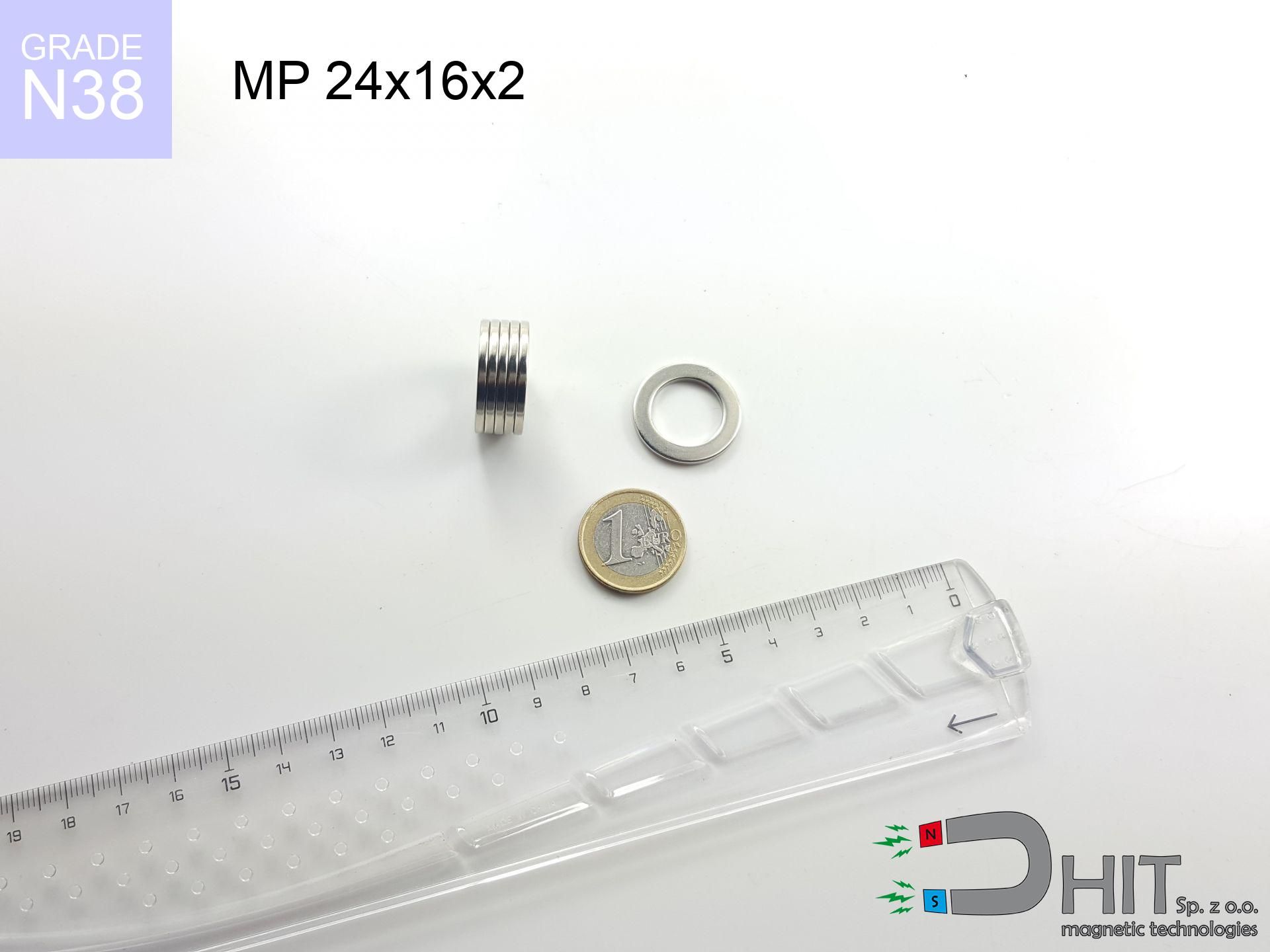

MP 24x16x2 / N38 - ring magnet

ring magnet

Catalog no 030495

GTIN/EAN: 5906301812364

Diameter

24 mm [±0,1 mm]

internal diameter Ø

16 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

3.77 g

Magnetization Direction

↑ axial

Load capacity

0.94 kg / 9.22 N

Magnetic Induction

101.91 mT / 1019 Gs

Coating

[NiCuNi] Nickel

3.69 ZŁ with VAT / pcs + price for transport

3.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 22 499 98 98

otherwise let us know by means of

request form

the contact page.

Parameters as well as shape of neodymium magnets can be checked with our

power calculator.

Orders submitted before 14:00 will be dispatched today!

Technical details - MP 24x16x2 / N38 - ring magnet

Specification / characteristics - MP 24x16x2 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030495 |

| GTIN/EAN | 5906301812364 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 24 mm [±0,1 mm] |

| internal diameter Ø | 16 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 3.77 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.94 kg / 9.22 N |

| Magnetic Induction ~ ? | 101.91 mT / 1019 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the assembly - report

Presented data constitute the outcome of a physical calculation. Results rely on algorithms for the class Nd2Fe14B. Actual performance might slightly differ. Please consider these calculations as a supplementary guide during assembly planning.

Table 1: Static force (pull vs distance) - power drop

MP 24x16x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5807 Gs

580.7 mT

|

0.94 kg / 2.07 lbs

940.0 g / 9.2 N

|

weak grip |

| 1 mm |

5318 Gs

531.8 mT

|

0.79 kg / 1.74 lbs

788.4 g / 7.7 N

|

weak grip |

| 2 mm |

4833 Gs

483.3 mT

|

0.65 kg / 1.44 lbs

651.1 g / 6.4 N

|

weak grip |

| 3 mm |

4366 Gs

436.6 mT

|

0.53 kg / 1.17 lbs

531.5 g / 5.2 N

|

weak grip |

| 5 mm |

3517 Gs

351.7 mT

|

0.34 kg / 0.76 lbs

344.9 g / 3.4 N

|

weak grip |

| 10 mm |

1995 Gs

199.5 mT

|

0.11 kg / 0.24 lbs

111.0 g / 1.1 N

|

weak grip |

| 15 mm |

1168 Gs

116.8 mT

|

0.04 kg / 0.08 lbs

38.0 g / 0.4 N

|

weak grip |

| 20 mm |

727 Gs

72.7 mT

|

0.01 kg / 0.03 lbs

14.7 g / 0.1 N

|

weak grip |

| 30 mm |

332 Gs

33.2 mT

|

0.00 kg / 0.01 lbs

3.1 g / 0.0 N

|

weak grip |

| 50 mm |

106 Gs

10.6 mT

|

0.00 kg / 0.00 lbs

0.3 g / 0.0 N

|

weak grip |

Table 2: Slippage force (wall)

MP 24x16x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.19 kg / 0.41 lbs

188.0 g / 1.8 N

|

| 1 mm | Stal (~0.2) |

0.16 kg / 0.35 lbs

158.0 g / 1.5 N

|

| 2 mm | Stal (~0.2) |

0.13 kg / 0.29 lbs

130.0 g / 1.3 N

|

| 3 mm | Stal (~0.2) |

0.11 kg / 0.23 lbs

106.0 g / 1.0 N

|

| 5 mm | Stal (~0.2) |

0.07 kg / 0.15 lbs

68.0 g / 0.7 N

|

| 10 mm | Stal (~0.2) |

0.02 kg / 0.05 lbs

22.0 g / 0.2 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MP 24x16x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.28 kg / 0.62 lbs

282.0 g / 2.8 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.19 kg / 0.41 lbs

188.0 g / 1.8 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.09 kg / 0.21 lbs

94.0 g / 0.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.47 kg / 1.04 lbs

470.0 g / 4.6 N

|

Table 4: Material efficiency (substrate influence) - power losses

MP 24x16x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.09 kg / 0.21 lbs

94.0 g / 0.9 N

|

| 1 mm |

|

0.24 kg / 0.52 lbs

235.0 g / 2.3 N

|

| 2 mm |

|

0.47 kg / 1.04 lbs

470.0 g / 4.6 N

|

| 3 mm |

|

0.71 kg / 1.55 lbs

705.0 g / 6.9 N

|

| 5 mm |

|

0.94 kg / 2.07 lbs

940.0 g / 9.2 N

|

| 10 mm |

|

0.94 kg / 2.07 lbs

940.0 g / 9.2 N

|

| 11 mm |

|

0.94 kg / 2.07 lbs

940.0 g / 9.2 N

|

| 12 mm |

|

0.94 kg / 2.07 lbs

940.0 g / 9.2 N

|

Table 5: Working in heat (stability) - resistance threshold

MP 24x16x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.94 kg / 2.07 lbs

940.0 g / 9.2 N

|

OK |

| 40 °C | -2.2% |

0.92 kg / 2.03 lbs

919.3 g / 9.0 N

|

OK |

| 60 °C | -4.4% |

0.90 kg / 1.98 lbs

898.6 g / 8.8 N

|

OK |

| 80 °C | -6.6% |

0.88 kg / 1.94 lbs

878.0 g / 8.6 N

|

|

| 100 °C | -28.8% |

0.67 kg / 1.48 lbs

669.3 g / 6.6 N

|

Table 6: Two magnets (repulsion) - forces in the system

MP 24x16x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

79.38 kg / 175.01 lbs

6 091 Gs

|

11.91 kg / 26.25 lbs

11908 g / 116.8 N

|

N/A |

| 1 mm |

72.89 kg / 160.70 lbs

11 129 Gs

|

10.93 kg / 24.11 lbs

10934 g / 107.3 N

|

65.60 kg / 144.63 lbs

~0 Gs

|

| 2 mm |

66.58 kg / 146.78 lbs

10 636 Gs

|

9.99 kg / 22.02 lbs

9987 g / 98.0 N

|

59.92 kg / 132.10 lbs

~0 Gs

|

| 3 mm |

60.60 kg / 133.60 lbs

10 147 Gs

|

9.09 kg / 20.04 lbs

9090 g / 89.2 N

|

54.54 kg / 120.24 lbs

~0 Gs

|

| 5 mm |

49.75 kg / 109.67 lbs

9 194 Gs

|

7.46 kg / 16.45 lbs

7462 g / 73.2 N

|

44.77 kg / 98.70 lbs

~0 Gs

|

| 10 mm |

29.13 kg / 64.21 lbs

7 035 Gs

|

4.37 kg / 9.63 lbs

4369 g / 42.9 N

|

26.21 kg / 57.79 lbs

~0 Gs

|

| 20 mm |

9.37 kg / 20.67 lbs

3 991 Gs

|

1.41 kg / 3.10 lbs

1406 g / 13.8 N

|

8.44 kg / 18.60 lbs

~0 Gs

|

| 50 mm |

0.54 kg / 1.19 lbs

958 Gs

|

0.08 kg / 0.18 lbs

81 g / 0.8 N

|

0.49 kg / 1.07 lbs

~0 Gs

|

| 60 mm |

0.26 kg / 0.57 lbs

663 Gs

|

0.04 kg / 0.09 lbs

39 g / 0.4 N

|

0.23 kg / 0.51 lbs

~0 Gs

|

| 70 mm |

0.13 kg / 0.30 lbs

478 Gs

|

0.02 kg / 0.04 lbs

20 g / 0.2 N

|

0.12 kg / 0.27 lbs

~0 Gs

|

| 80 mm |

0.07 kg / 0.16 lbs

356 Gs

|

0.01 kg / 0.02 lbs

11 g / 0.1 N

|

0.07 kg / 0.15 lbs

~0 Gs

|

| 90 mm |

0.04 kg / 0.10 lbs

272 Gs

|

0.01 kg / 0.01 lbs

7 g / 0.1 N

|

0.04 kg / 0.09 lbs

~0 Gs

|

| 100 mm |

0.03 kg / 0.06 lbs

213 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.02 kg / 0.05 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - precautionary measures

MP 24x16x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 16.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 13.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 10.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 7.5 cm |

| Remote | 50 Gs (5.0 mT) | 7.0 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MP 24x16x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

17.06 km/h

(4.74 m/s)

|

0.04 J | |

| 30 mm |

27.64 km/h

(7.68 m/s)

|

0.11 J | |

| 50 mm |

35.62 km/h

(9.89 m/s)

|

0.18 J | |

| 100 mm |

50.36 km/h

(13.99 m/s)

|

0.37 J |

Table 9: Coating parameters (durability)

MP 24x16x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MP 24x16x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 23 520 Mx | 235.2 µWb |

| Pc Coefficient | 1.04 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MP 24x16x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.94 kg | Standard |

| Water (riverbed) |

1.08 kg

(+0.14 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet holds only approx. 20-30% of its max power.

2. Steel saturation

*Thin steel (e.g. computer case) significantly reduces the holding force.

3. Heat tolerance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.04

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Pros and cons of rare earth magnets.

Benefits

- They virtually do not lose strength, because even after ten years the decline in efficiency is only ~1% (based on calculations),

- Neodymium magnets prove to be highly resistant to loss of magnetic properties caused by external magnetic fields,

- By covering with a lustrous layer of gold, the element has an elegant look,

- The surface of neodymium magnets generates a powerful magnetic field – this is a key feature,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to flexibility in designing and the capacity to customize to specific needs,

- Versatile presence in innovative solutions – they are utilized in hard drives, electromotive mechanisms, precision medical tools, and multitasking production systems.

- Thanks to their power density, small magnets offer high operating force, in miniature format,

Cons

- To avoid cracks upon strong impacts, we suggest using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation and corrosion.

- We recommend casing - magnetic mechanism, due to difficulties in producing threads inside the magnet and complicated shapes.

- Health risk to health – tiny shards of magnets can be dangerous, if swallowed, which becomes key in the aspect of protecting the youngest. Furthermore, tiny parts of these magnets can be problematic in diagnostics medical in case of swallowing.

- Due to complex production process, their price exceeds standard values,

Pull force analysis

Breakaway strength of the magnet in ideal conditions – what it depends on?

- on a base made of mild steel, optimally conducting the magnetic field

- with a cross-section of at least 10 mm

- with an ground contact surface

- with direct contact (without paint)

- during pulling in a direction vertical to the plane

- at ambient temperature approx. 20 degrees Celsius

Determinants of lifting force in real conditions

- Clearance – the presence of any layer (rust, tape, air) interrupts the magnetic circuit, which reduces power rapidly (even by 50% at 0.5 mm).

- Load vector – highest force is obtained only during perpendicular pulling. The shear force of the magnet along the plate is standardly several times lower (approx. 1/5 of the lifting capacity).

- Base massiveness – too thin sheet does not accept the full field, causing part of the power to be escaped to the other side.

- Steel grade – the best choice is pure iron steel. Hardened steels may have worse magnetic properties.

- Plate texture – ground elements ensure maximum contact, which increases force. Uneven metal reduce efficiency.

- Temperature – temperature increase causes a temporary drop of force. Check the maximum operating temperature for a given model.

Lifting capacity was measured by applying a smooth steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, however under attempts to slide the magnet the load capacity is reduced by as much as fivefold. Moreover, even a slight gap between the magnet’s surface and the plate decreases the lifting capacity.

Safe handling of neodymium magnets

Fire warning

Drilling and cutting of NdFeB material carries a risk of fire hazard. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Finger safety

Risk of injury: The pulling power is so immense that it can result in blood blisters, crushing, and broken bones. Protective gloves are recommended.

Safe operation

Handle with care. Neodymium magnets attract from a long distance and snap with huge force, often quicker than you can react.

Allergy Warning

Warning for allergy sufferers: The nickel-copper-nickel coating contains nickel. If redness appears, cease working with magnets and use protective gear.

Medical implants

Warning for patients: Strong magnetic fields disrupt electronics. Maintain at least 30 cm distance or ask another person to handle the magnets.

Keep away from children

Only for adults. Small elements pose a choking risk, leading to serious injuries. Store away from children and animals.

Material brittleness

Beware of splinters. Magnets can explode upon violent connection, launching sharp fragments into the air. Eye protection is mandatory.

Keep away from computers

Do not bring magnets near a wallet, computer, or screen. The magnetism can permanently damage these devices and erase data from cards.

Maximum temperature

Keep cool. NdFeB magnets are susceptible to temperature. If you require resistance above 80°C, inquire about HT versions (H, SH, UH).

Threat to navigation

A strong magnetic field negatively affects the operation of magnetometers in phones and GPS navigation. Maintain magnets near a device to avoid breaking the sensors.

![SM 32x150 [2xM8] / N52 - magnetic separator SM 32x150 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x150-2xm8-xuc.jpg)

![SM 25x325 [2xM8] / N52 - magnetic separator SM 25x325 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x325-2xm8-bit.jpg)

![UMH 42x9x46 [M6] / N38 - magnetic holder with hook UMH 42x9x46 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-42x9x46-m6-vat.jpg)