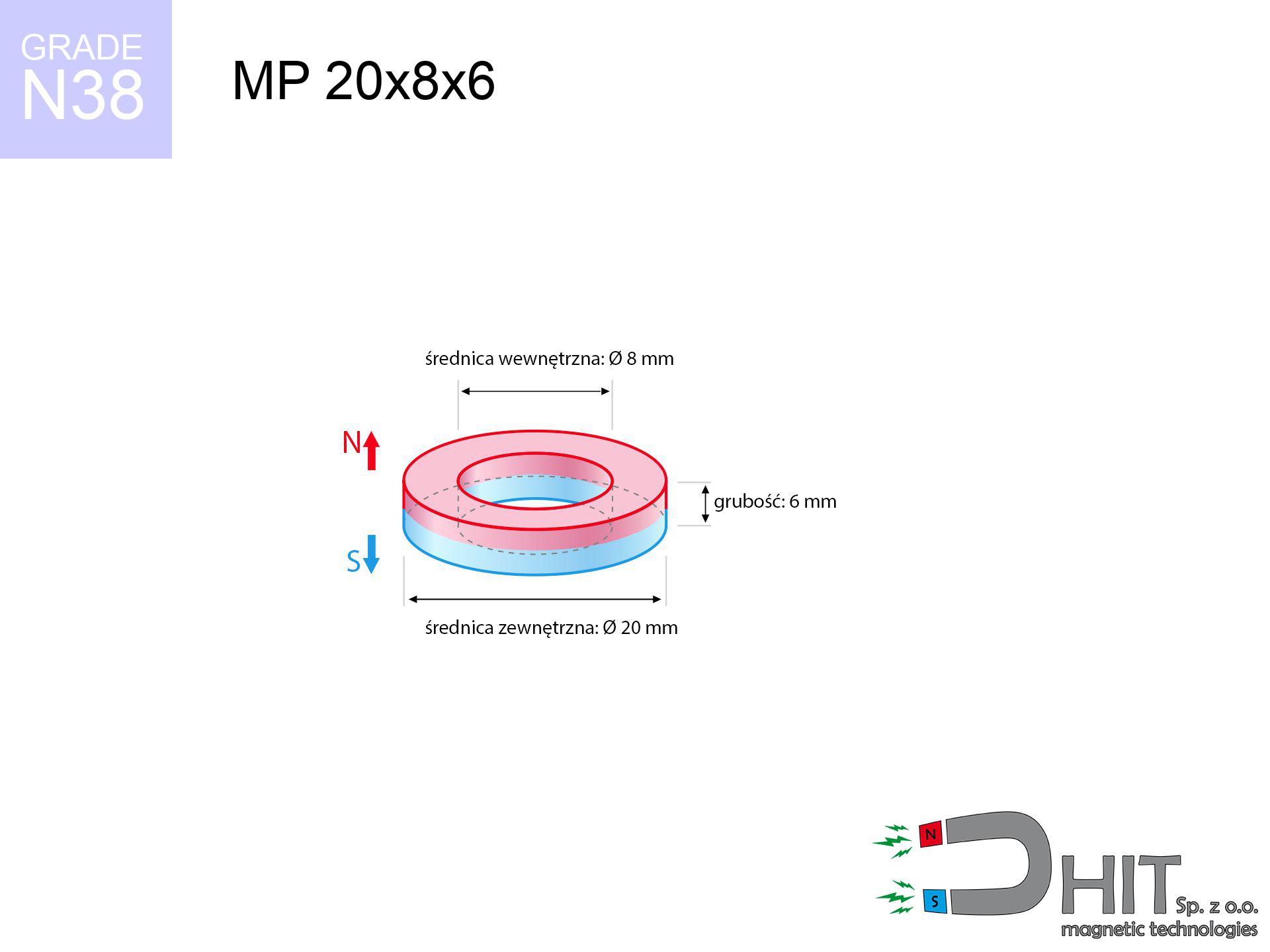

MP 20x8x6 / N38 - ring magnet

ring magnet

Catalog no 030189

GTIN/EAN: 5906301812067

Diameter

20 mm [±0,1 mm]

internal diameter Ø

8 mm [±0,1 mm]

Height

6 mm [±0,1 mm]

Weight

11.88 g

Magnetization Direction

↑ axial

Load capacity

7.22 kg / 70.81 N

Magnetic Induction

318.85 mT / 3188 Gs

Coating

[NiCuNi] Nickel

5.17 ZŁ with VAT / pcs + price for transport

4.20 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

if you prefer send us a note using

request form

the contact section.

Lifting power and appearance of neodymium magnets can be estimated using our

online calculation tool.

Orders submitted before 14:00 will be dispatched today!

Detailed specification - MP 20x8x6 / N38 - ring magnet

Specification / characteristics - MP 20x8x6 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030189 |

| GTIN/EAN | 5906301812067 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 20 mm [±0,1 mm] |

| internal diameter Ø | 8 mm [±0,1 mm] |

| Height | 6 mm [±0,1 mm] |

| Weight | 11.88 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.22 kg / 70.81 N |

| Magnetic Induction ~ ? | 318.85 mT / 3188 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical simulation of the magnet - data

Presented values represent the result of a mathematical analysis. Values are based on algorithms for the material Nd2Fe14B. Operational conditions might slightly differ. Treat these data as a supplementary guide for designers.

Table 1: Static pull force (force vs distance) - interaction chart

MP 20x8x6 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5917 Gs

591.7 mT

|

7.22 kg / 15.92 pounds

7220.0 g / 70.8 N

|

strong |

| 1 mm |

5321 Gs

532.1 mT

|

5.84 kg / 12.87 pounds

5839.8 g / 57.3 N

|

strong |

| 2 mm |

4736 Gs

473.6 mT

|

4.63 kg / 10.20 pounds

4626.6 g / 45.4 N

|

strong |

| 3 mm |

4184 Gs

418.4 mT

|

3.61 kg / 7.96 pounds

3610.0 g / 35.4 N

|

strong |

| 5 mm |

3216 Gs

321.6 mT

|

2.13 kg / 4.70 pounds

2132.9 g / 20.9 N

|

strong |

| 10 mm |

1650 Gs

165.0 mT

|

0.56 kg / 1.24 pounds

561.3 g / 5.5 N

|

low risk |

| 15 mm |

907 Gs

90.7 mT

|

0.17 kg / 0.37 pounds

169.7 g / 1.7 N

|

low risk |

| 20 mm |

544 Gs

54.4 mT

|

0.06 kg / 0.13 pounds

61.1 g / 0.6 N

|

low risk |

| 30 mm |

240 Gs

24.0 mT

|

0.01 kg / 0.03 pounds

11.9 g / 0.1 N

|

low risk |

| 50 mm |

75 Gs

7.5 mT

|

0.00 kg / 0.00 pounds

1.2 g / 0.0 N

|

low risk |

Table 2: Sliding load (wall)

MP 20x8x6 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.44 kg / 3.18 pounds

1444.0 g / 14.2 N

|

| 1 mm | Stal (~0.2) |

1.17 kg / 2.57 pounds

1168.0 g / 11.5 N

|

| 2 mm | Stal (~0.2) |

0.93 kg / 2.04 pounds

926.0 g / 9.1 N

|

| 3 mm | Stal (~0.2) |

0.72 kg / 1.59 pounds

722.0 g / 7.1 N

|

| 5 mm | Stal (~0.2) |

0.43 kg / 0.94 pounds

426.0 g / 4.2 N

|

| 10 mm | Stal (~0.2) |

0.11 kg / 0.25 pounds

112.0 g / 1.1 N

|

| 15 mm | Stal (~0.2) |

0.03 kg / 0.07 pounds

34.0 g / 0.3 N

|

| 20 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

12.0 g / 0.1 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MP 20x8x6 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.17 kg / 4.78 pounds

2166.0 g / 21.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.44 kg / 3.18 pounds

1444.0 g / 14.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.72 kg / 1.59 pounds

722.0 g / 7.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.61 kg / 7.96 pounds

3610.0 g / 35.4 N

|

Table 4: Steel thickness (saturation) - power losses

MP 20x8x6 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.72 kg / 1.59 pounds

722.0 g / 7.1 N

|

| 1 mm |

|

1.81 kg / 3.98 pounds

1805.0 g / 17.7 N

|

| 2 mm |

|

3.61 kg / 7.96 pounds

3610.0 g / 35.4 N

|

| 3 mm |

|

5.42 kg / 11.94 pounds

5415.0 g / 53.1 N

|

| 5 mm |

|

7.22 kg / 15.92 pounds

7220.0 g / 70.8 N

|

| 10 mm |

|

7.22 kg / 15.92 pounds

7220.0 g / 70.8 N

|

| 11 mm |

|

7.22 kg / 15.92 pounds

7220.0 g / 70.8 N

|

| 12 mm |

|

7.22 kg / 15.92 pounds

7220.0 g / 70.8 N

|

Table 5: Thermal stability (material behavior) - power drop

MP 20x8x6 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.22 kg / 15.92 pounds

7220.0 g / 70.8 N

|

OK |

| 40 °C | -2.2% |

7.06 kg / 15.57 pounds

7061.2 g / 69.3 N

|

OK |

| 60 °C | -4.4% |

6.90 kg / 15.22 pounds

6902.3 g / 67.7 N

|

OK |

| 80 °C | -6.6% |

6.74 kg / 14.87 pounds

6743.5 g / 66.2 N

|

|

| 100 °C | -28.8% |

5.14 kg / 11.33 pounds

5140.6 g / 50.4 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MP 20x8x6 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

52.44 kg / 115.62 pounds

6 121 Gs

|

7.87 kg / 17.34 pounds

7867 g / 77.2 N

|

N/A |

| 1 mm |

47.33 kg / 104.35 pounds

11 242 Gs

|

7.10 kg / 15.65 pounds

7100 g / 69.6 N

|

42.60 kg / 93.91 pounds

~0 Gs

|

| 2 mm |

42.42 kg / 93.52 pounds

10 642 Gs

|

6.36 kg / 14.03 pounds

6363 g / 62.4 N

|

38.18 kg / 84.16 pounds

~0 Gs

|

| 3 mm |

37.84 kg / 83.42 pounds

10 051 Gs

|

5.68 kg / 12.51 pounds

5675 g / 55.7 N

|

34.05 kg / 75.07 pounds

~0 Gs

|

| 5 mm |

29.73 kg / 65.55 pounds

8 910 Gs

|

4.46 kg / 9.83 pounds

4460 g / 43.8 N

|

26.76 kg / 59.00 pounds

~0 Gs

|

| 10 mm |

15.49 kg / 34.16 pounds

6 432 Gs

|

2.32 kg / 5.12 pounds

2324 g / 22.8 N

|

13.94 kg / 30.74 pounds

~0 Gs

|

| 20 mm |

4.08 kg / 8.99 pounds

3 299 Gs

|

0.61 kg / 1.35 pounds

612 g / 6.0 N

|

3.67 kg / 8.09 pounds

~0 Gs

|

| 50 mm |

0.18 kg / 0.41 pounds

702 Gs

|

0.03 kg / 0.06 pounds

28 g / 0.3 N

|

0.17 kg / 0.37 pounds

~0 Gs

|

| 60 mm |

0.09 kg / 0.19 pounds

480 Gs

|

0.01 kg / 0.03 pounds

13 g / 0.1 N

|

0.08 kg / 0.17 pounds

~0 Gs

|

| 70 mm |

0.04 kg / 0.10 pounds

342 Gs

|

0.01 kg / 0.01 pounds

7 g / 0.1 N

|

0.04 kg / 0.09 pounds

~0 Gs

|

| 80 mm |

0.02 kg / 0.05 pounds

253 Gs

|

0.00 kg / 0.01 pounds

4 g / 0.0 N

|

0.02 kg / 0.05 pounds

~0 Gs

|

| 90 mm |

0.01 kg / 0.03 pounds

193 Gs

|

0.00 kg / 0.00 pounds

2 g / 0.0 N

|

0.01 kg / 0.03 pounds

~0 Gs

|

| 100 mm |

0.01 kg / 0.02 pounds

150 Gs

|

0.00 kg / 0.00 pounds

1 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MP 20x8x6 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 14.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 11.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 9.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 6.5 cm |

| Remote | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MP 20x8x6 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

26.04 km/h

(7.23 m/s)

|

0.31 J | |

| 30 mm |

43.11 km/h

(11.97 m/s)

|

0.85 J | |

| 50 mm |

55.60 km/h

(15.44 m/s)

|

1.42 J | |

| 100 mm |

78.62 km/h

(21.84 m/s)

|

2.83 J |

Table 9: Anti-corrosion coating durability

MP 20x8x6 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 20x8x6 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 15 688 Mx | 156.9 µWb |

| Pc Coefficient | 1.14 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MP 20x8x6 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.22 kg | Standard |

| Water (riverbed) |

8.27 kg

(+1.05 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet holds only ~20% of its nominal pull.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Heat tolerance

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.14

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also products

Advantages and disadvantages of neodymium magnets.

Advantages

- They do not lose magnetism, even over nearly ten years – the drop in power is only ~1% (based on measurements),

- They do not lose their magnetic properties even under external field action,

- The use of an shiny layer of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- Neodymium magnets deliver maximum magnetic induction on a small surface, which ensures high operational effectiveness,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can work (depending on the shape) even at a temperature of 230°C or more...

- Possibility of accurate creating as well as adapting to concrete applications,

- Huge importance in modern technologies – they serve a role in HDD drives, electric drive systems, precision medical tools, also other advanced devices.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Limitations

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a special holder, which not only secures them against impacts but also raises their durability

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we advise using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in producing threads and complex shapes in magnets, we propose using cover - magnetic holder.

- Health risk related to microscopic parts of magnets are risky, when accidentally swallowed, which is particularly important in the context of child safety. Furthermore, tiny parts of these devices can be problematic in diagnostics medical when they are in the body.

- Due to neodymium price, their price is relatively high,

Pull force analysis

Optimal lifting capacity of a neodymium magnet – what affects it?

- on a block made of mild steel, effectively closing the magnetic flux

- whose thickness equals approx. 10 mm

- with a plane free of scratches

- without any insulating layer between the magnet and steel

- during pulling in a direction perpendicular to the mounting surface

- in neutral thermal conditions

Practical lifting capacity: influencing factors

- Clearance – existence of any layer (rust, dirt, air) interrupts the magnetic circuit, which lowers capacity steeply (even by 50% at 0.5 mm).

- Force direction – catalog parameter refers to detachment vertically. When applying parallel force, the magnet holds much less (typically approx. 20-30% of maximum force).

- Wall thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of converting into lifting capacity.

- Steel grade – the best choice is high-permeability steel. Cast iron may attract less.

- Surface condition – smooth surfaces ensure maximum contact, which increases field saturation. Rough surfaces weaken the grip.

- Temperature – temperature increase causes a temporary drop of force. Check the maximum operating temperature for a given model.

Lifting capacity was assessed by applying a steel plate with a smooth surface of suitable thickness (min. 20 mm), under perpendicular pulling force, however under parallel forces the lifting capacity is smaller. Moreover, even a small distance between the magnet and the plate decreases the holding force.

Safety rules for work with NdFeB magnets

Warning for heart patients

Patients with a ICD have to maintain an absolute distance from magnets. The magnetism can disrupt the functioning of the implant.

Respect the power

Handle magnets with awareness. Their powerful strength can shock even professionals. Be vigilant and do not underestimate their power.

Magnet fragility

NdFeB magnets are ceramic materials, which means they are very brittle. Impact of two magnets leads to them breaking into small pieces.

Precision electronics

Note: neodymium magnets produce a field that confuses sensitive sensors. Maintain a separation from your phone, device, and GPS.

Safe distance

Avoid bringing magnets near a wallet, laptop, or TV. The magnetic field can irreversibly ruin these devices and wipe information from cards.

Nickel coating and allergies

Some people have a sensitization to nickel, which is the typical protective layer for neodymium magnets. Extended handling might lead to dermatitis. We suggest wear safety gloves.

Heat warning

Control the heat. Exposing the magnet to high heat will ruin its properties and pulling force.

Keep away from children

These products are not toys. Swallowing several magnets may result in them connecting inside the digestive tract, which constitutes a severe health hazard and necessitates immediate surgery.

Bone fractures

Pinching hazard: The attraction force is so immense that it can cause blood blisters, crushing, and broken bones. Protective gloves are recommended.

Dust is flammable

Drilling and cutting of neodymium magnets poses a fire hazard. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

![SM 32x350 [2xM8] / N42 - magnetic separator SM 32x350 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x350-2xm8-nih.jpg)

![SM 32x200 [2xM8] / N42 - magnetic separator SM 32x200 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x200-2xm8-fub.jpg)

![SM 25x150 [2xM8] / N42 - magnetic separator SM 25x150 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x150-2xm8-cim.jpg)