SM 25x100 [2xM8] / N52 - magnetic separator

magnetic separator

Catalog no 130366

GTIN/EAN: 5906301813149

Diameter Ø

25 mm [±1 mm]

Height

100 mm [±1 mm]

Weight

360 g

Magnetic Flux

~ 8 500 Gauss [±5%]

319.80 ZŁ with VAT / pcs + price for transport

260.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

otherwise drop us a message by means of

request form

the contact page.

Parameters along with structure of a neodymium magnet can be analyzed on our

our magnetic calculator.

Order by 14:00 and we’ll ship today!

Detailed specification - SM 25x100 [2xM8] / N52 - magnetic separator

Specification / characteristics - SM 25x100 [2xM8] / N52 - magnetic separator

| properties | values |

|---|---|

| Cat. no. | 130366 |

| GTIN/EAN | 5906301813149 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 25 mm [±1 mm] |

| Height | 100 mm [±1 mm] |

| Weight | 360 g |

| Material Type | Stainless steel AISI 304 / A2 |

| Magnetic Flux | ~ 8 500 Gauss [±5%] |

| Size/Mount Quantity | M8x2 |

| Polarity | circumferential - 3 poles |

| Casing Tube Thickness | 1 mm |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N52

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 14.2-14.7 | kGs |

| remenance Br [min. - max.] ? | 1420-1470 | mT |

| coercivity bHc ? | 10.8-12.5 | kOe |

| coercivity bHc ? | 860-995 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 48-53 | BH max MGOe |

| energy density [min. - max.] ? | 380-422 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

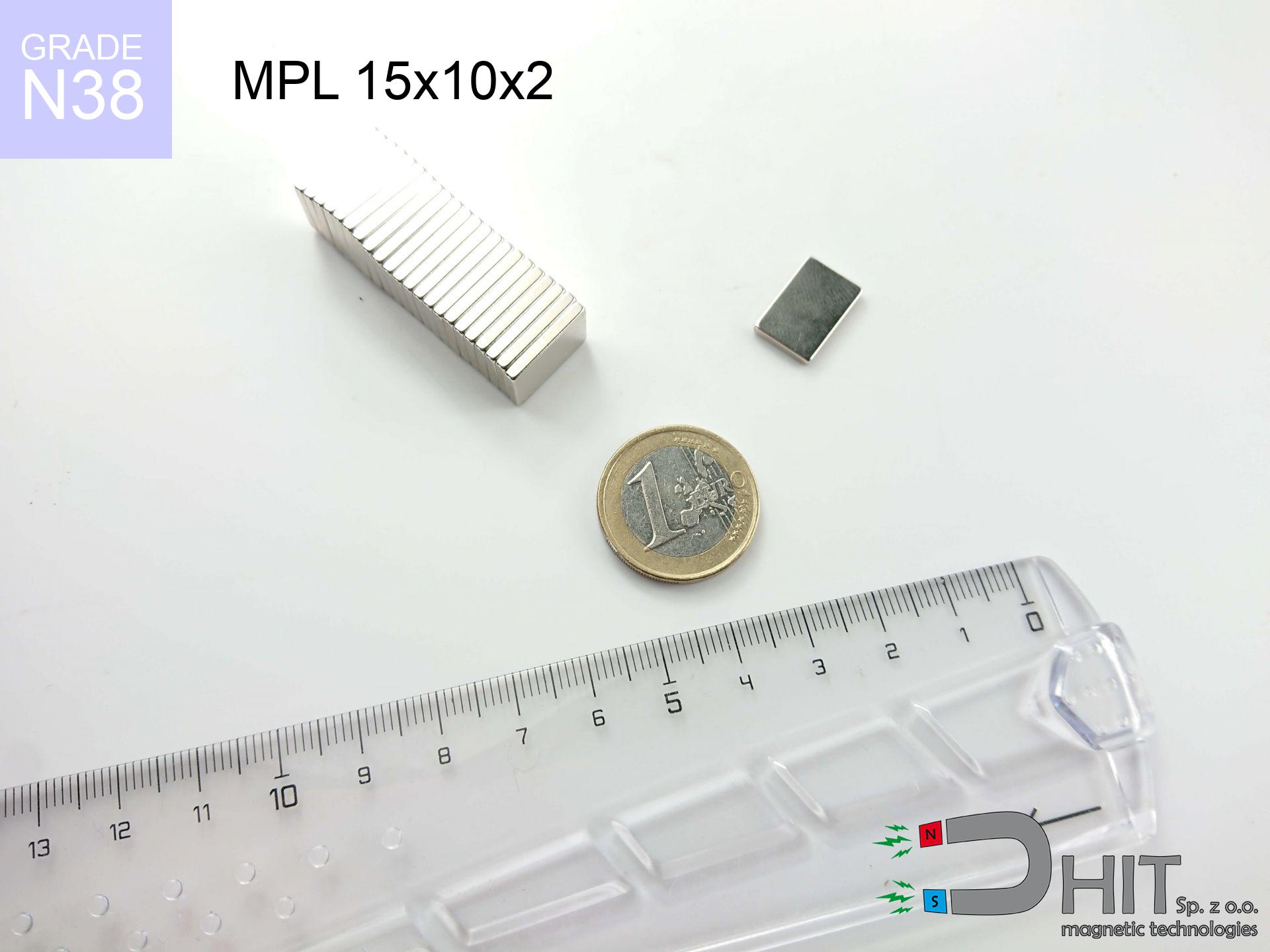

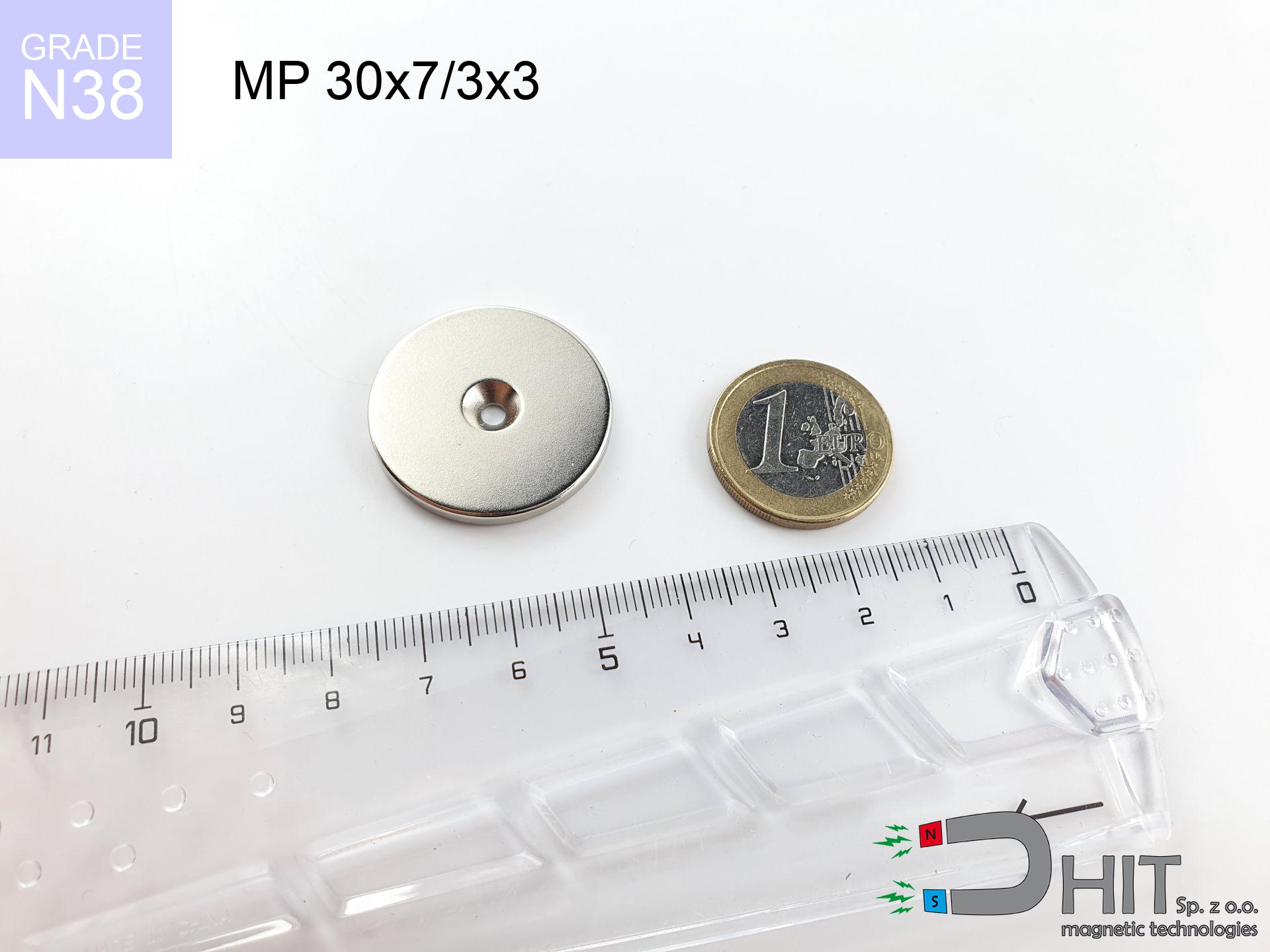

Table 1: Rod construction

SM 25x100 [2xM8] / N52

| Parameter | Value | Description / Unit |

|---|---|---|

| Diameter (Ø) | 25 | mm |

| Total length | 100 | mm (L) |

| Active length | 64 | mm |

| Section count | 2 | modules |

| Dead zone | 36 | mm (2x 18mm starter) |

| Weight (est.) | ~373 | g |

| Active area | 50 | cm² (Area) |

| Housing material | AISI 304 | 1.4301 (Inox) |

| Surface finish | Ra < 0.8 µm | Polished |

| Temp. class | 80°C | Standard (N) |

| Force loss (at max °C) | -12.8% | Reversible loss (physics) |

| Force (calculated) | 18.1 | kg (theor.) |

| Induction (surface) | ~8 500 | Gauss (Max) |

Chart 2: Field profile (2 sections)

Chart 3: Temperature performance

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages and disadvantages of neodymium magnets.

Benefits

- They have unchanged lifting capacity, and over nearly ten years their performance decreases symbolically – ~1% (according to theory),

- They do not lose their magnetic properties even under close interference source,

- The use of an elegant finish of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- Neodymium magnets generate maximum magnetic induction on a their surface, which increases force concentration,

- Neodymium magnets are characterized by very high magnetic induction on the magnet surface and can work (depending on the shape) even at a temperature of 230°C or more...

- Considering the potential of precise molding and adaptation to specialized requirements, magnetic components can be created in a variety of forms and dimensions, which expands the range of possible applications,

- Fundamental importance in modern technologies – they find application in computer drives, motor assemblies, medical devices, also technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in compact dimensions, which makes them useful in small systems

Cons

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a special holder, which not only protects them against impacts but also increases their durability

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation as well as corrosion.

- Limited possibility of making nuts in the magnet and complicated shapes - preferred is a housing - mounting mechanism.

- Potential hazard related to microscopic parts of magnets pose a threat, in case of ingestion, which gains importance in the context of child safety. Additionally, small components of these magnets are able to disrupt the diagnostic process medical in case of swallowing.

- With large orders the cost of neodymium magnets is a challenge,

Pull force analysis

Maximum holding power of the magnet – what contributes to it?

- using a sheet made of mild steel, functioning as a circuit closing element

- possessing a thickness of min. 10 mm to ensure full flux closure

- with a plane perfectly flat

- with zero gap (without impurities)

- for force acting at a right angle (pull-off, not shear)

- in stable room temperature

Key elements affecting lifting force

- Gap (between the magnet and the metal), as even a very small clearance (e.g. 0.5 mm) leads to a drastic drop in lifting capacity by up to 50% (this also applies to paint, rust or dirt).

- Loading method – catalog parameter refers to detachment vertically. When slipping, the magnet holds much less (typically approx. 20-30% of nominal force).

- Steel thickness – insufficiently thick sheet does not close the flux, causing part of the flux to be lost to the other side.

- Material type – the best choice is pure iron steel. Stainless steels may attract less.

- Surface quality – the smoother and more polished the surface, the better the adhesion and stronger the hold. Unevenness acts like micro-gaps.

- Thermal conditions – NdFeB sinters have a sensitivity to temperature. At higher temperatures they lose power, and at low temperatures they can be stronger (up to a certain limit).

Holding force was tested on the plate surface of 20 mm thickness, when a perpendicular force was applied, whereas under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet and the plate lowers the load capacity.

Safety rules for work with neodymium magnets

Cards and drives

Do not bring magnets close to a wallet, computer, or screen. The magnetic field can irreversibly ruin these devices and erase data from cards.

Danger to pacemakers

Health Alert: Neodymium magnets can deactivate heart devices and defibrillators. Do not approach if you have medical devices.

Protective goggles

NdFeB magnets are ceramic materials, which means they are very brittle. Collision of two magnets will cause them shattering into small pieces.

Maximum temperature

Regular neodymium magnets (grade N) undergo demagnetization when the temperature goes above 80°C. The loss of strength is permanent.

Immense force

Use magnets consciously. Their powerful strength can shock even professionals. Stay alert and do not underestimate their force.

Keep away from children

Product intended for adults. Tiny parts pose a choking risk, leading to severe trauma. Keep away from children and animals.

Threat to navigation

GPS units and mobile phones are highly sensitive to magnetism. Direct contact with a strong magnet can ruin the sensors in your phone.

Warning for allergy sufferers

Some people have a contact allergy to Ni, which is the common plating for NdFeB magnets. Prolonged contact can result in an allergic reaction. We suggest use safety gloves.

Combustion hazard

Machining of neodymium magnets carries a risk of fire hazard. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

Pinching danger

Big blocks can break fingers instantly. Under no circumstances put your hand betwixt two attracting surfaces.

![Magnetic bar SM 25x100 [2xM8] / N52 Magnetic bar SM 25x100 [2xM8] / N52](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![SM 25x100 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-fin.jpg)

![BM 450x180x70 [4x M8] - magnetic beam BM 450x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-450x180x70-4x-m8-duh.jpg)