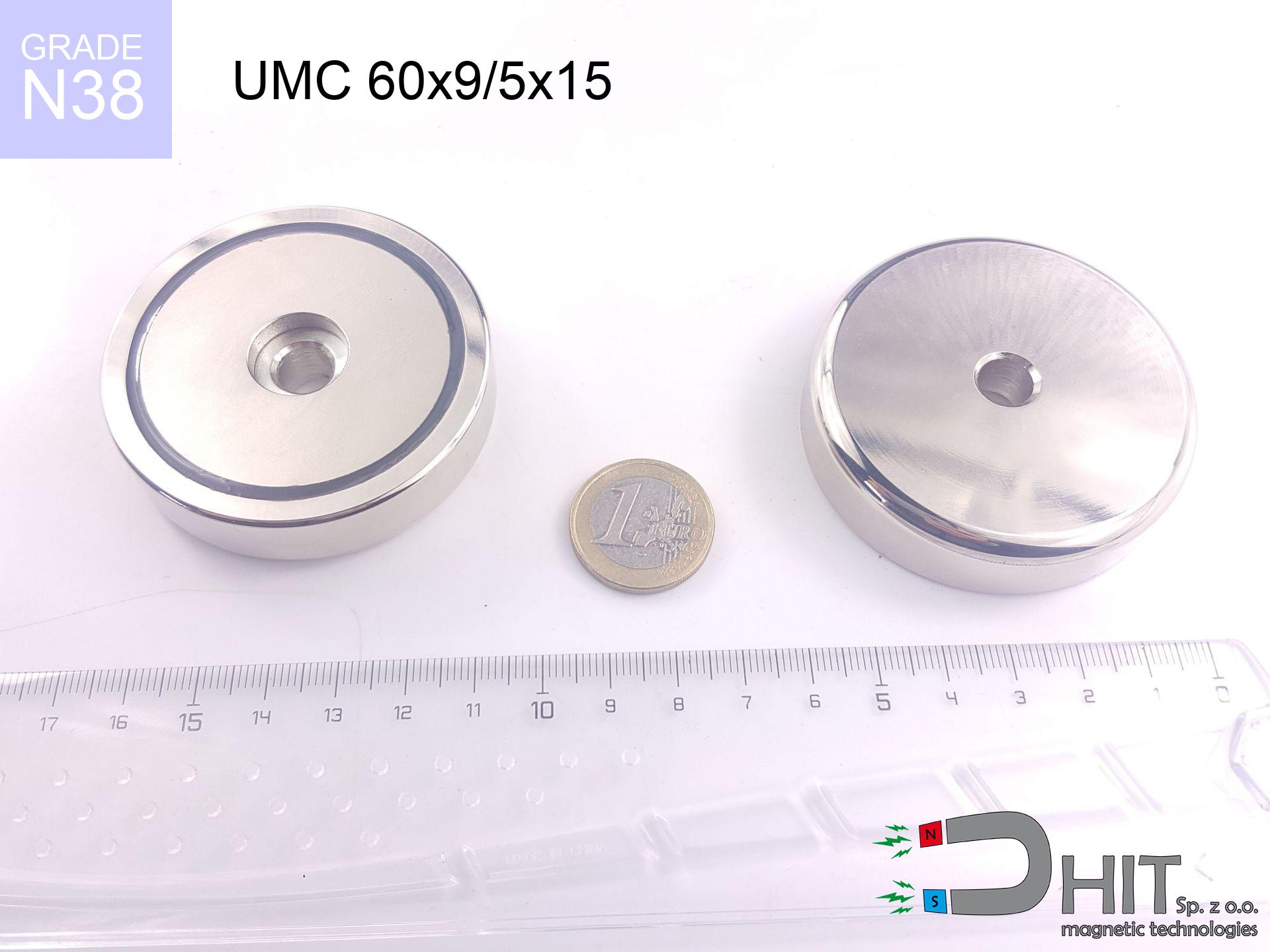

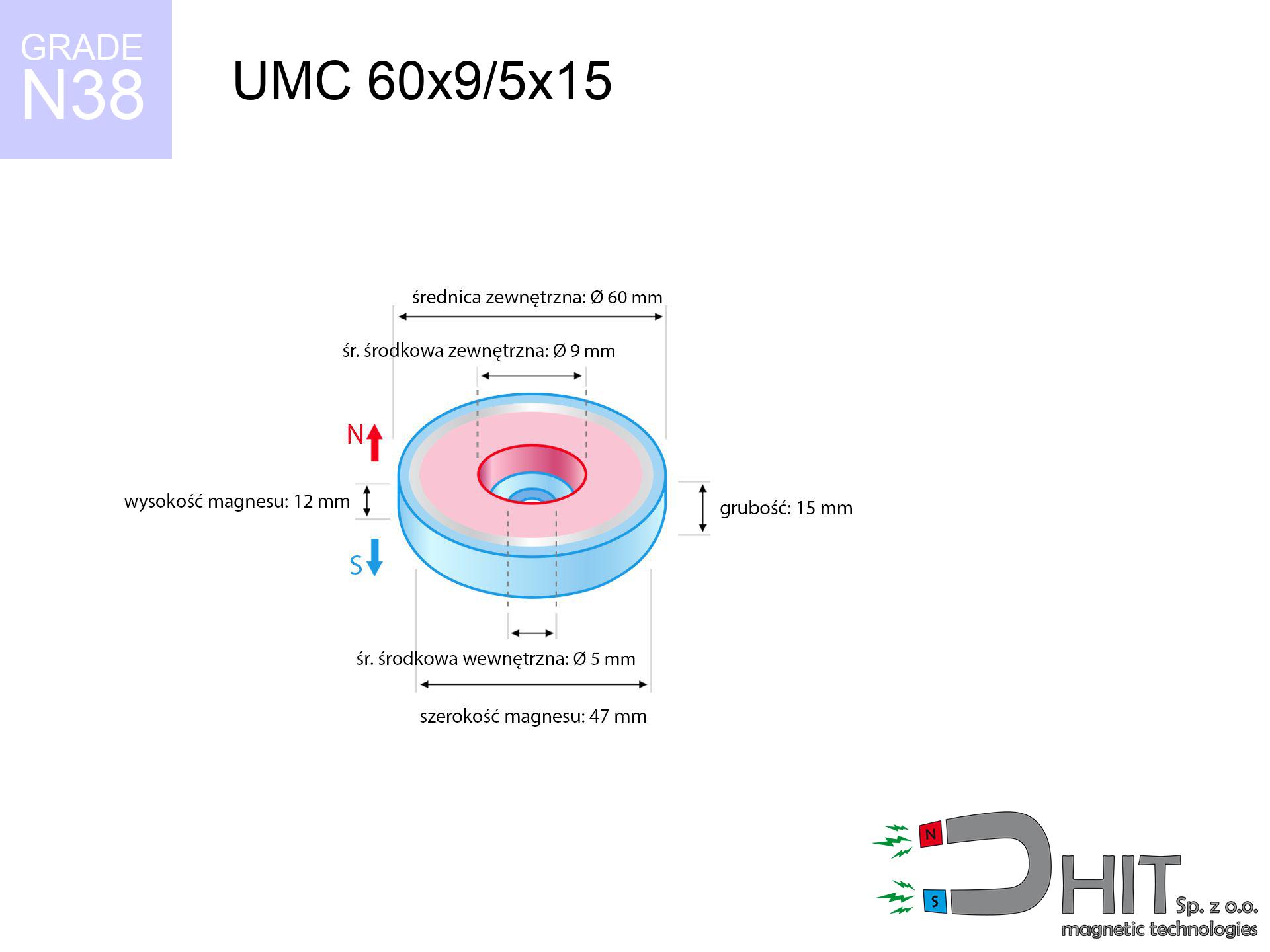

UMC 60x9/5x15 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320413

GTIN: 5906301814696

Diameter

60 mm [±1 mm]

internal diameter Ø

9/5 mm [±1 mm]

Height

15 mm [±1 mm]

Weight

240 g

Load capacity

95 kg / 931.63 N

Coating

[NiCuNi] nickel

64.94 ZŁ with VAT / pcs + price for transport

52.80 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Not sure about your choice?

Contact us by phone

+48 888 99 98 98

if you prefer let us know via

form

our website.

Lifting power as well as appearance of neodymium magnets can be analyzed on our

modular calculator.

Same-day shipping for orders placed before 14:00.

Magnetic properties of material N38

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

Shopping tips

Pros and cons of neodymium magnets.

Besides their stability, neodymium magnets are valued for these benefits:

- They retain magnetic properties for nearly 10 years – the loss is just ~1% (in theory),

- Magnets perfectly defend themselves against demagnetization caused by foreign field sources,

- By covering with a shiny layer of gold, the element acquires an elegant look,

- Neodymium magnets create maximum magnetic induction on a small surface, which allows for strong attraction,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- Considering the potential of precise molding and adaptation to individualized needs, neodymium magnets can be modeled in a wide range of shapes and sizes, which amplifies use scope,

- Universal use in future technologies – they are commonly used in HDD drives, motor assemblies, precision medical tools, and complex engineering applications.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Problematic aspects of neodymium magnets: tips and applications.

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth securing magnets in special housings. Such protection not only protects the magnet but also increases its resistance to damage

- Neodymium magnets lose their power under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- Due to limitations in creating nuts and complex forms in magnets, we recommend using casing - magnetic holder.

- Possible danger to health – tiny shards of magnets pose a threat, if swallowed, which becomes key in the context of child safety. Furthermore, small components of these devices are able to complicate diagnosis medical after entering the body.

- Due to expensive raw materials, their price is higher than average,

Maximum lifting force for a neodymium magnet – what it depends on?

The lifting capacity listed is a measurement result executed under specific, ideal conditions:

- on a base made of mild steel, effectively closing the magnetic field

- possessing a thickness of at least 10 mm to avoid saturation

- with an ideally smooth touching surface

- under conditions of no distance (surface-to-surface)

- under vertical force vector (90-degree angle)

- at conditions approx. 20°C

What influences lifting capacity in practice

Bear in mind that the working load may be lower subject to elements below, in order of importance:

- Space between surfaces – even a fraction of a millimeter of distance (caused e.g. by varnish or unevenness) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Loading method – declared lifting capacity refers to pulling vertically. When applying parallel force, the magnet holds much less (typically approx. 20-30% of maximum force).

- Element thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the attraction force (the magnet "punches through" it).

- Material type – ideal substrate is pure iron steel. Cast iron may generate lower lifting capacity.

- Smoothness – full contact is obtained only on smooth steel. Rough texture create air cushions, weakening the magnet.

- Thermal conditions – NdFeB sinters have a sensitivity to temperature. At higher temperatures they lose power, and at low temperatures they can be stronger (up to a certain limit).

* Holding force was checked on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, in contrast under parallel forces the holding force is lower. Additionally, even a small distance {between} the magnet and the plate decreases the load capacity.

Safe handling of NdFeB magnets

Danger to the youngest

Adult use only. Small elements pose a choking risk, leading to serious injuries. Keep away from children and animals.

Life threat

For implant holders: Powerful magnets disrupt medical devices. Maintain at least 30 cm distance or ask another person to handle the magnets.

Electronic hazard

Avoid bringing magnets near a wallet, computer, or screen. The magnetic field can permanently damage these devices and erase data from cards.

Serious injuries

Risk of injury: The pulling power is so great that it can cause hematomas, pinching, and broken bones. Protective gloves are recommended.

Combustion hazard

Drilling and cutting of neodymium magnets poses a fire risk. Magnetic powder reacts violently with oxygen and is difficult to extinguish.

Precision electronics

GPS units and mobile phones are highly susceptible to magnetism. Close proximity with a powerful NdFeB magnet can ruin the sensors in your phone.

Warning for allergy sufferers

A percentage of the population have a contact allergy to nickel, which is the standard coating for NdFeB magnets. Prolonged contact can result in skin redness. We suggest wear protective gloves.

Beware of splinters

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting shards into the air. We recommend safety glasses.

Demagnetization risk

Standard neodymium magnets (grade N) lose magnetization when the temperature surpasses 80°C. Damage is permanent.

Respect the power

Before use, check safety instructions. Uncontrolled attraction can destroy the magnet or hurt your hand. Be predictive.

Important!

Details about hazards in the article: Magnet Safety Guide.

![SM 25x100 [2xM8] / N42 - magnetic separator SM 25x100 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-feg.jpg)

![UMGZ 20x15x7 [M4] GZ / N38 - magnetic holder external thread UMGZ 20x15x7 [M4] GZ / N38 - magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/um-20x15x7-m4-gz-vaf.jpg)