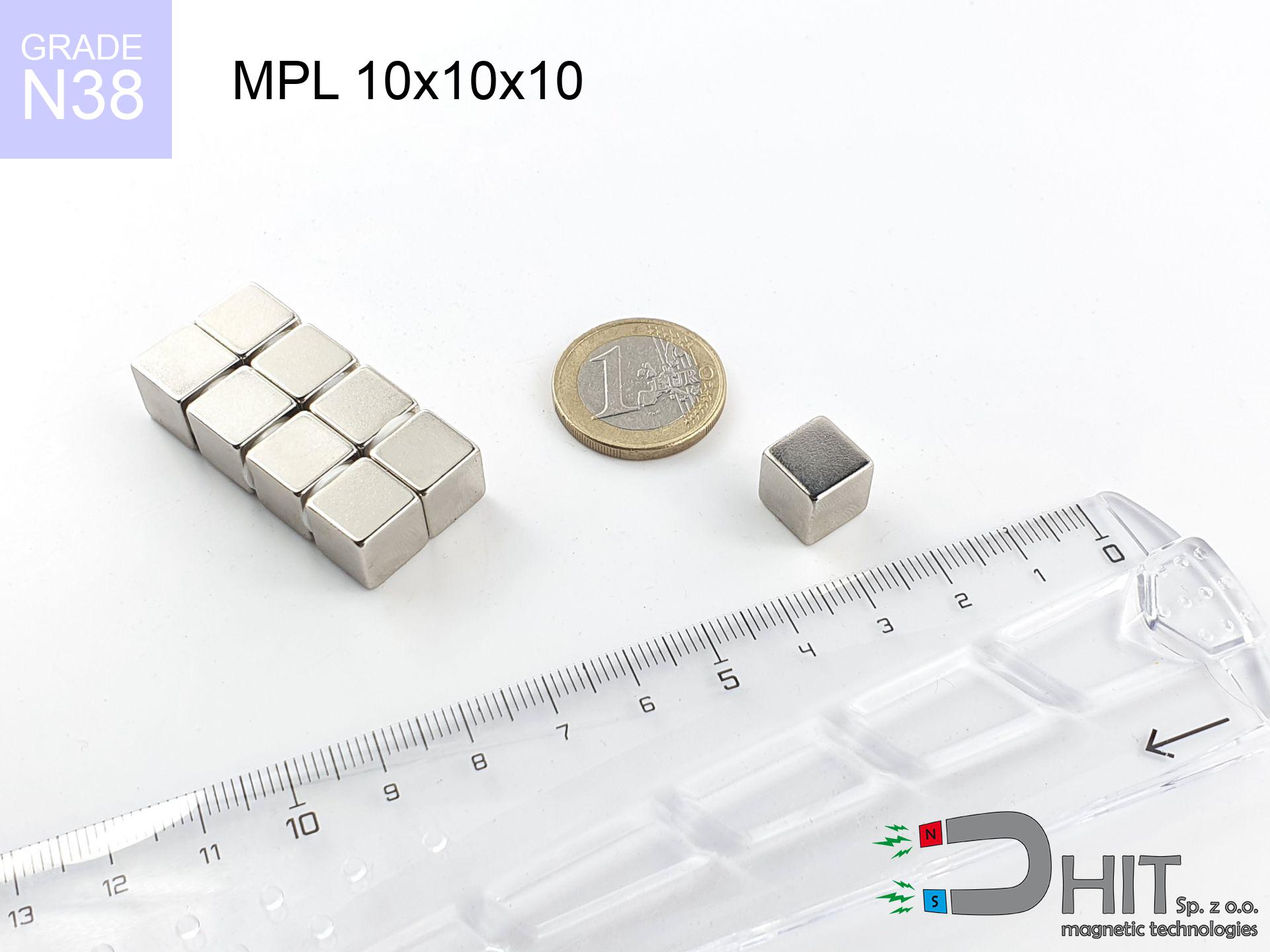

MPL 10x10x10 / N38 - lamellar magnet

lamellar magnet

Catalog no 020110

GTIN/EAN: 5906301811169

length

10 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

7.5 g

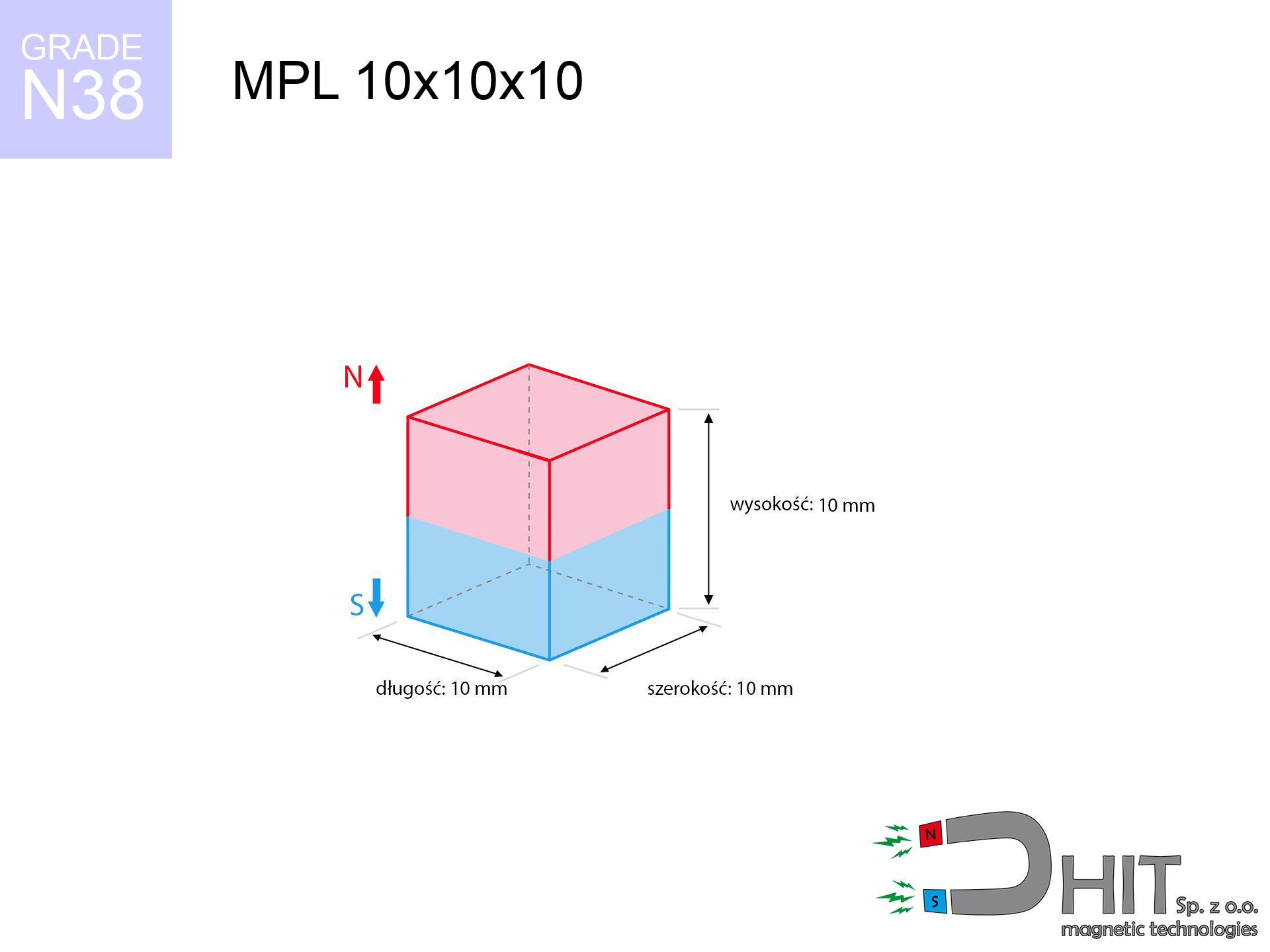

Magnetization Direction

↑ axial

Load capacity

3.84 kg / 37.71 N

Magnetic Induction

539.91 mT / 5399 Gs

Coating

[NiCuNi] Nickel

5.29 ZŁ with VAT / pcs + price for transport

4.30 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

if you prefer get in touch using

our online form

the contact page.

Specifications along with shape of neodymium magnets can be reviewed on our

online calculation tool.

Same-day processing for orders placed before 14:00.

Technical data of the product - MPL 10x10x10 / N38 - lamellar magnet

Specification / characteristics - MPL 10x10x10 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020110 |

| GTIN/EAN | 5906301811169 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 10 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 7.5 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.84 kg / 37.71 N |

| Magnetic Induction ~ ? | 539.91 mT / 5399 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the assembly - technical parameters

Presented data are the direct effect of a engineering analysis. Results were calculated on models for the class Nd2Fe14B. Real-world conditions might slightly differ. Treat these data as a supplementary guide when designing systems.

Table 1: Static force (force vs distance) - power drop

MPL 10x10x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5395 Gs

539.5 mT

|

3.84 kg / 8.47 lbs

3840.0 g / 37.7 N

|

strong |

| 1 mm |

4423 Gs

442.3 mT

|

2.58 kg / 5.69 lbs

2580.1 g / 25.3 N

|

strong |

| 2 mm |

3516 Gs

351.6 mT

|

1.63 kg / 3.60 lbs

1631.0 g / 16.0 N

|

weak grip |

| 3 mm |

2751 Gs

275.1 mT

|

1.00 kg / 2.20 lbs

998.0 g / 9.8 N

|

weak grip |

| 5 mm |

1671 Gs

167.1 mT

|

0.37 kg / 0.81 lbs

368.5 g / 3.6 N

|

weak grip |

| 10 mm |

562 Gs

56.2 mT

|

0.04 kg / 0.09 lbs

41.7 g / 0.4 N

|

weak grip |

| 15 mm |

244 Gs

24.4 mT

|

0.01 kg / 0.02 lbs

7.8 g / 0.1 N

|

weak grip |

| 20 mm |

126 Gs

12.6 mT

|

0.00 kg / 0.00 lbs

2.1 g / 0.0 N

|

weak grip |

| 30 mm |

46 Gs

4.6 mT

|

0.00 kg / 0.00 lbs

0.3 g / 0.0 N

|

weak grip |

| 50 mm |

12 Gs

1.2 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

Table 2: Shear hold (vertical surface)

MPL 10x10x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.77 kg / 1.69 lbs

768.0 g / 7.5 N

|

| 1 mm | Stal (~0.2) |

0.52 kg / 1.14 lbs

516.0 g / 5.1 N

|

| 2 mm | Stal (~0.2) |

0.33 kg / 0.72 lbs

326.0 g / 3.2 N

|

| 3 mm | Stal (~0.2) |

0.20 kg / 0.44 lbs

200.0 g / 2.0 N

|

| 5 mm | Stal (~0.2) |

0.07 kg / 0.16 lbs

74.0 g / 0.7 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MPL 10x10x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.15 kg / 2.54 lbs

1152.0 g / 11.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.77 kg / 1.69 lbs

768.0 g / 7.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.38 kg / 0.85 lbs

384.0 g / 3.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.92 kg / 4.23 lbs

1920.0 g / 18.8 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 10x10x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.38 kg / 0.85 lbs

384.0 g / 3.8 N

|

| 1 mm |

|

0.96 kg / 2.12 lbs

960.0 g / 9.4 N

|

| 2 mm |

|

1.92 kg / 4.23 lbs

1920.0 g / 18.8 N

|

| 3 mm |

|

2.88 kg / 6.35 lbs

2880.0 g / 28.3 N

|

| 5 mm |

|

3.84 kg / 8.47 lbs

3840.0 g / 37.7 N

|

| 10 mm |

|

3.84 kg / 8.47 lbs

3840.0 g / 37.7 N

|

| 11 mm |

|

3.84 kg / 8.47 lbs

3840.0 g / 37.7 N

|

| 12 mm |

|

3.84 kg / 8.47 lbs

3840.0 g / 37.7 N

|

Table 5: Thermal stability (material behavior) - power drop

MPL 10x10x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.84 kg / 8.47 lbs

3840.0 g / 37.7 N

|

OK |

| 40 °C | -2.2% |

3.76 kg / 8.28 lbs

3755.5 g / 36.8 N

|

OK |

| 60 °C | -4.4% |

3.67 kg / 8.09 lbs

3671.0 g / 36.0 N

|

OK |

| 80 °C | -6.6% |

3.59 kg / 7.91 lbs

3586.6 g / 35.2 N

|

|

| 100 °C | -28.8% |

2.73 kg / 6.03 lbs

2734.1 g / 26.8 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MPL 10x10x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

17.95 kg / 39.56 lbs

5 957 Gs

|

2.69 kg / 5.93 lbs

2692 g / 26.4 N

|

N/A |

| 1 mm |

14.86 kg / 32.77 lbs

9 821 Gs

|

2.23 kg / 4.92 lbs

2230 g / 21.9 N

|

13.38 kg / 29.49 lbs

~0 Gs

|

| 2 mm |

12.06 kg / 26.58 lbs

8 845 Gs

|

1.81 kg / 3.99 lbs

1809 g / 17.7 N

|

10.85 kg / 23.93 lbs

~0 Gs

|

| 3 mm |

9.64 kg / 21.26 lbs

7 909 Gs

|

1.45 kg / 3.19 lbs

1446 g / 14.2 N

|

8.68 kg / 19.13 lbs

~0 Gs

|

| 5 mm |

5.98 kg / 13.18 lbs

6 228 Gs

|

0.90 kg / 1.98 lbs

897 g / 8.8 N

|

5.38 kg / 11.86 lbs

~0 Gs

|

| 10 mm |

1.72 kg / 3.80 lbs

3 343 Gs

|

0.26 kg / 0.57 lbs

258 g / 2.5 N

|

1.55 kg / 3.42 lbs

~0 Gs

|

| 20 mm |

0.20 kg / 0.43 lbs

1 125 Gs

|

0.03 kg / 0.06 lbs

29 g / 0.3 N

|

0.18 kg / 0.39 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 lbs

146 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

92 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

62 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

43 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

32 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

24 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MPL 10x10x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.5 cm |

| Car key | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (kinetic energy) - collision effects

MPL 10x10x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.97 km/h

(6.38 m/s)

|

0.15 J | |

| 30 mm |

39.53 km/h

(10.98 m/s)

|

0.45 J | |

| 50 mm |

51.03 km/h

(14.17 m/s)

|

0.75 J | |

| 100 mm |

72.16 km/h

(20.05 m/s)

|

1.51 J |

Table 9: Surface protection spec

MPL 10x10x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 10x10x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 5 504 Mx | 55.0 µWb |

| Pc Coefficient | 0.84 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MPL 10x10x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.84 kg | Standard |

| Water (riverbed) |

4.40 kg

(+0.56 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet holds merely approx. 20-30% of its nominal pull.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) severely reduces the holding force.

3. Heat tolerance

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.84

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Pros and cons of rare earth magnets.

Benefits

- They have unchanged lifting capacity, and over nearly ten years their performance decreases symbolically – ~1% (in testing),

- Neodymium magnets prove to be remarkably resistant to loss of magnetic properties caused by magnetic disturbances,

- In other words, due to the metallic surface of silver, the element becomes visually attractive,

- They feature high magnetic induction at the operating surface, making them more effective,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to freedom in designing and the ability to adapt to specific needs,

- Wide application in electronics industry – they find application in magnetic memories, electric motors, medical devices, also modern systems.

- Relatively small size with high pulling force – neodymium magnets offer high power in small dimensions, which enables their usage in small systems

Weaknesses

- Brittleness is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a special holder, which not only secures them against impacts but also raises their durability

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- They oxidize in a humid environment. For use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- Limited possibility of producing threads in the magnet and complex shapes - preferred is casing - mounting mechanism.

- Possible danger resulting from small fragments of magnets can be dangerous, when accidentally swallowed, which is particularly important in the aspect of protecting the youngest. It is also worth noting that small components of these magnets can complicate diagnosis medical after entering the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Optimal lifting capacity of a neodymium magnet – what affects it?

- on a plate made of structural steel, perfectly concentrating the magnetic flux

- possessing a massiveness of at least 10 mm to ensure full flux closure

- with a surface cleaned and smooth

- without the slightest insulating layer between the magnet and steel

- during detachment in a direction perpendicular to the plane

- at conditions approx. 20°C

Practical aspects of lifting capacity – factors

- Air gap (between the magnet and the metal), since even a tiny distance (e.g. 0.5 mm) results in a reduction in lifting capacity by up to 50% (this also applies to varnish, corrosion or debris).

- Direction of force – maximum parameter is available only during perpendicular pulling. The resistance to sliding of the magnet along the surface is typically several times lower (approx. 1/5 of the lifting capacity).

- Wall thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of generating force.

- Metal type – not every steel attracts identically. High carbon content weaken the interaction with the magnet.

- Surface condition – smooth surfaces ensure maximum contact, which improves force. Uneven metal weaken the grip.

- Thermal environment – temperature increase causes a temporary drop of induction. Check the maximum operating temperature for a given model.

Lifting capacity testing was conducted on a smooth plate of suitable thickness, under a perpendicular pulling force, in contrast under shearing force the load capacity is reduced by as much as fivefold. In addition, even a minimal clearance between the magnet and the plate lowers the holding force.

Safe handling of NdFeB magnets

Medical implants

People with a heart stimulator should maintain an safe separation from magnets. The magnetic field can stop the functioning of the life-saving device.

Threat to electronics

Do not bring magnets near a wallet, laptop, or screen. The magnetic field can irreversibly ruin these devices and erase data from cards.

Do not drill into magnets

Combustion risk: Neodymium dust is explosive. Avoid machining magnets without safety gear as this risks ignition.

Permanent damage

Do not overheat. NdFeB magnets are susceptible to heat. If you need resistance above 80°C, inquire about HT versions (H, SH, UH).

Serious injuries

Protect your hands. Two large magnets will join instantly with a force of several hundred kilograms, destroying anything in their path. Be careful!

Caution required

Be careful. Neodymium magnets attract from a distance and connect with massive power, often quicker than you can move away.

Sensitization to coating

Warning for allergy sufferers: The nickel-copper-nickel coating contains nickel. If redness occurs, immediately stop handling magnets and use protective gear.

Compass and GPS

Navigation devices and smartphones are extremely sensitive to magnetism. Direct contact with a powerful NdFeB magnet can decalibrate the internal compass in your phone.

Product not for children

Absolutely store magnets out of reach of children. Ingestion danger is high, and the effects of magnets clamping inside the body are life-threatening.

Beware of splinters

Protect your eyes. Magnets can fracture upon violent connection, ejecting sharp fragments into the air. Eye protection is mandatory.

![SM 32x450 [2xM8] / N52 - magnetic separator SM 32x450 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x450-2xm8-bir.jpg)