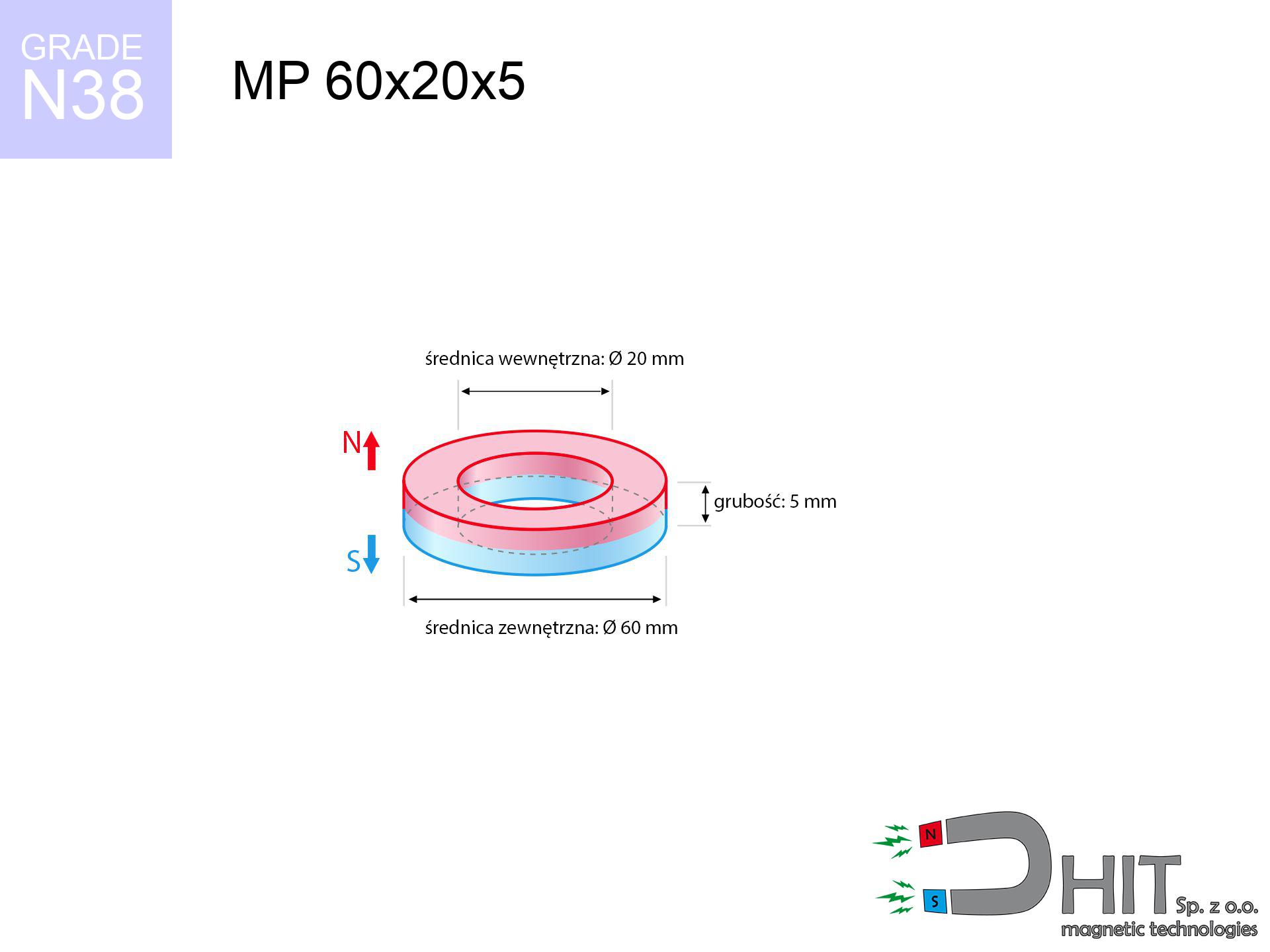

MP 60x20x5 / N38 - ring magnet

ring magnet

Catalog no 030204

GTIN/EAN: 5906301812210

Diameter

60 mm [±0,1 mm]

internal diameter Ø

20 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

94.25 g

Magnetization Direction

↑ axial

Load capacity

9.41 kg / 92.27 N

Magnetic Induction

101.92 mT / 1019 Gs

Coating

[NiCuNi] Nickel

47.99 ZŁ with VAT / pcs + price for transport

39.02 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

if you prefer get in touch via

request form

through our site.

Strength as well as appearance of neodymium magnets can be verified on our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical details - MP 60x20x5 / N38 - ring magnet

Specification / characteristics - MP 60x20x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030204 |

| GTIN/EAN | 5906301812210 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 60 mm [±0,1 mm] |

| internal diameter Ø | 20 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 94.25 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 9.41 kg / 92.27 N |

| Magnetic Induction ~ ? | 101.92 mT / 1019 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the assembly - data

Presented information represent the direct effect of a mathematical analysis. Results rely on models for the material Nd2Fe14B. Real-world conditions might slightly deviate from the simulation results. Treat these data as a supplementary guide during assembly planning.

Table 1: Static force (pull vs distance) - power drop

MP 60x20x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4541 Gs

454.1 mT

|

9.41 kg / 20.75 lbs

9410.0 g / 92.3 N

|

medium risk |

| 1 mm |

4400 Gs

440.0 mT

|

8.83 kg / 19.47 lbs

8832.4 g / 86.6 N

|

medium risk |

| 2 mm |

4254 Gs

425.4 mT

|

8.26 kg / 18.21 lbs

8258.2 g / 81.0 N

|

medium risk |

| 3 mm |

4107 Gs

410.7 mT

|

7.70 kg / 16.97 lbs

7697.5 g / 75.5 N

|

medium risk |

| 5 mm |

3812 Gs

381.2 mT

|

6.63 kg / 14.62 lbs

6630.0 g / 65.0 N

|

medium risk |

| 10 mm |

3097 Gs

309.7 mT

|

4.38 kg / 9.65 lbs

4375.1 g / 42.9 N

|

medium risk |

| 15 mm |

2463 Gs

246.3 mT

|

2.77 kg / 6.10 lbs

2767.8 g / 27.2 N

|

medium risk |

| 20 mm |

1939 Gs

193.9 mT

|

1.72 kg / 3.78 lbs

1715.2 g / 16.8 N

|

low risk |

| 30 mm |

1202 Gs

120.2 mT

|

0.66 kg / 1.45 lbs

659.2 g / 6.5 N

|

low risk |

| 50 mm |

509 Gs

50.9 mT

|

0.12 kg / 0.26 lbs

118.0 g / 1.2 N

|

low risk |

Table 2: Vertical capacity (vertical surface)

MP 60x20x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.88 kg / 4.15 lbs

1882.0 g / 18.5 N

|

| 1 mm | Stal (~0.2) |

1.77 kg / 3.89 lbs

1766.0 g / 17.3 N

|

| 2 mm | Stal (~0.2) |

1.65 kg / 3.64 lbs

1652.0 g / 16.2 N

|

| 3 mm | Stal (~0.2) |

1.54 kg / 3.40 lbs

1540.0 g / 15.1 N

|

| 5 mm | Stal (~0.2) |

1.33 kg / 2.92 lbs

1326.0 g / 13.0 N

|

| 10 mm | Stal (~0.2) |

0.88 kg / 1.93 lbs

876.0 g / 8.6 N

|

| 15 mm | Stal (~0.2) |

0.55 kg / 1.22 lbs

554.0 g / 5.4 N

|

| 20 mm | Stal (~0.2) |

0.34 kg / 0.76 lbs

344.0 g / 3.4 N

|

| 30 mm | Stal (~0.2) |

0.13 kg / 0.29 lbs

132.0 g / 1.3 N

|

| 50 mm | Stal (~0.2) |

0.02 kg / 0.05 lbs

24.0 g / 0.2 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MP 60x20x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.82 kg / 6.22 lbs

2823.0 g / 27.7 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.88 kg / 4.15 lbs

1882.0 g / 18.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.94 kg / 2.07 lbs

941.0 g / 9.2 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

4.71 kg / 10.37 lbs

4705.0 g / 46.2 N

|

Table 4: Steel thickness (substrate influence) - power losses

MP 60x20x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.94 kg / 2.07 lbs

941.0 g / 9.2 N

|

| 1 mm |

|

2.35 kg / 5.19 lbs

2352.5 g / 23.1 N

|

| 2 mm |

|

4.71 kg / 10.37 lbs

4705.0 g / 46.2 N

|

| 3 mm |

|

7.06 kg / 15.56 lbs

7057.5 g / 69.2 N

|

| 5 mm |

|

9.41 kg / 20.75 lbs

9410.0 g / 92.3 N

|

| 10 mm |

|

9.41 kg / 20.75 lbs

9410.0 g / 92.3 N

|

| 11 mm |

|

9.41 kg / 20.75 lbs

9410.0 g / 92.3 N

|

| 12 mm |

|

9.41 kg / 20.75 lbs

9410.0 g / 92.3 N

|

Table 5: Thermal resistance (material behavior) - power drop

MP 60x20x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

9.41 kg / 20.75 lbs

9410.0 g / 92.3 N

|

OK |

| 40 °C | -2.2% |

9.20 kg / 20.29 lbs

9203.0 g / 90.3 N

|

OK |

| 60 °C | -4.4% |

9.00 kg / 19.83 lbs

8996.0 g / 88.3 N

|

OK |

| 80 °C | -6.6% |

8.79 kg / 19.38 lbs

8788.9 g / 86.2 N

|

|

| 100 °C | -28.8% |

6.70 kg / 14.77 lbs

6699.9 g / 65.7 N

|

Table 6: Two magnets (attraction) - field collision

MP 60x20x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

303.46 kg / 669.01 lbs

5 621 Gs

|

45.52 kg / 100.35 lbs

45519 g / 446.5 N

|

N/A |

| 1 mm |

294.21 kg / 648.62 lbs

8 943 Gs

|

44.13 kg / 97.29 lbs

44132 g / 432.9 N

|

264.79 kg / 583.76 lbs

~0 Gs

|

| 2 mm |

284.83 kg / 627.94 lbs

8 800 Gs

|

42.72 kg / 94.19 lbs

42725 g / 419.1 N

|

256.35 kg / 565.15 lbs

~0 Gs

|

| 3 mm |

275.53 kg / 607.43 lbs

8 655 Gs

|

41.33 kg / 91.11 lbs

41329 g / 405.4 N

|

247.97 kg / 546.69 lbs

~0 Gs

|

| 5 mm |

257.21 kg / 567.06 lbs

8 362 Gs

|

38.58 kg / 85.06 lbs

38582 g / 378.5 N

|

231.49 kg / 510.35 lbs

~0 Gs

|

| 10 mm |

213.81 kg / 471.36 lbs

7 624 Gs

|

32.07 kg / 70.70 lbs

32071 g / 314.6 N

|

192.43 kg / 424.23 lbs

~0 Gs

|

| 20 mm |

141.09 kg / 311.05 lbs

6 193 Gs

|

21.16 kg / 46.66 lbs

21164 g / 207.6 N

|

126.98 kg / 279.95 lbs

~0 Gs

|

| 50 mm |

34.15 kg / 75.30 lbs

3 047 Gs

|

5.12 kg / 11.29 lbs

5123 g / 50.3 N

|

30.74 kg / 67.77 lbs

~0 Gs

|

| 60 mm |

21.26 kg / 46.87 lbs

2 404 Gs

|

3.19 kg / 7.03 lbs

3189 g / 31.3 N

|

19.13 kg / 42.18 lbs

~0 Gs

|

| 70 mm |

13.43 kg / 29.61 lbs

1 911 Gs

|

2.01 kg / 4.44 lbs

2015 g / 19.8 N

|

12.09 kg / 26.65 lbs

~0 Gs

|

| 80 mm |

8.65 kg / 19.06 lbs

1 533 Gs

|

1.30 kg / 2.86 lbs

1297 g / 12.7 N

|

7.78 kg / 17.16 lbs

~0 Gs

|

| 90 mm |

5.68 kg / 12.52 lbs

1 243 Gs

|

0.85 kg / 1.88 lbs

852 g / 8.4 N

|

5.11 kg / 11.27 lbs

~0 Gs

|

| 100 mm |

3.81 kg / 8.39 lbs

1 017 Gs

|

0.57 kg / 1.26 lbs

571 g / 5.6 N

|

3.43 kg / 7.55 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MP 60x20x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 31.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 24.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 19.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 15.0 cm |

| Car key | 50 Gs (5.0 mT) | 14.0 cm |

| Payment card | 400 Gs (40.0 mT) | 6.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 5.0 cm |

Table 8: Dynamics (cracking risk) - collision effects

MP 60x20x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

12.67 km/h

(3.52 m/s)

|

0.58 J | |

| 30 mm |

18.20 km/h

(5.06 m/s)

|

1.20 J | |

| 50 mm |

22.71 km/h

(6.31 m/s)

|

1.88 J | |

| 100 mm |

31.88 km/h

(8.85 m/s)

|

3.70 J |

Table 9: Anti-corrosion coating durability

MP 60x20x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MP 60x20x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 109 640 Mx | 1096.4 µWb |

| Pc Coefficient | 0.62 | High (Stable) |

Table 11: Hydrostatics and buoyancy

MP 60x20x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 9.41 kg | Standard |

| Water (riverbed) |

10.77 kg

(+1.36 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet retains only approx. 20-30% of its max power.

2. Plate thickness effect

*Thin metal sheet (e.g. computer case) drastically weakens the holding force.

3. Power loss vs temp

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.62

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Pros and cons of Nd2Fe14B magnets.

Pros

- They have stable power, and over more than 10 years their performance decreases symbolically – ~1% (in testing),

- They possess excellent resistance to weakening of magnetic properties due to external magnetic sources,

- Thanks to the shiny finish, the plating of nickel, gold, or silver gives an professional appearance,

- Magnetic induction on the working part of the magnet remains very high,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to the option of flexible forming and customization to custom solutions, NdFeB magnets can be created in a wide range of shapes and sizes, which increases their versatility,

- Key role in future technologies – they are used in data components, electric motors, medical devices, also multitasking production systems.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Cons

- At very strong impacts they can crack, therefore we advise placing them in special holders. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets decrease their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we recommend using water-impermeable magnets made of rubber, plastic or other material resistant to moisture

- We suggest cover - magnetic mechanism, due to difficulties in producing threads inside the magnet and complex shapes.

- Possible danger resulting from small fragments of magnets pose a threat, in case of ingestion, which gains importance in the context of child health protection. It is also worth noting that small elements of these products can disrupt the diagnostic process medical when they are in the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what contributes to it?

- using a plate made of low-carbon steel, serving as a ideal flux conductor

- whose transverse dimension is min. 10 mm

- with an ground touching surface

- under conditions of gap-free contact (metal-to-metal)

- during pulling in a direction vertical to the plane

- in temp. approx. 20°C

Determinants of practical lifting force of a magnet

- Distance (betwixt the magnet and the metal), since even a tiny distance (e.g. 0.5 mm) leads to a reduction in lifting capacity by up to 50% (this also applies to paint, corrosion or dirt).

- Force direction – declared lifting capacity refers to pulling vertically. When attempting to slide, the magnet exhibits much less (typically approx. 20-30% of nominal force).

- Element thickness – for full efficiency, the steel must be adequately massive. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Material composition – not every steel reacts the same. High carbon content weaken the attraction effect.

- Surface quality – the more even the plate, the larger the contact zone and higher the lifting capacity. Roughness acts like micro-gaps.

- Thermal environment – heating the magnet results in weakening of induction. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was determined using a steel plate with a smooth surface of optimal thickness (min. 20 mm), under vertically applied force, whereas under parallel forces the load capacity is reduced by as much as 5 times. Moreover, even a minimal clearance between the magnet and the plate lowers the holding force.

Safe handling of neodymium magnets

Fire risk

Dust created during grinding of magnets is combustible. Do not drill into magnets without proper cooling and knowledge.

Pinching danger

Danger of trauma: The pulling power is so immense that it can cause hematomas, crushing, and even bone fractures. Protective gloves are recommended.

Impact on smartphones

Navigation devices and mobile phones are extremely susceptible to magnetism. Close proximity with a powerful NdFeB magnet can ruin the sensors in your phone.

Magnetic media

Equipment safety: Neodymium magnets can damage payment cards and sensitive devices (heart implants, hearing aids, mechanical watches).

Do not overheat magnets

Monitor thermal conditions. Exposing the magnet to high heat will ruin its properties and strength.

Allergy Warning

Some people experience a sensitization to nickel, which is the common plating for NdFeB magnets. Frequent touching may cause skin redness. We recommend use protective gloves.

Health Danger

For implant holders: Powerful magnets disrupt electronics. Keep minimum 30 cm distance or request help to handle the magnets.

Handling rules

Exercise caution. Rare earth magnets attract from a long distance and snap with huge force, often faster than you can move away.

Eye protection

Protect your eyes. Magnets can fracture upon violent connection, launching sharp fragments into the air. We recommend safety glasses.

Adults only

Strictly keep magnets out of reach of children. Choking hazard is significant, and the effects of magnets connecting inside the body are tragic.

![UMGGZ 43x6 [M6] GZ / N38 - rubber magnetic holder external thread UMGGZ 43x6 [M6] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-43x6-m6-gz-miw.jpg)

![UMP 94x40 [3xM10] GW F550 Silver Black Lina / N52 - search holder UMP 94x40 [3xM10] GW F550 Silver Black Lina / N52 - search holder](https://cdn3.dhit.pl/graphics/products/ump-94x40-3xm10-gw-f550-lina-gub.jpg)