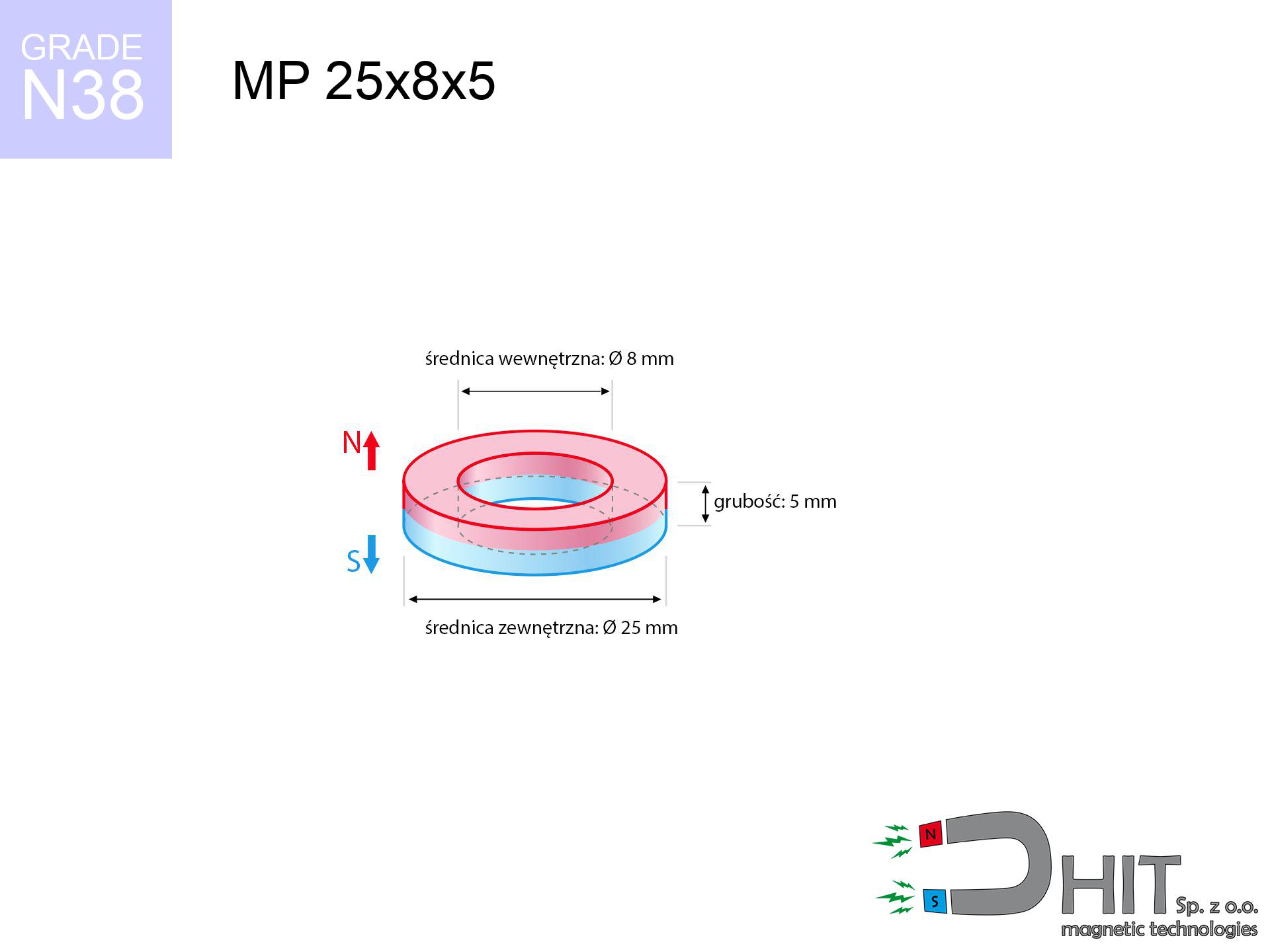

MP 25x8x5 / N38 - ring magnet

ring magnet

Catalog no 030196

GTIN/EAN: 5906301812135

Diameter

25 mm [±0,1 mm]

internal diameter Ø

8 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

16.52 g

Magnetization Direction

↑ axial

Load capacity

7.16 kg / 70.21 N

Magnetic Induction

230.20 mT / 2302 Gs

Coating

[NiCuNi] Nickel

5.90 ZŁ with VAT / pcs + price for transport

4.80 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

alternatively drop us a message via

request form

the contact section.

Force as well as shape of magnets can be calculated with our

magnetic mass calculator.

Same-day processing for orders placed before 14:00.

Technical details - MP 25x8x5 / N38 - ring magnet

Specification / characteristics - MP 25x8x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030196 |

| GTIN/EAN | 5906301812135 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 25 mm [±0,1 mm] |

| internal diameter Ø | 8 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 16.52 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.16 kg / 70.21 N |

| Magnetic Induction ~ ? | 230.20 mT / 2302 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering analysis of the product - technical parameters

These data constitute the direct effect of a engineering analysis. Values were calculated on algorithms for the class Nd2Fe14B. Actual performance may differ. Please consider these data as a preliminary roadmap when designing systems.

Table 1: Static pull force (pull vs gap) - characteristics

MP 25x8x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5777 Gs

577.7 mT

|

7.16 kg / 15.79 LBS

7160.0 g / 70.2 N

|

warning |

| 1 mm |

5310 Gs

531.0 mT

|

6.05 kg / 13.33 LBS

6048.6 g / 59.3 N

|

warning |

| 2 mm |

4846 Gs

484.6 mT

|

5.04 kg / 11.10 LBS

5036.9 g / 49.4 N

|

warning |

| 3 mm |

4397 Gs

439.7 mT

|

4.15 kg / 9.15 LBS

4148.2 g / 40.7 N

|

warning |

| 5 mm |

3576 Gs

357.6 mT

|

2.74 kg / 6.05 LBS

2743.2 g / 26.9 N

|

warning |

| 10 mm |

2073 Gs

207.3 mT

|

0.92 kg / 2.03 LBS

921.6 g / 9.0 N

|

weak grip |

| 15 mm |

1231 Gs

123.1 mT

|

0.33 kg / 0.72 LBS

325.2 g / 3.2 N

|

weak grip |

| 20 mm |

773 Gs

77.3 mT

|

0.13 kg / 0.28 LBS

128.0 g / 1.3 N

|

weak grip |

| 30 mm |

356 Gs

35.6 mT

|

0.03 kg / 0.06 LBS

27.2 g / 0.3 N

|

weak grip |

| 50 mm |

115 Gs

11.5 mT

|

0.00 kg / 0.01 LBS

2.8 g / 0.0 N

|

weak grip |

Table 2: Sliding capacity (vertical surface)

MP 25x8x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.43 kg / 3.16 LBS

1432.0 g / 14.0 N

|

| 1 mm | Stal (~0.2) |

1.21 kg / 2.67 LBS

1210.0 g / 11.9 N

|

| 2 mm | Stal (~0.2) |

1.01 kg / 2.22 LBS

1008.0 g / 9.9 N

|

| 3 mm | Stal (~0.2) |

0.83 kg / 1.83 LBS

830.0 g / 8.1 N

|

| 5 mm | Stal (~0.2) |

0.55 kg / 1.21 LBS

548.0 g / 5.4 N

|

| 10 mm | Stal (~0.2) |

0.18 kg / 0.41 LBS

184.0 g / 1.8 N

|

| 15 mm | Stal (~0.2) |

0.07 kg / 0.15 LBS

66.0 g / 0.6 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.06 LBS

26.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MP 25x8x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.15 kg / 4.74 LBS

2148.0 g / 21.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.43 kg / 3.16 LBS

1432.0 g / 14.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.72 kg / 1.58 LBS

716.0 g / 7.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.58 kg / 7.89 LBS

3580.0 g / 35.1 N

|

Table 4: Material efficiency (substrate influence) - power losses

MP 25x8x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.72 kg / 1.58 LBS

716.0 g / 7.0 N

|

| 1 mm |

|

1.79 kg / 3.95 LBS

1790.0 g / 17.6 N

|

| 2 mm |

|

3.58 kg / 7.89 LBS

3580.0 g / 35.1 N

|

| 3 mm |

|

5.37 kg / 11.84 LBS

5370.0 g / 52.7 N

|

| 5 mm |

|

7.16 kg / 15.79 LBS

7160.0 g / 70.2 N

|

| 10 mm |

|

7.16 kg / 15.79 LBS

7160.0 g / 70.2 N

|

| 11 mm |

|

7.16 kg / 15.79 LBS

7160.0 g / 70.2 N

|

| 12 mm |

|

7.16 kg / 15.79 LBS

7160.0 g / 70.2 N

|

Table 5: Thermal resistance (stability) - thermal limit

MP 25x8x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.16 kg / 15.79 LBS

7160.0 g / 70.2 N

|

OK |

| 40 °C | -2.2% |

7.00 kg / 15.44 LBS

7002.5 g / 68.7 N

|

OK |

| 60 °C | -4.4% |

6.84 kg / 15.09 LBS

6845.0 g / 67.1 N

|

OK |

| 80 °C | -6.6% |

6.69 kg / 14.74 LBS

6687.4 g / 65.6 N

|

|

| 100 °C | -28.8% |

5.10 kg / 11.24 LBS

5097.9 g / 50.0 N

|

Table 6: Two magnets (attraction) - field range

MP 25x8x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

82.42 kg / 181.72 LBS

6 082 Gs

|

12.36 kg / 27.26 LBS

12364 g / 121.3 N

|

N/A |

| 1 mm |

75.95 kg / 167.44 LBS

11 091 Gs

|

11.39 kg / 25.12 LBS

11392 g / 111.8 N

|

68.35 kg / 150.69 LBS

~0 Gs

|

| 2 mm |

69.63 kg / 153.51 LBS

10 620 Gs

|

10.44 kg / 23.03 LBS

10445 g / 102.5 N

|

62.67 kg / 138.16 LBS

~0 Gs

|

| 3 mm |

63.64 kg / 140.29 LBS

10 153 Gs

|

9.55 kg / 21.04 LBS

9545 g / 93.6 N

|

57.27 kg / 126.26 LBS

~0 Gs

|

| 5 mm |

52.69 kg / 116.16 LBS

9 238 Gs

|

7.90 kg / 17.42 LBS

7903 g / 77.5 N

|

47.42 kg / 104.54 LBS

~0 Gs

|

| 10 mm |

31.58 kg / 69.62 LBS

7 152 Gs

|

4.74 kg / 10.44 LBS

4737 g / 46.5 N

|

28.42 kg / 62.66 LBS

~0 Gs

|

| 20 mm |

10.61 kg / 23.39 LBS

4 145 Gs

|

1.59 kg / 3.51 LBS

1591 g / 15.6 N

|

9.55 kg / 21.05 LBS

~0 Gs

|

| 50 mm |

0.65 kg / 1.43 LBS

1 024 Gs

|

0.10 kg / 0.21 LBS

97 g / 1.0 N

|

0.58 kg / 1.28 LBS

~0 Gs

|

| 60 mm |

0.31 kg / 0.69 LBS

712 Gs

|

0.05 kg / 0.10 LBS

47 g / 0.5 N

|

0.28 kg / 0.62 LBS

~0 Gs

|

| 70 mm |

0.16 kg / 0.36 LBS

514 Gs

|

0.02 kg / 0.05 LBS

24 g / 0.2 N

|

0.15 kg / 0.32 LBS

~0 Gs

|

| 80 mm |

0.09 kg / 0.20 LBS

383 Gs

|

0.01 kg / 0.03 LBS

14 g / 0.1 N

|

0.08 kg / 0.18 LBS

~0 Gs

|

| 90 mm |

0.05 kg / 0.12 LBS

293 Gs

|

0.01 kg / 0.02 LBS

8 g / 0.1 N

|

0.05 kg / 0.11 LBS

~0 Gs

|

| 100 mm |

0.03 kg / 0.07 LBS

230 Gs

|

0.00 kg / 0.01 LBS

5 g / 0.0 N

|

0.03 kg / 0.06 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - warnings

MP 25x8x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 17.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 13.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 10.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 8.0 cm |

| Remote | 50 Gs (5.0 mT) | 7.5 cm |

| Payment card | 400 Gs (40.0 mT) | 3.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.5 cm |

Table 8: Impact energy (cracking risk) - collision effects

MP 25x8x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.62 km/h

(6.28 m/s)

|

0.33 J | |

| 30 mm |

36.45 km/h

(10.13 m/s)

|

0.85 J | |

| 50 mm |

46.96 km/h

(13.04 m/s)

|

1.41 J | |

| 100 mm |

66.40 km/h

(18.44 m/s)

|

2.81 J |

Table 9: Corrosion resistance

MP 25x8x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 25x8x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 24 536 Mx | 245.4 µWb |

| Pc Coefficient | 1.03 | High (Stable) |

Table 11: Submerged application

MP 25x8x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.16 kg | Standard |

| Water (riverbed) |

8.20 kg

(+1.04 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Warning: On a vertical surface, the magnet retains just ~20% of its nominal pull.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) drastically limits the holding force.

3. Temperature resistance

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.03

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also proposals

Advantages as well as disadvantages of neodymium magnets.

Strengths

- They retain magnetic properties for almost 10 years – the loss is just ~1% (in theory),

- They possess excellent resistance to weakening of magnetic properties due to opposing magnetic fields,

- Thanks to the elegant finish, the plating of Ni-Cu-Ni, gold-plated, or silver gives an aesthetic appearance,

- They are known for high magnetic induction at the operating surface, which increases their power,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Thanks to modularity in constructing and the ability to customize to unusual requirements,

- Significant place in modern industrial fields – they are used in computer drives, brushless drives, precision medical tools, as well as multitasking production systems.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Disadvantages

- At strong impacts they can break, therefore we recommend placing them in strong housings. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we advise using waterproof magnets made of rubber, plastic or other material protecting against moisture

- Limited possibility of producing threads in the magnet and complex shapes - preferred is casing - mounting mechanism.

- Possible danger related to microscopic parts of magnets pose a threat, if swallowed, which gains importance in the context of child health protection. Additionally, small elements of these products can disrupt the diagnostic process medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Lifting parameters

Maximum lifting force for a neodymium magnet – what it depends on?

- on a plate made of structural steel, perfectly concentrating the magnetic field

- whose thickness is min. 10 mm

- with an ideally smooth touching surface

- with direct contact (without paint)

- under perpendicular application of breakaway force (90-degree angle)

- at temperature approx. 20 degrees Celsius

Determinants of lifting force in real conditions

- Distance (between the magnet and the plate), because even a microscopic clearance (e.g. 0.5 mm) results in a decrease in lifting capacity by up to 50% (this also applies to varnish, rust or dirt).

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under shear forces, the holding force drops significantly, often to levels of 20-30% of the maximum value.

- Steel thickness – insufficiently thick sheet does not close the flux, causing part of the flux to be escaped into the air.

- Material type – ideal substrate is pure iron steel. Hardened steels may attract less.

- Smoothness – ideal contact is possible only on polished steel. Rough texture create air cushions, weakening the magnet.

- Thermal conditions – neodymium magnets have a negative temperature coefficient. At higher temperatures they are weaker, and at low temperatures gain strength (up to a certain limit).

Lifting capacity testing was performed on a smooth plate of optimal thickness, under a perpendicular pulling force, whereas under shearing force the lifting capacity is smaller. Moreover, even a slight gap between the magnet and the plate lowers the load capacity.

H&S for magnets

Health Danger

Life threat: Neodymium magnets can deactivate pacemakers and defibrillators. Do not approach if you have electronic implants.

Keep away from children

Always store magnets away from children. Choking hazard is significant, and the effects of magnets connecting inside the body are life-threatening.

Allergy Warning

It is widely known that nickel (standard magnet coating) is a potent allergen. If you have an allergy, prevent touching magnets with bare hands and select encased magnets.

Keep away from computers

Data protection: Neodymium magnets can ruin payment cards and delicate electronics (heart implants, medical aids, mechanical watches).

Protective goggles

Watch out for shards. Magnets can explode upon violent connection, launching shards into the air. We recommend safety glasses.

Keep away from electronics

GPS units and smartphones are highly sensitive to magnetism. Close proximity with a powerful NdFeB magnet can permanently damage the internal compass in your phone.

Power loss in heat

Standard neodymium magnets (grade N) lose power when the temperature exceeds 80°C. The loss of strength is permanent.

Machining danger

Drilling and cutting of neodymium magnets poses a fire hazard. Neodymium dust oxidizes rapidly with oxygen and is hard to extinguish.

Immense force

Use magnets consciously. Their immense force can surprise even experienced users. Plan your moves and respect their power.

Physical harm

Risk of injury: The attraction force is so great that it can cause hematomas, crushing, and broken bones. Use thick gloves.

![UMGZ 32x18x8 [M6] GZ / N38 - magnetic holder external thread UMGZ 32x18x8 [M6] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-32x18x8-m6-gz-jix.jpg)