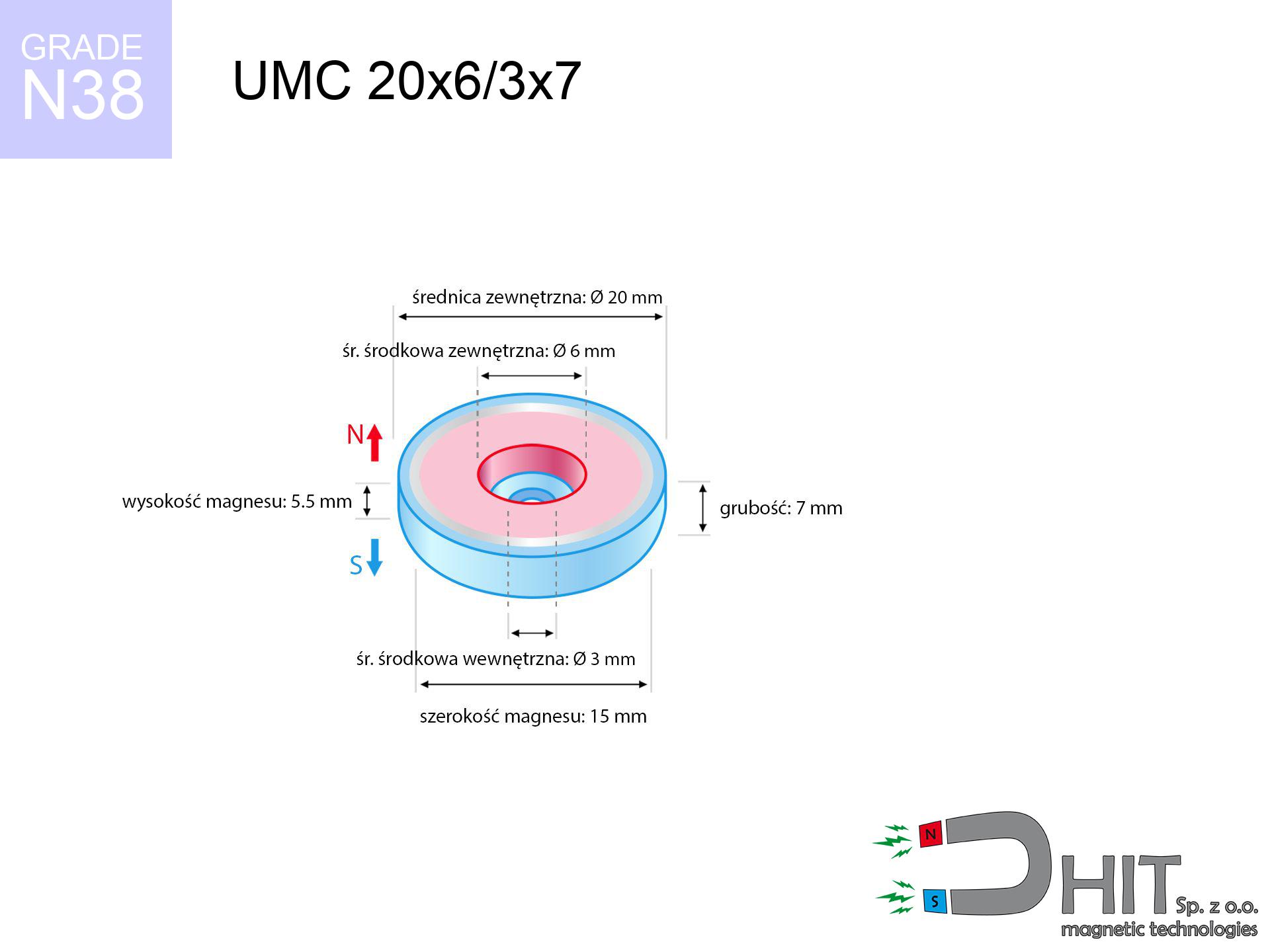

UMC 20x6/3x7 / N38 - cylindrical magnetic holder

cylindrical magnetic holder

Catalog no 320407

GTIN: 5906301814634

Diameter

20 mm [±1 mm]

internal diameter Ø

6/3 mm [±1 mm]

Height

7 mm [±1 mm]

Weight

12 g

Load capacity

6.00 kg / 58.84 N

Coating

[NiCuNi] Nickel

6.99 ZŁ with VAT / pcs + price for transport

5.68 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Want to talk magnets?

Pick up the phone and ask

+48 888 99 98 98

otherwise get in touch using

request form

the contact page.

Specifications and appearance of a neodymium magnet can be checked using our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

UMC 20x6/3x7 / N38 - cylindrical magnetic holder

Specification / characteristics UMC 20x6/3x7 / N38 - cylindrical magnetic holder

| properties | values |

|---|---|

| Cat. no. | 320407 |

| GTIN | 5906301814634 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter | 20 mm [±1 mm] |

| internal diameter Ø | 6/3 mm [±1 mm] |

| Height | 7 mm [±1 mm] |

| Weight | 12 g |

| Load capacity ~ ? | 6.00 kg / 58.84 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [Min. - Max.] ? | 12.2-12.6 | kGs |

| remenance Br [Min. - Max.] ? | 1220-1260 | T |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [Min. - Max.] ? | 36-38 | BH max MGOe |

| energy density [Min. - Max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅Cm |

| Bending strength | 250 | Mpa |

| Compressive strength | 1000~1100 | Mpa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 106 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Jak rozdzielać?

Nie próbuj odrywać magnesów siłą!

Zawsze zsuwaj je na bok krawędzi stołu.

Elektronika

Trzymaj z dala od dysków HDD, kart płatniczych i telefonów.

Rozruszniki Serca

Osoby z rozrusznikiem muszą zachować dystans min. 10 cm.

Nie dla dzieci

Ryzyko połknięcia. Połknięcie dwóch magnesów grozi śmiercią.

Kruchy materiał

Magnes to ceramika! Uderzenie o inny magnes spowoduje odpryski.

Do czego użyć tego magnesu?

Sprawdzone zastosowania dla wymiaru 15x10x2 mm

Elektronika i Czujniki

Idealny jako element wyzwalający dla czujników Halla oraz kontaktronów w systemach alarmowych. Płaski kształt (2mm) pozwala na ukrycie go w wąskich szczelinach obudowy.

Modelarstwo i Druk 3D

Stosowany do tworzenia niewidocznych zamknięć w modelach drukowanych 3D. Można go wprasować w wydruk lub wkleić w kieszeń zaprojektowaną w modelu CAD.

Meble i Fronty

Używany jako "domykacz" lekkich drzwiczek szafkowych, gdzie standardowe magnesy meblowe są za grube. Wymaga wklejenia w płytkie podfrezowanie.

View more offers

Advantages and disadvantages of neodymium magnets.

Besides their stability, neodymium magnets are valued for these benefits:

- They do not lose strength, even after nearly 10 years – the drop in lifting capacity is only ~1% (theoretically),

- They show high resistance to demagnetization induced by presence of other magnetic fields,

- By using a smooth coating of gold, the element presents an elegant look,

- Neodymium magnets generate maximum magnetic induction on a small area, which increases force concentration,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, enabling functioning at temperatures reaching 230°C and above...

- Thanks to versatility in shaping and the capacity to customize to individual projects,

- Key role in innovative solutions – they are used in mass storage devices, electromotive mechanisms, diagnostic systems, and multitasking production systems.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Disadvantages of neodymium magnets:

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only protects the magnet but also increases its resistance to damage

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture

- We suggest casing - magnetic mount, due to difficulties in creating threads inside the magnet and complex forms.

- Possible danger resulting from small fragments of magnets can be dangerous, in case of ingestion, which gains importance in the context of child health protection. Furthermore, small components of these devices are able to be problematic in diagnostics medical in case of swallowing.

- With large orders the cost of neodymium magnets is a challenge,

Best holding force of the magnet in ideal parameters – what contributes to it?

Holding force of 6.00 kg is a result of laboratory testing performed under the following configuration:

- with the use of a sheet made of low-carbon steel, ensuring maximum field concentration

- whose thickness equals approx. 10 mm

- with a surface free of scratches

- with zero gap (without impurities)

- during detachment in a direction perpendicular to the plane

- at ambient temperature approx. 20 degrees Celsius

Magnet lifting force in use – key factors

In practice, the real power depends on many variables, presented from crucial:

- Distance – the presence of any layer (paint, tape, air) acts as an insulator, which reduces power rapidly (even by 50% at 0.5 mm).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Wall thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field penetrates through instead of generating force.

- Steel grade – ideal substrate is pure iron steel. Stainless steels may generate lower lifting capacity.

- Surface finish – ideal contact is possible only on smooth steel. Rough texture reduce the real contact area, weakening the magnet.

- Thermal factor – high temperature weakens pulling force. Too high temperature can permanently damage the magnet.

* Lifting capacity testing was performed on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, in contrast under shearing force the load capacity is reduced by as much as fivefold. In addition, even a minimal clearance {between} the magnet’s surface and the plate decreases the lifting capacity.

Safety rules for work with NdFeB magnets

Phone sensors

Navigation devices and smartphones are highly sensitive to magnetic fields. Direct contact with a strong magnet can decalibrate the internal compass in your phone.

Permanent damage

Regular neodymium magnets (grade N) undergo demagnetization when the temperature goes above 80°C. The loss of strength is permanent.

Powerful field

Before starting, check safety instructions. Uncontrolled attraction can destroy the magnet or hurt your hand. Be predictive.

Avoid contact if allergic

Some people suffer from a contact allergy to Ni, which is the common plating for NdFeB magnets. Frequent touching may cause an allergic reaction. We suggest wear safety gloves.

Physical harm

Big blocks can crush fingers in a fraction of a second. Under no circumstances put your hand betwixt two strong magnets.

Medical implants

Medical warning: Strong magnets can deactivate heart devices and defibrillators. Do not approach if you have electronic implants.

Keep away from computers

Do not bring magnets near a purse, computer, or screen. The magnetism can irreversibly ruin these devices and erase data from cards.

Magnet fragility

Despite the nickel coating, the material is delicate and not impact-resistant. Do not hit, as the magnet may shatter into sharp, dangerous pieces.

Dust is flammable

Fire warning: Rare earth powder is explosive. Avoid machining magnets without safety gear as this may cause fire.

Adults only

These products are not intended for children. Eating several magnets may result in them pinching intestinal walls, which constitutes a critical condition and requires immediate surgery.

Attention!

Looking for details? Check our post: Are neodymium magnets dangerous?

![MPL 40x10x4x2[7/3.5] / N38 - lamellar magnet MPL 40x10x4x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl40x10x4x27-3.5-suw.jpg)