SM 32x175 [2xM8] / N42 - magnetic separator

magnetic separator

Catalog no 130353

GTIN/EAN: 5906301813019

Diameter Ø

32 mm [±1 mm]

Height

175 mm [±1 mm]

Weight

940 g

Magnetic Flux

~ 8 000 Gauss [±5%]

528.90 ZŁ with VAT / pcs + price for transport

430.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

otherwise send us a note via

request form

our website.

Force as well as structure of neodymium magnets can be checked using our

power calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - SM 32x175 [2xM8] / N42 - magnetic separator

Specification / characteristics - SM 32x175 [2xM8] / N42 - magnetic separator

| properties | values |

|---|---|

| Cat. no. | 130353 |

| GTIN/EAN | 5906301813019 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 32 mm [±1 mm] |

| Height | 175 mm [±1 mm] |

| Weight | 940 g |

| Material Type | Stainless steel AISI 304 / A2 |

| Magnetic Flux | ~ 8 000 Gauss [±5%] |

| Size/Mount Quantity | 2xM8 |

| Polarity | circumferential - 6 poles |

| Casing Tube Thickness | 1 mm |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N42

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.9-13.2 | kGs |

| remenance Br [min. - max.] ? | 1290-1320 | mT |

| coercivity bHc ? | 10.8-12.0 | kOe |

| coercivity bHc ? | 860-955 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 40-42 | BH max MGOe |

| energy density [min. - max.] ? | 318-334 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

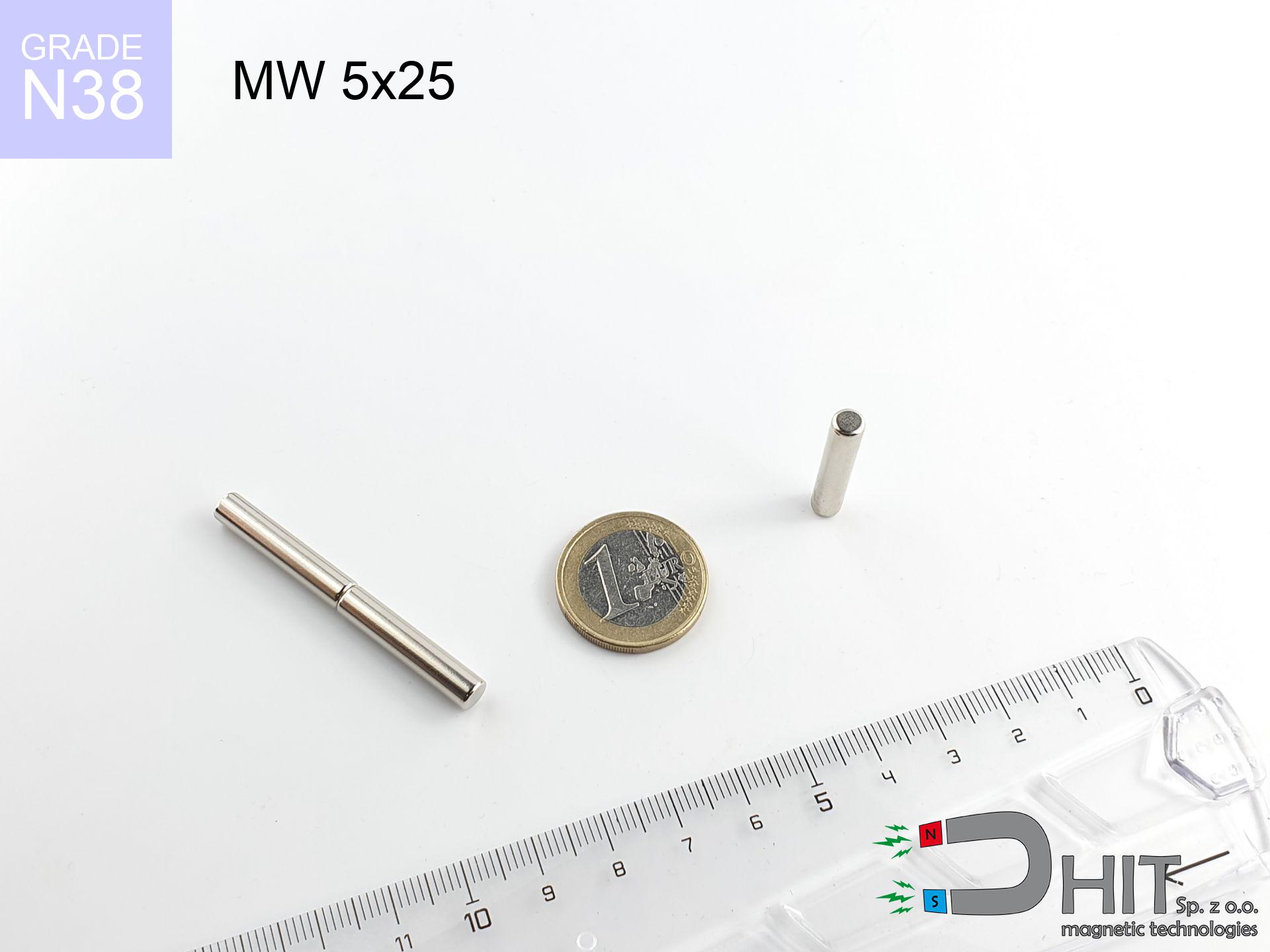

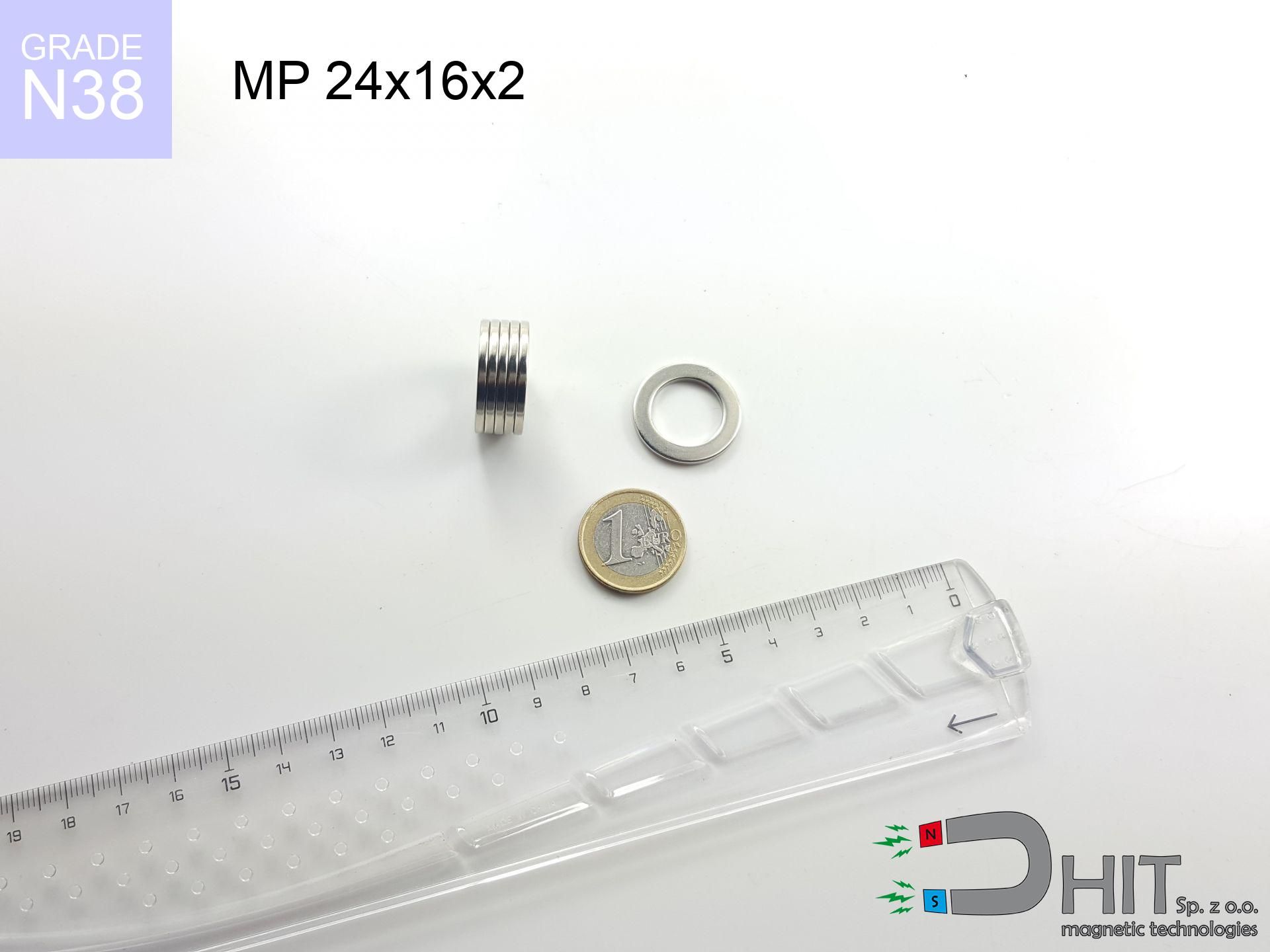

Table 1: Rod construction

SM 32x175 [2xM8] / N42

| Parameter | Value | Description / Unit |

|---|---|---|

| Diameter (Ø) | 32 | mm |

| Total length | 175 | mm (L) |

| Active length | 139 | mm |

| Section count | 6 | modules |

| Dead zone | 36 | mm (2x 18mm starter) |

| Weight (est.) | ~1070 | g |

| Active area | 140 | cm² (Area) |

| Housing material | AISI 304 | 1.4301 (Inox) |

| Surface finish | Ra < 0.8 µm | Polished |

| Temp. class | 80°C | Standard (N) |

| Force loss (at max °C) | -12.8% | Reversible loss (physics) |

| Force (calculated) | 26.2 | kg (theor.) |

| Induction (surface) | ~8 000 | Gauss (Max) |

Chart 2: Field profile (6 sections)

Chart 3: Temperature performance

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Advantages and disadvantages of rare earth magnets.

Advantages

- They retain magnetic properties for almost ten years – the loss is just ~1% (according to analyses),

- They are resistant to demagnetization induced by external disturbances,

- In other words, due to the aesthetic surface of gold, the element gains a professional look,

- They show high magnetic induction at the operating surface, which affects their effectiveness,

- Thanks to resistance to high temperature, they can operate (depending on the form) even at temperatures up to 230°C and higher...

- Possibility of precise machining as well as optimizing to specific requirements,

- Fundamental importance in modern technologies – they serve a role in data components, electric motors, medical equipment, and modern systems.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Limitations

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a steel housing, which not only protects them against impacts but also raises their durability

- Neodymium magnets decrease their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture, when using outdoors

- Limited possibility of producing nuts in the magnet and complicated forms - recommended is a housing - mounting mechanism.

- Health risk related to microscopic parts of magnets are risky, if swallowed, which gains importance in the context of child safety. Additionally, small components of these magnets are able to be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Lifting parameters

Highest magnetic holding force – what contributes to it?

- using a plate made of mild steel, functioning as a magnetic yoke

- with a cross-section no less than 10 mm

- with an ideally smooth touching surface

- without any air gap between the magnet and steel

- during detachment in a direction vertical to the mounting surface

- at ambient temperature approx. 20 degrees Celsius

Lifting capacity in practice – influencing factors

- Clearance – the presence of any layer (paint, dirt, gap) interrupts the magnetic circuit, which lowers power steeply (even by 50% at 0.5 mm).

- Force direction – declared lifting capacity refers to pulling vertically. When applying parallel force, the magnet exhibits significantly lower power (often approx. 20-30% of maximum force).

- Steel thickness – insufficiently thick sheet does not close the flux, causing part of the flux to be wasted to the other side.

- Metal type – not every steel attracts identically. High carbon content worsen the interaction with the magnet.

- Surface condition – smooth surfaces ensure maximum contact, which improves force. Uneven metal weaken the grip.

- Thermal factor – hot environment reduces magnetic field. Too high temperature can permanently damage the magnet.

Lifting capacity was assessed by applying a smooth steel plate of suitable thickness (min. 20 mm), under vertically applied force, however under attempts to slide the magnet the load capacity is reduced by as much as 75%. In addition, even a minimal clearance between the magnet’s surface and the plate decreases the load capacity.

H&S for magnets

Do not underestimate power

Be careful. Rare earth magnets attract from a distance and snap with huge force, often quicker than you can move away.

Fire warning

Dust generated during cutting of magnets is self-igniting. Avoid drilling into magnets without proper cooling and knowledge.

ICD Warning

Warning for patients: Powerful magnets affect electronics. Keep at least 30 cm distance or request help to work with the magnets.

Danger to the youngest

Strictly keep magnets out of reach of children. Ingestion danger is high, and the effects of magnets connecting inside the body are life-threatening.

Nickel allergy

It is widely known that the nickel plating (standard magnet coating) is a strong allergen. If you have an allergy, avoid direct skin contact or opt for encased magnets.

Compass and GPS

Navigation devices and mobile phones are highly sensitive to magnetic fields. Direct contact with a strong magnet can decalibrate the sensors in your phone.

Cards and drives

Equipment safety: Strong magnets can ruin data carriers and sensitive devices (pacemakers, hearing aids, timepieces).

Physical harm

Protect your hands. Two powerful magnets will snap together instantly with a force of several hundred kilograms, destroying everything in their path. Be careful!

Material brittleness

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting shards into the air. Eye protection is mandatory.

Do not overheat magnets

Control the heat. Heating the magnet to high heat will destroy its properties and strength.

![Magnetic bar SM 32x175 [2xM8] / N42 Magnetic bar SM 32x175 [2xM8] / N42](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![SM 32x175 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x175-2xm8-tej.jpg)

![SM 18x225 [2xM5] / N42 - magnetic separator SM 18x225 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x225-2xm5-wiv.jpg)

![SM 32x425 [2xM8] / N52 - magnetic separator SM 32x425 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x425-2xm8-tas.jpg)