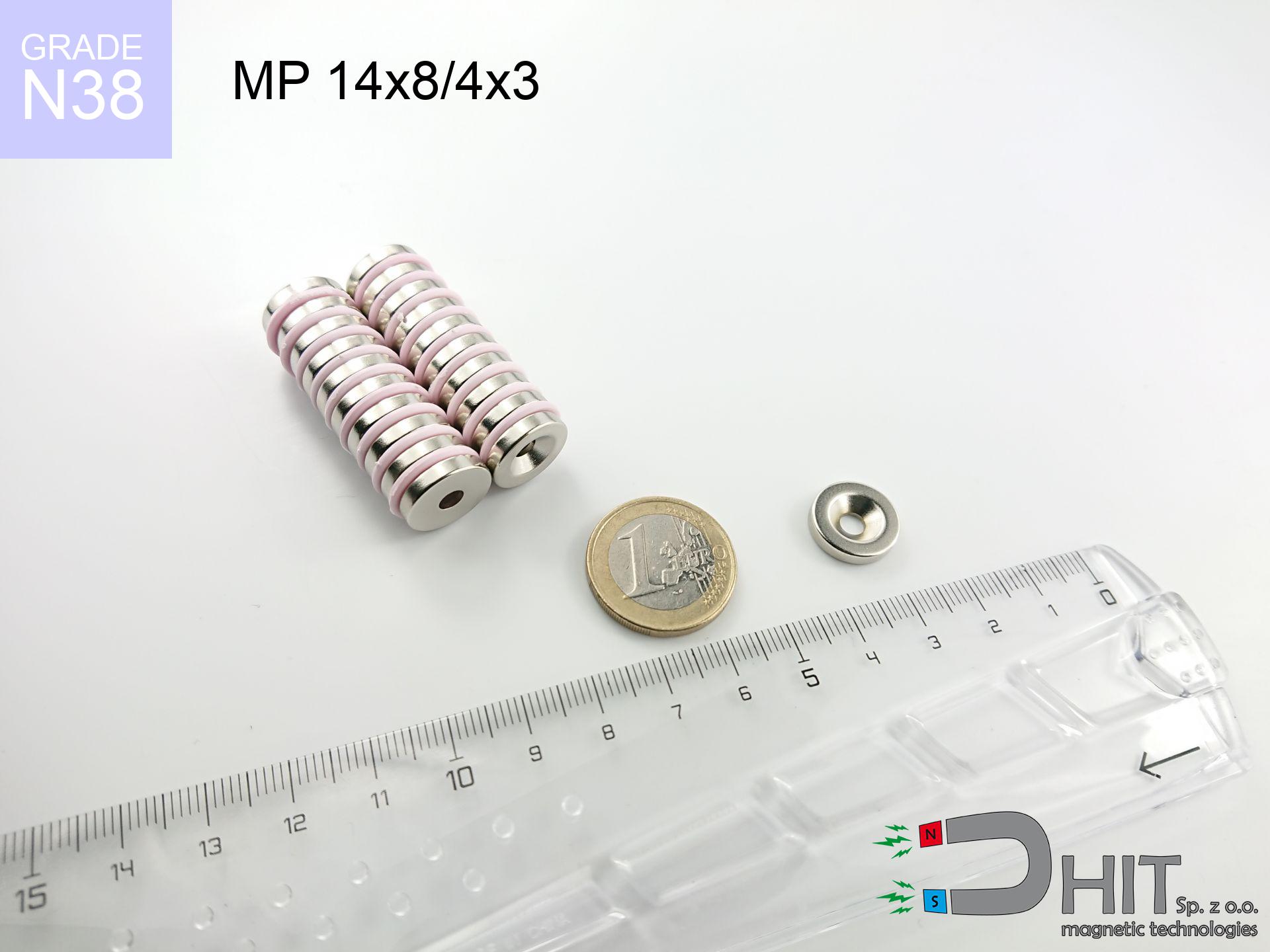

MP 14x8/4x3 / N38 - ring magnet

ring magnet

Catalog no 030181

GTIN/EAN: 5906301811985

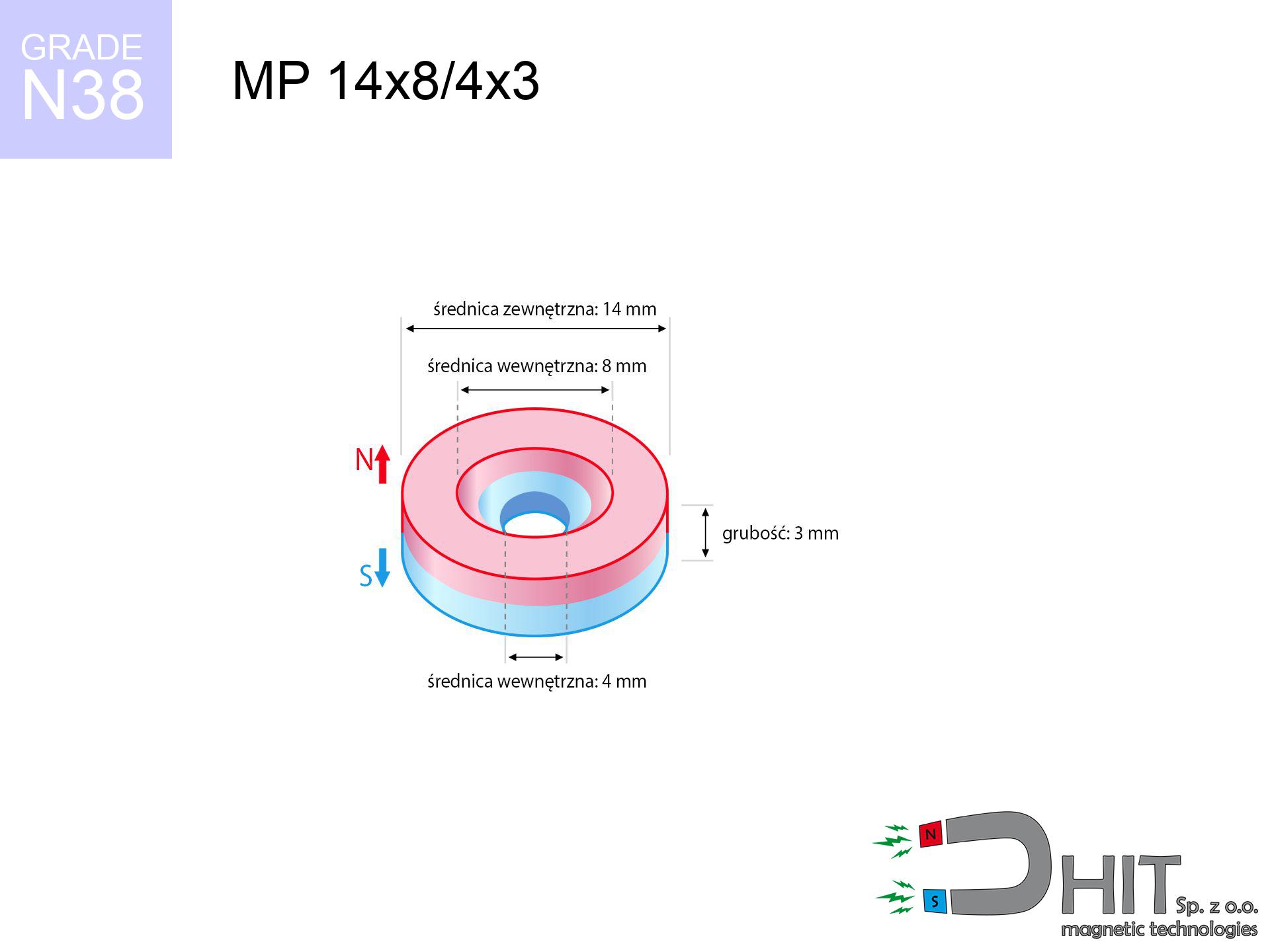

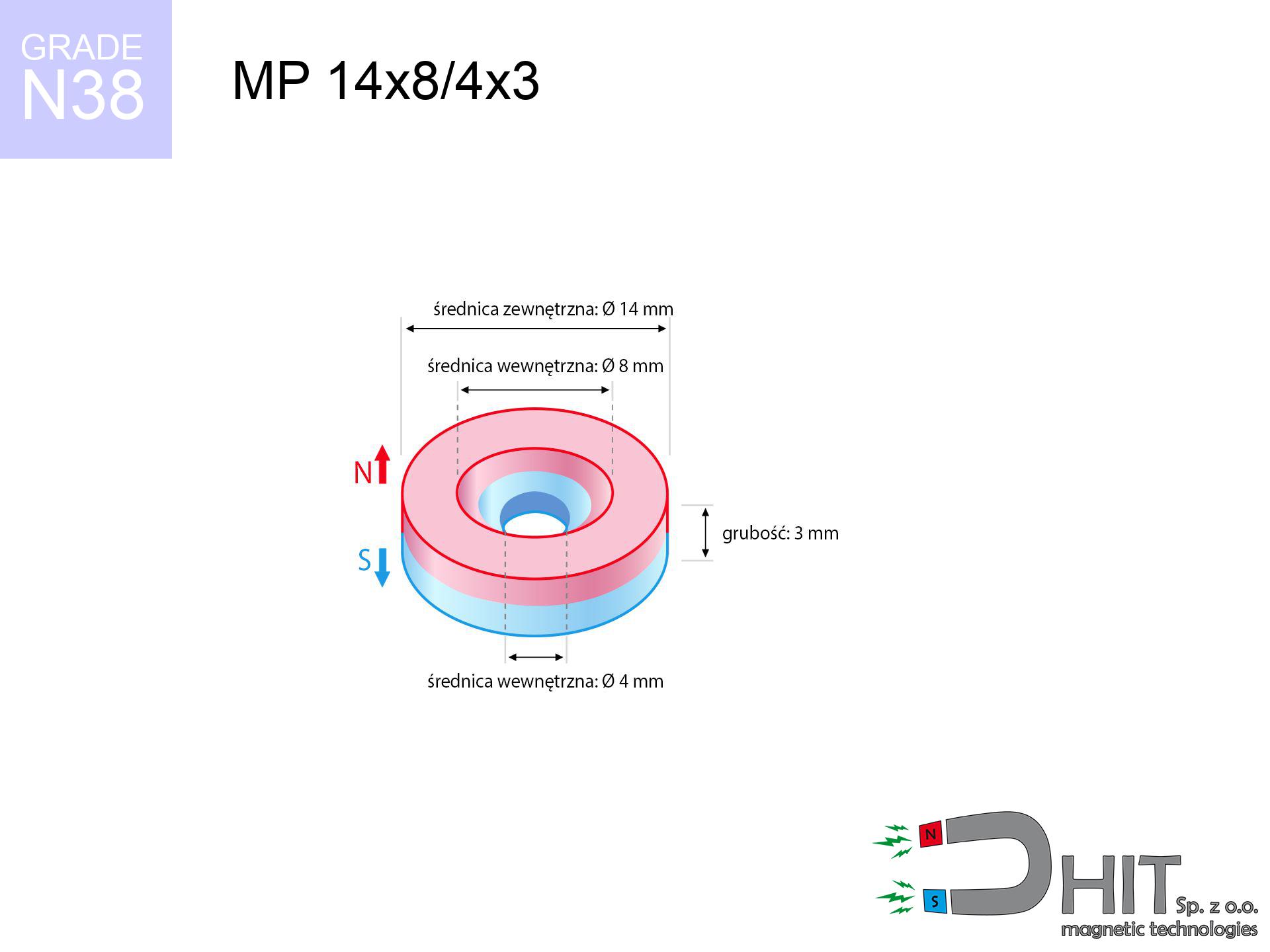

Diameter

14 mm [±0,1 mm]

internal diameter Ø

8/4 mm [±0,1 mm]

Height

3 mm [±0,1 mm]

Weight

3.18 g

Magnetization Direction

↑ axial

Load capacity

2.53 kg / 24.85 N

Magnetic Induction

244.11 mT / 2441 Gs

Coating

[NiCuNi] Nickel

2.47 ZŁ with VAT / pcs + price for transport

2.01 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

alternatively let us know using

inquiry form

our website.

Strength as well as appearance of a neodymium magnet can be reviewed with our

magnetic calculator.

Order by 14:00 and we’ll ship today!

Detailed specification - MP 14x8/4x3 / N38 - ring magnet

Specification / characteristics - MP 14x8/4x3 / N38 - ring magnet

| properties | values |

|---|---|

| Cat. no. | 030181 |

| GTIN/EAN | 5906301811985 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 14 mm [±0,1 mm] |

| internal diameter Ø | 8/4 mm [±0,1 mm] |

| Height | 3 mm [±0,1 mm] |

| Weight | 3.18 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 2.53 kg / 24.85 N |

| Magnetic Induction ~ ? | 244.11 mT / 2441 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the magnet - data

The following information are the outcome of a mathematical analysis. Values were calculated on algorithms for the class Nd2Fe14B. Real-world parameters might slightly deviate from the simulation results. Treat these calculations as a preliminary roadmap when designing systems.

Table 1: Static pull force (force vs distance) - power drop

MP 14x8/4x3 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2121 Gs

212.1 mT

|

2.53 kg / 5.58 pounds

2530.0 g / 24.8 N

|

medium risk |

| 1 mm |

1927 Gs

192.7 mT

|

2.09 kg / 4.61 pounds

2090.1 g / 20.5 N

|

medium risk |

| 2 mm |

1676 Gs

167.6 mT

|

1.58 kg / 3.48 pounds

1579.6 g / 15.5 N

|

safe |

| 3 mm |

1410 Gs

141.0 mT

|

1.12 kg / 2.46 pounds

1117.9 g / 11.0 N

|

safe |

| 5 mm |

943 Gs

94.3 mT

|

0.50 kg / 1.10 pounds

500.1 g / 4.9 N

|

safe |

| 10 mm |

335 Gs

33.5 mT

|

0.06 kg / 0.14 pounds

63.3 g / 0.6 N

|

safe |

| 15 mm |

140 Gs

14.0 mT

|

0.01 kg / 0.02 pounds

11.1 g / 0.1 N

|

safe |

| 20 mm |

69 Gs

6.9 mT

|

0.00 kg / 0.01 pounds

2.7 g / 0.0 N

|

safe |

| 30 mm |

24 Gs

2.4 mT

|

0.00 kg / 0.00 pounds

0.3 g / 0.0 N

|

safe |

| 50 mm |

6 Gs

0.6 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Shear load (vertical surface)

MP 14x8/4x3 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.51 kg / 1.12 pounds

506.0 g / 5.0 N

|

| 1 mm | Stal (~0.2) |

0.42 kg / 0.92 pounds

418.0 g / 4.1 N

|

| 2 mm | Stal (~0.2) |

0.32 kg / 0.70 pounds

316.0 g / 3.1 N

|

| 3 mm | Stal (~0.2) |

0.22 kg / 0.49 pounds

224.0 g / 2.2 N

|

| 5 mm | Stal (~0.2) |

0.10 kg / 0.22 pounds

100.0 g / 1.0 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

12.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MP 14x8/4x3 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.76 kg / 1.67 pounds

759.0 g / 7.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.51 kg / 1.12 pounds

506.0 g / 5.0 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.25 kg / 0.56 pounds

253.0 g / 2.5 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.27 kg / 2.79 pounds

1265.0 g / 12.4 N

|

Table 4: Material efficiency (substrate influence) - power losses

MP 14x8/4x3 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.25 kg / 0.56 pounds

253.0 g / 2.5 N

|

| 1 mm |

|

0.63 kg / 1.39 pounds

632.5 g / 6.2 N

|

| 2 mm |

|

1.27 kg / 2.79 pounds

1265.0 g / 12.4 N

|

| 3 mm |

|

1.90 kg / 4.18 pounds

1897.5 g / 18.6 N

|

| 5 mm |

|

2.53 kg / 5.58 pounds

2530.0 g / 24.8 N

|

| 10 mm |

|

2.53 kg / 5.58 pounds

2530.0 g / 24.8 N

|

| 11 mm |

|

2.53 kg / 5.58 pounds

2530.0 g / 24.8 N

|

| 12 mm |

|

2.53 kg / 5.58 pounds

2530.0 g / 24.8 N

|

Table 5: Thermal resistance (stability) - thermal limit

MP 14x8/4x3 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

2.53 kg / 5.58 pounds

2530.0 g / 24.8 N

|

OK |

| 40 °C | -2.2% |

2.47 kg / 5.45 pounds

2474.3 g / 24.3 N

|

OK |

| 60 °C | -4.4% |

2.42 kg / 5.33 pounds

2418.7 g / 23.7 N

|

|

| 80 °C | -6.6% |

2.36 kg / 5.21 pounds

2363.0 g / 23.2 N

|

|

| 100 °C | -28.8% |

1.80 kg / 3.97 pounds

1801.4 g / 17.7 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MP 14x8/4x3 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.33 kg / 7.34 pounds

3 647 Gs

|

0.50 kg / 1.10 pounds

500 g / 4.9 N

|

N/A |

| 1 mm |

3.07 kg / 6.76 pounds

4 070 Gs

|

0.46 kg / 1.01 pounds

460 g / 4.5 N

|

2.76 kg / 6.09 pounds

~0 Gs

|

| 2 mm |

2.75 kg / 6.07 pounds

3 855 Gs

|

0.41 kg / 0.91 pounds

413 g / 4.0 N

|

2.48 kg / 5.46 pounds

~0 Gs

|

| 3 mm |

2.42 kg / 5.33 pounds

3 612 Gs

|

0.36 kg / 0.80 pounds

362 g / 3.6 N

|

2.17 kg / 4.79 pounds

~0 Gs

|

| 5 mm |

1.76 kg / 3.88 pounds

3 084 Gs

|

0.26 kg / 0.58 pounds

264 g / 2.6 N

|

1.59 kg / 3.50 pounds

~0 Gs

|

| 10 mm |

0.66 kg / 1.45 pounds

1 886 Gs

|

0.10 kg / 0.22 pounds

99 g / 1.0 N

|

0.59 kg / 1.31 pounds

~0 Gs

|

| 20 mm |

0.08 kg / 0.18 pounds

671 Gs

|

0.01 kg / 0.03 pounds

13 g / 0.1 N

|

0.08 kg / 0.17 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

77 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

47 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

31 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

21 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

15 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

11 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (implants) - precautionary measures

MP 14x8/4x3 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (kinetic energy) - warning

MP 14x8/4x3 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

28.89 km/h

(8.02 m/s)

|

0.10 J | |

| 30 mm |

49.27 km/h

(13.69 m/s)

|

0.30 J | |

| 50 mm |

63.61 km/h

(17.67 m/s)

|

0.50 J | |

| 100 mm |

89.96 km/h

(24.99 m/s)

|

0.99 J |

Table 9: Anti-corrosion coating durability

MP 14x8/4x3 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MP 14x8/4x3 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 101 Mx | 31.0 µWb |

| Pc Coefficient | 0.28 | Low (Flat) |

Table 11: Submerged application

MP 14x8/4x3 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 2.53 kg | Standard |

| Water (riverbed) |

2.90 kg

(+0.37 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical wall, the magnet retains merely ~20% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. 0.5mm PC case) severely weakens the holding force.

3. Thermal stability

*For standard magnets, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.28

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also products

Advantages as well as disadvantages of rare earth magnets.

Advantages

- They have stable power, and over more than 10 years their performance decreases symbolically – ~1% (in testing),

- They possess excellent resistance to magnetism drop as a result of external magnetic sources,

- In other words, due to the reflective finish of nickel, the element looks attractive,

- The surface of neodymium magnets generates a concentrated magnetic field – this is a key feature,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, allowing for action at temperatures approaching 230°C and above...

- Possibility of precise forming as well as adjusting to specific needs,

- Significant place in innovative solutions – they serve a role in mass storage devices, drive modules, diagnostic systems, also complex engineering applications.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which enables their usage in small systems

Limitations

- To avoid cracks under impact, we suggest using special steel holders. Such a solution secures the magnet and simultaneously increases its durability.

- Neodymium magnets lose strength when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as magnets in rubber or plastics, which prevent oxidation and corrosion.

- Due to limitations in creating threads and complex forms in magnets, we recommend using a housing - magnetic mount.

- Health risk resulting from small fragments of magnets pose a threat, if swallowed, which becomes key in the context of child health protection. Additionally, tiny parts of these magnets can disrupt the diagnostic process medical after entering the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which hinders application in large quantities

Holding force characteristics

Highest magnetic holding force – what contributes to it?

- using a sheet made of low-carbon steel, acting as a magnetic yoke

- whose thickness reaches at least 10 mm

- characterized by even structure

- with direct contact (no coatings)

- under perpendicular force vector (90-degree angle)

- at ambient temperature approx. 20 degrees Celsius

Practical lifting capacity: influencing factors

- Gap (betwixt the magnet and the plate), because even a very small distance (e.g. 0.5 mm) can cause a drastic drop in lifting capacity by up to 50% (this also applies to varnish, rust or dirt).

- Angle of force application – highest force is reached only during perpendicular pulling. The shear force of the magnet along the surface is usually many times smaller (approx. 1/5 of the lifting capacity).

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of converting into lifting capacity.

- Chemical composition of the base – low-carbon steel gives the best results. Alloy steels reduce magnetic properties and lifting capacity.

- Smoothness – full contact is obtained only on smooth steel. Any scratches and bumps create air cushions, weakening the magnet.

- Temperature – heating the magnet causes a temporary drop of induction. Check the maximum operating temperature for a given model.

Lifting capacity testing was conducted on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, in contrast under attempts to slide the magnet the lifting capacity is smaller. In addition, even a minimal clearance between the magnet and the plate reduces the lifting capacity.

H&S for magnets

Bone fractures

Watch your fingers. Two large magnets will join instantly with a force of several hundred kilograms, crushing everything in their path. Be careful!

Skin irritation risks

Some people have a hypersensitivity to nickel, which is the typical protective layer for neodymium magnets. Frequent touching might lead to a rash. We recommend wear safety gloves.

This is not a toy

Strictly store magnets out of reach of children. Choking hazard is significant, and the effects of magnets clamping inside the body are fatal.

Compass and GPS

Remember: rare earth magnets generate a field that confuses sensitive sensors. Maintain a safe distance from your phone, tablet, and navigation systems.

Operating temperature

Regular neodymium magnets (N-type) lose power when the temperature exceeds 80°C. The loss of strength is permanent.

Data carriers

Very strong magnetic fields can corrupt files on credit cards, hard drives, and other magnetic media. Keep a distance of at least 10 cm.

Conscious usage

Before starting, read the rules. Uncontrolled attraction can break the magnet or injure your hand. Be predictive.

Beware of splinters

Neodymium magnets are sintered ceramics, which means they are fragile like glass. Impact of two magnets leads to them cracking into shards.

Implant safety

Patients with a pacemaker should keep an large gap from magnets. The magnetic field can disrupt the operation of the implant.

Fire risk

Dust generated during machining of magnets is flammable. Avoid drilling into magnets without proper cooling and knowledge.

![SM 25x325 [2xM8] / N52 - magnetic separator SM 25x325 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x325-2xm8-bit.jpg)