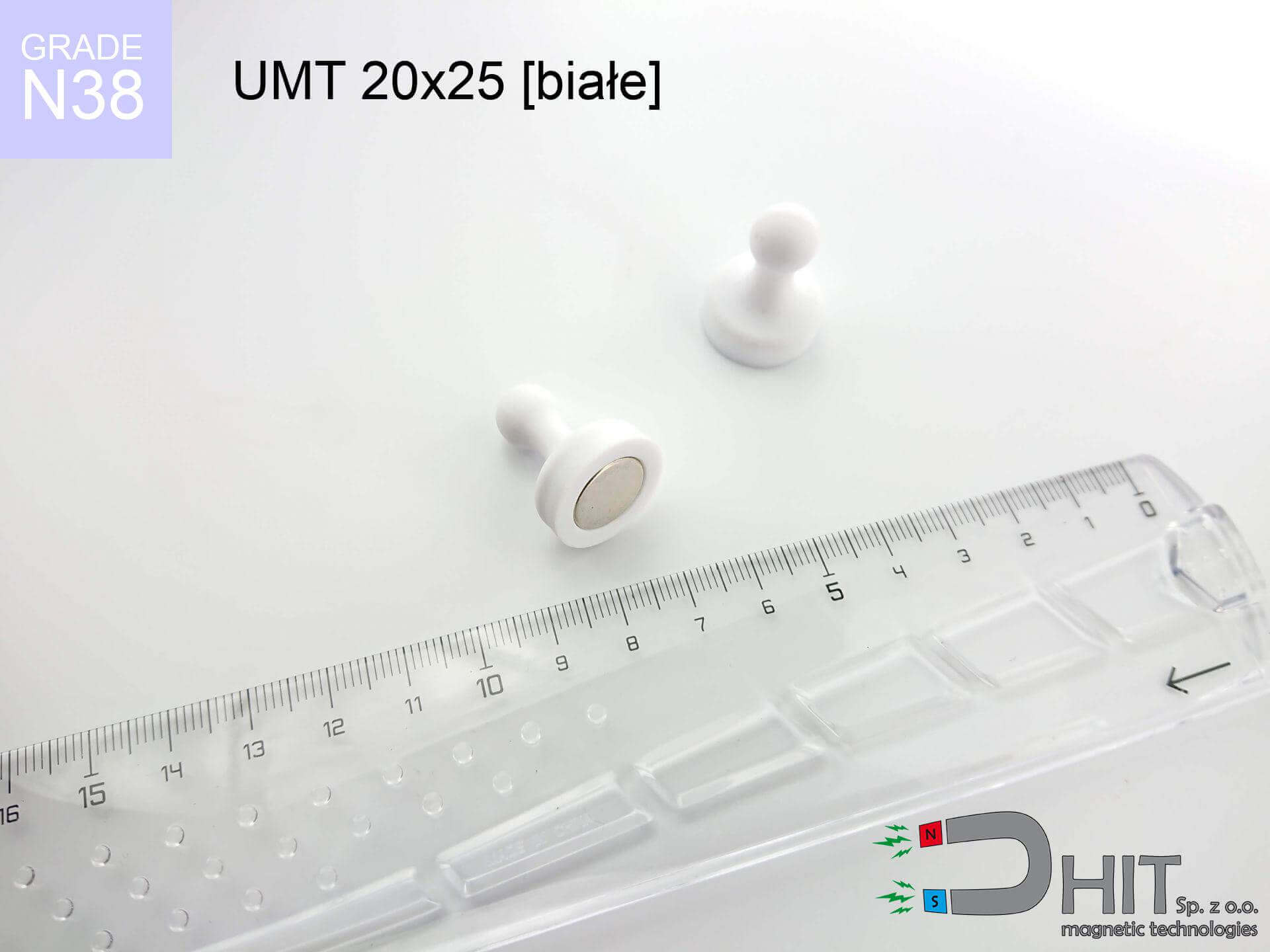

UMT 20x25 white / N38 - board holder

board holder

Catalog no 230262

GTIN/EAN: 5906301814252

Diameter Ø

20 mm [±1 mm]

Height

25 mm [±1 mm]

Weight

7 g

Coating

[NiCuNi] Nickel

3.49 ZŁ with VAT / pcs + price for transport

2.84 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

otherwise send us a note using

inquiry form

our website.

Lifting power and appearance of a magnet can be analyzed with our

power calculator.

Order by 14:00 and we’ll ship today!

Technical - UMT 20x25 white / N38 - board holder

Specification / characteristics - UMT 20x25 white / N38 - board holder

| properties | values |

|---|---|

| Cat. no. | 230262 |

| GTIN/EAN | 5906301814252 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 20 mm [±1 mm] |

| Height | 25 mm [±1 mm] |

| Weight | 7 g |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also proposals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Advantages

- Their power is maintained, and after around 10 years it decreases only by ~1% (according to research),

- They have excellent resistance to weakening of magnetic properties as a result of external magnetic sources,

- In other words, due to the reflective layer of silver, the element gains visual value,

- They are known for high magnetic induction at the operating surface, making them more effective,

- Through (adequate) combination of ingredients, they can achieve high thermal resistance, allowing for action at temperatures reaching 230°C and above...

- Possibility of accurate machining as well as optimizing to concrete requirements,

- Significant place in future technologies – they find application in mass storage devices, brushless drives, medical devices, also industrial machines.

- Thanks to efficiency per cm³, small magnets offer high operating force, with minimal size,

Limitations

- To avoid cracks under impact, we recommend using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- When exposed to humidity, magnets usually rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation and corrosion.

- We recommend cover - magnetic mount, due to difficulties in creating nuts inside the magnet and complicated forms.

- Potential hazard to health – tiny shards of magnets pose a threat, in case of ingestion, which is particularly important in the context of child safety. Furthermore, small elements of these products can be problematic in diagnostics medical in case of swallowing.

- With budget limitations the cost of neodymium magnets is economically unviable,

Lifting parameters

Maximum holding power of the magnet – what affects it?

- on a block made of structural steel, effectively closing the magnetic flux

- with a cross-section minimum 10 mm

- characterized by smoothness

- under conditions of no distance (metal-to-metal)

- for force applied at a right angle (pull-off, not shear)

- in neutral thermal conditions

Practical lifting capacity: influencing factors

- Gap (betwixt the magnet and the metal), because even a microscopic distance (e.g. 0.5 mm) results in a decrease in force by up to 50% (this also applies to paint, rust or debris).

- Loading method – declared lifting capacity refers to pulling vertically. When attempting to slide, the magnet exhibits significantly lower power (often approx. 20-30% of nominal force).

- Element thickness – for full efficiency, the steel must be adequately massive. Thin sheet limits the attraction force (the magnet "punches through" it).

- Steel grade – the best choice is pure iron steel. Stainless steels may have worse magnetic properties.

- Surface finish – ideal contact is obtained only on polished steel. Any scratches and bumps reduce the real contact area, reducing force.

- Thermal environment – temperature increase results in weakening of induction. Check the maximum operating temperature for a given model.

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under perpendicular forces, however under parallel forces the lifting capacity is smaller. Moreover, even a slight gap between the magnet’s surface and the plate decreases the load capacity.

Precautions when working with neodymium magnets

Nickel allergy

Medical facts indicate that nickel (the usual finish) is a strong allergen. If your skin reacts to metals, prevent touching magnets with bare hands or opt for encased magnets.

No play value

Always store magnets out of reach of children. Choking hazard is high, and the consequences of magnets connecting inside the body are very dangerous.

Combustion hazard

Machining of NdFeB material poses a fire risk. Magnetic powder reacts violently with oxygen and is hard to extinguish.

Handling guide

Be careful. Rare earth magnets attract from a long distance and snap with huge force, often quicker than you can move away.

Keep away from electronics

Navigation devices and mobile phones are extremely susceptible to magnetism. Close proximity with a strong magnet can permanently damage the sensors in your phone.

Beware of splinters

Despite metallic appearance, neodymium is brittle and cannot withstand shocks. Do not hit, as the magnet may shatter into hazardous fragments.

Thermal limits

Regular neodymium magnets (grade N) undergo demagnetization when the temperature goes above 80°C. This process is irreversible.

Cards and drives

Intense magnetic fields can corrupt files on credit cards, hard drives, and storage devices. Maintain a gap of min. 10 cm.

Physical harm

Large magnets can smash fingers in a fraction of a second. Do not place your hand between two attracting surfaces.

Life threat

People with a heart stimulator must keep an large gap from magnets. The magnetic field can disrupt the functioning of the life-saving device.

![SM 25x350 [2xM8] / N42 - magnetic separator SM 25x350 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x350-2xm8-pim.jpg)

![AM ucho małe [M8] - magnetic accessories AM ucho małe [M8] - magnetic accessories](https://cdn3.dhit.pl/graphics/products/am-ucho-małe-m8-zud.jpg)