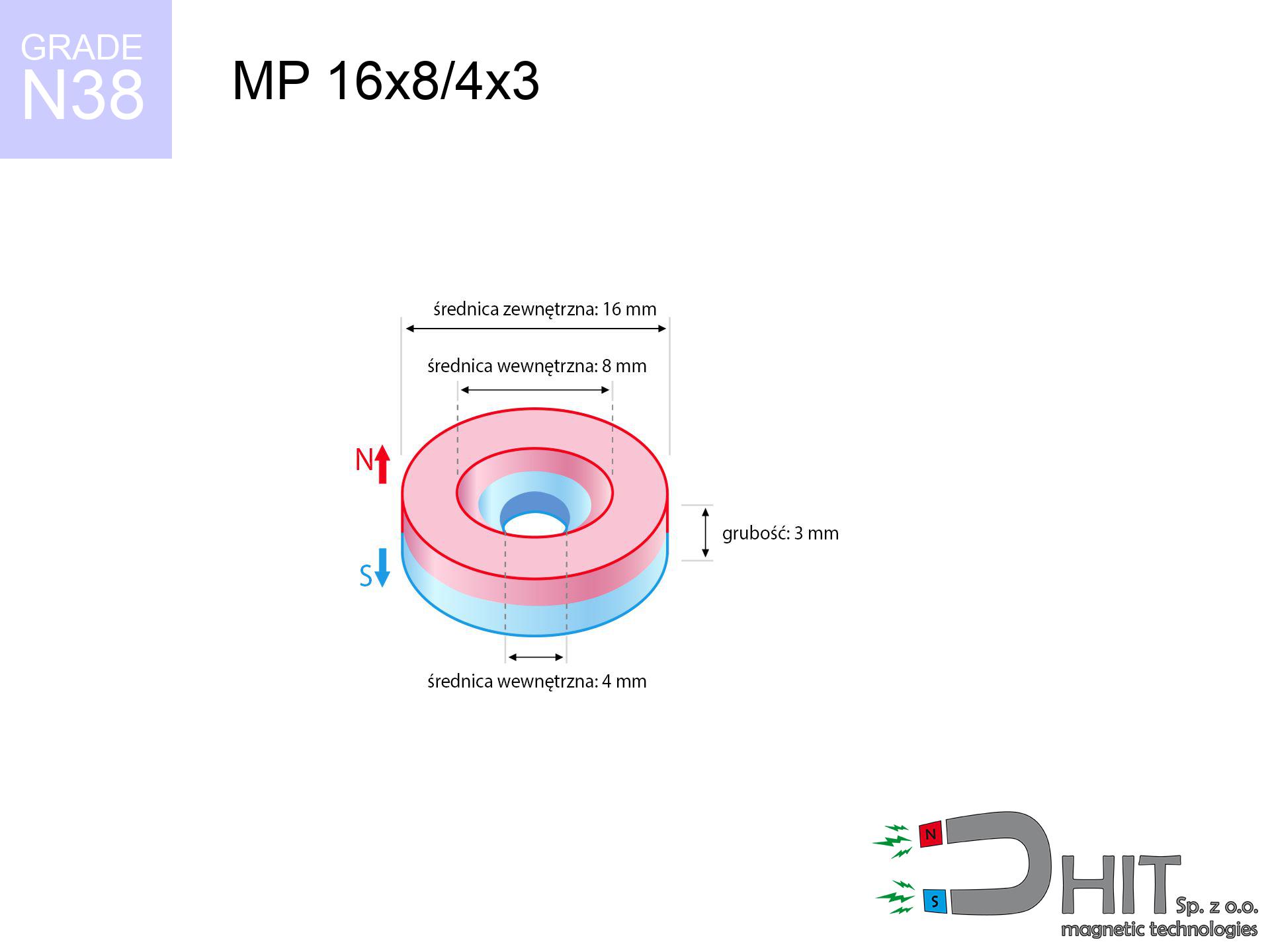

MP 16x8/4x3 / N38 - ring magnet

ring magnet

Catalog no 030396

GTIN/EAN: 5906301812333

Diameter

16 mm [±0,1 mm]

internal diameter Ø

8/4 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

4.24 g

Magnetization Direction

↑ axial

Load capacity

2.78 kg / 27.29 N

Magnetic Induction

217.61 mT / 2176 Gs

Coating

[NiCuNi] Nickel

2.50 ZŁ with VAT / pcs + price for transport

2.03 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

otherwise contact us through

request form

the contact form page.

Strength as well as form of magnets can be analyzed with our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Technical parameters of the product - MP 16x8/4x3 / N38 - ring magnet

Specification / characteristics - MP 16x8/4x3 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030396 |

| GTIN/EAN | 5906301812333 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 16 mm [±0,1 mm] |

| internal diameter Ø | 8/4 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 4.24 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.78 kg / 27.29 N |

| Magnetic Induction ~ ? | 217.61 mT / 2176 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical modeling of the assembly - technical parameters

Presented information represent the outcome of a physical analysis. Results are based on algorithms for the material Nd2Fe14B. Operational performance might slightly differ from theoretical values. Use these data as a reference point for designers.

Table 1: Static pull force (force vs gap) - characteristics

MP 16x8/4x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1882 Gs

188.2 mT

|

2.78 kg / 6.13 LBS

2780.0 g / 27.3 N

|

medium risk |

| 1 mm |

1746 Gs

174.6 mT

|

2.39 kg / 5.27 LBS

2392.4 g / 23.5 N

|

medium risk |

| 2 mm |

1561 Gs

156.1 mT

|

1.91 kg / 4.22 LBS

1913.9 g / 18.8 N

|

safe |

| 3 mm |

1357 Gs

135.7 mT

|

1.45 kg / 3.19 LBS

1445.8 g / 14.2 N

|

safe |

| 5 mm |

969 Gs

96.9 mT

|

0.74 kg / 1.63 LBS

737.7 g / 7.2 N

|

safe |

| 10 mm |

387 Gs

38.7 mT

|

0.12 kg / 0.26 LBS

117.4 g / 1.2 N

|

safe |

| 15 mm |

171 Gs

17.1 mT

|

0.02 kg / 0.05 LBS

22.9 g / 0.2 N

|

safe |

| 20 mm |

87 Gs

8.7 mT

|

0.01 kg / 0.01 LBS

5.9 g / 0.1 N

|

safe |

| 30 mm |

30 Gs

3.0 mT

|

0.00 kg / 0.00 LBS

0.7 g / 0.0 N

|

safe |

| 50 mm |

7 Gs

0.7 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

safe |

Table 2: Slippage load (vertical surface)

MP 16x8/4x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.56 kg / 1.23 LBS

556.0 g / 5.5 N

|

| 1 mm | Stal (~0.2) |

0.48 kg / 1.05 LBS

478.0 g / 4.7 N

|

| 2 mm | Stal (~0.2) |

0.38 kg / 0.84 LBS

382.0 g / 3.7 N

|

| 3 mm | Stal (~0.2) |

0.29 kg / 0.64 LBS

290.0 g / 2.8 N

|

| 5 mm | Stal (~0.2) |

0.15 kg / 0.33 LBS

148.0 g / 1.5 N

|

| 10 mm | Stal (~0.2) |

0.02 kg / 0.05 LBS

24.0 g / 0.2 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MP 16x8/4x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.83 kg / 1.84 LBS

834.0 g / 8.2 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.56 kg / 1.23 LBS

556.0 g / 5.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.28 kg / 0.61 LBS

278.0 g / 2.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.39 kg / 3.06 LBS

1390.0 g / 13.6 N

|

Table 4: Steel thickness (substrate influence) - power losses

MP 16x8/4x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.28 kg / 0.61 LBS

278.0 g / 2.7 N

|

| 1 mm |

|

0.70 kg / 1.53 LBS

695.0 g / 6.8 N

|

| 2 mm |

|

1.39 kg / 3.06 LBS

1390.0 g / 13.6 N

|

| 3 mm |

|

2.09 kg / 4.60 LBS

2085.0 g / 20.5 N

|

| 5 mm |

|

2.78 kg / 6.13 LBS

2780.0 g / 27.3 N

|

| 10 mm |

|

2.78 kg / 6.13 LBS

2780.0 g / 27.3 N

|

| 11 mm |

|

2.78 kg / 6.13 LBS

2780.0 g / 27.3 N

|

| 12 mm |

|

2.78 kg / 6.13 LBS

2780.0 g / 27.3 N

|

Table 5: Thermal stability (stability) - thermal limit

MP 16x8/4x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.78 kg / 6.13 LBS

2780.0 g / 27.3 N

|

OK |

| 40 °C | -2.2% |

2.72 kg / 5.99 LBS

2718.8 g / 26.7 N

|

OK |

| 60 °C | -4.4% |

2.66 kg / 5.86 LBS

2657.7 g / 26.1 N

|

|

| 80 °C | -6.6% |

2.60 kg / 5.72 LBS

2596.5 g / 25.5 N

|

|

| 100 °C | -28.8% |

1.98 kg / 4.36 LBS

1979.4 g / 19.4 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MP 16x8/4x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.50 kg / 7.71 LBS

3 330 Gs

|

0.52 kg / 1.16 LBS

525 g / 5.1 N

|

N/A |

| 1 mm |

3.28 kg / 7.23 LBS

3 644 Gs

|

0.49 kg / 1.08 LBS

492 g / 4.8 N

|

2.95 kg / 6.51 LBS

~0 Gs

|

| 2 mm |

3.01 kg / 6.64 LBS

3 492 Gs

|

0.45 kg / 1.00 LBS

452 g / 4.4 N

|

2.71 kg / 5.97 LBS

~0 Gs

|

| 3 mm |

2.71 kg / 5.98 LBS

3 316 Gs

|

0.41 kg / 0.90 LBS

407 g / 4.0 N

|

2.44 kg / 5.39 LBS

~0 Gs

|

| 5 mm |

2.11 kg / 4.64 LBS

2 920 Gs

|

0.32 kg / 0.70 LBS

316 g / 3.1 N

|

1.90 kg / 4.18 LBS

~0 Gs

|

| 10 mm |

0.93 kg / 2.05 LBS

1 939 Gs

|

0.14 kg / 0.31 LBS

139 g / 1.4 N

|

0.84 kg / 1.84 LBS

~0 Gs

|

| 20 mm |

0.15 kg / 0.33 LBS

773 Gs

|

0.02 kg / 0.05 LBS

22 g / 0.2 N

|

0.13 kg / 0.29 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 LBS

98 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

60 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

40 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

27 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

20 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

14 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MP 16x8/4x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.0 cm |

| Remote | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - collision effects

MP 16x8/4x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

26.50 km/h

(7.36 m/s)

|

0.11 J | |

| 30 mm |

44.74 km/h

(12.43 m/s)

|

0.33 J | |

| 50 mm |

57.74 km/h

(16.04 m/s)

|

0.55 J | |

| 100 mm |

81.66 km/h

(22.68 m/s)

|

1.09 J |

Table 9: Surface protection spec

MP 16x8/4x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MP 16x8/4x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 743 Mx | 37.4 µWb |

| Pc Coefficient | 0.24 | Low (Flat) |

Table 11: Physics of underwater searching

MP 16x8/4x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.78 kg | Standard |

| Water (riverbed) |

3.18 kg

(+0.40 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical surface, the magnet holds merely a fraction of its nominal pull.

2. Efficiency vs thickness

*Thin metal sheet (e.g. computer case) significantly reduces the holding force.

3. Power loss vs temp

*For N38 grade, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.24

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out more products

Advantages as well as disadvantages of rare earth magnets.

Pros

- They retain full power for nearly 10 years – the loss is just ~1% (according to analyses),

- They feature excellent resistance to magnetism drop when exposed to opposing magnetic fields,

- The use of an metallic coating of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- They show high magnetic induction at the operating surface, which increases their power,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can work (depending on the form) even at a temperature of 230°C or more...

- In view of the possibility of flexible forming and adaptation to specialized solutions, NdFeB magnets can be produced in a variety of forms and dimensions, which amplifies use scope,

- Key role in advanced technology sectors – they are commonly used in HDD drives, brushless drives, advanced medical instruments, as well as industrial machines.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Disadvantages

- At strong impacts they can break, therefore we advise placing them in strong housings. A metal housing provides additional protection against damage and increases the magnet's durability.

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Limited ability of making nuts in the magnet and complicated shapes - preferred is cover - magnet mounting.

- Potential hazard resulting from small fragments of magnets are risky, if swallowed, which is particularly important in the context of child health protection. Furthermore, tiny parts of these products can complicate diagnosis medical when they are in the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Lifting parameters

Breakaway strength of the magnet in ideal conditions – what it depends on?

- with the contact of a yoke made of low-carbon steel, guaranteeing full magnetic saturation

- whose transverse dimension reaches at least 10 mm

- with a surface cleaned and smooth

- without the slightest air gap between the magnet and steel

- during detachment in a direction vertical to the mounting surface

- in temp. approx. 20°C

Determinants of practical lifting force of a magnet

- Space between surfaces – every millimeter of distance (caused e.g. by varnish or dirt) diminishes the pulling force, often by half at just 0.5 mm.

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under shear forces, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Element thickness – for full efficiency, the steel must be sufficiently thick. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Metal type – not every steel attracts identically. Alloy additives worsen the attraction effect.

- Surface finish – full contact is possible only on polished steel. Any scratches and bumps create air cushions, reducing force.

- Operating temperature – NdFeB sinters have a negative temperature coefficient. When it is hot they lose power, and in frost they can be stronger (up to a certain limit).

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under a perpendicular pulling force, however under shearing force the holding force is lower. Moreover, even a minimal clearance between the magnet’s surface and the plate lowers the load capacity.

Safety rules for work with neodymium magnets

Shattering risk

Despite metallic appearance, the material is brittle and cannot withstand shocks. Do not hit, as the magnet may crumble into hazardous fragments.

Permanent damage

Watch the temperature. Heating the magnet to high heat will destroy its magnetic structure and strength.

Compass and GPS

A powerful magnetic field interferes with the functioning of magnetometers in smartphones and GPS navigation. Keep magnets near a smartphone to avoid damaging the sensors.

Mechanical processing

Combustion risk: Rare earth powder is highly flammable. Do not process magnets without safety gear as this risks ignition.

Sensitization to coating

Warning for allergy sufferers: The nickel-copper-nickel coating contains nickel. If skin irritation occurs, immediately stop handling magnets and wear gloves.

Crushing force

Risk of injury: The attraction force is so great that it can result in hematomas, crushing, and broken bones. Use thick gloves.

Protect data

Very strong magnetic fields can destroy records on payment cards, hard drives, and storage devices. Keep a distance of at least 10 cm.

Respect the power

Before starting, read the rules. Uncontrolled attraction can break the magnet or injure your hand. Think ahead.

Pacemakers

Life threat: Strong magnets can deactivate heart devices and defibrillators. Do not approach if you have medical devices.

Danger to the youngest

These products are not intended for children. Accidental ingestion of several magnets may result in them connecting inside the digestive tract, which constitutes a direct threat to life and requires immediate surgery.

![HH 42x8.8 [M6] / N38 - through hole magnetic holder HH 42x8.8 [M6] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-42x8.8-m6-hin.jpg)

![UMP 75x25 [M10x3] GW F200 PLATINIUM / N52 - search holder UMP 75x25 [M10x3] GW F200 PLATINIUM / N52 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-platinium-tav.jpg)

![HH 16x5.3 [M3] / N38 - through hole magnetic holder HH 16x5.3 [M3] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-16x5.3-m3-sud.jpg)