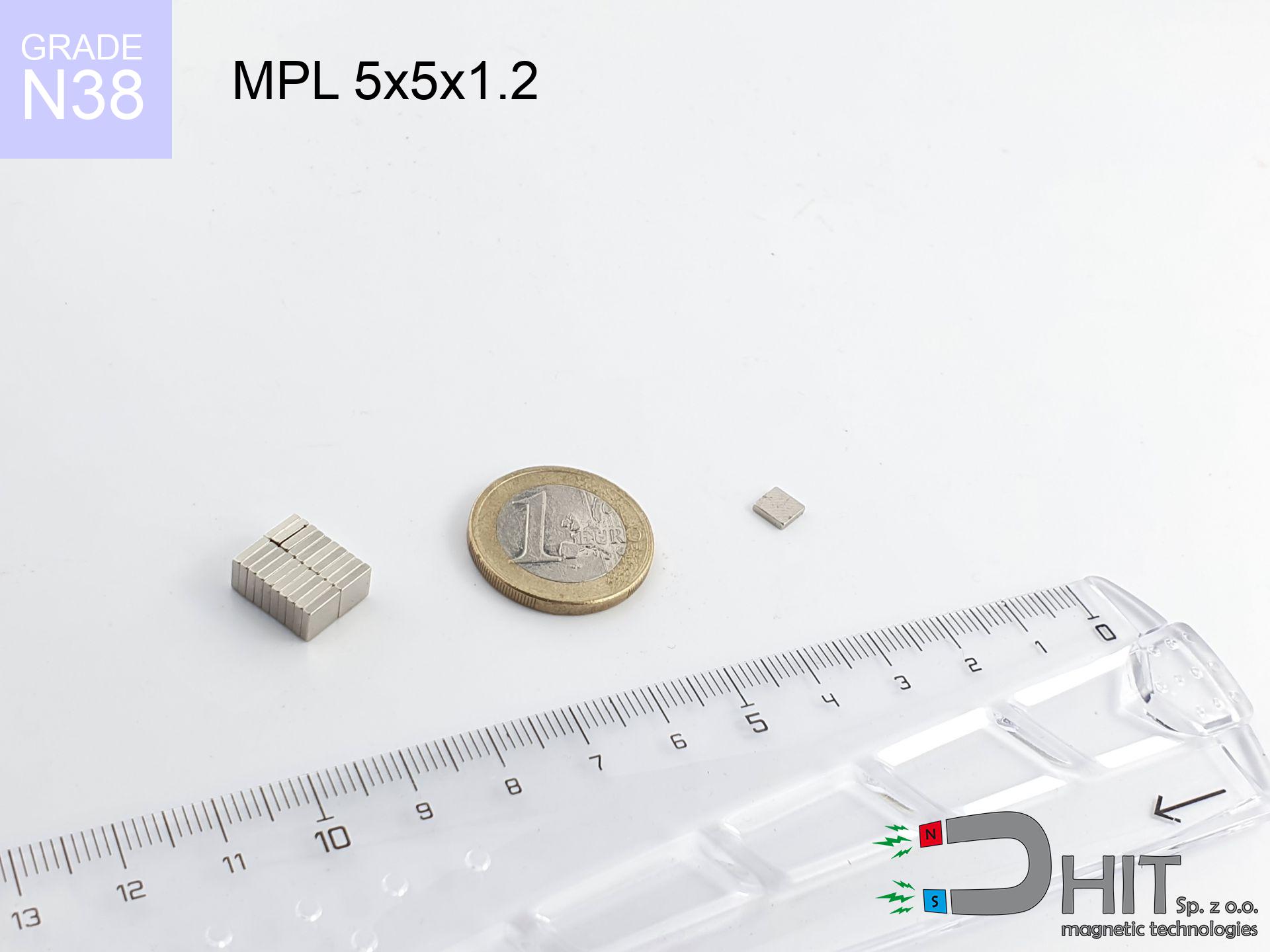

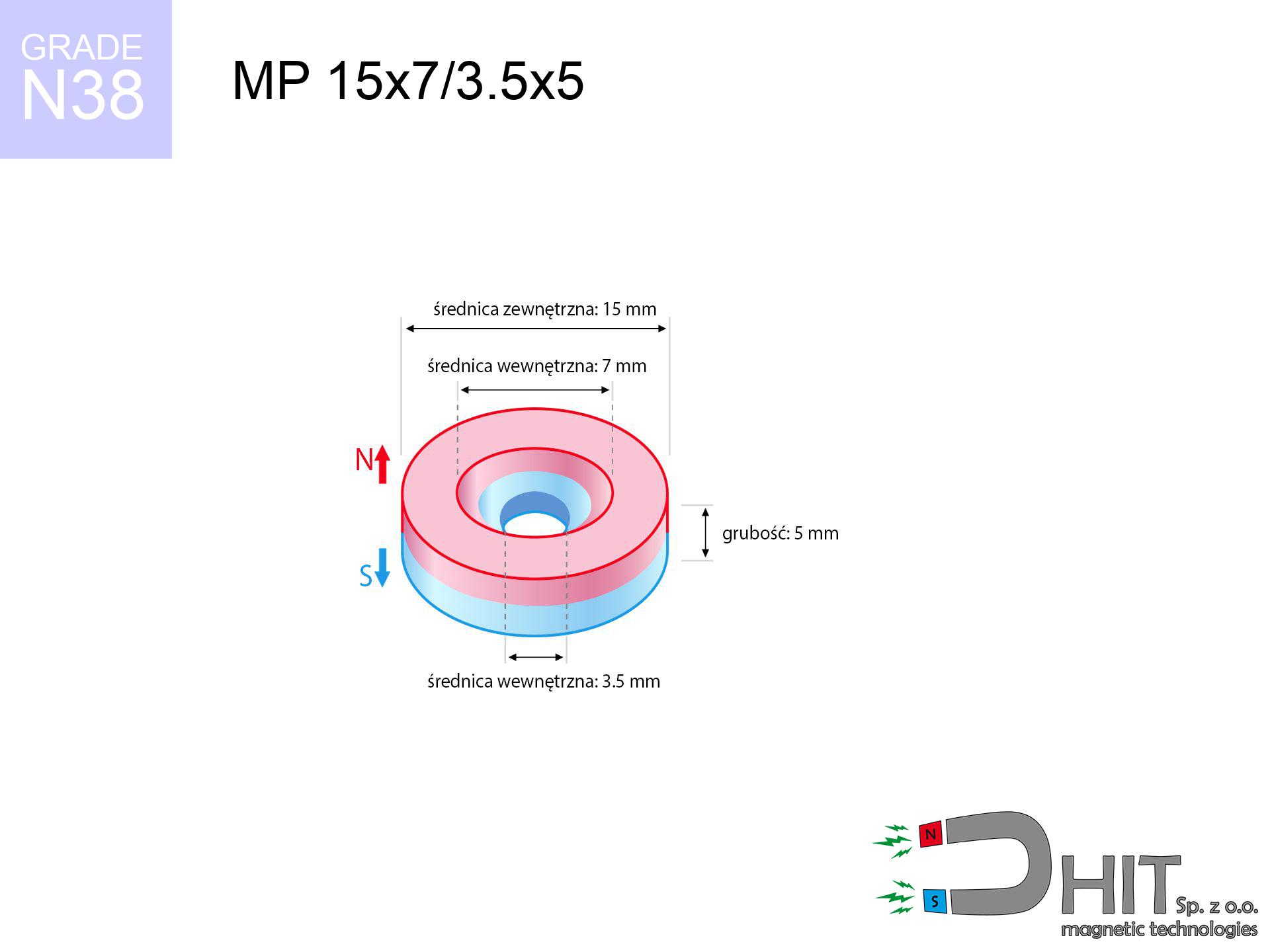

MP 15x7/3.5x5 / N38 - ring magnet

ring magnet

Catalog no 030390

GTIN/EAN: 5906301812302

Diameter

15 mm [±0,1 mm]

internal diameter Ø

7/3.5 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

6.27 g

Magnetization Direction

↑ axial

Load capacity

5.09 kg / 49.95 N

Magnetic Induction

343.70 mT / 3437 Gs

Coating

[NiCuNi] Nickel

3.44 ZŁ with VAT / pcs + price for transport

2.80 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 888 99 98 98

otherwise get in touch through

our online form

the contact section.

Force along with shape of magnets can be reviewed with our

modular calculator.

Same-day shipping for orders placed before 14:00.

Detailed specification - MP 15x7/3.5x5 / N38 - ring magnet

Specification / characteristics - MP 15x7/3.5x5 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030390 |

| GTIN/EAN | 5906301812302 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 15 mm [±0,1 mm] |

| internal diameter Ø | 7/3.5 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 6.27 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 5.09 kg / 49.95 N |

| Magnetic Induction ~ ? | 343.70 mT / 3437 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the magnet - data

The following information are the direct effect of a mathematical calculation. Results are based on algorithms for the material Nd2Fe14B. Real-world parameters might slightly differ. Treat these data as a preliminary roadmap when designing systems.

Table 1: Static pull force (force vs distance) - interaction chart

MP 15x7/3.5x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3054 Gs

305.4 mT

|

5.09 kg / 11.22 LBS

5090.0 g / 49.9 N

|

warning |

| 1 mm |

2736 Gs

273.6 mT

|

4.09 kg / 9.01 LBS

4085.7 g / 40.1 N

|

warning |

| 2 mm |

2372 Gs

237.2 mT

|

3.07 kg / 6.77 LBS

3069.9 g / 30.1 N

|

warning |

| 3 mm |

2007 Gs

200.7 mT

|

2.20 kg / 4.84 LBS

2197.4 g / 21.6 N

|

warning |

| 5 mm |

1377 Gs

137.7 mT

|

1.03 kg / 2.28 LBS

1034.5 g / 10.1 N

|

low risk |

| 10 mm |

526 Gs

52.6 mT

|

0.15 kg / 0.33 LBS

151.3 g / 1.5 N

|

low risk |

| 15 mm |

232 Gs

23.2 mT

|

0.03 kg / 0.06 LBS

29.3 g / 0.3 N

|

low risk |

| 20 mm |

118 Gs

11.8 mT

|

0.01 kg / 0.02 LBS

7.6 g / 0.1 N

|

low risk |

| 30 mm |

42 Gs

4.2 mT

|

0.00 kg / 0.00 LBS

0.9 g / 0.0 N

|

low risk |

| 50 mm |

10 Gs

1.0 mT

|

0.00 kg / 0.00 LBS

0.1 g / 0.0 N

|

low risk |

Table 2: Shear capacity (wall)

MP 15x7/3.5x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.02 kg / 2.24 LBS

1018.0 g / 10.0 N

|

| 1 mm | Stal (~0.2) |

0.82 kg / 1.80 LBS

818.0 g / 8.0 N

|

| 2 mm | Stal (~0.2) |

0.61 kg / 1.35 LBS

614.0 g / 6.0 N

|

| 3 mm | Stal (~0.2) |

0.44 kg / 0.97 LBS

440.0 g / 4.3 N

|

| 5 mm | Stal (~0.2) |

0.21 kg / 0.45 LBS

206.0 g / 2.0 N

|

| 10 mm | Stal (~0.2) |

0.03 kg / 0.07 LBS

30.0 g / 0.3 N

|

| 15 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MP 15x7/3.5x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.53 kg / 3.37 LBS

1527.0 g / 15.0 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.02 kg / 2.24 LBS

1018.0 g / 10.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.51 kg / 1.12 LBS

509.0 g / 5.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.55 kg / 5.61 LBS

2545.0 g / 25.0 N

|

Table 4: Material efficiency (substrate influence) - power losses

MP 15x7/3.5x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.51 kg / 1.12 LBS

509.0 g / 5.0 N

|

| 1 mm |

|

1.27 kg / 2.81 LBS

1272.5 g / 12.5 N

|

| 2 mm |

|

2.55 kg / 5.61 LBS

2545.0 g / 25.0 N

|

| 3 mm |

|

3.82 kg / 8.42 LBS

3817.5 g / 37.4 N

|

| 5 mm |

|

5.09 kg / 11.22 LBS

5090.0 g / 49.9 N

|

| 10 mm |

|

5.09 kg / 11.22 LBS

5090.0 g / 49.9 N

|

| 11 mm |

|

5.09 kg / 11.22 LBS

5090.0 g / 49.9 N

|

| 12 mm |

|

5.09 kg / 11.22 LBS

5090.0 g / 49.9 N

|

Table 5: Thermal resistance (material behavior) - power drop

MP 15x7/3.5x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

5.09 kg / 11.22 LBS

5090.0 g / 49.9 N

|

OK |

| 40 °C | -2.2% |

4.98 kg / 10.97 LBS

4978.0 g / 48.8 N

|

OK |

| 60 °C | -4.4% |

4.87 kg / 10.73 LBS

4866.0 g / 47.7 N

|

|

| 80 °C | -6.6% |

4.75 kg / 10.48 LBS

4754.1 g / 46.6 N

|

|

| 100 °C | -28.8% |

3.62 kg / 7.99 LBS

3624.1 g / 35.6 N

|

Table 6: Magnet-Magnet interaction (attraction) - forces in the system

MP 15x7/3.5x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

8.17 kg / 18.00 LBS

4 643 Gs

|

1.22 kg / 2.70 LBS

1225 g / 12.0 N

|

N/A |

| 1 mm |

7.39 kg / 16.29 LBS

5 810 Gs

|

1.11 kg / 2.44 LBS

1108 g / 10.9 N

|

6.65 kg / 14.66 LBS

~0 Gs

|

| 2 mm |

6.55 kg / 14.45 LBS

5 472 Gs

|

0.98 kg / 2.17 LBS

983 g / 9.6 N

|

5.90 kg / 13.01 LBS

~0 Gs

|

| 3 mm |

5.72 kg / 12.62 LBS

5 113 Gs

|

0.86 kg / 1.89 LBS

858 g / 8.4 N

|

5.15 kg / 11.35 LBS

~0 Gs

|

| 5 mm |

4.19 kg / 9.23 LBS

4 374 Gs

|

0.63 kg / 1.38 LBS

628 g / 6.2 N

|

3.77 kg / 8.31 LBS

~0 Gs

|

| 10 mm |

1.66 kg / 3.66 LBS

2 753 Gs

|

0.25 kg / 0.55 LBS

249 g / 2.4 N

|

1.49 kg / 3.29 LBS

~0 Gs

|

| 20 mm |

0.24 kg / 0.54 LBS

1 053 Gs

|

0.04 kg / 0.08 LBS

36 g / 0.4 N

|

0.22 kg / 0.48 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.01 LBS

134 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

83 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

55 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

38 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

27 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

20 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MP 15x7/3.5x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 6.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 5.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 4.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 3.5 cm |

| Remote | 50 Gs (5.0 mT) | 3.0 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - collision effects

MP 15x7/3.5x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

29.26 km/h

(8.13 m/s)

|

0.21 J | |

| 30 mm |

49.78 km/h

(13.83 m/s)

|

0.60 J | |

| 50 mm |

64.25 km/h

(17.85 m/s)

|

1.00 J | |

| 100 mm |

90.87 km/h

(25.24 m/s)

|

2.00 J |

Table 9: Corrosion resistance

MP 15x7/3.5x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MP 15x7/3.5x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 4 791 Mx | 47.9 µWb |

| Pc Coefficient | 0.39 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MP 15x7/3.5x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 5.09 kg | Standard |

| Water (riverbed) |

5.83 kg

(+0.74 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical wall, the magnet holds just approx. 20-30% of its nominal pull.

2. Plate thickness effect

*Thin metal sheet (e.g. 0.5mm PC case) significantly weakens the holding force.

3. Power loss vs temp

*For N38 material, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.39

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more proposals

Pros as well as cons of rare earth magnets.

Strengths

- They retain full power for nearly ten years – the loss is just ~1% (according to analyses),

- Neodymium magnets prove to be remarkably resistant to loss of magnetic properties caused by external interference,

- In other words, due to the aesthetic surface of nickel, the element looks attractive,

- Magnetic induction on the top side of the magnet remains maximum,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Thanks to versatility in shaping and the ability to modify to unusual requirements,

- Fundamental importance in future technologies – they find application in mass storage devices, brushless drives, diagnostic systems, and industrial machines.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Cons

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only protects the magnet but also improves its resistance to damage

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which secure oxidation as well as corrosion.

- Limited possibility of producing nuts in the magnet and complicated shapes - preferred is casing - magnet mounting.

- Potential hazard resulting from small fragments of magnets pose a threat, if swallowed, which becomes key in the aspect of protecting the youngest. Additionally, tiny parts of these devices are able to be problematic in diagnostics medical when they are in the body.

- Due to neodymium price, their price is higher than average,

Lifting parameters

Magnetic strength at its maximum – what contributes to it?

- on a base made of mild steel, perfectly concentrating the magnetic field

- possessing a thickness of minimum 10 mm to ensure full flux closure

- with an ideally smooth contact surface

- with total lack of distance (no coatings)

- under vertical force vector (90-degree angle)

- in stable room temperature

Magnet lifting force in use – key factors

- Distance – existence of foreign body (paint, dirt, air) acts as an insulator, which lowers power rapidly (even by 50% at 0.5 mm).

- Loading method – declared lifting capacity refers to pulling vertically. When slipping, the magnet holds significantly lower power (typically approx. 20-30% of nominal force).

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field penetrates through instead of generating force.

- Chemical composition of the base – mild steel gives the best results. Alloy admixtures decrease magnetic properties and lifting capacity.

- Smoothness – full contact is obtained only on polished steel. Any scratches and bumps create air cushions, weakening the magnet.

- Heat – NdFeB sinters have a sensitivity to temperature. At higher temperatures they lose power, and in frost they can be stronger (up to a certain limit).

Lifting capacity was assessed with the use of a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular detachment force, in contrast under parallel forces the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet and the plate decreases the holding force.

Safety rules for work with NdFeB magnets

Heat warning

Standard neodymium magnets (N-type) undergo demagnetization when the temperature goes above 80°C. The loss of strength is permanent.

Respect the power

Use magnets consciously. Their immense force can shock even professionals. Stay alert and respect their power.

Keep away from computers

Do not bring magnets near a purse, laptop, or TV. The magnetic field can irreversibly ruin these devices and wipe information from cards.

Protective goggles

Watch out for shards. Magnets can explode upon uncontrolled impact, launching shards into the air. We recommend safety glasses.

Swallowing risk

Strictly keep magnets out of reach of children. Ingestion danger is high, and the effects of magnets connecting inside the body are very dangerous.

Warning for heart patients

Individuals with a heart stimulator should maintain an large gap from magnets. The magnetic field can disrupt the operation of the life-saving device.

Physical harm

Mind your fingers. Two large magnets will snap together immediately with a force of massive weight, destroying anything in their path. Exercise extreme caution!

Fire warning

Powder created during grinding of magnets is self-igniting. Do not drill into magnets unless you are an expert.

Warning for allergy sufferers

Certain individuals suffer from a hypersensitivity to Ni, which is the standard coating for neodymium magnets. Extended handling might lead to dermatitis. We suggest wear safety gloves.

Keep away from electronics

Note: rare earth magnets generate a field that interferes with precision electronics. Keep a safe distance from your mobile, device, and GPS.

![SM 18x175 [2xM5] / N42 - magnetic separator SM 18x175 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x175-2xm5-rov.jpg)