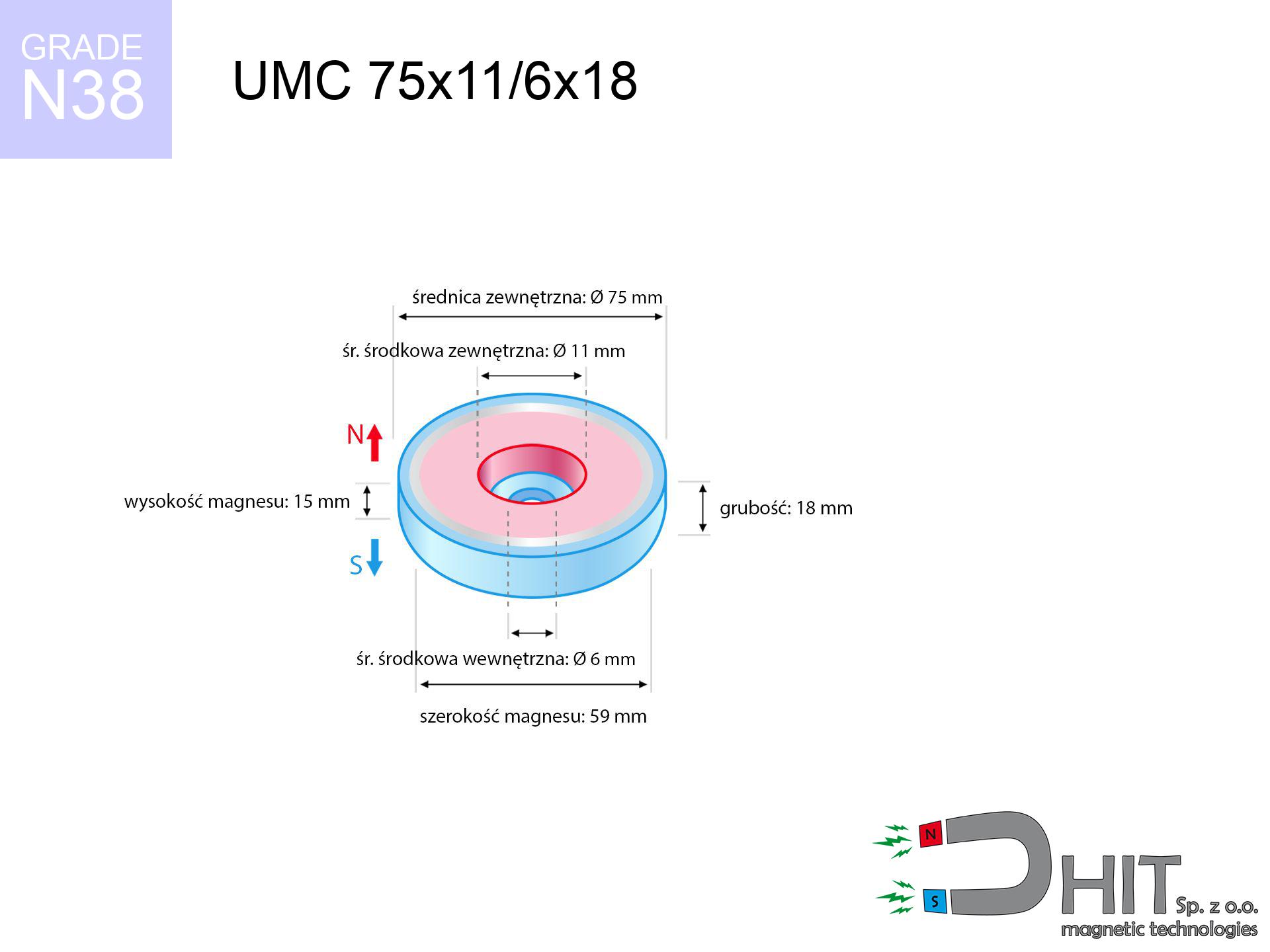

UMC 75x11/6x18 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320414

GTIN: 5906301814702

Diameter [±0,1 mm]

75 mm

internal diameter Ø [±0,1 mm]

11/6 mm

Height [±0,1 mm]

18 mm

Weight

465 g

Load capacity

155 kg / 1520.03 N

Coating

[NiCuNi] nickel

169.86 ZŁ with VAT / pcs + price for transport

138.10 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Want to talk magnets?

Contact us by phone

+48 888 99 98 98

otherwise let us know using

contact form

through our site.

Parameters along with shape of magnetic components can be checked using our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

UMC 75x11/6x18 / N38 - cylindrical magnetic holder

Magnetic properties of material N38

Physical properties of NdFeB

Shopping tips

Advantages and disadvantages of neodymium magnets NdFeB.

In addition to their tremendous pulling force, neodymium magnets offer the following advantages:

- They have stable power, and over around 10 years their attraction force decreases symbolically – ~1% (in testing),

- Their ability to resist magnetic interference from external fields is among the best,

- By applying a reflective layer of nickel, the element gains a modern look,

- Magnetic induction on the surface of these magnets is very strong,

- They are suitable for high-temperature applications, operating effectively at 230°C+ due to advanced heat resistance and form-specific properties,

- The ability for accurate shaping and adjustment to custom needs – neodymium magnets can be manufactured in many forms and dimensions, which amplifies their functionality across industries,

- Wide application in advanced technical fields – they find application in hard drives, rotating machines, clinical machines along with high-tech tools,

- Relatively small size with high magnetic force – neodymium magnets offer strong power in tiny dimensions, which makes them ideal in small systems

Disadvantages of magnetic elements:

- They are fragile when subjected to a strong impact. If the magnets are exposed to shocks, it is suggested to place them in a steel housing. The steel housing, in the form of a holder, protects the magnet from breakage , and at the same time strengthens its overall strength,

- High temperatures may significantly reduce the holding force of neodymium magnets. Typically, above 80°C, they experience permanent deterioration in performance (depending on shape). To prevent this, we offer heat-resistant magnets marked [AH], capable of working up to 230°C, which makes them perfect for high-temperature use,

- Due to corrosion risk in humid conditions, it is recommended to use sealed magnets made of rubber for outdoor use,

- The use of a protective casing or external holder is recommended, since machining threads in neodymium magnets is risky,

- Safety concern related to magnet particles may arise, in case of ingestion, which is significant in the protection of children. Moreover, miniature parts from these assemblies may interfere with diagnostics after being swallowed,

- Due to the price of neodymium, their cost is considerably higher,

Maximum lifting force for a neodymium magnet – what it depends on?

The given pulling force of the magnet corresponds to the maximum force, calculated in ideal conditions, specifically:

- with the use of low-carbon steel plate serving as a magnetic yoke

- of a thickness of at least 10 mm

- with a smooth surface

- in conditions of no clearance

- with vertical force applied

- at room temperature

Key elements affecting lifting force

Practical lifting force is dependent on factors, by priority:

- Air gap between the magnet and the plate, because even a very small distance (e.g. 0.5 mm) can cause a drop in lifting force of up to 50%.

- Direction of applied force, because the maximum lifting capacity is achieved under perpendicular application. The force required to slide the magnet along the plate is usually several times lower.

- Thickness of the plate, as a plate that is too thin causes part of the magnetic flux not to be used and to remain wasted in the air.

- Material of the plate, because higher carbon content lowers holding force, while higher iron content increases it. The best choice is steel with high magnetic permeability and high saturation induction.

- Surface of the plate, because the more smooth and polished it is, the better the contact and consequently the greater the magnetic saturation.

- Operating temperature, since all permanent magnets have a negative temperature coefficient. This means that at high temperatures they are weaker, while at sub-zero temperatures they become slightly stronger.

* Lifting capacity was assessed using a smooth steel plate of optimal thickness (min. 20 mm), under perpendicular detachment force, whereas under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a small distance {between} the magnet’s surface and the plate decreases the holding force.

Exercise Caution with Neodymium Magnets

Neodymium magnets are the strongest, most remarkable magnets on the planet, and the surprising force between them can shock you at first.

To handle magnets properly, it is best to familiarize yourself with our information beforehand. This will help you avoid significant harm to your body and the magnets themselves.

Neodymium magnets are not recommended for people with pacemakers.

Neodymium magnets generate very strong magnetic fields that can interfere with the operation of a pacemaker. This is because many of these devices are equipped with a function that deactivates the device in a magnetic field.

It is crucial not to allow the magnets to pinch together uncontrollably or place your fingers in their path as they attract to each other.

Neodymium magnets bounce and touch each other mutually within a radius of several to around 10 cm from each other.

Keep neodymium magnets away from TV, wallet, and computer HDD.

Magnetic fields generated by neodymium magnets can damage magnetic storage media such as floppy disks, credit cards, magnetic ID cards, cassette tapes, video tapes, or other similar devices. In addition, they can damage televisions, VCRs, computer monitors, and CRT displays. You should especially avoid placing neodymium magnets near electronic devices.

Neodymium magnets can demagnetize at high temperatures.

Despite the general resilience of magnets, their ability to retain their magnetic strength can be influenced by factors like the type of material used, the magnet's shape, and the intended purpose for which it is employed.

Dust and powder from neodymium magnets are flammable.

Avoid drilling or mechanical processing of neodymium magnets. If the magnet is crushed into fine powder or dust, it becomes highly flammable.

Do not give neodymium magnets to children.

Not all neodymium magnets are toys, so do not let children play with them. Small magnets pose a serious choking hazard or can attract to each other in the intestines. In such cases, the only solution is to undergo surgery to remove the magnets, and otherwise, it can even lead to death.

Avoid contact with neodymium magnets if you have a nickel allergy.

Studies clearly indicate a small percentage of people who suffer from metal allergies such as nickel. An allergic reaction often manifests as skin redness and rash. If you have a nickel allergy, try wearing gloves or avoid direct contact with nickel-plated neodymium magnets.

Magnets made of neodymium are highly delicate, they easily fall apart and can become damaged.

In the event of a collision between two neodymium magnets, it can result in them getting chipped. They are coated with a shiny nickel plating similar to steel, but they are not as hard. At the moment of connection between the magnets, small sharp metal pieces can be propelled in various directions at high speed. Eye protection is recommended.

Avoid bringing neodymium magnets close to a phone or GPS.

Neodymium magnets produce intense magnetic fields that interfere with magnetometers and compasses used in navigation, as well as internal compasses of smartphones and GPS devices.

Safety rules!

Please read the article - What danger lies in neodymium magnets? You will learn how to handle them properly.

![UMH 16x5x32 [M4] / N38 - magnetic holder with hook UMH 16x5x32 [M4] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-16x5x32-m4-lak.jpg)