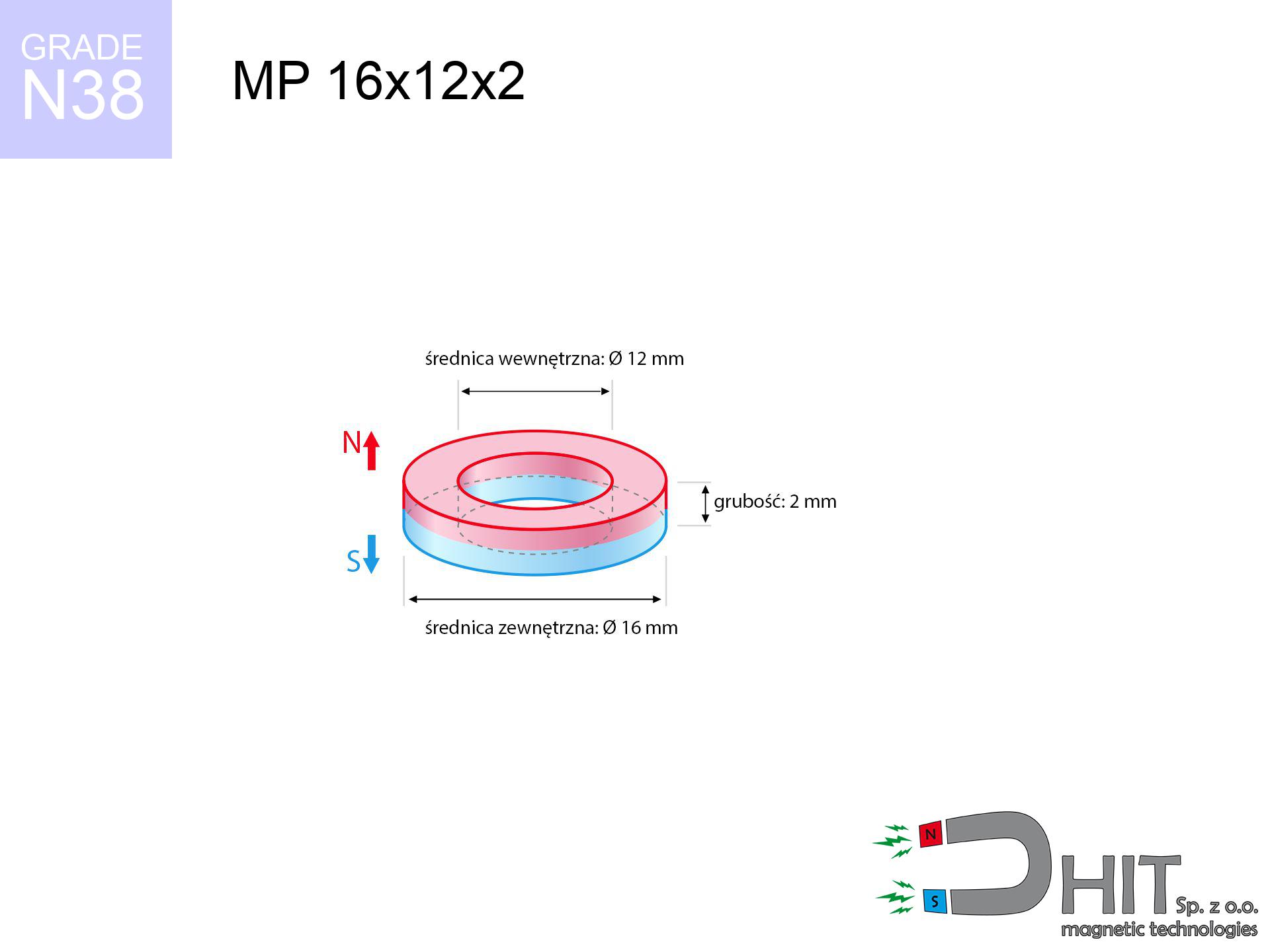

MP 16x12x2 / N38 - ring magnet

ring magnet

Catalog no 030183

GTIN/EAN: 5906301812005

Diameter

16 mm [±0,1 mm]

internal diameter Ø

12 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

1.32 g

Magnetization Direction

↑ axial

Load capacity

0.68 kg / 6.62 N

Magnetic Induction

150.33 mT / 1503 Gs

Coating

[NiCuNi] Nickel

1.304 ZŁ with VAT / pcs + price for transport

1.060 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

if you prefer send us a note by means of

request form

through our site.

Lifting power along with structure of a neodymium magnet can be reviewed on our

our magnetic calculator.

Same-day shipping for orders placed before 14:00.

Technical details - MP 16x12x2 / N38 - ring magnet

Specification / characteristics - MP 16x12x2 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030183 |

| GTIN/EAN | 5906301812005 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 16 mm [±0,1 mm] |

| internal diameter Ø | 12 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 1.32 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.68 kg / 6.62 N |

| Magnetic Induction ~ ? | 150.33 mT / 1503 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - technical parameters

Presented data are the result of a engineering calculation. Results rely on models for the class Nd2Fe14B. Real-world conditions might slightly differ from theoretical values. Please consider these calculations as a supplementary guide for designers.

Table 1: Static force (pull vs distance) - power drop

MP 16x12x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

6011 Gs

601.1 mT

|

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

safe |

| 1 mm |

5259 Gs

525.9 mT

|

0.52 kg / 1.15 lbs

520.7 g / 5.1 N

|

safe |

| 2 mm |

4534 Gs

453.4 mT

|

0.39 kg / 0.85 lbs

387.0 g / 3.8 N

|

safe |

| 3 mm |

3870 Gs

387.0 mT

|

0.28 kg / 0.62 lbs

281.9 g / 2.8 N

|

safe |

| 5 mm |

2776 Gs

277.6 mT

|

0.15 kg / 0.32 lbs

145.1 g / 1.4 N

|

safe |

| 10 mm |

1251 Gs

125.1 mT

|

0.03 kg / 0.06 lbs

29.4 g / 0.3 N

|

safe |

| 15 mm |

643 Gs

64.3 mT

|

0.01 kg / 0.02 lbs

7.8 g / 0.1 N

|

safe |

| 20 mm |

372 Gs

37.2 mT

|

0.00 kg / 0.01 lbs

2.6 g / 0.0 N

|

safe |

| 30 mm |

159 Gs

15.9 mT

|

0.00 kg / 0.00 lbs

0.5 g / 0.0 N

|

safe |

| 50 mm |

49 Gs

4.9 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

safe |

Table 2: Slippage hold (vertical surface)

MP 16x12x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.14 kg / 0.30 lbs

136.0 g / 1.3 N

|

| 1 mm | Stal (~0.2) |

0.10 kg / 0.23 lbs

104.0 g / 1.0 N

|

| 2 mm | Stal (~0.2) |

0.08 kg / 0.17 lbs

78.0 g / 0.8 N

|

| 3 mm | Stal (~0.2) |

0.06 kg / 0.12 lbs

56.0 g / 0.5 N

|

| 5 mm | Stal (~0.2) |

0.03 kg / 0.07 lbs

30.0 g / 0.3 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.01 lbs

6.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MP 16x12x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.20 kg / 0.45 lbs

204.0 g / 2.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.14 kg / 0.30 lbs

136.0 g / 1.3 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.07 kg / 0.15 lbs

68.0 g / 0.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.34 kg / 0.75 lbs

340.0 g / 3.3 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MP 16x12x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.07 kg / 0.15 lbs

68.0 g / 0.7 N

|

| 1 mm |

|

0.17 kg / 0.37 lbs

170.0 g / 1.7 N

|

| 2 mm |

|

0.34 kg / 0.75 lbs

340.0 g / 3.3 N

|

| 3 mm |

|

0.51 kg / 1.12 lbs

510.0 g / 5.0 N

|

| 5 mm |

|

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

| 10 mm |

|

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

| 11 mm |

|

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

| 12 mm |

|

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

Table 5: Thermal stability (stability) - thermal limit

MP 16x12x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.68 kg / 1.50 lbs

680.0 g / 6.7 N

|

OK |

| 40 °C | -2.2% |

0.67 kg / 1.47 lbs

665.0 g / 6.5 N

|

OK |

| 60 °C | -4.4% |

0.65 kg / 1.43 lbs

650.1 g / 6.4 N

|

OK |

| 80 °C | -6.6% |

0.64 kg / 1.40 lbs

635.1 g / 6.2 N

|

|

| 100 °C | -28.8% |

0.48 kg / 1.07 lbs

484.2 g / 4.7 N

|

Table 6: Two magnets (attraction) - forces in the system

MP 16x12x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

37.47 kg / 82.60 lbs

6 145 Gs

|

5.62 kg / 12.39 lbs

5620 g / 55.1 N

|

N/A |

| 1 mm |

32.95 kg / 72.65 lbs

11 273 Gs

|

4.94 kg / 10.90 lbs

4943 g / 48.5 N

|

29.66 kg / 65.38 lbs

~0 Gs

|

| 2 mm |

28.69 kg / 63.25 lbs

10 519 Gs

|

4.30 kg / 9.49 lbs

4303 g / 42.2 N

|

25.82 kg / 56.92 lbs

~0 Gs

|

| 3 mm |

24.81 kg / 54.69 lbs

9 781 Gs

|

3.72 kg / 8.20 lbs

3721 g / 36.5 N

|

22.33 kg / 49.22 lbs

~0 Gs

|

| 5 mm |

18.24 kg / 40.20 lbs

8 386 Gs

|

2.74 kg / 6.03 lbs

2735 g / 26.8 N

|

16.41 kg / 36.18 lbs

~0 Gs

|

| 10 mm |

7.99 kg / 17.62 lbs

5 552 Gs

|

1.20 kg / 2.64 lbs

1199 g / 11.8 N

|

7.19 kg / 15.86 lbs

~0 Gs

|

| 20 mm |

1.62 kg / 3.58 lbs

2 501 Gs

|

0.24 kg / 0.54 lbs

243 g / 2.4 N

|

1.46 kg / 3.22 lbs

~0 Gs

|

| 50 mm |

0.06 kg / 0.13 lbs

471 Gs

|

0.01 kg / 0.02 lbs

9 g / 0.1 N

|

0.05 kg / 0.11 lbs

~0 Gs

|

| 60 mm |

0.03 kg / 0.06 lbs

318 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.02 kg / 0.05 lbs

~0 Gs

|

| 70 mm |

0.01 kg / 0.03 lbs

225 Gs

|

0.00 kg / 0.00 lbs

2 g / 0.0 N

|

0.01 kg / 0.03 lbs

~0 Gs

|

| 80 mm |

0.01 kg / 0.02 lbs

166 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.01 lbs

126 Gs

|

0.00 kg / 0.00 lbs

1 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.01 lbs

98 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Safety (HSE) (implants) - warnings

MP 16x12x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 12.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 9.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 7.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 5.5 cm |

| Car key | 50 Gs (5.0 mT) | 5.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Dynamics (cracking risk) - collision effects

MP 16x12x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

23.50 km/h

(6.53 m/s)

|

0.03 J | |

| 30 mm |

39.66 km/h

(11.02 m/s)

|

0.08 J | |

| 50 mm |

51.19 km/h

(14.22 m/s)

|

0.13 J | |

| 100 mm |

72.39 km/h

(20.11 m/s)

|

0.27 J |

Table 9: Surface protection spec

MP 16x12x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MP 16x12x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 11 219 Mx | 112.2 µWb |

| Pc Coefficient | 1.22 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MP 16x12x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.68 kg | Standard |

| Water (riverbed) |

0.78 kg

(+0.10 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical wall, the magnet holds just ~20% of its nominal pull.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) significantly limits the holding force.

3. Temperature resistance

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.22

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths and weaknesses of neodymium magnets.

Strengths

- They retain magnetic properties for around 10 years – the loss is just ~1% (according to analyses),

- Neodymium magnets are characterized by exceptionally resistant to loss of magnetic properties caused by external magnetic fields,

- In other words, due to the smooth layer of nickel, the element becomes visually attractive,

- The surface of neodymium magnets generates a unique magnetic field – this is one of their assets,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Thanks to versatility in forming and the capacity to modify to unusual requirements,

- Wide application in electronics industry – they are utilized in hard drives, electric motors, medical equipment, also complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in compact dimensions, which enables their usage in small systems

Cons

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- Neodymium magnets decrease their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain durability even at temperatures up to 230°C

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which secure oxidation as well as corrosion.

- We suggest a housing - magnetic mechanism, due to difficulties in producing nuts inside the magnet and complex shapes.

- Potential hazard related to microscopic parts of magnets can be dangerous, in case of ingestion, which is particularly important in the aspect of protecting the youngest. Furthermore, tiny parts of these devices can disrupt the diagnostic process medical after entering the body.

- Due to expensive raw materials, their price is relatively high,

Pull force analysis

Maximum lifting force for a neodymium magnet – what contributes to it?

- on a base made of mild steel, optimally conducting the magnetic field

- with a thickness of at least 10 mm

- with a plane cleaned and smooth

- with direct contact (without impurities)

- under axial force direction (90-degree angle)

- at conditions approx. 20°C

What influences lifting capacity in practice

- Distance (between the magnet and the metal), as even a microscopic distance (e.g. 0.5 mm) can cause a decrease in lifting capacity by up to 50% (this also applies to paint, corrosion or dirt).

- Force direction – note that the magnet holds strongest perpendicularly. Under shear forces, the holding force drops drastically, often to levels of 20-30% of the maximum value.

- Element thickness – for full efficiency, the steel must be adequately massive. Thin sheet limits the attraction force (the magnet "punches through" it).

- Plate material – low-carbon steel gives the best results. Higher carbon content reduce magnetic properties and lifting capacity.

- Surface structure – the more even the surface, the larger the contact zone and higher the lifting capacity. Unevenness acts like micro-gaps.

- Temperature influence – hot environment reduces magnetic field. Too high temperature can permanently damage the magnet.

Lifting capacity was measured with the use of a steel plate with a smooth surface of optimal thickness (min. 20 mm), under vertically applied force, however under attempts to slide the magnet the holding force is lower. Moreover, even a slight gap between the magnet and the plate reduces the lifting capacity.

Warnings

Dust explosion hazard

Combustion risk: Rare earth powder is highly flammable. Avoid machining magnets without safety gear as this risks ignition.

Safe distance

Very strong magnetic fields can erase data on payment cards, hard drives, and other magnetic media. Maintain a gap of min. 10 cm.

Handling guide

Before starting, read the rules. Sudden snapping can break the magnet or injure your hand. Think ahead.

Precision electronics

Be aware: rare earth magnets produce a field that interferes with sensitive sensors. Keep a safe distance from your mobile, device, and GPS.

Pinching danger

Protect your hands. Two large magnets will join immediately with a force of massive weight, crushing anything in their path. Exercise extreme caution!

Shattering risk

Neodymium magnets are ceramic materials, meaning they are fragile like glass. Collision of two magnets leads to them shattering into shards.

Do not overheat magnets

Standard neodymium magnets (N-type) undergo demagnetization when the temperature surpasses 80°C. This process is irreversible.

Pacemakers

People with a heart stimulator have to keep an large gap from magnets. The magnetism can stop the functioning of the life-saving device.

Do not give to children

Only for adults. Small elements pose a choking risk, causing intestinal necrosis. Keep out of reach of children and animals.

Nickel allergy

A percentage of the population experience a hypersensitivity to Ni, which is the common plating for neodymium magnets. Prolonged contact might lead to skin redness. We strongly advise wear safety gloves.

![SM 25x400 [2xM8] / N52 - magnetic separator SM 25x400 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x400-2xm8-hoj.jpg)

![SM 25x150 [2xM8] / N42 - magnetic separator SM 25x150 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x150-2xm8-cim.jpg)