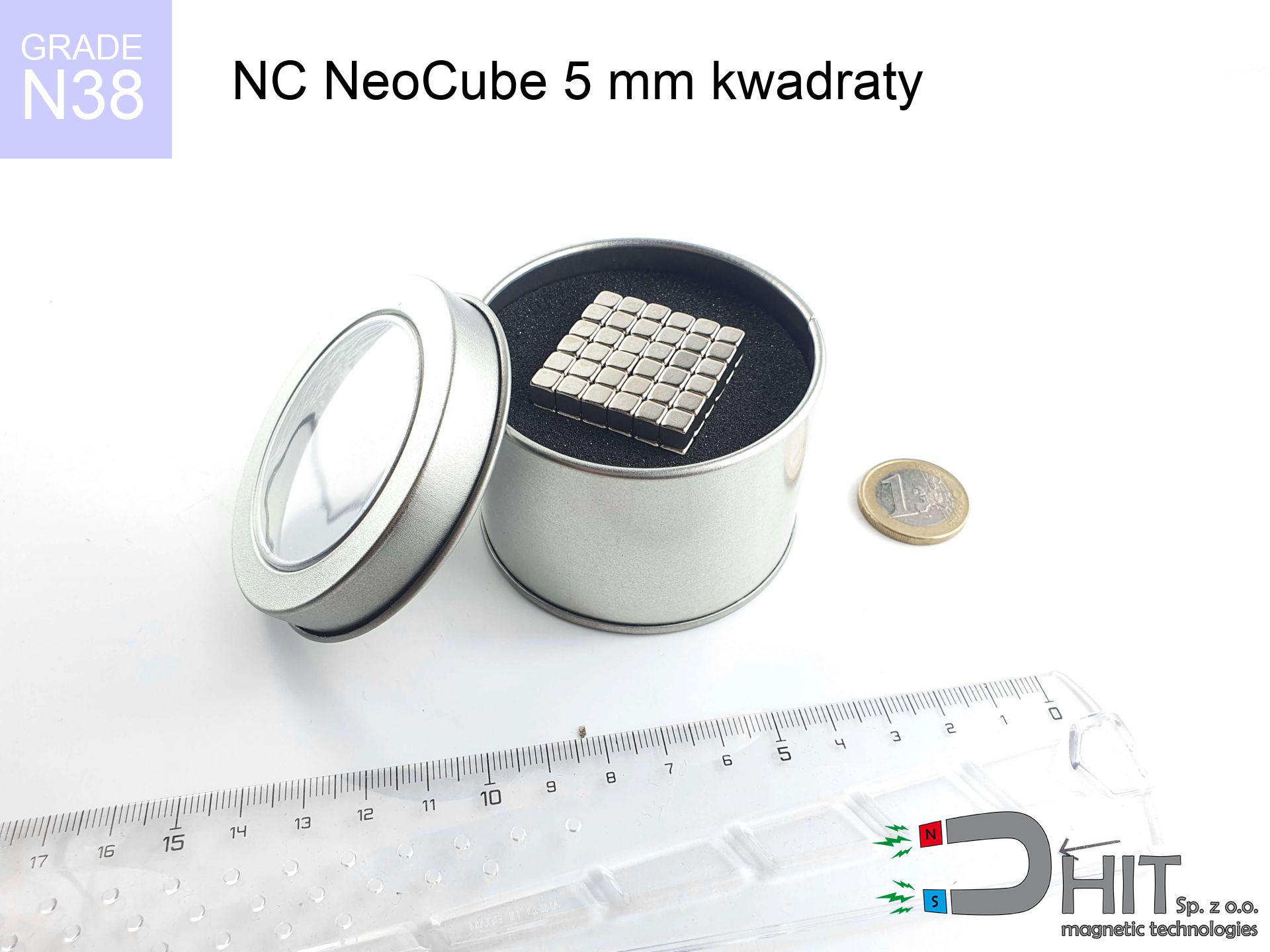

NC NeoCube 5 mm kwadraty / N38 - neocube

neocube

Catalog no 120227

GTIN/EAN: 5906301812661

Weight

216.5 g

Magnetization Direction

↑ axial

Coating

[NiCuNi] Nickel

49.99 ZŁ with VAT / pcs + price for transport

40.64 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

alternatively contact us via

inquiry form

the contact section.

Lifting power along with structure of magnetic components can be checked with our

online calculation tool.

Same-day shipping for orders placed before 14:00.

Technical parameters of the product - NC NeoCube 5 mm kwadraty / N38 - neocube

Specification / characteristics - NC NeoCube 5 mm kwadraty / N38 - neocube

| properties | values |

|---|---|

| Cat. no. | 120227 |

| GTIN/EAN | 5906301812661 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 216.5 g |

| Magnetization Direction | ↑ axial |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros as well as cons of rare earth magnets.

Advantages

- They have stable power, and over more than 10 years their attraction force decreases symbolically – ~1% (in testing),

- Neodymium magnets prove to be highly resistant to magnetic field loss caused by external field sources,

- A magnet with a metallic gold surface has better aesthetics,

- They feature high magnetic induction at the operating surface, which improves attraction properties,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- Thanks to freedom in designing and the ability to customize to unusual requirements,

- Huge importance in electronics industry – they find application in computer drives, drive modules, advanced medical instruments, also other advanced devices.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in tiny dimensions, which enables their usage in miniature devices

Disadvantages

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only protects the magnet but also improves its resistance to damage

- We warn that neodymium magnets can reduce their power at high temperatures. To prevent this, we recommend our specialized [AH] magnets, which work effectively even at 230°C.

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, in case of application outdoors

- Limited ability of creating threads in the magnet and complex shapes - recommended is casing - magnet mounting.

- Health risk resulting from small fragments of magnets can be dangerous, if swallowed, which is particularly important in the context of child safety. Additionally, small elements of these products can be problematic in diagnostics medical in case of swallowing.

- Due to expensive raw materials, their price is higher than average,

Lifting parameters

Magnetic strength at its maximum – what contributes to it?

- on a block made of structural steel, effectively closing the magnetic field

- whose transverse dimension is min. 10 mm

- with an ideally smooth touching surface

- with total lack of distance (without impurities)

- for force acting at a right angle (pull-off, not shear)

- at standard ambient temperature

Key elements affecting lifting force

- Distance (between the magnet and the plate), since even a tiny clearance (e.g. 0.5 mm) results in a reduction in lifting capacity by up to 50% (this also applies to paint, rust or debris).

- Force direction – remember that the magnet holds strongest perpendicularly. Under shear forces, the capacity drops drastically, often to levels of 20-30% of the maximum value.

- Element thickness – for full efficiency, the steel must be adequately massive. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Metal type – not every steel reacts the same. Alloy additives worsen the attraction effect.

- Base smoothness – the smoother and more polished the surface, the better the adhesion and stronger the hold. Roughness acts like micro-gaps.

- Temperature – temperature increase results in weakening of force. It is worth remembering the thermal limit for a given model.

Lifting capacity was determined with the use of a polished steel plate of optimal thickness (min. 20 mm), under perpendicular pulling force, whereas under shearing force the load capacity is reduced by as much as 5 times. In addition, even a small distance between the magnet’s surface and the plate reduces the holding force.

Safe handling of NdFeB magnets

Do not overheat magnets

Control the heat. Heating the magnet above 80 degrees Celsius will ruin its magnetic structure and pulling force.

Keep away from computers

Avoid bringing magnets near a wallet, computer, or TV. The magnetism can destroy these devices and wipe information from cards.

Medical implants

Medical warning: Neodymium magnets can deactivate heart devices and defibrillators. Stay away if you have electronic implants.

Machining danger

Drilling and cutting of NdFeB material carries a risk of fire hazard. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Threat to navigation

Be aware: rare earth magnets produce a field that disrupts sensitive sensors. Maintain a safe distance from your mobile, device, and navigation systems.

Risk of cracking

Despite metallic appearance, neodymium is brittle and not impact-resistant. Avoid impacts, as the magnet may shatter into hazardous fragments.

Avoid contact if allergic

It is widely known that the nickel plating (the usual finish) is a potent allergen. If your skin reacts to metals, refrain from direct skin contact or opt for versions in plastic housing.

Physical harm

Danger of trauma: The pulling power is so great that it can cause blood blisters, crushing, and broken bones. Protective gloves are recommended.

Handling guide

Use magnets with awareness. Their huge power can surprise even experienced users. Plan your moves and respect their power.

Do not give to children

NdFeB magnets are not toys. Accidental ingestion of a few magnets can lead to them pinching intestinal walls, which poses a direct threat to life and necessitates immediate surgery.

![SM 32x375 [2xM8] / N52 - magnetic separator SM 32x375 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x375-2xm8-mif.jpg)

![SM 32x325 [2xM8] / N52 - magnetic separator SM 32x325 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x325-2xm8-xec.jpg)

![BM 380x180x70 [4x M8] - magnetic beam BM 380x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-380x180x70-4x-m8-wex.jpg)

![UMP 97x40 [M8+M10] GW F300 Lina / N38 - search holder UMP 97x40 [M8+M10] GW F300 Lina / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump-97x40-m8+m10-gw-f300-+lina-ful.jpg)