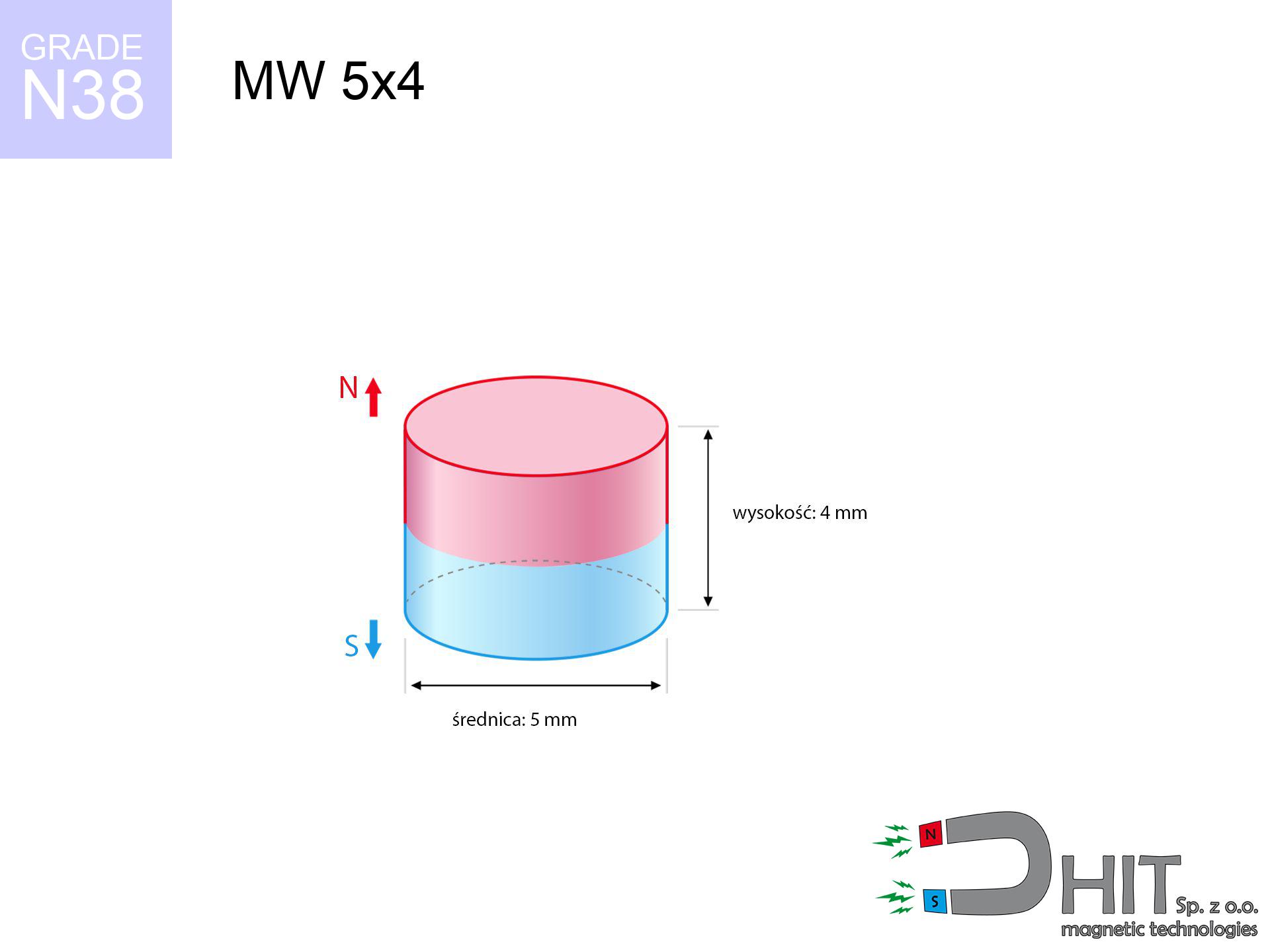

MW 5x4 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010089

GTIN/EAN: 5906301810889

Diameter Ø

5 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

0.59 g

Magnetization Direction

↑ axial

Load capacity

0.84 kg / 8.26 N

Magnetic Induction

524.45 mT / 5244 Gs

Coating

[NiCuNi] Nickel

0.369 ZŁ with VAT / pcs + price for transport

0.300 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

or drop us a message via

our online form

the contact page.

Specifications and shape of neodymium magnets can be verified with our

magnetic mass calculator.

Order by 14:00 and we’ll ship today!

Physical properties - MW 5x4 / N38 - cylindrical magnet

Specification / characteristics - MW 5x4 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010089 |

| GTIN/EAN | 5906301810889 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 5 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 0.59 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.84 kg / 8.26 N |

| Magnetic Induction ~ ? | 524.45 mT / 5244 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the magnet - data

Presented information represent the outcome of a physical simulation. Results rely on models for the class Nd2Fe14B. Actual parameters may deviate from the simulation results. Treat these data as a preliminary roadmap during assembly planning.

Table 1: Static pull force (force vs distance) - interaction chart

MW 5x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5236 Gs

523.6 mT

|

0.84 kg / 1.85 lbs

840.0 g / 8.2 N

|

weak grip |

| 1 mm |

3243 Gs

324.3 mT

|

0.32 kg / 0.71 lbs

322.1 g / 3.2 N

|

weak grip |

| 2 mm |

1850 Gs

185.0 mT

|

0.10 kg / 0.23 lbs

104.8 g / 1.0 N

|

weak grip |

| 3 mm |

1076 Gs

107.6 mT

|

0.04 kg / 0.08 lbs

35.5 g / 0.3 N

|

weak grip |

| 5 mm |

428 Gs

42.8 mT

|

0.01 kg / 0.01 lbs

5.6 g / 0.1 N

|

weak grip |

| 10 mm |

89 Gs

8.9 mT

|

0.00 kg / 0.00 lbs

0.2 g / 0.0 N

|

weak grip |

| 15 mm |

31 Gs

3.1 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

| 20 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

| 30 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

Table 2: Vertical force (wall)

MW 5x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.17 kg / 0.37 lbs

168.0 g / 1.6 N

|

| 1 mm | Stal (~0.2) |

0.06 kg / 0.14 lbs

64.0 g / 0.6 N

|

| 2 mm | Stal (~0.2) |

0.02 kg / 0.04 lbs

20.0 g / 0.2 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.02 lbs

8.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 5x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.25 kg / 0.56 lbs

252.0 g / 2.5 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.17 kg / 0.37 lbs

168.0 g / 1.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.08 kg / 0.19 lbs

84.0 g / 0.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.42 kg / 0.93 lbs

420.0 g / 4.1 N

|

Table 4: Steel thickness (saturation) - power losses

MW 5x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.08 kg / 0.19 lbs

84.0 g / 0.8 N

|

| 1 mm |

|

0.21 kg / 0.46 lbs

210.0 g / 2.1 N

|

| 2 mm |

|

0.42 kg / 0.93 lbs

420.0 g / 4.1 N

|

| 3 mm |

|

0.63 kg / 1.39 lbs

630.0 g / 6.2 N

|

| 5 mm |

|

0.84 kg / 1.85 lbs

840.0 g / 8.2 N

|

| 10 mm |

|

0.84 kg / 1.85 lbs

840.0 g / 8.2 N

|

| 11 mm |

|

0.84 kg / 1.85 lbs

840.0 g / 8.2 N

|

| 12 mm |

|

0.84 kg / 1.85 lbs

840.0 g / 8.2 N

|

Table 5: Working in heat (stability) - resistance threshold

MW 5x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.84 kg / 1.85 lbs

840.0 g / 8.2 N

|

OK |

| 40 °C | -2.2% |

0.82 kg / 1.81 lbs

821.5 g / 8.1 N

|

OK |

| 60 °C | -4.4% |

0.80 kg / 1.77 lbs

803.0 g / 7.9 N

|

OK |

| 80 °C | -6.6% |

0.78 kg / 1.73 lbs

784.6 g / 7.7 N

|

|

| 100 °C | -28.8% |

0.60 kg / 1.32 lbs

598.1 g / 5.9 N

|

Table 6: Two magnets (repulsion) - field range

MW 5x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.32 kg / 7.32 lbs

5 894 Gs

|

0.50 kg / 1.10 lbs

498 g / 4.9 N

|

N/A |

| 1 mm |

2.14 kg / 4.72 lbs

8 408 Gs

|

0.32 kg / 0.71 lbs

321 g / 3.1 N

|

1.93 kg / 4.24 lbs

~0 Gs

|

| 2 mm |

1.27 kg / 2.81 lbs

6 486 Gs

|

0.19 kg / 0.42 lbs

191 g / 1.9 N

|

1.15 kg / 2.53 lbs

~0 Gs

|

| 3 mm |

0.73 kg / 1.61 lbs

4 909 Gs

|

0.11 kg / 0.24 lbs

109 g / 1.1 N

|

0.66 kg / 1.45 lbs

~0 Gs

|

| 5 mm |

0.24 kg / 0.53 lbs

2 805 Gs

|

0.04 kg / 0.08 lbs

36 g / 0.4 N

|

0.21 kg / 0.47 lbs

~0 Gs

|

| 10 mm |

0.02 kg / 0.05 lbs

857 Gs

|

0.00 kg / 0.01 lbs

3 g / 0.0 N

|

0.02 kg / 0.04 lbs

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 lbs

177 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

16 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

9 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

6 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

4 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

3 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

2 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Hazards (electronics) - precautionary measures

MW 5x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Dynamics (cracking risk) - collision effects

MW 5x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

38.06 km/h

(10.57 m/s)

|

0.03 J | |

| 30 mm |

65.91 km/h

(18.31 m/s)

|

0.10 J | |

| 50 mm |

85.09 km/h

(23.64 m/s)

|

0.16 J | |

| 100 mm |

120.34 km/h

(33.43 m/s)

|

0.33 J |

Table 9: Corrosion resistance

MW 5x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 5x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 046 Mx | 10.5 µWb |

| Pc Coefficient | 0.79 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 5x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.84 kg | Standard |

| Water (riverbed) |

0.96 kg

(+0.12 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Caution: On a vertical surface, the magnet retains merely ~20% of its perpendicular strength.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) drastically weakens the holding force.

3. Power loss vs temp

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.79

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Strengths as well as weaknesses of neodymium magnets.

Pros

- They do not lose power, even after nearly ten years – the decrease in lifting capacity is only ~1% (theoretically),

- They possess excellent resistance to magnetism drop as a result of external fields,

- A magnet with a shiny nickel surface has an effective appearance,

- Magnets are characterized by huge magnetic induction on the outer layer,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can work (depending on the form) even at a temperature of 230°C or more...

- Thanks to freedom in designing and the ability to customize to client solutions,

- Key role in innovative solutions – they are utilized in magnetic memories, electric drive systems, diagnostic systems, also industrial machines.

- Compactness – despite small sizes they generate large force, making them ideal for precision applications

Limitations

- Brittleness is one of their disadvantages. Upon intense impact they can break. We recommend keeping them in a strong case, which not only secures them against impacts but also raises their durability

- Neodymium magnets lose their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They rust in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Limited possibility of making threads in the magnet and complicated shapes - recommended is cover - mounting mechanism.

- Possible danger to health – tiny shards of magnets pose a threat, if swallowed, which gains importance in the aspect of protecting the youngest. It is also worth noting that tiny parts of these magnets can disrupt the diagnostic process medical when they are in the body.

- Due to expensive raw materials, their price is relatively high,

Holding force characteristics

Maximum lifting capacity of the magnet – what it depends on?

- using a plate made of high-permeability steel, functioning as a magnetic yoke

- possessing a massiveness of minimum 10 mm to ensure full flux closure

- characterized by even structure

- with direct contact (no paint)

- for force applied at a right angle (in the magnet axis)

- at ambient temperature approx. 20 degrees Celsius

Magnet lifting force in use – key factors

- Gap between surfaces – even a fraction of a millimeter of separation (caused e.g. by varnish or unevenness) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Loading method – catalog parameter refers to pulling vertically. When applying parallel force, the magnet exhibits significantly lower power (typically approx. 20-30% of nominal force).

- Wall thickness – the thinner the sheet, the weaker the hold. Part of the magnetic field passes through the material instead of generating force.

- Chemical composition of the base – mild steel gives the best results. Higher carbon content decrease magnetic properties and lifting capacity.

- Surface condition – ground elements ensure maximum contact, which improves force. Rough surfaces reduce efficiency.

- Thermal environment – temperature increase results in weakening of force. Check the maximum operating temperature for a given model.

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under perpendicular forces, in contrast under parallel forces the lifting capacity is smaller. Moreover, even a minimal clearance between the magnet’s surface and the plate lowers the load capacity.

Precautions when working with NdFeB magnets

Medical interference

People with a heart stimulator should keep an safe separation from magnets. The magnetism can stop the functioning of the implant.

Threat to navigation

Remember: rare earth magnets produce a field that confuses sensitive sensors. Keep a safe distance from your phone, tablet, and GPS.

Combustion hazard

Mechanical processing of neodymium magnets poses a fire hazard. Magnetic powder reacts violently with oxygen and is hard to extinguish.

Cards and drives

Intense magnetic fields can corrupt files on payment cards, hard drives, and storage devices. Stay away of min. 10 cm.

Do not underestimate power

Before use, read the rules. Uncontrolled attraction can break the magnet or hurt your hand. Think ahead.

Shattering risk

NdFeB magnets are sintered ceramics, which means they are very brittle. Impact of two magnets will cause them cracking into shards.

Thermal limits

Watch the temperature. Exposing the magnet to high heat will permanently weaken its magnetic structure and strength.

No play value

Adult use only. Tiny parts pose a choking risk, leading to severe trauma. Keep out of reach of kids and pets.

Allergy Warning

Nickel alert: The Ni-Cu-Ni coating contains nickel. If an allergic reaction occurs, immediately stop handling magnets and wear gloves.

Crushing force

Risk of injury: The pulling power is so great that it can result in hematomas, crushing, and even bone fractures. Use thick gloves.