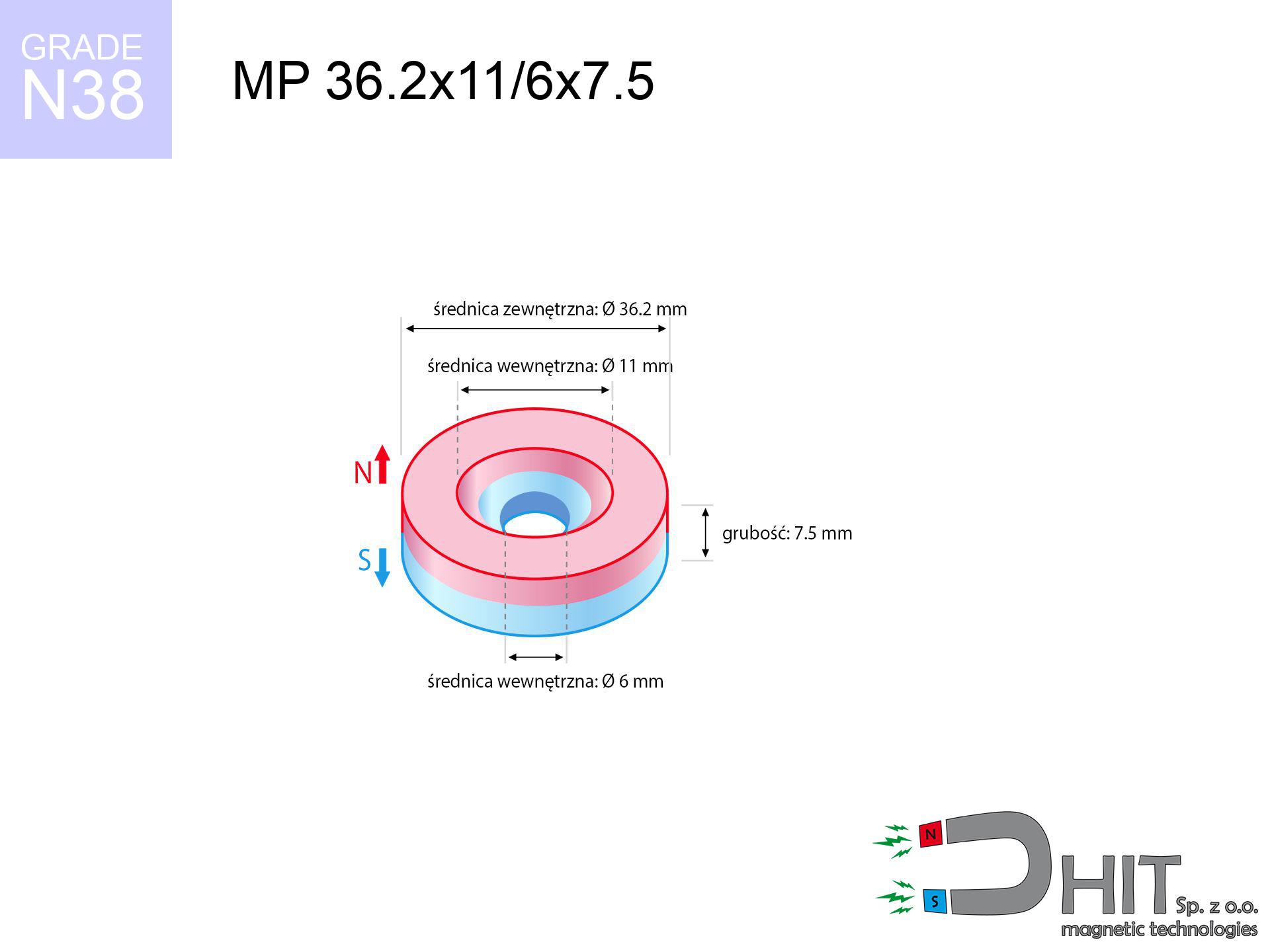

MP 36.2x11/6x7.5 / N38 - ring magnet

ring magnet

Catalog no 030248

GTIN/EAN: 5906301812241

Diameter

36.2 mm [±0,1 mm]

internal diameter Ø

11/6 mm [±0,1 mm]

Height

7.5 mm [±0,1 mm]

Weight

56.3 g

Magnetization Direction

↑ axial

Load capacity

17.12 kg / 167.95 N

Magnetic Induction

237.29 mT / 2373 Gs

Coating

[NiCuNi] Nickel

35.01 ZŁ with VAT / pcs + price for transport

28.46 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

alternatively get in touch using

request form

our website.

Strength along with form of a magnet can be reviewed with our

magnetic mass calculator.

Same-day shipping for orders placed before 14:00.

Technical - MP 36.2x11/6x7.5 / N38 - ring magnet

Specification / characteristics - MP 36.2x11/6x7.5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030248 |

| GTIN/EAN | 5906301812241 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 36.2 mm [±0,1 mm] |

| internal diameter Ø | 11/6 mm [±0,1 mm] |

| Height | 7.5 mm [±0,1 mm] |

| Weight | 56.3 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 17.12 kg / 167.95 N |

| Magnetic Induction ~ ? | 237.29 mT / 2373 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the product - data

The following information represent the outcome of a engineering analysis. Values are based on models for the class Nd2Fe14B. Actual parameters may differ from theoretical values. Use these data as a preliminary roadmap when designing systems.

Table 1: Static pull force (force vs gap) - interaction chart

MP 36.2x11/6x7.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2059 Gs

205.9 mT

|

17.12 kg / 37.74 pounds

17120.0 g / 167.9 N

|

critical level |

| 1 mm |

1997 Gs

199.7 mT

|

16.11 kg / 35.52 pounds

16110.1 g / 158.0 N

|

critical level |

| 2 mm |

1923 Gs

192.3 mT

|

14.93 kg / 32.91 pounds

14925.7 g / 146.4 N

|

critical level |

| 3 mm |

1838 Gs

183.8 mT

|

13.64 kg / 30.06 pounds

13636.4 g / 133.8 N

|

critical level |

| 5 mm |

1648 Gs

164.8 mT

|

10.97 kg / 24.18 pounds

10968.0 g / 107.6 N

|

critical level |

| 10 mm |

1161 Gs

116.1 mT

|

5.44 kg / 12.00 pounds

5444.8 g / 53.4 N

|

medium risk |

| 15 mm |

775 Gs

77.5 mT

|

2.43 kg / 5.35 pounds

2427.5 g / 23.8 N

|

medium risk |

| 20 mm |

515 Gs

51.5 mT

|

1.07 kg / 2.36 pounds

1071.1 g / 10.5 N

|

low risk |

| 30 mm |

242 Gs

24.2 mT

|

0.24 kg / 0.52 pounds

236.8 g / 2.3 N

|

low risk |

| 50 mm |

73 Gs

7.3 mT

|

0.02 kg / 0.05 pounds

21.8 g / 0.2 N

|

low risk |

Table 2: Vertical force (wall)

MP 36.2x11/6x7.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

3.42 kg / 7.55 pounds

3424.0 g / 33.6 N

|

| 1 mm | Stal (~0.2) |

3.22 kg / 7.10 pounds

3222.0 g / 31.6 N

|

| 2 mm | Stal (~0.2) |

2.99 kg / 6.58 pounds

2986.0 g / 29.3 N

|

| 3 mm | Stal (~0.2) |

2.73 kg / 6.01 pounds

2728.0 g / 26.8 N

|

| 5 mm | Stal (~0.2) |

2.19 kg / 4.84 pounds

2194.0 g / 21.5 N

|

| 10 mm | Stal (~0.2) |

1.09 kg / 2.40 pounds

1088.0 g / 10.7 N

|

| 15 mm | Stal (~0.2) |

0.49 kg / 1.07 pounds

486.0 g / 4.8 N

|

| 20 mm | Stal (~0.2) |

0.21 kg / 0.47 pounds

214.0 g / 2.1 N

|

| 30 mm | Stal (~0.2) |

0.05 kg / 0.11 pounds

48.0 g / 0.5 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - vertical pull

MP 36.2x11/6x7.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

5.14 kg / 11.32 pounds

5136.0 g / 50.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

3.42 kg / 7.55 pounds

3424.0 g / 33.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.71 kg / 3.77 pounds

1712.0 g / 16.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

8.56 kg / 18.87 pounds

8560.0 g / 84.0 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MP 36.2x11/6x7.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.86 kg / 1.89 pounds

856.0 g / 8.4 N

|

| 1 mm |

|

2.14 kg / 4.72 pounds

2140.0 g / 21.0 N

|

| 2 mm |

|

4.28 kg / 9.44 pounds

4280.0 g / 42.0 N

|

| 3 mm |

|

6.42 kg / 14.15 pounds

6420.0 g / 63.0 N

|

| 5 mm |

|

10.70 kg / 23.59 pounds

10700.0 g / 105.0 N

|

| 10 mm |

|

17.12 kg / 37.74 pounds

17120.0 g / 167.9 N

|

| 11 mm |

|

17.12 kg / 37.74 pounds

17120.0 g / 167.9 N

|

| 12 mm |

|

17.12 kg / 37.74 pounds

17120.0 g / 167.9 N

|

Table 5: Thermal stability (stability) - power drop

MP 36.2x11/6x7.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

17.12 kg / 37.74 pounds

17120.0 g / 167.9 N

|

OK |

| 40 °C | -2.2% |

16.74 kg / 36.91 pounds

16743.4 g / 164.3 N

|

OK |

| 60 °C | -4.4% |

16.37 kg / 36.08 pounds

16366.7 g / 160.6 N

|

|

| 80 °C | -6.6% |

15.99 kg / 35.25 pounds

15990.1 g / 156.9 N

|

|

| 100 °C | -28.8% |

12.19 kg / 26.87 pounds

12189.4 g / 119.6 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field collision

MP 36.2x11/6x7.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

22.24 kg / 49.03 pounds

3 569 Gs

|

3.34 kg / 7.35 pounds

3336 g / 32.7 N

|

N/A |

| 1 mm |

21.62 kg / 47.67 pounds

4 061 Gs

|

3.24 kg / 7.15 pounds

3243 g / 31.8 N

|

19.46 kg / 42.90 pounds

~0 Gs

|

| 2 mm |

20.93 kg / 46.14 pounds

3 995 Gs

|

3.14 kg / 6.92 pounds

3139 g / 30.8 N

|

18.84 kg / 41.52 pounds

~0 Gs

|

| 3 mm |

20.18 kg / 44.49 pounds

3 923 Gs

|

3.03 kg / 6.67 pounds

3027 g / 29.7 N

|

18.16 kg / 40.04 pounds

~0 Gs

|

| 5 mm |

18.56 kg / 40.93 pounds

3 763 Gs

|

2.78 kg / 6.14 pounds

2785 g / 27.3 N

|

16.71 kg / 36.83 pounds

~0 Gs

|

| 10 mm |

14.25 kg / 31.41 pounds

3 296 Gs

|

2.14 kg / 4.71 pounds

2137 g / 21.0 N

|

12.82 kg / 28.27 pounds

~0 Gs

|

| 20 mm |

7.07 kg / 15.59 pounds

2 322 Gs

|

1.06 kg / 2.34 pounds

1061 g / 10.4 N

|

6.37 kg / 14.03 pounds

~0 Gs

|

| 50 mm |

0.64 kg / 1.40 pounds

697 Gs

|

0.10 kg / 0.21 pounds

96 g / 0.9 N

|

0.57 kg / 1.26 pounds

~0 Gs

|

| 60 mm |

0.31 kg / 0.68 pounds

484 Gs

|

0.05 kg / 0.10 pounds

46 g / 0.5 N

|

0.28 kg / 0.61 pounds

~0 Gs

|

| 70 mm |

0.16 kg / 0.35 pounds

346 Gs

|

0.02 kg / 0.05 pounds

24 g / 0.2 N

|

0.14 kg / 0.31 pounds

~0 Gs

|

| 80 mm |

0.08 kg / 0.19 pounds

254 Gs

|

0.01 kg / 0.03 pounds

13 g / 0.1 N

|

0.08 kg / 0.17 pounds

~0 Gs

|

| 90 mm |

0.05 kg / 0.11 pounds

191 Gs

|

0.01 kg / 0.02 pounds

7 g / 0.1 N

|

0.04 kg / 0.10 pounds

~0 Gs

|

| 100 mm |

0.03 kg / 0.06 pounds

147 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.03 kg / 0.06 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MP 36.2x11/6x7.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 13.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 10.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 8.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 6.5 cm |

| Car key | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Dynamics (kinetic energy) - collision effects

MP 36.2x11/6x7.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

20.79 km/h

(5.78 m/s)

|

0.94 J | |

| 30 mm |

30.72 km/h

(8.53 m/s)

|

2.05 J | |

| 50 mm |

39.36 km/h

(10.93 m/s)

|

3.36 J | |

| 100 mm |

55.61 km/h

(15.45 m/s)

|

6.72 J |

Table 9: Surface protection spec

MP 36.2x11/6x7.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MP 36.2x11/6x7.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 21 038 Mx | 210.4 µWb |

| Pc Coefficient | 0.26 | Low (Flat) |

Table 11: Physics of underwater searching

MP 36.2x11/6x7.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 17.12 kg | Standard |

| Water (riverbed) |

19.60 kg

(+2.48 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical wall, the magnet retains only approx. 20-30% of its max power.

2. Steel saturation

*Thin metal sheet (e.g. computer case) drastically limits the holding force.

3. Heat tolerance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.26

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Benefits

- They have unchanged lifting capacity, and over more than 10 years their performance decreases symbolically – ~1% (according to theory),

- Neodymium magnets remain highly resistant to loss of magnetic properties caused by external field sources,

- The use of an aesthetic finish of noble metals (nickel, gold, silver) causes the element to present itself better,

- The surface of neodymium magnets generates a intense magnetic field – this is one of their assets,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Considering the option of free forming and customization to specialized requirements, magnetic components can be manufactured in a wide range of geometric configurations, which increases their versatility,

- Universal use in modern industrial fields – they are commonly used in HDD drives, electromotive mechanisms, medical equipment, and modern systems.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Weaknesses

- Brittleness is one of their disadvantages. Upon strong impact they can fracture. We advise keeping them in a steel housing, which not only secures them against impacts but also raises their durability

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Magnets exposed to a humid environment can rust. Therefore when using outdoors, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture

- We recommend a housing - magnetic holder, due to difficulties in realizing threads inside the magnet and complicated shapes.

- Potential hazard resulting from small fragments of magnets can be dangerous, when accidentally swallowed, which is particularly important in the context of child health protection. Additionally, tiny parts of these devices are able to be problematic in diagnostics medical after entering the body.

- Due to expensive raw materials, their price is higher than average,

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what it depends on?

- on a base made of mild steel, optimally conducting the magnetic field

- with a thickness of at least 10 mm

- with an ideally smooth touching surface

- without any clearance between the magnet and steel

- during pulling in a direction perpendicular to the plane

- at temperature room level

Practical lifting capacity: influencing factors

- Distance (betwixt the magnet and the plate), because even a very small distance (e.g. 0.5 mm) leads to a reduction in force by up to 50% (this also applies to paint, corrosion or debris).

- Force direction – catalog parameter refers to detachment vertically. When applying parallel force, the magnet exhibits significantly lower power (often approx. 20-30% of maximum force).

- Plate thickness – too thin plate does not accept the full field, causing part of the power to be wasted to the other side.

- Material type – the best choice is pure iron steel. Hardened steels may attract less.

- Plate texture – smooth surfaces ensure maximum contact, which increases field saturation. Uneven metal weaken the grip.

- Heat – neodymium magnets have a sensitivity to temperature. When it is hot they are weaker, and at low temperatures gain strength (up to a certain limit).

Lifting capacity was determined by applying a polished steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, whereas under parallel forces the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet’s surface and the plate reduces the lifting capacity.

H&S for magnets

Mechanical processing

Fire warning: Neodymium dust is highly flammable. Avoid machining magnets in home conditions as this risks ignition.

GPS and phone interference

An intense magnetic field disrupts the operation of compasses in smartphones and GPS navigation. Do not bring magnets near a smartphone to prevent damaging the sensors.

Hand protection

Watch your fingers. Two powerful magnets will join instantly with a force of massive weight, crushing anything in their path. Be careful!

Caution required

Be careful. Rare earth magnets act from a distance and snap with massive power, often quicker than you can move away.

Demagnetization risk

Standard neodymium magnets (grade N) lose power when the temperature surpasses 80°C. This process is irreversible.

Warning for allergy sufferers

It is widely known that the nickel plating (standard magnet coating) is a strong allergen. If your skin reacts to metals, refrain from touching magnets with bare hands or choose versions in plastic housing.

Danger to pacemakers

For implant holders: Strong magnetic fields disrupt medical devices. Maintain at least 30 cm distance or request help to work with the magnets.

Electronic hazard

Powerful magnetic fields can corrupt files on payment cards, hard drives, and storage devices. Keep a distance of at least 10 cm.

Fragile material

Neodymium magnets are sintered ceramics, which means they are very brittle. Collision of two magnets will cause them cracking into small pieces.

Keep away from children

Only for adults. Small elements pose a choking risk, leading to intestinal necrosis. Keep away from children and animals.

![UMGZ 48x24x11.5 [M8] GZ / N38 - magnetic holder external thread UMGZ 48x24x11.5 [M8] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umgw-48x24x11.5-m8-gz-bit.jpg)

![UMH 42x9x46 [M6] / N38 - magnetic holder with hook UMH 42x9x46 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-42x9x46-m6-vat.jpg)