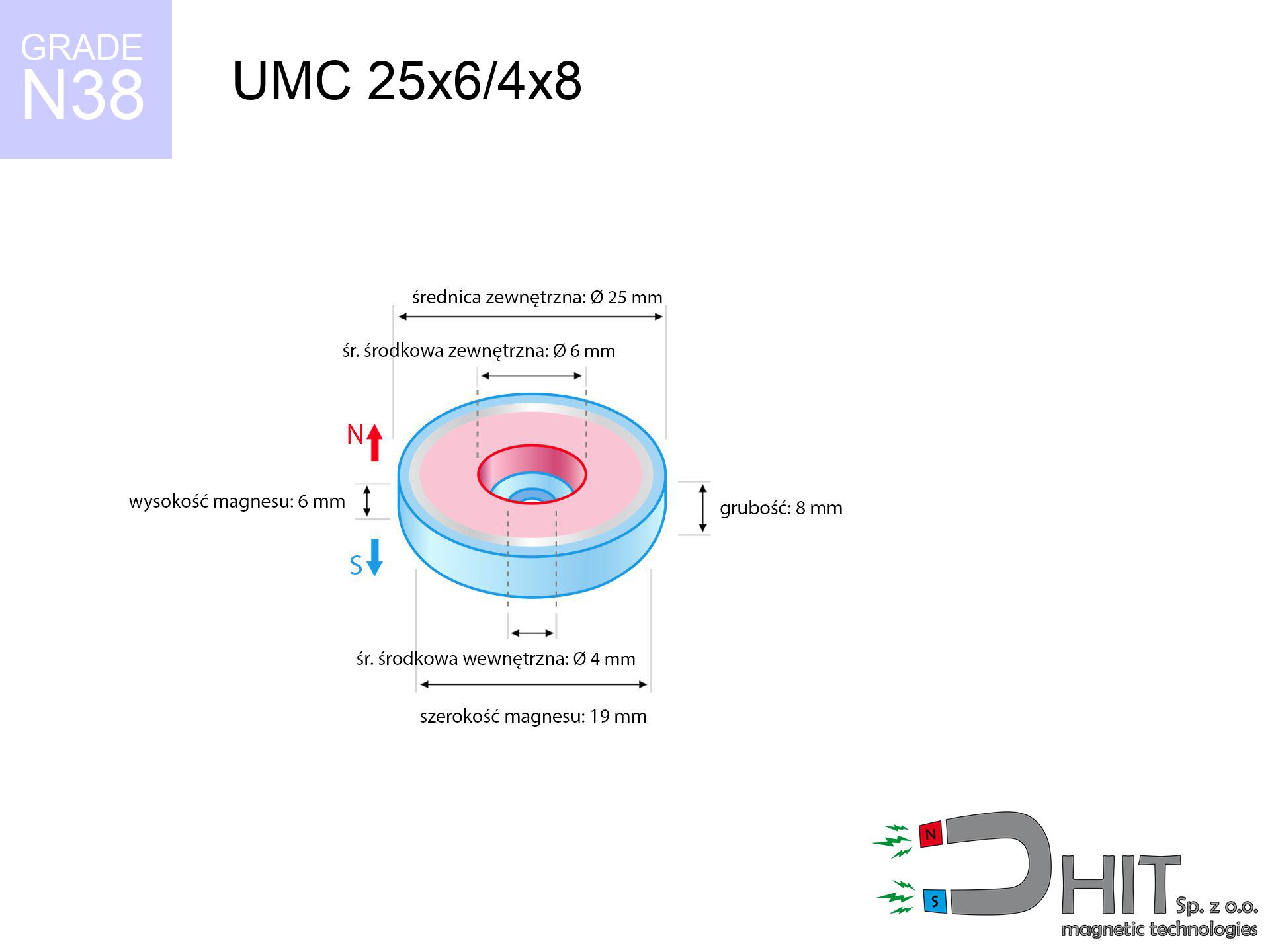

UMC 25x6/4x8 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320408

GTIN/EAN: 5906301814641

Diameter

25 mm [±1 mm]

internal diameter Ø

6/4 mm [±1 mm]

Height

8 mm [±1 mm]

Weight

21 g

Load capacity

14.00 kg / 137.29 N

Coating

[NiCuNi] Nickel

11.70 ZŁ with VAT / pcs + price for transport

9.51 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

otherwise contact us using

request form

the contact form page.

Specifications and form of magnetic components can be reviewed using our

power calculator.

Order by 14:00 and we’ll ship today!

Model data UMC 25x6/4x8 / N38 - cylindrical magnetic holder

Specification / characteristics - UMC 25x6/4x8 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320408 |

| GTIN/EAN | 5906301814641 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 25 mm [±1 mm] |

| internal diameter Ø | 6/4 mm [±1 mm] |

| Height | 8 mm [±1 mm] |

| Weight | 21 g |

| Load capacity ~ ? | 14.00 kg / 137.29 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Pros as well as cons of Nd2Fe14B magnets.

Strengths

- They virtually do not lose power, because even after 10 years the decline in efficiency is only ~1% (based on calculations),

- They do not lose their magnetic properties even under close interference source,

- A magnet with a smooth nickel surface is more attractive,

- Magnets have exceptionally strong magnetic induction on the working surface,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Thanks to flexibility in forming and the ability to modify to unusual requirements,

- Significant place in electronics industry – they serve a role in computer drives, motor assemblies, precision medical tools, as well as technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which makes them useful in compact constructions

Limitations

- At very strong impacts they can crack, therefore we recommend placing them in special holders. A metal housing provides additional protection against damage and increases the magnet's durability.

- When exposed to high temperature, neodymium magnets experience a drop in force. Often, when the temperature exceeds 80°C, their power decreases (depending on the size, as well as shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- When exposed to humidity, magnets usually rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation and corrosion.

- Limited ability of making threads in the magnet and complex shapes - recommended is casing - magnetic holder.

- Health risk to health – tiny shards of magnets pose a threat, if swallowed, which is particularly important in the aspect of protecting the youngest. Furthermore, small components of these products can be problematic in diagnostics medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Pull force analysis

Highest magnetic holding force – what affects it?

- with the use of a sheet made of low-carbon steel, ensuring full magnetic saturation

- with a thickness no less than 10 mm

- characterized by smoothness

- with direct contact (without impurities)

- for force applied at a right angle (in the magnet axis)

- at conditions approx. 20°C

Lifting capacity in real conditions – factors

- Gap between magnet and steel – even a fraction of a millimeter of separation (caused e.g. by veneer or unevenness) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Force direction – remember that the magnet holds strongest perpendicularly. Under sliding down, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Wall thickness – thin material does not allow full use of the magnet. Part of the magnetic field penetrates through instead of generating force.

- Steel type – low-carbon steel gives the best results. Alloy steels reduce magnetic permeability and lifting capacity.

- Surface condition – smooth surfaces guarantee perfect abutment, which increases force. Uneven metal reduce efficiency.

- Temperature influence – high temperature reduces pulling force. Too high temperature can permanently damage the magnet.

Lifting capacity was measured with the use of a smooth steel plate of optimal thickness (min. 20 mm), under vertically applied force, whereas under shearing force the load capacity is reduced by as much as fivefold. In addition, even a slight gap between the magnet and the plate decreases the lifting capacity.

H&S for magnets

Crushing force

Big blocks can smash fingers instantly. Under no circumstances put your hand betwixt two strong magnets.

Metal Allergy

It is widely known that nickel (standard magnet coating) is a potent allergen. If you have an allergy, prevent touching magnets with bare hands or choose versions in plastic housing.

Phone sensors

Be aware: neodymium magnets generate a field that disrupts precision electronics. Maintain a separation from your phone, device, and GPS.

Electronic devices

Intense magnetic fields can destroy records on payment cards, hard drives, and storage devices. Keep a distance of at least 10 cm.

Power loss in heat

Standard neodymium magnets (grade N) lose magnetization when the temperature goes above 80°C. Damage is permanent.

Beware of splinters

Protect your eyes. Magnets can explode upon violent connection, ejecting sharp fragments into the air. We recommend safety glasses.

Swallowing risk

These products are not intended for children. Swallowing several magnets can lead to them pinching intestinal walls, which poses a critical condition and requires immediate surgery.

Machining danger

Mechanical processing of neodymium magnets carries a risk of fire risk. Neodymium dust oxidizes rapidly with oxygen and is difficult to extinguish.

Medical interference

Warning for patients: Powerful magnets disrupt electronics. Maintain minimum 30 cm distance or request help to work with the magnets.

Do not underestimate power

Exercise caution. Neodymium magnets act from a long distance and connect with massive power, often faster than you can move away.

![SM 32x150 [2xM8] / N52 - magnetic separator SM 32x150 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x150-2xm8-xuc.jpg)