UMH 48x11x65 [M6] / N38 - magnetic holder with hook

magnetic holder with hook

Catalog no 310430

GTIN/EAN: 5906301814597

Diameter Ø

48 mm [±1 mm]

Height

65 mm [±1 mm]

Height

11 mm [±1 mm]

Weight

145 g

Magnetization Direction

↑ axial

Load capacity

88.00 kg / 862.99 N

Coating

[NiCuNi] Nickel

68.88 ZŁ with VAT / pcs + price for transport

56.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

otherwise contact us by means of

inquiry form

through our site.

Lifting power and shape of a magnet can be analyzed using our

online calculation tool.

Orders placed before 14:00 will be shipped the same business day.

Technical data - UMH 48x11x65 [M6] / N38 - magnetic holder with hook

Specification / characteristics - UMH 48x11x65 [M6] / N38 - magnetic holder with hook

| properties | values |

|---|---|

| Cat. no. | 310430 |

| GTIN/EAN | 5906301814597 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

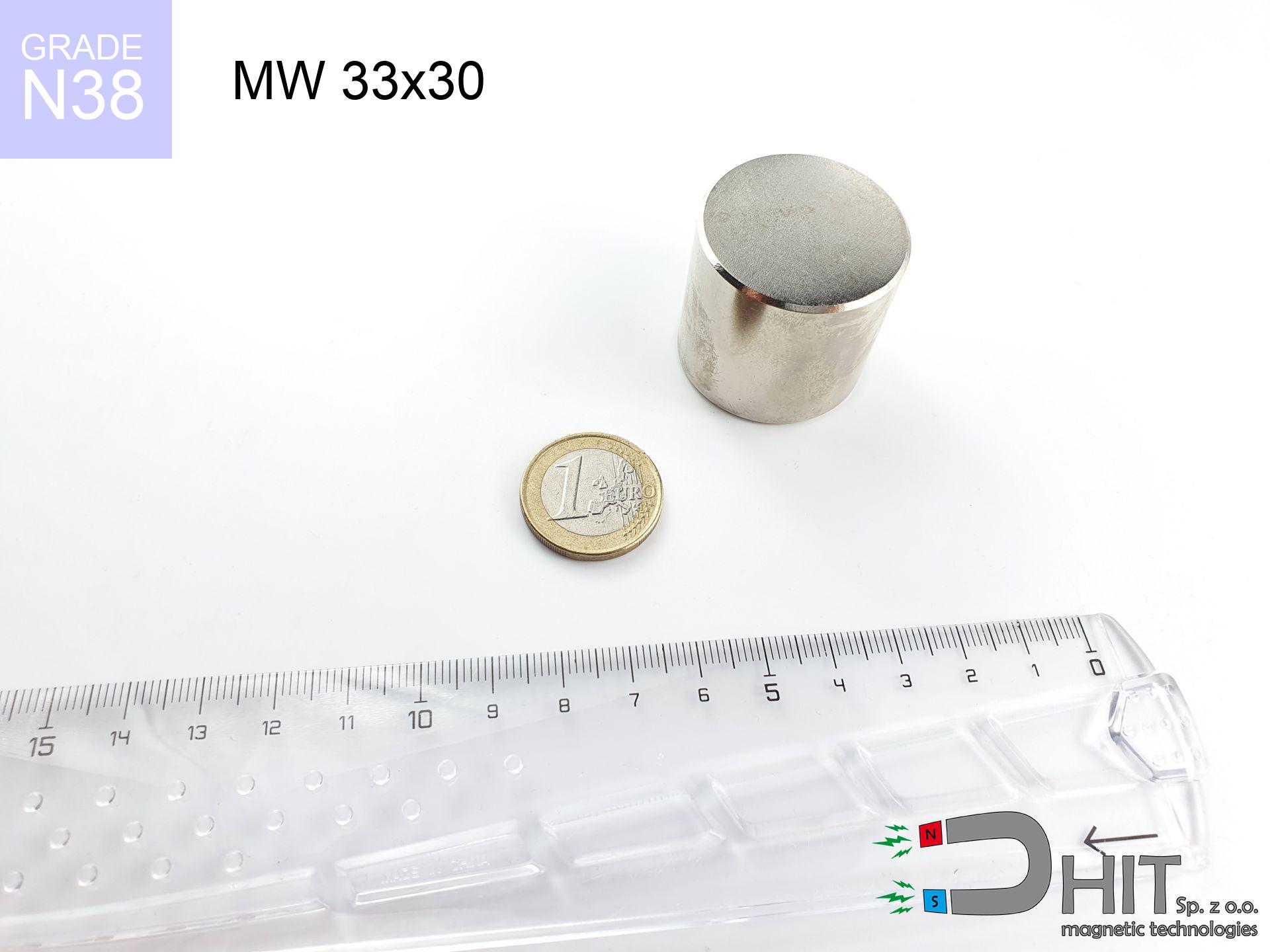

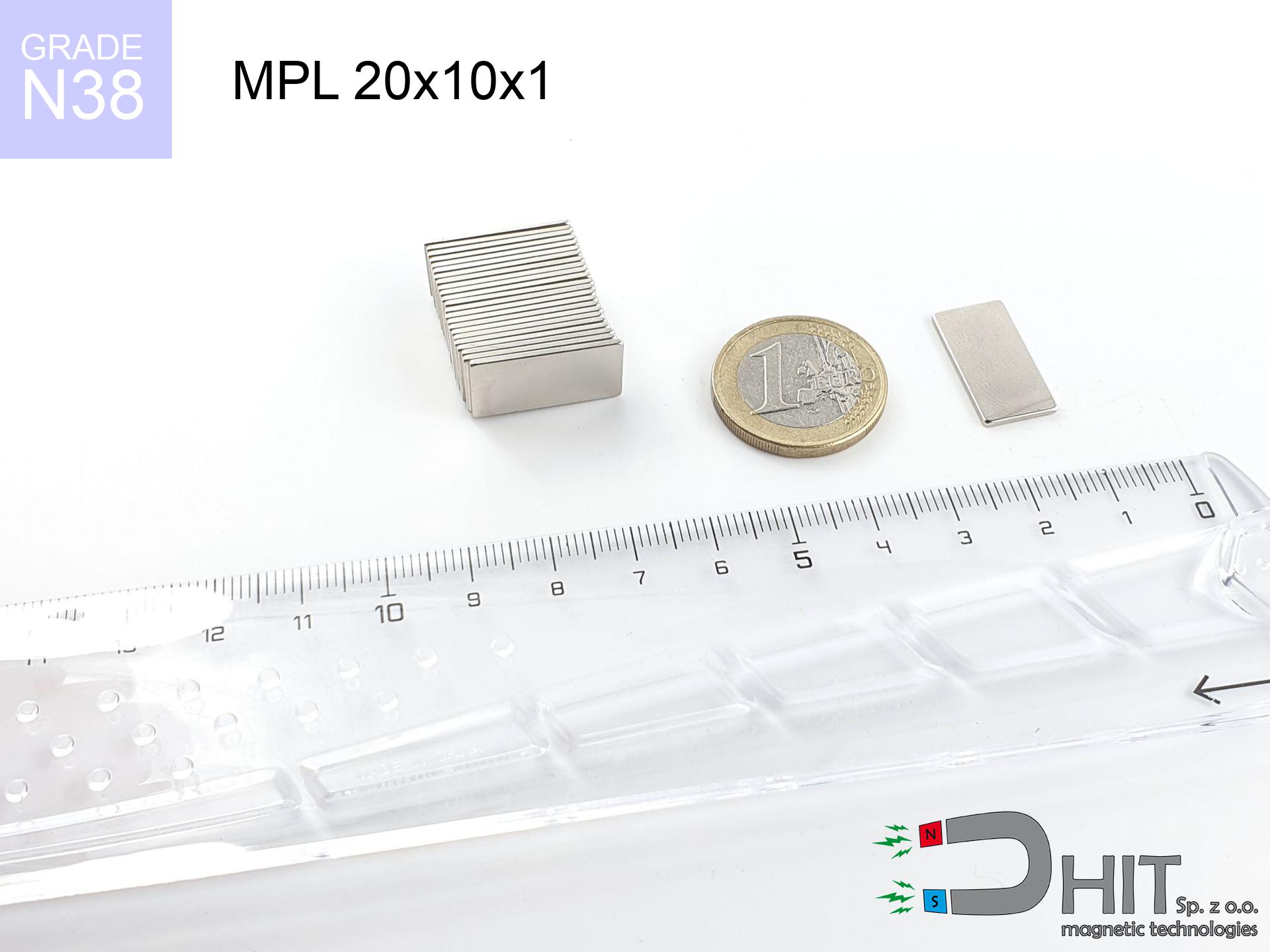

| Diameter Ø | 48 mm [±1 mm] |

| Height | 65 mm [±1 mm] |

| Height | 11 mm [±1 mm] |

| Weight | 145 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 88.00 kg / 862.99 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also deals

Pros as well as cons of rare earth magnets.

Advantages

- They retain full power for nearly 10 years – the drop is just ~1% (according to analyses),

- Magnets perfectly defend themselves against loss of magnetization caused by external fields,

- A magnet with a smooth nickel surface has better aesthetics,

- Magnets possess impressive magnetic induction on the active area,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to versatility in forming and the capacity to modify to unusual requirements,

- Versatile presence in future technologies – they find application in mass storage devices, motor assemblies, precision medical tools, as well as technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in compact dimensions, which makes them useful in miniature devices

Cons

- They are prone to damage upon too strong impacts. To avoid cracks, it is worth securing magnets in a protective case. Such protection not only protects the magnet but also improves its resistance to damage

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation as well as corrosion.

- Limited ability of producing threads in the magnet and complicated forms - recommended is a housing - mounting mechanism.

- Health risk related to microscopic parts of magnets are risky, if swallowed, which is particularly important in the context of child health protection. Furthermore, small elements of these devices can be problematic in diagnostics medical when they are in the body.

- High unit price – neodymium magnets are more expensive than other types of magnets (e.g. ferrite), which can limit application in large quantities

Lifting parameters

Detachment force of the magnet in optimal conditions – what affects it?

- on a base made of structural steel, optimally conducting the magnetic flux

- with a cross-section minimum 10 mm

- with an polished touching surface

- without the slightest insulating layer between the magnet and steel

- during pulling in a direction perpendicular to the mounting surface

- at conditions approx. 20°C

Magnet lifting force in use – key factors

- Clearance – existence of any layer (rust, tape, gap) acts as an insulator, which lowers capacity steeply (even by 50% at 0.5 mm).

- Force direction – note that the magnet has greatest strength perpendicularly. Under shear forces, the capacity drops significantly, often to levels of 20-30% of the nominal value.

- Element thickness – to utilize 100% power, the steel must be sufficiently thick. Thin sheet limits the lifting capacity (the magnet "punches through" it).

- Steel grade – the best choice is pure iron steel. Hardened steels may have worse magnetic properties.

- Surface condition – smooth surfaces ensure maximum contact, which improves field saturation. Uneven metal reduce efficiency.

- Thermal environment – temperature increase causes a temporary drop of induction. It is worth remembering the maximum operating temperature for a given model.

Lifting capacity was assessed using a smooth steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, in contrast under attempts to slide the magnet the holding force is lower. In addition, even a slight gap between the magnet and the plate reduces the load capacity.

Safe handling of neodymium magnets

Magnets are brittle

Beware of splinters. Magnets can explode upon uncontrolled impact, ejecting shards into the air. Eye protection is mandatory.

Immense force

Handle magnets consciously. Their huge power can shock even experienced users. Stay alert and do not underestimate their power.

Fire risk

Powder created during cutting of magnets is combustible. Avoid drilling into magnets unless you are an expert.

Keep away from children

Always keep magnets out of reach of children. Ingestion danger is high, and the effects of magnets connecting inside the body are life-threatening.

GPS and phone interference

An intense magnetic field interferes with the functioning of magnetometers in smartphones and navigation systems. Maintain magnets near a smartphone to prevent damaging the sensors.

Do not overheat magnets

Avoid heat. Neodymium magnets are sensitive to heat. If you need operation above 80°C, inquire about special high-temperature series (H, SH, UH).

Allergy Warning

Medical facts indicate that the nickel plating (standard magnet coating) is a potent allergen. For allergy sufferers, refrain from direct skin contact and opt for versions in plastic housing.

Health Danger

For implant holders: Powerful magnets affect electronics. Maintain at least 30 cm distance or request help to work with the magnets.

Magnetic media

Equipment safety: Neodymium magnets can damage payment cards and delicate electronics (pacemakers, hearing aids, mechanical watches).

Crushing risk

Large magnets can crush fingers in a fraction of a second. Under no circumstances put your hand betwixt two strong magnets.

![Magnet with hook UMH 48x11x65 [M6] / N38 Magnet with hook UMH 48x11x65 [M6] / N38](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UMH 48x11x65 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-48x11x65-m6-wiw.jpg)

![UMH 48x11x65 [M6] / N38 - magnetic holder with hook - ujęcie 2](https://cdn3.dhit.pl/graphics/products/umh-48x11x65-m6-soh.jpg)

![UMP 75x25 [M10x3] GW F200 PLATINIUM / N52 - search holder UMP 75x25 [M10x3] GW F200 PLATINIUM / N52 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-platinium-tav.jpg)

![UMP 67x28 [M8+M10] GW F120 Lina / N38 - search holder UMP 67x28 [M8+M10] GW F120 Lina / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump-67x28-m8+m10-gw-f-120+-lina-xiw.jpg)