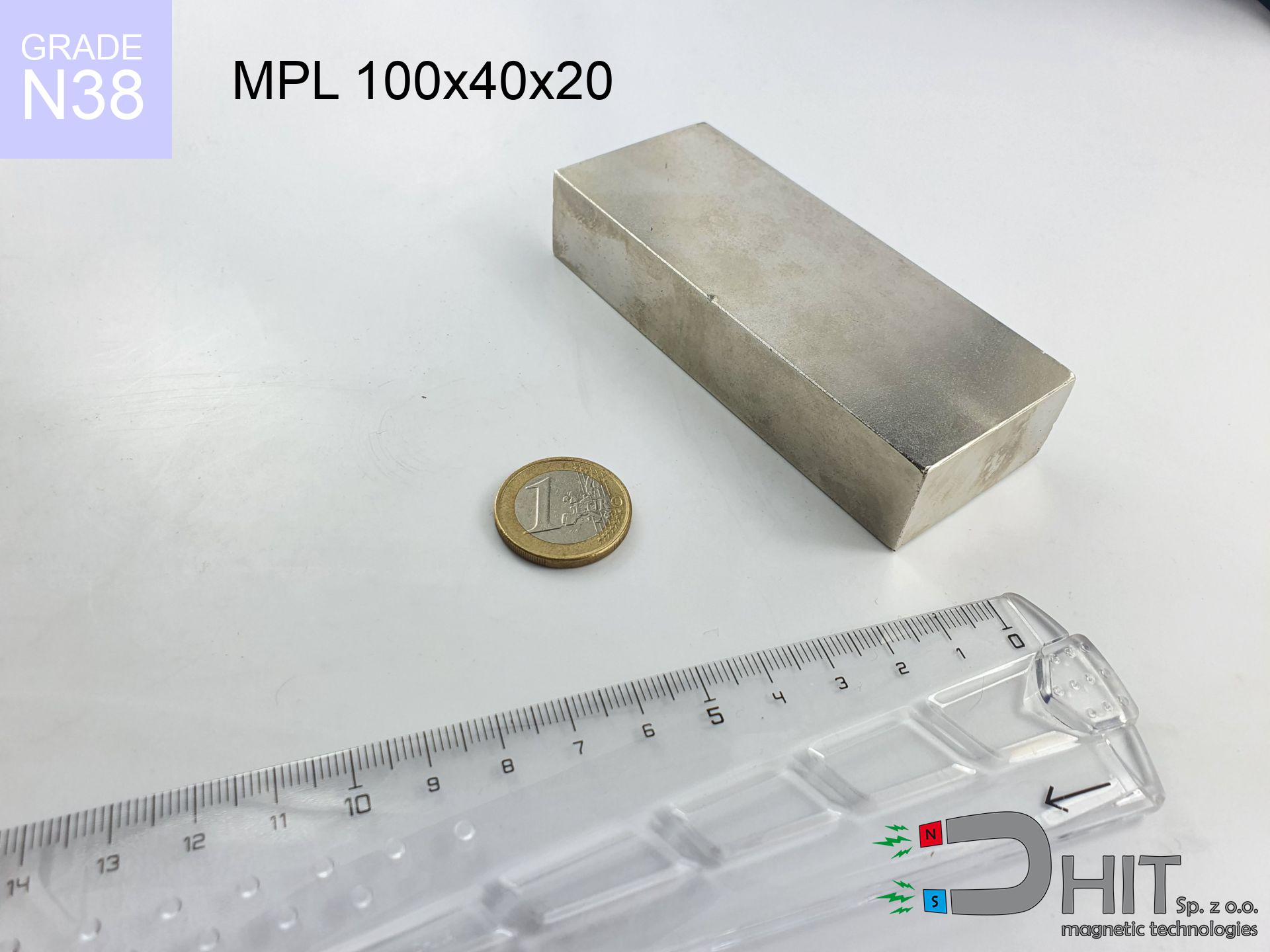

MPL 100x40x20 / N38 - lamellar magnet

lamellar magnet

Catalog no 020109

GTIN/EAN: 5906301811152

length

100 mm [±0,1 mm]

Width

40 mm [±0,1 mm]

Height

20 mm [±0,1 mm]

Weight

600 g

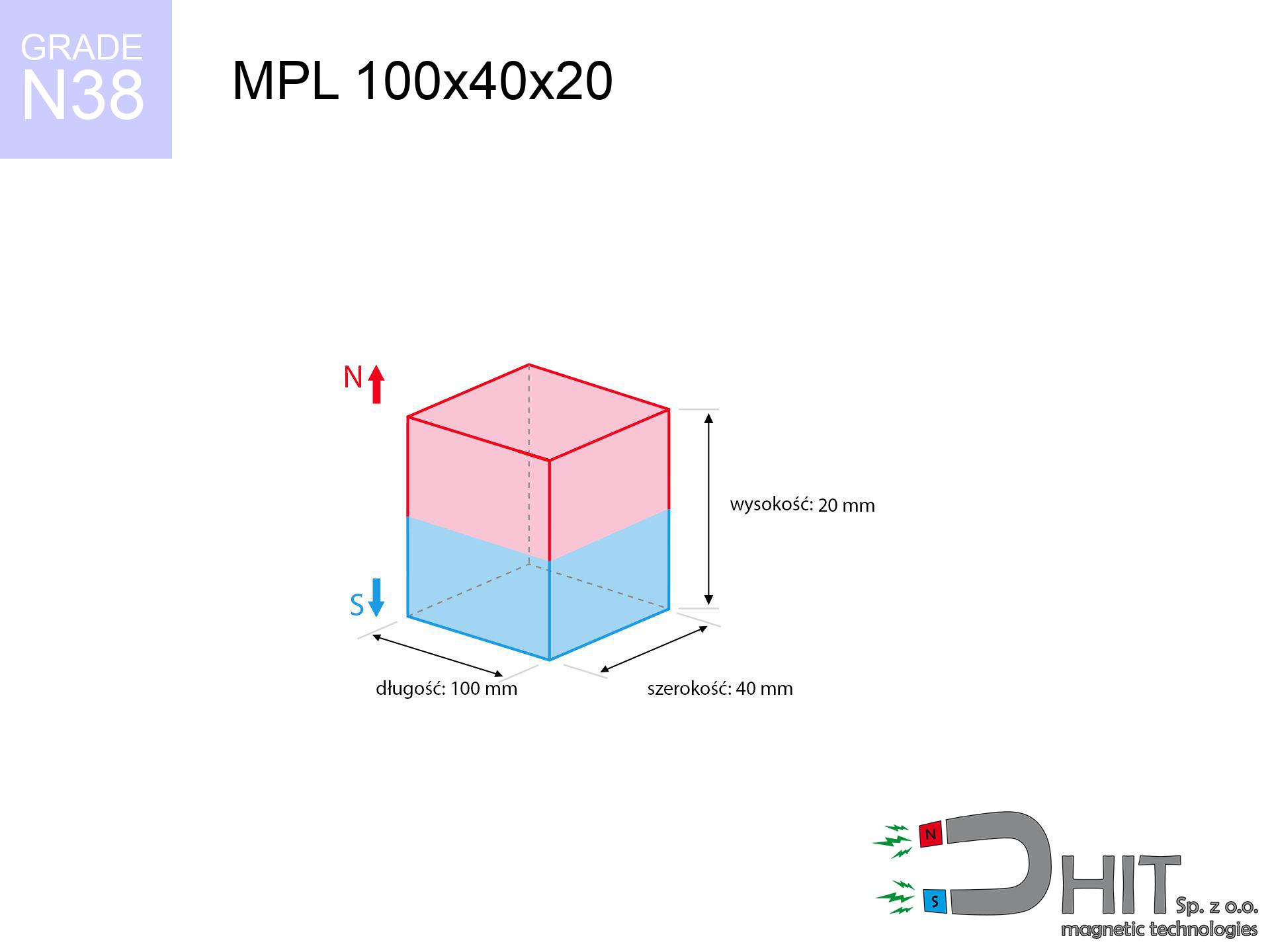

Magnetization Direction

↑ axial

Load capacity

120.01 kg / 1177.33 N

Magnetic Induction

337.24 mT / 3372 Gs

Coating

[NiCuNi] Nickel

335.30 ZŁ with VAT / pcs + price for transport

272.60 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

or send us a note by means of

our online form

the contact section.

Strength along with appearance of a neodymium magnet can be tested with our

online calculation tool.

Same-day processing for orders placed before 14:00.

Physical properties - MPL 100x40x20 / N38 - lamellar magnet

Specification / characteristics - MPL 100x40x20 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020109 |

| GTIN/EAN | 5906301811152 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 100 mm [±0,1 mm] |

| Width | 40 mm [±0,1 mm] |

| Height | 20 mm [±0,1 mm] |

| Weight | 600 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 120.01 kg / 1177.33 N |

| Magnetic Induction ~ ? | 337.24 mT / 3372 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the assembly - report

The following data are the direct effect of a engineering calculation. Values were calculated on algorithms for the material Nd2Fe14B. Actual parameters might slightly deviate from the simulation results. Treat these calculations as a preliminary roadmap when designing systems.

Table 1: Static pull force (force vs distance) - power drop

MPL 100x40x20 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3372 Gs

337.2 mT

|

120.01 kg / 264.58 LBS

120010.0 g / 1177.3 N

|

critical level |

| 1 mm |

3268 Gs

326.8 mT

|

112.70 kg / 248.45 LBS

112695.4 g / 1105.5 N

|

critical level |

| 2 mm |

3158 Gs

315.8 mT

|

105.27 kg / 232.09 LBS

105272.6 g / 1032.7 N

|

critical level |

| 3 mm |

3046 Gs

304.6 mT

|

97.92 kg / 215.88 LBS

97921.3 g / 960.6 N

|

critical level |

| 5 mm |

2818 Gs

281.8 mT

|

83.78 kg / 184.71 LBS

83783.3 g / 821.9 N

|

critical level |

| 10 mm |

2266 Gs

226.6 mT

|

54.17 kg / 119.43 LBS

54174.5 g / 531.5 N

|

critical level |

| 15 mm |

1794 Gs

179.4 mT

|

33.96 kg / 74.86 LBS

33955.7 g / 333.1 N

|

critical level |

| 20 mm |

1419 Gs

141.9 mT

|

21.25 kg / 46.84 LBS

21248.1 g / 208.4 N

|

critical level |

| 30 mm |

908 Gs

90.8 mT

|

8.70 kg / 19.17 LBS

8696.3 g / 85.3 N

|

strong |

| 50 mm |

416 Gs

41.6 mT

|

1.83 kg / 4.02 LBS

1825.4 g / 17.9 N

|

weak grip |

Table 2: Sliding force (vertical surface)

MPL 100x40x20 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

24.00 kg / 52.92 LBS

24002.0 g / 235.5 N

|

| 1 mm | Stal (~0.2) |

22.54 kg / 49.69 LBS

22540.0 g / 221.1 N

|

| 2 mm | Stal (~0.2) |

21.05 kg / 46.42 LBS

21054.0 g / 206.5 N

|

| 3 mm | Stal (~0.2) |

19.58 kg / 43.18 LBS

19584.0 g / 192.1 N

|

| 5 mm | Stal (~0.2) |

16.76 kg / 36.94 LBS

16756.0 g / 164.4 N

|

| 10 mm | Stal (~0.2) |

10.83 kg / 23.88 LBS

10834.0 g / 106.3 N

|

| 15 mm | Stal (~0.2) |

6.79 kg / 14.97 LBS

6792.0 g / 66.6 N

|

| 20 mm | Stal (~0.2) |

4.25 kg / 9.37 LBS

4250.0 g / 41.7 N

|

| 30 mm | Stal (~0.2) |

1.74 kg / 3.84 LBS

1740.0 g / 17.1 N

|

| 50 mm | Stal (~0.2) |

0.37 kg / 0.81 LBS

366.0 g / 3.6 N

|

Table 3: Wall mounting (shearing) - vertical pull

MPL 100x40x20 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

36.00 kg / 79.37 LBS

36003.0 g / 353.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

24.00 kg / 52.92 LBS

24002.0 g / 235.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

12.00 kg / 26.46 LBS

12001.0 g / 117.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

60.01 kg / 132.29 LBS

60005.0 g / 588.6 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MPL 100x40x20 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

4.00 kg / 8.82 LBS

4000.3 g / 39.2 N

|

| 1 mm |

|

10.00 kg / 22.05 LBS

10000.8 g / 98.1 N

|

| 2 mm |

|

20.00 kg / 44.10 LBS

20001.7 g / 196.2 N

|

| 3 mm |

|

30.00 kg / 66.14 LBS

30002.5 g / 294.3 N

|

| 5 mm |

|

50.00 kg / 110.24 LBS

50004.2 g / 490.5 N

|

| 10 mm |

|

100.01 kg / 220.48 LBS

100008.3 g / 981.1 N

|

| 11 mm |

|

110.01 kg / 242.53 LBS

110009.2 g / 1079.2 N

|

| 12 mm |

|

120.01 kg / 264.58 LBS

120010.0 g / 1177.3 N

|

Table 5: Working in heat (material behavior) - power drop

MPL 100x40x20 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

120.01 kg / 264.58 LBS

120010.0 g / 1177.3 N

|

OK |

| 40 °C | -2.2% |

117.37 kg / 258.76 LBS

117369.8 g / 1151.4 N

|

OK |

| 60 °C | -4.4% |

114.73 kg / 252.94 LBS

114729.6 g / 1125.5 N

|

|

| 80 °C | -6.6% |

112.09 kg / 247.11 LBS

112089.3 g / 1099.6 N

|

|

| 100 °C | -28.8% |

85.45 kg / 188.38 LBS

85447.1 g / 838.2 N

|

Table 6: Two magnets (repulsion) - field collision

MPL 100x40x20 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

280.40 kg / 618.18 LBS

4 790 Gs

|

42.06 kg / 92.73 LBS

42060 g / 412.6 N

|

N/A |

| 1 mm |

271.97 kg / 599.59 LBS

6 642 Gs

|

40.80 kg / 89.94 LBS

40796 g / 400.2 N

|

244.77 kg / 539.63 LBS

~0 Gs

|

| 2 mm |

263.31 kg / 580.50 LBS

6 535 Gs

|

39.50 kg / 87.08 LBS

39497 g / 387.5 N

|

236.98 kg / 522.45 LBS

~0 Gs

|

| 3 mm |

254.63 kg / 561.37 LBS

6 427 Gs

|

38.20 kg / 84.21 LBS

38195 g / 374.7 N

|

229.17 kg / 505.24 LBS

~0 Gs

|

| 5 mm |

237.35 kg / 523.26 LBS

6 205 Gs

|

35.60 kg / 78.49 LBS

35602 g / 349.3 N

|

213.61 kg / 470.93 LBS

~0 Gs

|

| 10 mm |

195.76 kg / 431.58 LBS

5 635 Gs

|

29.36 kg / 64.74 LBS

29364 g / 288.1 N

|

176.18 kg / 388.42 LBS

~0 Gs

|

| 20 mm |

126.58 kg / 279.06 LBS

4 531 Gs

|

18.99 kg / 41.86 LBS

18987 g / 186.3 N

|

113.92 kg / 251.15 LBS

~0 Gs

|

| 50 mm |

31.47 kg / 69.38 LBS

2 259 Gs

|

4.72 kg / 10.41 LBS

4721 g / 46.3 N

|

28.32 kg / 62.44 LBS

~0 Gs

|

| 60 mm |

20.32 kg / 44.80 LBS

1 815 Gs

|

3.05 kg / 6.72 LBS

3048 g / 29.9 N

|

18.29 kg / 40.32 LBS

~0 Gs

|

| 70 mm |

13.38 kg / 29.50 LBS

1 473 Gs

|

2.01 kg / 4.42 LBS

2007 g / 19.7 N

|

12.04 kg / 26.55 LBS

~0 Gs

|

| 80 mm |

8.98 kg / 19.80 LBS

1 207 Gs

|

1.35 kg / 2.97 LBS

1347 g / 13.2 N

|

8.08 kg / 17.82 LBS

~0 Gs

|

| 90 mm |

6.14 kg / 13.53 LBS

998 Gs

|

0.92 kg / 2.03 LBS

920 g / 9.0 N

|

5.52 kg / 12.18 LBS

~0 Gs

|

| 100 mm |

4.27 kg / 9.40 LBS

832 Gs

|

0.64 kg / 1.41 LBS

640 g / 6.3 N

|

3.84 kg / 8.46 LBS

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MPL 100x40x20 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 30.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 24.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 18.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 14.5 cm |

| Remote | 50 Gs (5.0 mT) | 13.5 cm |

| Payment card | 400 Gs (40.0 mT) | 5.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 4.5 cm |

Table 8: Impact energy (kinetic energy) - warning

MPL 100x40x20 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.84 km/h

(4.96 m/s)

|

7.37 J | |

| 30 mm |

25.80 km/h

(7.17 m/s)

|

15.41 J | |

| 50 mm |

32.20 km/h

(8.94 m/s)

|

23.99 J | |

| 100 mm |

45.13 km/h

(12.54 m/s)

|

47.14 J |

Table 9: Coating parameters (durability)

MPL 100x40x20 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 100x40x20 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 131 922 Mx | 1319.2 µWb |

| Pc Coefficient | 0.38 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 100x40x20 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 120.01 kg | Standard |

| Water (riverbed) |

137.41 kg

(+17.40 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical wall, the magnet retains just ~20% of its perpendicular strength.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Heat tolerance

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.38

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

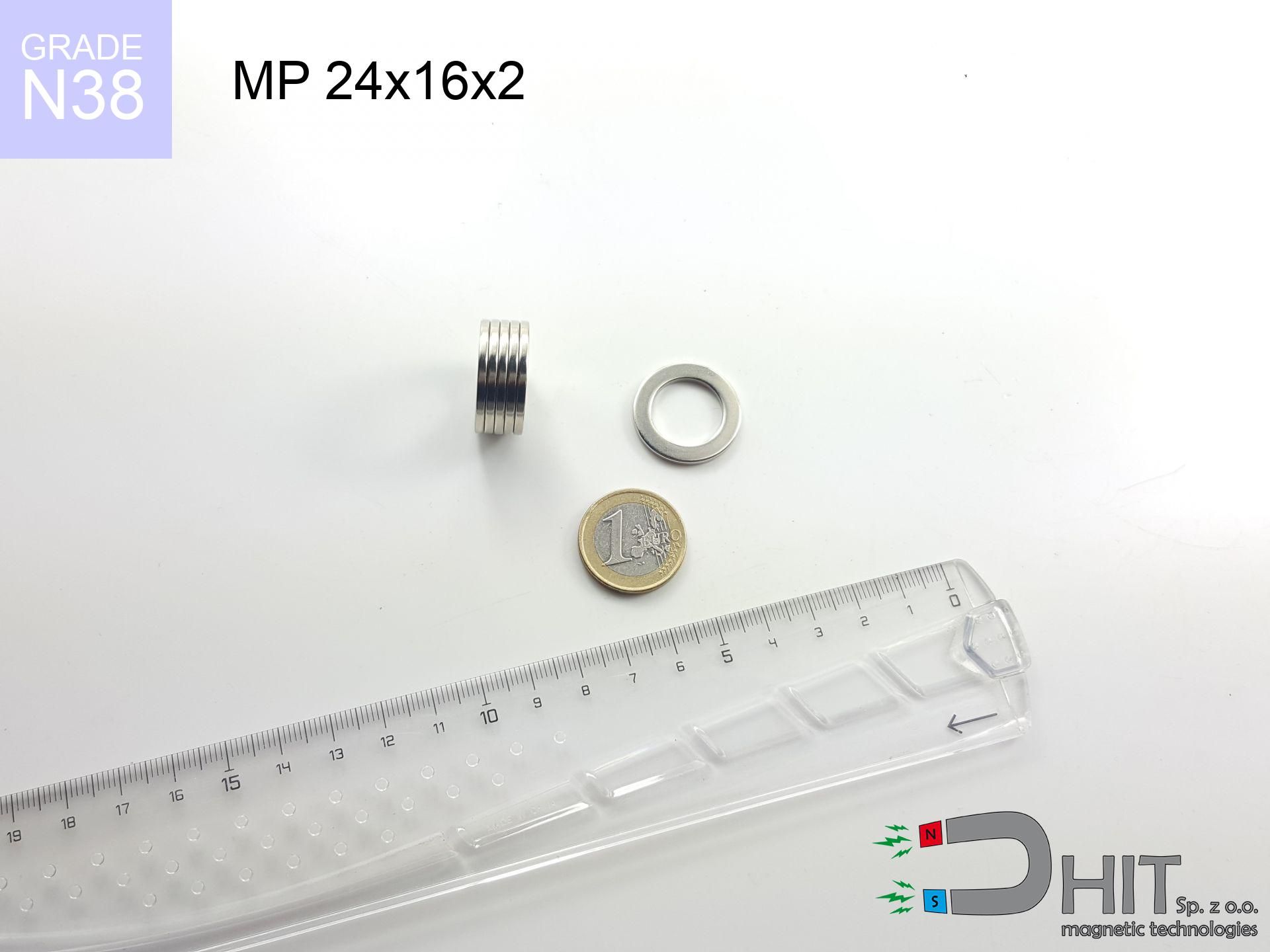

View also proposals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Pros

- They do not lose power, even after around 10 years – the drop in strength is only ~1% (based on measurements),

- They maintain their magnetic properties even under strong external field,

- A magnet with a smooth gold surface is more attractive,

- Magnetic induction on the surface of the magnet turns out to be maximum,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and are able to act (depending on the form) even at a temperature of 230°C or more...

- Thanks to versatility in shaping and the capacity to modify to client solutions,

- Huge importance in modern industrial fields – they find application in computer drives, electric drive systems, precision medical tools, and complex engineering applications.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Cons

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only shields the magnet but also improves its resistance to damage

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in realizing nuts and complicated shapes in magnets, we propose using a housing - magnetic mechanism.

- Health risk to health – tiny shards of magnets are risky, in case of ingestion, which becomes key in the context of child health protection. It is also worth noting that small components of these magnets are able to complicate diagnosis medical when they are in the body.

- Due to complex production process, their price is higher than average,

Pull force analysis

Detachment force of the magnet in optimal conditions – what contributes to it?

- using a sheet made of high-permeability steel, serving as a circuit closing element

- possessing a massiveness of minimum 10 mm to ensure full flux closure

- with a plane cleaned and smooth

- without any air gap between the magnet and steel

- under axial force direction (90-degree angle)

- at temperature approx. 20 degrees Celsius

Magnet lifting force in use – key factors

- Gap between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by varnish or unevenness) significantly weakens the pulling force, often by half at just 0.5 mm.

- Angle of force application – maximum parameter is obtained only during pulling at a 90° angle. The shear force of the magnet along the surface is standardly several times smaller (approx. 1/5 of the lifting capacity).

- Plate thickness – insufficiently thick sheet does not accept the full field, causing part of the flux to be lost to the other side.

- Steel type – low-carbon steel gives the best results. Alloy steels decrease magnetic permeability and lifting capacity.

- Surface structure – the more even the plate, the better the adhesion and higher the lifting capacity. Unevenness acts like micro-gaps.

- Thermal factor – hot environment reduces magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Holding force was tested on the plate surface of 20 mm thickness, when a perpendicular force was applied, however under shearing force the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet and the plate decreases the load capacity.

Precautions when working with neodymium magnets

Implant safety

For implant holders: Strong magnetic fields disrupt medical devices. Keep at least 30 cm distance or ask another person to handle the magnets.

Hand protection

Risk of injury: The pulling power is so great that it can cause hematomas, crushing, and broken bones. Use thick gloves.

Thermal limits

Standard neodymium magnets (N-type) undergo demagnetization when the temperature goes above 80°C. This process is irreversible.

Warning for allergy sufferers

Warning for allergy sufferers: The Ni-Cu-Ni coating consists of nickel. If an allergic reaction occurs, immediately stop working with magnets and use protective gear.

Combustion hazard

Fire hazard: Neodymium dust is highly flammable. Do not process magnets without safety gear as this may cause fire.

Fragile material

Despite the nickel coating, the material is delicate and not impact-resistant. Avoid impacts, as the magnet may crumble into hazardous fragments.

Protect data

Powerful magnetic fields can corrupt files on payment cards, HDDs, and other magnetic media. Stay away of at least 10 cm.

Phone sensors

A strong magnetic field negatively affects the operation of magnetometers in phones and navigation systems. Do not bring magnets close to a device to avoid damaging the sensors.

Danger to the youngest

NdFeB magnets are not intended for children. Accidental ingestion of several magnets may result in them pinching intestinal walls, which constitutes a severe health hazard and requires immediate surgery.

Safe operation

Use magnets consciously. Their huge power can surprise even professionals. Stay alert and respect their force.

![HH 42x8.8 [M6] / N38 - through hole magnetic holder HH 42x8.8 [M6] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-42x8.8-m6-hin.jpg)

![BM 950x180x70 [4x M8] - magnetic beam BM 950x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-950x180x70-4x-m8-ves.jpg)