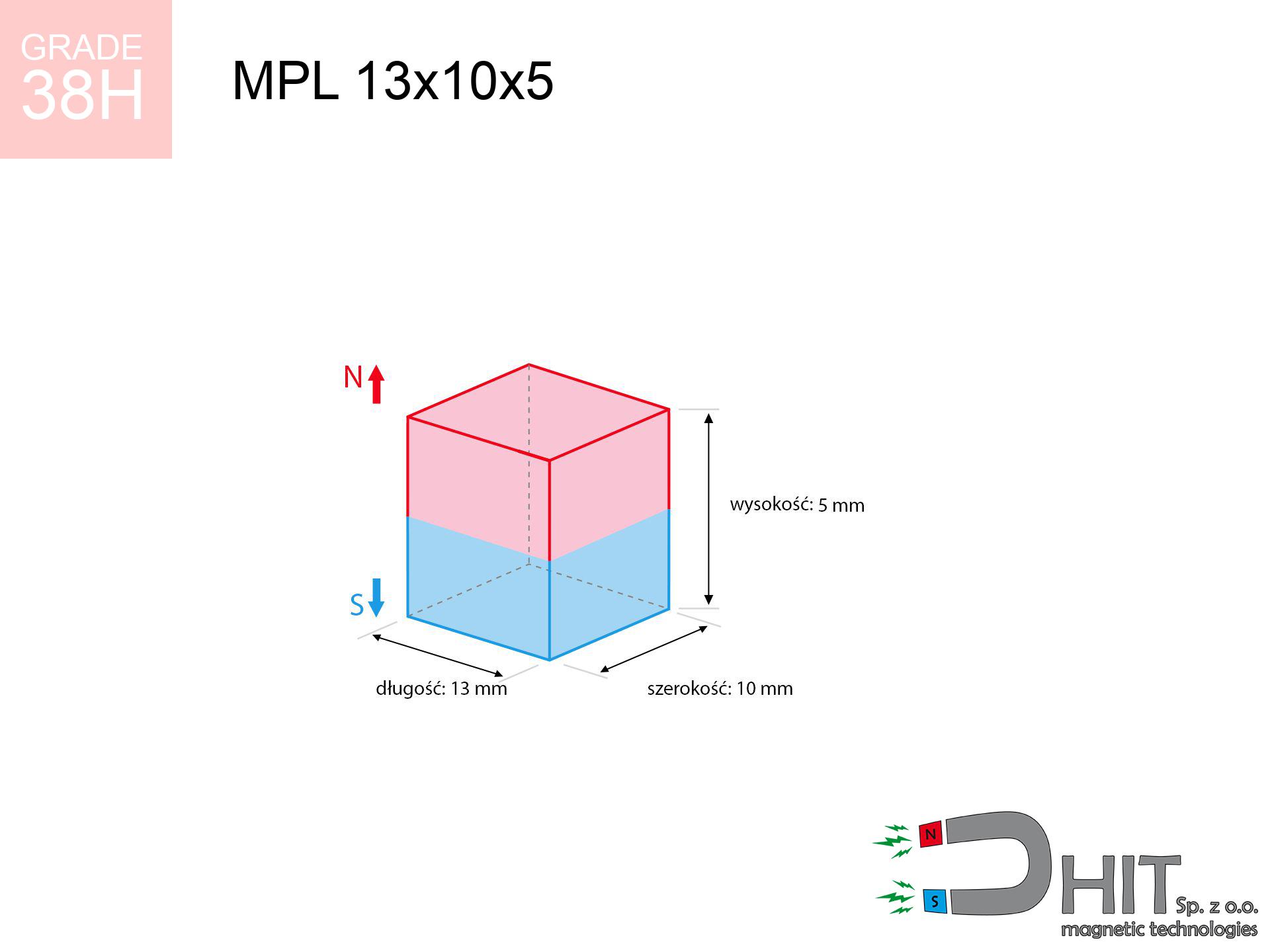

MPL 13x10x5 / N35H - lamellar magnet

lamellar magnet

Catalog no 020119

GTIN/EAN: 5906301811251

length

13 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

4.88 g

Magnetization Direction

↑ axial

Load capacity

4.03 kg / 39.54 N

Magnetic Induction

369.32 mT / 3693 Gs

Coating

[NiCuNi] Nickel

2.58 ZŁ with VAT / pcs + price for transport

2.10 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

alternatively contact us through

request form

through our site.

Lifting power along with shape of a neodymium magnet can be reviewed on our

magnetic mass calculator.

Same-day shipping for orders placed before 14:00.

Technical specification of the product - MPL 13x10x5 / N35H - lamellar magnet

Specification / characteristics - MPL 13x10x5 / N35H - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020119 |

| GTIN/EAN | 5906301811251 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 13 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 4.88 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.03 kg / 39.54 N |

| Magnetic Induction ~ ? | 369.32 mT / 3693 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N35H

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 11.7-12.1 | kGs |

| remenance Br [min. - max.] ? | 1170-1210 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 17 | kOe |

| actual internal force iHc | ≥ 1353 | kA/m |

| energy density [min. - max.] ? | 33-35 | BH max MGOe |

| energy density [min. - max.] ? | 263-279 | BH max KJ/m |

| max. temperature ? | ≤ 120 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the assembly - report

Presented data constitute the outcome of a physical analysis. Results are based on algorithms for the class Nd2Fe14B. Real-world performance may differ from theoretical values. Treat these data as a preliminary roadmap during assembly planning.

Table 1: Static pull force (pull vs gap) - interaction chart

MPL 13x10x5 / N35H

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3691 Gs

369.1 mT

|

4.03 kg / 8.88 LBS

4030.0 g / 39.5 N

|

medium risk |

| 1 mm |

3152 Gs

315.2 mT

|

2.94 kg / 6.48 LBS

2938.4 g / 28.8 N

|

medium risk |

| 2 mm |

2595 Gs

259.5 mT

|

1.99 kg / 4.39 LBS

1991.8 g / 19.5 N

|

safe |

| 3 mm |

2089 Gs

208.9 mT

|

1.29 kg / 2.85 LBS

1291.2 g / 12.7 N

|

safe |

| 5 mm |

1321 Gs

132.1 mT

|

0.52 kg / 1.14 LBS

516.1 g / 5.1 N

|

safe |

| 10 mm |

455 Gs

45.5 mT

|

0.06 kg / 0.14 LBS

61.2 g / 0.6 N

|

safe |

| 15 mm |

193 Gs

19.3 mT

|

0.01 kg / 0.02 LBS

11.1 g / 0.1 N

|

safe |

| 20 mm |

97 Gs

9.7 mT

|

0.00 kg / 0.01 LBS

2.8 g / 0.0 N

|

safe |

| 30 mm |

34 Gs

3.4 mT

|

0.00 kg / 0.00 LBS

0.3 g / 0.0 N

|

safe |

| 50 mm |

8 Gs

0.8 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Vertical hold (wall)

MPL 13x10x5 / N35H

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.81 kg / 1.78 LBS

806.0 g / 7.9 N

|

| 1 mm | Stal (~0.2) |

0.59 kg / 1.30 LBS

588.0 g / 5.8 N

|

| 2 mm | Stal (~0.2) |

0.40 kg / 0.88 LBS

398.0 g / 3.9 N

|

| 3 mm | Stal (~0.2) |

0.26 kg / 0.57 LBS

258.0 g / 2.5 N

|

| 5 mm | Stal (~0.2) |

0.10 kg / 0.23 LBS

104.0 g / 1.0 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

12.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MPL 13x10x5 / N35H

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.21 kg / 2.67 LBS

1209.0 g / 11.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.81 kg / 1.78 LBS

806.0 g / 7.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.40 kg / 0.89 LBS

403.0 g / 4.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.02 kg / 4.44 LBS

2015.0 g / 19.8 N

|

Table 4: Steel thickness (saturation) - power losses

MPL 13x10x5 / N35H

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.40 kg / 0.89 LBS

403.0 g / 4.0 N

|

| 1 mm |

|

1.01 kg / 2.22 LBS

1007.5 g / 9.9 N

|

| 2 mm |

|

2.02 kg / 4.44 LBS

2015.0 g / 19.8 N

|

| 3 mm |

|

3.02 kg / 6.66 LBS

3022.5 g / 29.7 N

|

| 5 mm |

|

4.03 kg / 8.88 LBS

4030.0 g / 39.5 N

|

| 10 mm |

|

4.03 kg / 8.88 LBS

4030.0 g / 39.5 N

|

| 11 mm |

|

4.03 kg / 8.88 LBS

4030.0 g / 39.5 N

|

| 12 mm |

|

4.03 kg / 8.88 LBS

4030.0 g / 39.5 N

|

Table 5: Thermal resistance (stability) - resistance threshold

MPL 13x10x5 / N35H

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.03 kg / 8.88 LBS

4030.0 g / 39.5 N

|

OK |

| 80 °C | -6.6% |

3.76 kg / 8.30 LBS

3764.0 g / 36.9 N

|

|

| 120 °C | -11.0% |

3.59 kg / 7.91 LBS

3586.7 g / 35.2 N

|

|

| 140 °C | -33.2% |

2.69 kg / 5.93 LBS

2692.0 g / 26.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MPL 13x10x5 / N35H

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

10.92 kg / 24.08 LBS

5 009 Gs

|

1.64 kg / 3.61 LBS

1638 g / 16.1 N

|

N/A |

| 1 mm |

9.43 kg / 20.80 LBS

6 862 Gs

|

1.42 kg / 3.12 LBS

1415 g / 13.9 N

|

8.49 kg / 18.72 LBS

~0 Gs

|

| 2 mm |

7.96 kg / 17.55 LBS

6 304 Gs

|

1.19 kg / 2.63 LBS

1194 g / 11.7 N

|

7.17 kg / 15.80 LBS

~0 Gs

|

| 3 mm |

6.60 kg / 14.56 LBS

5 740 Gs

|

0.99 kg / 2.18 LBS

990 g / 9.7 N

|

5.94 kg / 13.10 LBS

~0 Gs

|

| 5 mm |

4.36 kg / 9.62 LBS

4 667 Gs

|

0.65 kg / 1.44 LBS

655 g / 6.4 N

|

3.93 kg / 8.66 LBS

~0 Gs

|

| 10 mm |

1.40 kg / 3.08 LBS

2 642 Gs

|

0.21 kg / 0.46 LBS

210 g / 2.1 N

|

1.26 kg / 2.78 LBS

~0 Gs

|

| 20 mm |

0.17 kg / 0.37 LBS

910 Gs

|

0.02 kg / 0.05 LBS

25 g / 0.2 N

|

0.15 kg / 0.33 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 LBS

110 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

68 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

45 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

31 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

22 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

17 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MPL 13x10x5 / N35H

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 4.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 3.0 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Dynamics (kinetic energy) - warning

MPL 13x10x5 / N35H

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

29.26 km/h

(8.13 m/s)

|

0.16 J | |

| 30 mm |

50.20 km/h

(13.94 m/s)

|

0.47 J | |

| 50 mm |

64.81 km/h

(18.00 m/s)

|

0.79 J | |

| 100 mm |

91.65 km/h

(25.46 m/s)

|

1.58 J |

Table 9: Coating parameters (durability)

MPL 13x10x5 / N35H

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 13x10x5 / N35H

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 4 919 Mx | 49.2 µWb |

| Pc Coefficient | 0.49 | Low (Flat) |

Table 11: Submerged application

MPL 13x10x5 / N35H

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.03 kg | Standard |

| Water (riverbed) |

4.61 kg

(+0.58 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical surface, the magnet retains just approx. 20-30% of its max power.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) drastically reduces the holding force.

3. Heat tolerance

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.49

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths as well as weaknesses of neodymium magnets.

Advantages

- They do not lose strength, even after approximately 10 years – the decrease in strength is only ~1% (according to tests),

- They maintain their magnetic properties even under close interference source,

- A magnet with a metallic gold surface has better aesthetics,

- They are known for high magnetic induction at the operating surface, making them more effective,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, allowing for operation at temperatures reaching 230°C and above...

- Thanks to the ability of precise forming and customization to specialized requirements, neodymium magnets can be manufactured in a broad palette of forms and dimensions, which increases their versatility,

- Fundamental importance in high-tech industry – they are utilized in computer drives, electric drive systems, medical equipment, and modern systems.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in tiny dimensions, which makes them useful in small systems

Disadvantages

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only protects the magnet but also increases its resistance to damage

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- Due to limitations in realizing nuts and complicated shapes in magnets, we propose using cover - magnetic mechanism.

- Potential hazard related to microscopic parts of magnets pose a threat, if swallowed, which is particularly important in the context of child safety. Furthermore, tiny parts of these products are able to disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Breakaway strength of the magnet in ideal conditions – what contributes to it?

- on a block made of mild steel, optimally conducting the magnetic flux

- possessing a massiveness of minimum 10 mm to ensure full flux closure

- with an ideally smooth touching surface

- with zero gap (without impurities)

- for force acting at a right angle (pull-off, not shear)

- in temp. approx. 20°C

Key elements affecting lifting force

- Distance – existence of foreign body (rust, dirt, air) acts as an insulator, which lowers power steeply (even by 50% at 0.5 mm).

- Direction of force – highest force is reached only during perpendicular pulling. The shear force of the magnet along the plate is usually several times lower (approx. 1/5 of the lifting capacity).

- Plate thickness – insufficiently thick plate does not accept the full field, causing part of the flux to be wasted into the air.

- Material type – the best choice is pure iron steel. Stainless steels may have worse magnetic properties.

- Base smoothness – the more even the plate, the larger the contact zone and stronger the hold. Roughness acts like micro-gaps.

- Thermal environment – temperature increase causes a temporary drop of force. Check the thermal limit for a given model.

Lifting capacity testing was carried out on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, in contrast under attempts to slide the magnet the load capacity is reduced by as much as 75%. Moreover, even a minimal clearance between the magnet’s surface and the plate lowers the load capacity.

Safe handling of neodymium magnets

Avoid contact if allergic

Allergy Notice: The Ni-Cu-Ni coating contains nickel. If redness appears, cease handling magnets and use protective gear.

Medical interference

Medical warning: Neodymium magnets can deactivate pacemakers and defibrillators. Stay away if you have medical devices.

Fragile material

NdFeB magnets are ceramic materials, which means they are prone to chipping. Impact of two magnets leads to them cracking into small pieces.

Electronic devices

Avoid bringing magnets close to a purse, laptop, or TV. The magnetic field can permanently damage these devices and erase data from cards.

This is not a toy

Absolutely store magnets away from children. Ingestion danger is significant, and the effects of magnets clamping inside the body are fatal.

GPS Danger

Note: rare earth magnets generate a field that confuses precision electronics. Maintain a safe distance from your mobile, device, and GPS.

Combustion hazard

Combustion risk: Rare earth powder is explosive. Avoid machining magnets without safety gear as this risks ignition.

Demagnetization risk

Standard neodymium magnets (grade N) lose magnetization when the temperature exceeds 80°C. This process is irreversible.

Bone fractures

Large magnets can smash fingers in a fraction of a second. Never put your hand betwixt two strong magnets.

Conscious usage

Handle magnets with awareness. Their powerful strength can surprise even experienced users. Plan your moves and respect their power.

![HH 36x7.5 [M6] / N38 - through hole magnetic holder HH 36x7.5 [M6] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-36x7.5-m6-bez.jpg)

![SM 32x175 [2xM8] / N52 - magnetic separator SM 32x175 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x175-2xm8-cep.jpg)