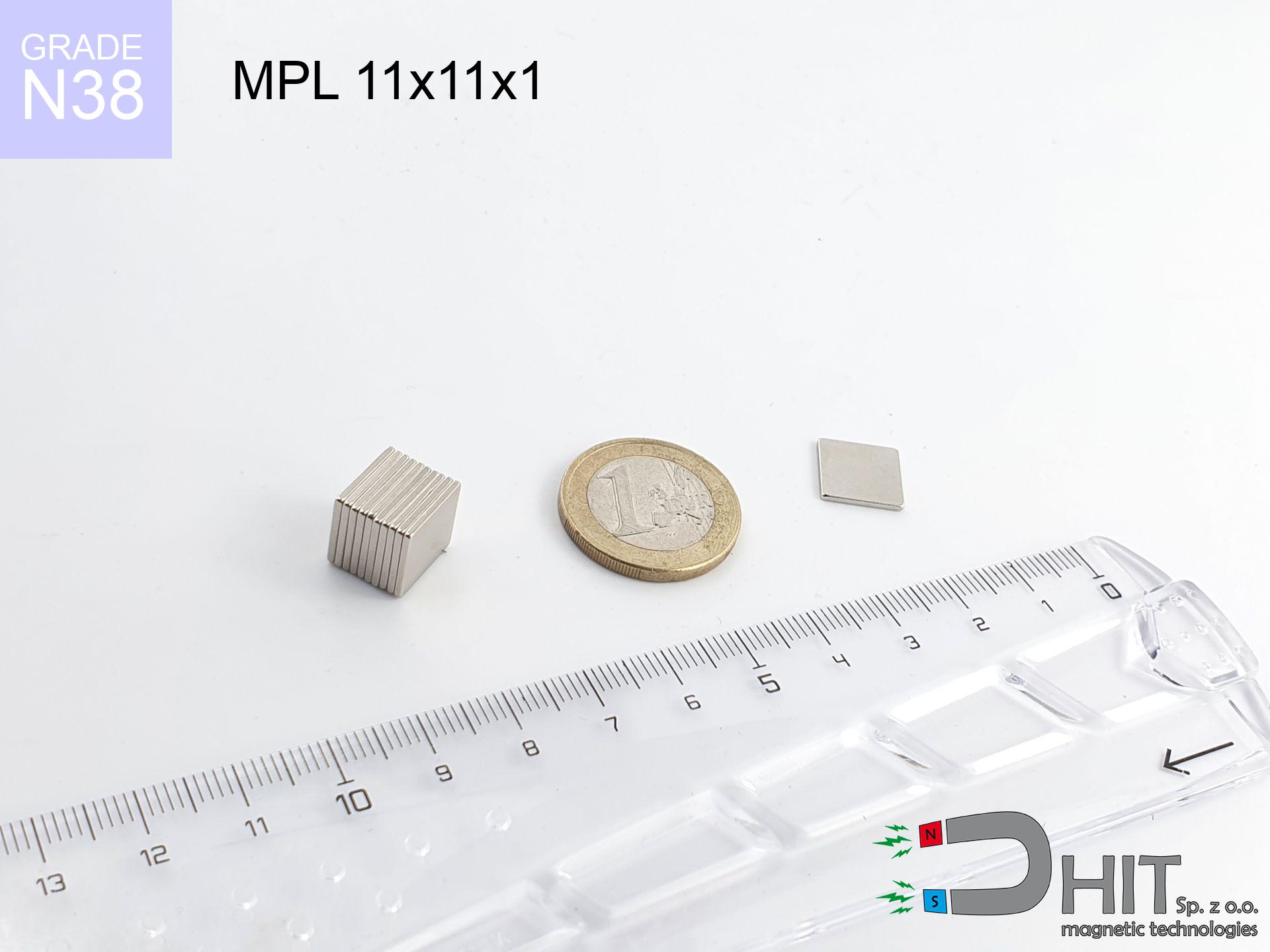

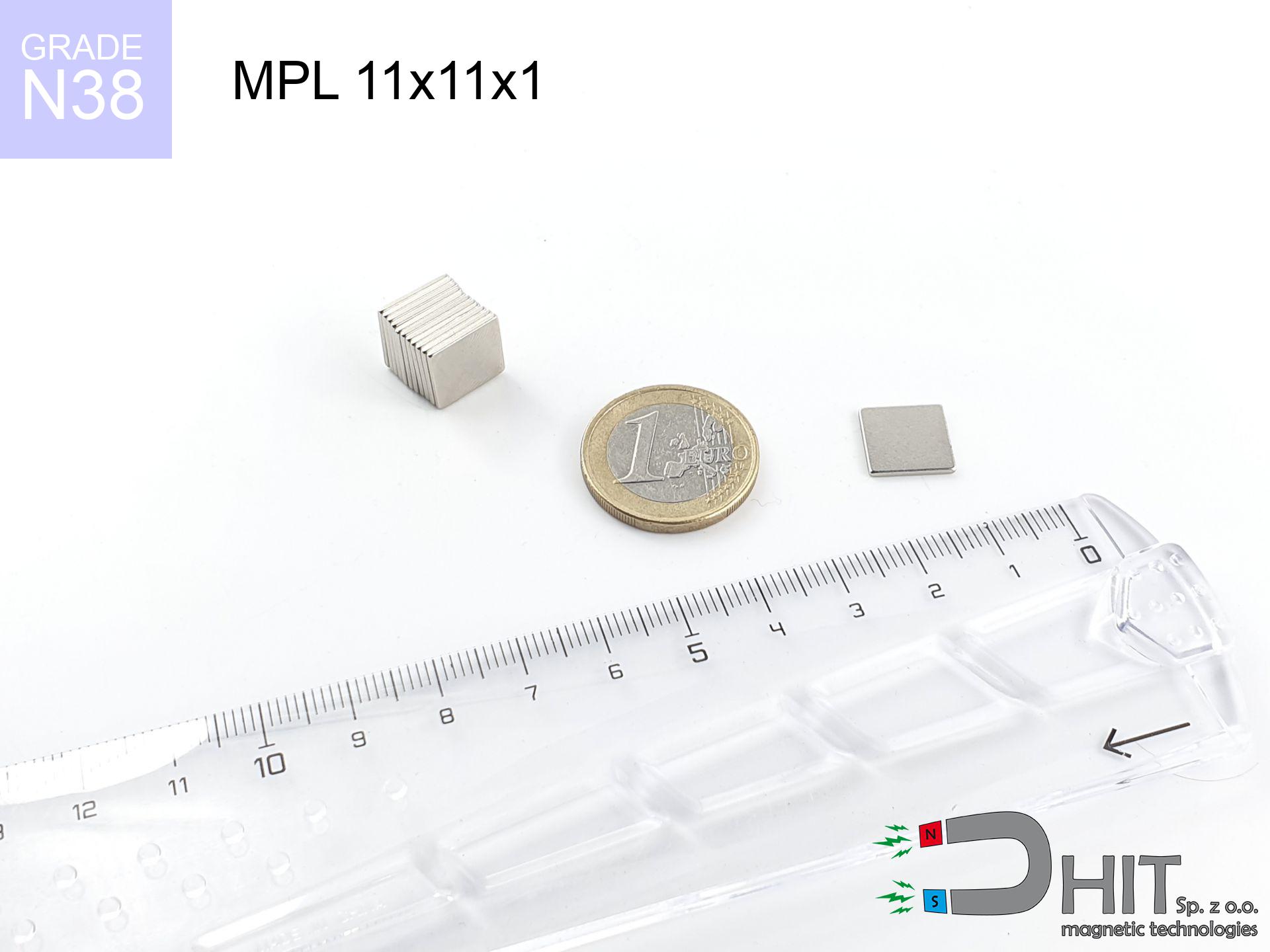

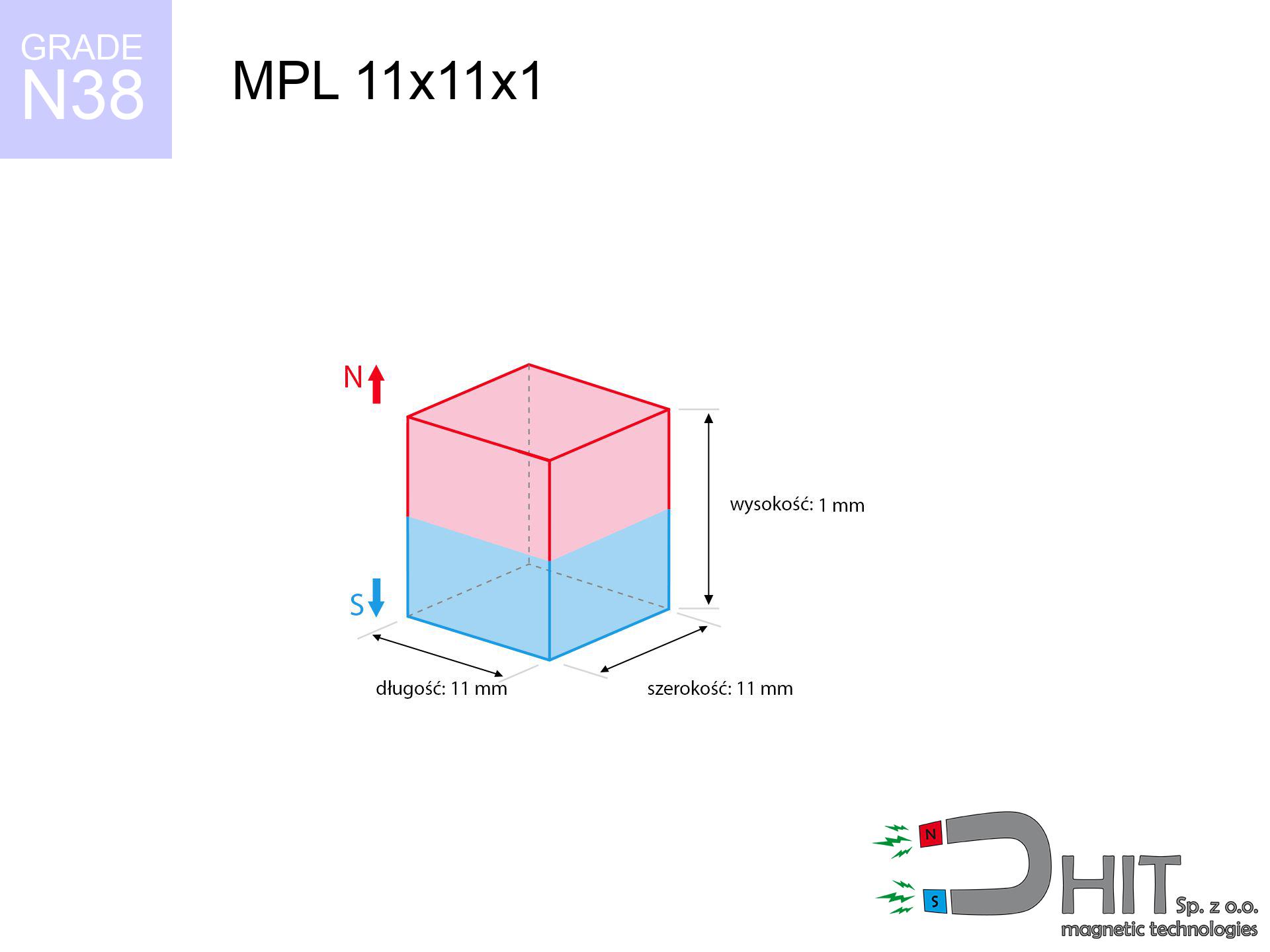

MPL 11x11x1 / N38 - lamellar magnet

lamellar magnet

Catalog no 020116

GTIN/EAN: 5906301811220

length

11 mm [±0,1 mm]

Width

11 mm [±0,1 mm]

Height

1 mm [±0,1 mm]

Weight

0.91 g

Magnetization Direction

↑ axial

Load capacity

0.43 kg / 4.24 N

Magnetic Induction

100.10 mT / 1001 Gs

Coating

[NiCuNi] Nickel

0.873 ZŁ with VAT / pcs + price for transport

0.710 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer contact us via

form

the contact form page.

Strength along with shape of magnets can be analyzed using our

our magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Technical specification - MPL 11x11x1 / N38 - lamellar magnet

Specification / characteristics - MPL 11x11x1 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020116 |

| GTIN/EAN | 5906301811220 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 11 mm [±0,1 mm] |

| Width | 11 mm [±0,1 mm] |

| Height | 1 mm [±0,1 mm] |

| Weight | 0.91 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.43 kg / 4.24 N |

| Magnetic Induction ~ ? | 100.10 mT / 1001 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the product - technical parameters

Presented data are the result of a mathematical simulation. Values were calculated on models for the class Nd2Fe14B. Real-world parameters may differ from theoretical values. Use these data as a supplementary guide when designing systems.

Table 1: Static force (force vs gap) - power drop

MPL 11x11x1 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1001 Gs

100.1 mT

|

0.43 kg / 0.95 pounds

430.0 g / 4.2 N

|

safe |

| 1 mm |

925 Gs

92.5 mT

|

0.37 kg / 0.81 pounds

367.7 g / 3.6 N

|

safe |

| 2 mm |

800 Gs

80.0 mT

|

0.27 kg / 0.61 pounds

274.9 g / 2.7 N

|

safe |

| 3 mm |

659 Gs

65.9 mT

|

0.19 kg / 0.41 pounds

186.5 g / 1.8 N

|

safe |

| 5 mm |

415 Gs

41.5 mT

|

0.07 kg / 0.16 pounds

74.0 g / 0.7 N

|

safe |

| 10 mm |

130 Gs

13.0 mT

|

0.01 kg / 0.02 pounds

7.3 g / 0.1 N

|

safe |

| 15 mm |

51 Gs

5.1 mT

|

0.00 kg / 0.00 pounds

1.1 g / 0.0 N

|

safe |

| 20 mm |

24 Gs

2.4 mT

|

0.00 kg / 0.00 pounds

0.3 g / 0.0 N

|

safe |

| 30 mm |

8 Gs

0.8 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

| 50 mm |

2 Gs

0.2 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Slippage force (vertical surface)

MPL 11x11x1 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.09 kg / 0.19 pounds

86.0 g / 0.8 N

|

| 1 mm | Stal (~0.2) |

0.07 kg / 0.16 pounds

74.0 g / 0.7 N

|

| 2 mm | Stal (~0.2) |

0.05 kg / 0.12 pounds

54.0 g / 0.5 N

|

| 3 mm | Stal (~0.2) |

0.04 kg / 0.08 pounds

38.0 g / 0.4 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

14.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MPL 11x11x1 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.13 kg / 0.28 pounds

129.0 g / 1.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.09 kg / 0.19 pounds

86.0 g / 0.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.04 kg / 0.09 pounds

43.0 g / 0.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.22 kg / 0.47 pounds

215.0 g / 2.1 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 11x11x1 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.04 kg / 0.09 pounds

43.0 g / 0.4 N

|

| 1 mm |

|

0.11 kg / 0.24 pounds

107.5 g / 1.1 N

|

| 2 mm |

|

0.22 kg / 0.47 pounds

215.0 g / 2.1 N

|

| 3 mm |

|

0.32 kg / 0.71 pounds

322.5 g / 3.2 N

|

| 5 mm |

|

0.43 kg / 0.95 pounds

430.0 g / 4.2 N

|

| 10 mm |

|

0.43 kg / 0.95 pounds

430.0 g / 4.2 N

|

| 11 mm |

|

0.43 kg / 0.95 pounds

430.0 g / 4.2 N

|

| 12 mm |

|

0.43 kg / 0.95 pounds

430.0 g / 4.2 N

|

Table 5: Working in heat (material behavior) - thermal limit

MPL 11x11x1 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.43 kg / 0.95 pounds

430.0 g / 4.2 N

|

OK |

| 40 °C | -2.2% |

0.42 kg / 0.93 pounds

420.5 g / 4.1 N

|

OK |

| 60 °C | -4.4% |

0.41 kg / 0.91 pounds

411.1 g / 4.0 N

|

|

| 80 °C | -6.6% |

0.40 kg / 0.89 pounds

401.6 g / 3.9 N

|

|

| 100 °C | -28.8% |

0.31 kg / 0.67 pounds

306.2 g / 3.0 N

|

Table 6: Two magnets (repulsion) - field range

MPL 11x11x1 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

0.75 kg / 1.65 pounds

1 925 Gs

|

0.11 kg / 0.25 pounds

112 g / 1.1 N

|

N/A |

| 1 mm |

0.70 kg / 1.55 pounds

1 943 Gs

|

0.11 kg / 0.23 pounds

106 g / 1.0 N

|

0.63 kg / 1.40 pounds

~0 Gs

|

| 2 mm |

0.64 kg / 1.41 pounds

1 851 Gs

|

0.10 kg / 0.21 pounds

96 g / 0.9 N

|

0.58 kg / 1.27 pounds

~0 Gs

|

| 3 mm |

0.56 kg / 1.24 pounds

1 734 Gs

|

0.08 kg / 0.19 pounds

84 g / 0.8 N

|

0.50 kg / 1.11 pounds

~0 Gs

|

| 5 mm |

0.40 kg / 0.88 pounds

1 460 Gs

|

0.06 kg / 0.13 pounds

60 g / 0.6 N

|

0.36 kg / 0.79 pounds

~0 Gs

|

| 10 mm |

0.13 kg / 0.28 pounds

831 Gs

|

0.02 kg / 0.04 pounds

19 g / 0.2 N

|

0.12 kg / 0.26 pounds

~0 Gs

|

| 20 mm |

0.01 kg / 0.03 pounds

261 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.03 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

26 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

16 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

10 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

7 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

5 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

4 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MPL 11x11x1 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 4.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 3.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.0 cm |

| Car key | 50 Gs (5.0 mT) | 2.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Impact energy (cracking risk) - warning

MPL 11x11x1 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.15 km/h

(6.15 m/s)

|

0.02 J | |

| 30 mm |

37.97 km/h

(10.55 m/s)

|

0.05 J | |

| 50 mm |

49.02 km/h

(13.62 m/s)

|

0.08 J | |

| 100 mm |

69.33 km/h

(19.26 m/s)

|

0.17 J |

Table 9: Anti-corrosion coating durability

MPL 11x11x1 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MPL 11x11x1 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 627 Mx | 16.3 µWb |

| Pc Coefficient | 0.13 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 11x11x1 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.43 kg | Standard |

| Water (riverbed) |

0.49 kg

(+0.06 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical surface, the magnet holds merely ~20% of its nominal pull.

2. Steel saturation

*Thin metal sheet (e.g. computer case) severely weakens the holding force.

3. Thermal stability

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.13

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

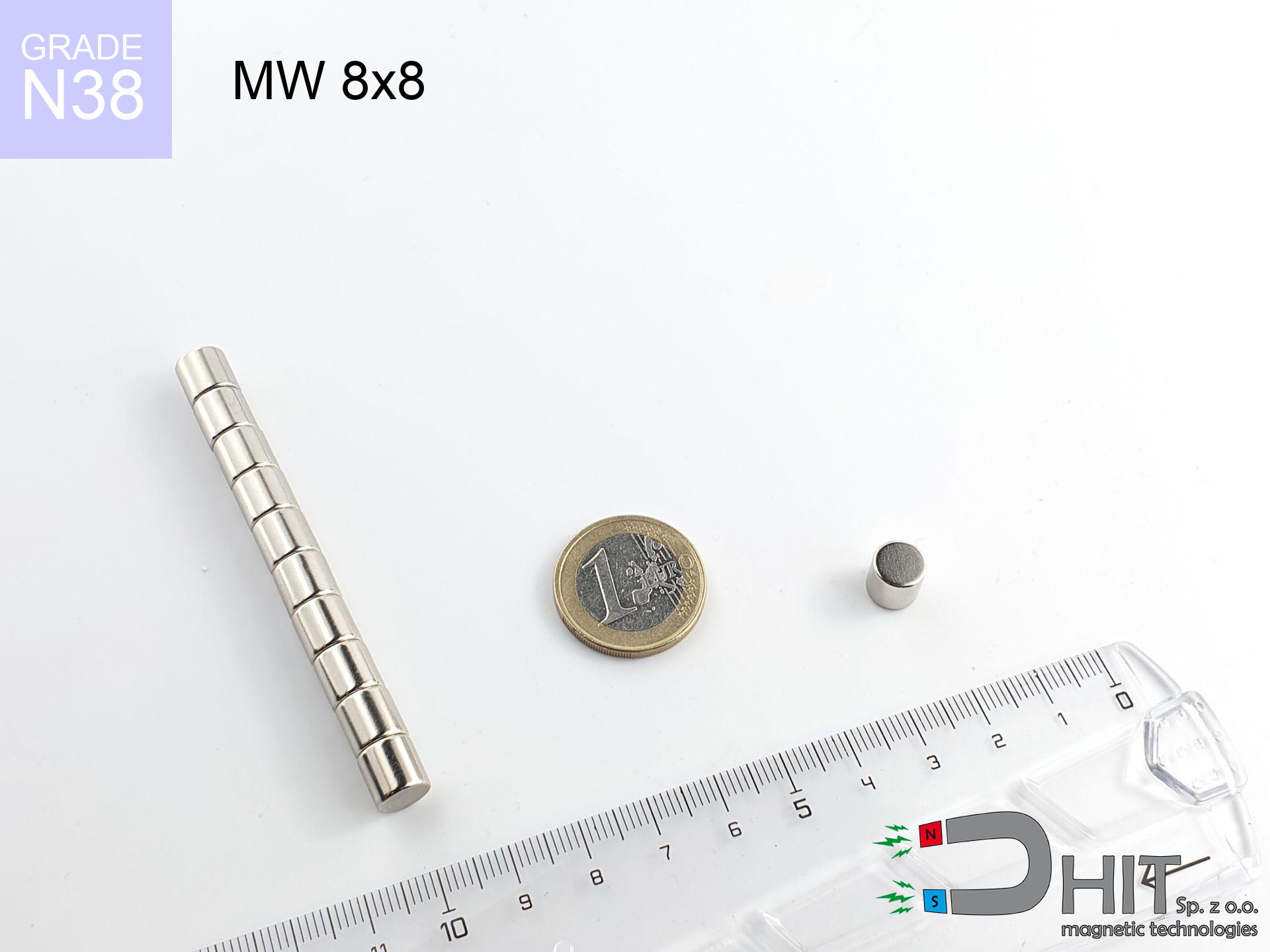

Other deals

Advantages as well as disadvantages of rare earth magnets.

Benefits

- They do not lose magnetism, even during nearly ten years – the reduction in power is only ~1% (according to tests),

- They possess excellent resistance to weakening of magnetic properties as a result of external magnetic sources,

- The use of an metallic layer of noble metals (nickel, gold, silver) causes the element to present itself better,

- Magnetic induction on the working part of the magnet remains impressive,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, allowing for action at temperatures approaching 230°C and above...

- Possibility of precise shaping and adjusting to specific requirements,

- Key role in modern industrial fields – they are commonly used in magnetic memories, electric drive systems, medical devices, and multitasking production systems.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Weaknesses

- At very strong impacts they can crack, therefore we advise placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- We recommend cover - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complex forms.

- Possible danger resulting from small fragments of magnets pose a threat, in case of ingestion, which becomes key in the aspect of protecting the youngest. Furthermore, tiny parts of these products can be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what affects it?

- with the contact of a yoke made of special test steel, ensuring full magnetic saturation

- whose thickness equals approx. 10 mm

- characterized by even structure

- without any insulating layer between the magnet and steel

- during pulling in a direction perpendicular to the plane

- at room temperature

Lifting capacity in real conditions – factors

- Air gap (betwixt the magnet and the metal), since even a very small clearance (e.g. 0.5 mm) can cause a decrease in lifting capacity by up to 50% (this also applies to paint, rust or debris).

- Pull-off angle – remember that the magnet holds strongest perpendicularly. Under shear forces, the holding force drops drastically, often to levels of 20-30% of the maximum value.

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Material type – ideal substrate is high-permeability steel. Hardened steels may attract less.

- Surface finish – full contact is obtained only on polished steel. Rough texture reduce the real contact area, reducing force.

- Temperature – heating the magnet causes a temporary drop of force. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was measured by applying a steel plate with a smooth surface of optimal thickness (min. 20 mm), under vertically applied force, whereas under parallel forces the lifting capacity is smaller. Additionally, even a slight gap between the magnet’s surface and the plate lowers the holding force.

Warnings

Risk of cracking

Despite the nickel coating, the material is delicate and not impact-resistant. Avoid impacts, as the magnet may shatter into sharp, dangerous pieces.

Electronic hazard

Very strong magnetic fields can erase data on credit cards, hard drives, and storage devices. Stay away of at least 10 cm.

Danger to the youngest

Adult use only. Tiny parts can be swallowed, leading to serious injuries. Keep out of reach of kids and pets.

Handling rules

Exercise caution. Rare earth magnets act from a long distance and connect with massive power, often quicker than you can move away.

Fire risk

Fire warning: Rare earth powder is explosive. Avoid machining magnets in home conditions as this risks ignition.

ICD Warning

Individuals with a ICD have to maintain an safe separation from magnets. The magnetism can stop the functioning of the life-saving device.

Phone sensors

A strong magnetic field interferes with the operation of magnetometers in phones and navigation systems. Do not bring magnets near a smartphone to avoid damaging the sensors.

Maximum temperature

Monitor thermal conditions. Heating the magnet to high heat will ruin its magnetic structure and strength.

Metal Allergy

It is widely known that the nickel plating (standard magnet coating) is a strong allergen. If you have an allergy, refrain from direct skin contact and opt for coated magnets.

Crushing force

Watch your fingers. Two large magnets will snap together immediately with a force of several hundred kilograms, destroying everything in their path. Exercise extreme caution!