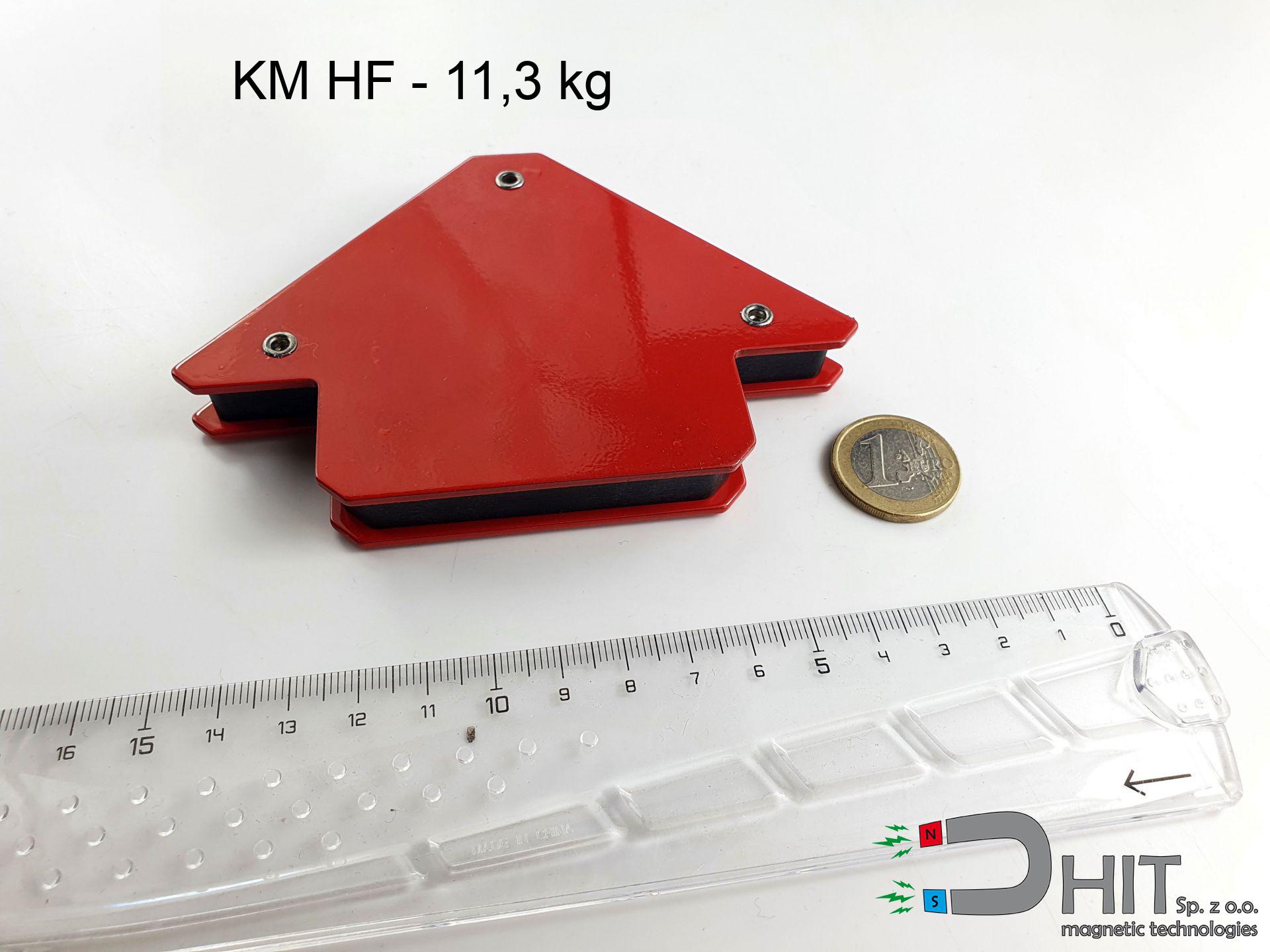

KM HF - 11,3 kg - magnetic bracket

magnetic bracket

Catalog no 170256

GTIN/EAN: 5906301813682

Weight

304 g

Load capacity

11.30 kg / 110.82 N

24.60 ZŁ with VAT / pcs + price for transport

20.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

or get in touch by means of

our online form

the contact page.

Force as well as form of magnets can be checked with our

online calculation tool.

Orders placed before 14:00 will be shipped the same business day.

Technical parameters - KM HF - 11,3 kg - magnetic bracket

Specification / characteristics - KM HF - 11,3 kg - magnetic bracket

| properties | values |

|---|---|

| Cat. no. | 170256 |

| GTIN/EAN | 5906301813682 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 304 g |

| Load capacity ~ ? | 11.30 kg / 110.82 N |

| Manufacturing Tolerance | ±1 mm |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Strengths as well as weaknesses of neodymium magnets.

Strengths

- Their strength remains stable, and after around ten years it decreases only by ~1% (according to research),

- They retain their magnetic properties even under close interference source,

- Thanks to the shiny finish, the layer of Ni-Cu-Ni, gold-plated, or silver gives an modern appearance,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to flexibility in shaping and the ability to modify to client solutions,

- Key role in innovative solutions – they serve a role in computer drives, motor assemblies, diagnostic systems, and technologically advanced constructions.

- Thanks to efficiency per cm³, small magnets offer high operating force, in miniature format,

Disadvantages

- At strong impacts they can crack, therefore we advise placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Limited possibility of creating nuts in the magnet and complex shapes - recommended is a housing - magnet mounting.

- Possible danger to health – tiny shards of magnets pose a threat, in case of ingestion, which gains importance in the context of child health protection. Furthermore, small components of these products are able to be problematic in diagnostics medical in case of swallowing.

- With large orders the cost of neodymium magnets is economically unviable,

Lifting parameters

Best holding force of the magnet in ideal parameters – what contributes to it?

- on a plate made of structural steel, optimally conducting the magnetic field

- whose thickness equals approx. 10 mm

- with an ground contact surface

- with direct contact (without paint)

- under perpendicular force vector (90-degree angle)

- at temperature room level

Determinants of lifting force in real conditions

- Gap between surfaces – even a fraction of a millimeter of separation (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Loading method – catalog parameter refers to pulling vertically. When slipping, the magnet exhibits much less (typically approx. 20-30% of maximum force).

- Base massiveness – insufficiently thick sheet does not close the flux, causing part of the power to be escaped to the other side.

- Chemical composition of the base – low-carbon steel gives the best results. Alloy steels lower magnetic properties and lifting capacity.

- Smoothness – ideal contact is possible only on smooth steel. Rough texture reduce the real contact area, reducing force.

- Operating temperature – neodymium magnets have a negative temperature coefficient. When it is hot they lose power, and at low temperatures gain strength (up to a certain limit).

Lifting capacity testing was conducted on a smooth plate of suitable thickness, under a perpendicular pulling force, however under parallel forces the holding force is lower. In addition, even a slight gap between the magnet’s surface and the plate lowers the load capacity.

Safe handling of neodymium magnets

Danger to the youngest

Always keep magnets away from children. Ingestion danger is significant, and the effects of magnets clamping inside the body are fatal.

Crushing risk

Big blocks can break fingers in a fraction of a second. Do not put your hand betwixt two attracting surfaces.

Threat to navigation

A strong magnetic field disrupts the operation of magnetometers in phones and GPS navigation. Maintain magnets near a smartphone to prevent breaking the sensors.

Electronic hazard

Intense magnetic fields can erase data on payment cards, HDDs, and other magnetic media. Maintain a gap of at least 10 cm.

Danger to pacemakers

Individuals with a ICD have to maintain an safe separation from magnets. The magnetism can stop the operation of the implant.

Powerful field

Handle magnets consciously. Their powerful strength can surprise even experienced users. Stay alert and respect their force.

Allergy Warning

Some people experience a hypersensitivity to Ni, which is the standard coating for neodymium magnets. Extended handling may cause dermatitis. We suggest wear protective gloves.

Thermal limits

Standard neodymium magnets (grade N) undergo demagnetization when the temperature exceeds 80°C. Damage is permanent.

Magnets are brittle

Despite the nickel coating, neodymium is delicate and not impact-resistant. Avoid impacts, as the magnet may crumble into hazardous fragments.

Mechanical processing

Fire hazard: Rare earth powder is highly flammable. Do not process magnets without safety gear as this risks ignition.