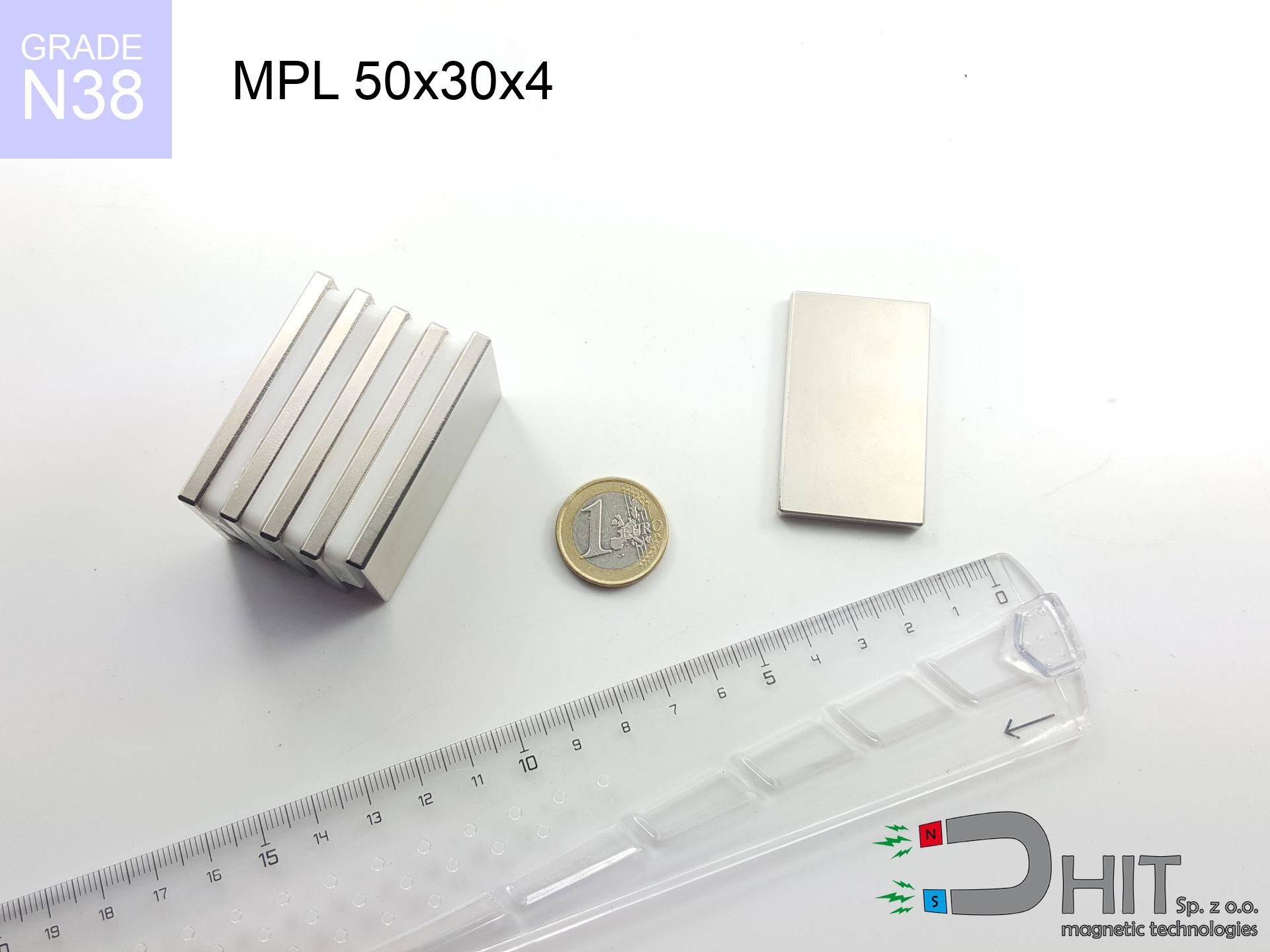

MPL 50x30x4 / N38 - lamellar magnet

lamellar magnet

Catalog no 020497

GTIN/EAN: 5906301814955

length

50 mm [±0,1 mm]

Width

30 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

45 g

Magnetization Direction

↑ axial

Load capacity

7.57 kg / 74.26 N

Magnetic Induction

120.04 mT / 1200 Gs

Coating

[NiCuNi] Nickel

25.83 ZŁ with VAT / pcs + price for transport

21.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Give us a call

+48 22 499 98 98

if you prefer let us know by means of

our online form

our website.

Weight as well as shape of a neodymium magnet can be verified using our

our magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Technical of the product - MPL 50x30x4 / N38 - lamellar magnet

Specification / characteristics - MPL 50x30x4 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020497 |

| GTIN/EAN | 5906301814955 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 50 mm [±0,1 mm] |

| Width | 30 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 45 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 7.57 kg / 74.26 N |

| Magnetic Induction ~ ? | 120.04 mT / 1200 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the magnet - technical parameters

The following information are the result of a physical calculation. Values are based on models for the material Nd2Fe14B. Real-world performance may differ. Please consider these calculations as a reference point during assembly planning.

Table 1: Static force (force vs gap) - power drop

MPL 50x30x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1200 Gs

120.0 mT

|

7.57 kg / 16.69 pounds

7570.0 g / 74.3 N

|

warning |

| 1 mm |

1176 Gs

117.6 mT

|

7.27 kg / 16.03 pounds

7270.9 g / 71.3 N

|

warning |

| 2 mm |

1144 Gs

114.4 mT

|

6.88 kg / 15.16 pounds

6877.1 g / 67.5 N

|

warning |

| 3 mm |

1105 Gs

110.5 mT

|

6.41 kg / 14.14 pounds

6414.7 g / 62.9 N

|

warning |

| 5 mm |

1012 Gs

101.2 mT

|

5.38 kg / 11.86 pounds

5381.2 g / 52.8 N

|

warning |

| 10 mm |

754 Gs

75.4 mT

|

2.99 kg / 6.59 pounds

2990.1 g / 29.3 N

|

warning |

| 15 mm |

535 Gs

53.5 mT

|

1.50 kg / 3.31 pounds

1503.5 g / 14.7 N

|

low risk |

| 20 mm |

376 Gs

37.6 mT

|

0.74 kg / 1.64 pounds

743.3 g / 7.3 N

|

low risk |

| 30 mm |

193 Gs

19.3 mT

|

0.20 kg / 0.43 pounds

195.8 g / 1.9 N

|

low risk |

| 50 mm |

64 Gs

6.4 mT

|

0.02 kg / 0.05 pounds

21.4 g / 0.2 N

|

low risk |

Table 2: Vertical load (vertical surface)

MPL 50x30x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

1.51 kg / 3.34 pounds

1514.0 g / 14.9 N

|

| 1 mm | Stal (~0.2) |

1.45 kg / 3.21 pounds

1454.0 g / 14.3 N

|

| 2 mm | Stal (~0.2) |

1.38 kg / 3.03 pounds

1376.0 g / 13.5 N

|

| 3 mm | Stal (~0.2) |

1.28 kg / 2.83 pounds

1282.0 g / 12.6 N

|

| 5 mm | Stal (~0.2) |

1.08 kg / 2.37 pounds

1076.0 g / 10.6 N

|

| 10 mm | Stal (~0.2) |

0.60 kg / 1.32 pounds

598.0 g / 5.9 N

|

| 15 mm | Stal (~0.2) |

0.30 kg / 0.66 pounds

300.0 g / 2.9 N

|

| 20 mm | Stal (~0.2) |

0.15 kg / 0.33 pounds

148.0 g / 1.5 N

|

| 30 mm | Stal (~0.2) |

0.04 kg / 0.09 pounds

40.0 g / 0.4 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.01 pounds

4.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MPL 50x30x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

2.27 kg / 5.01 pounds

2271.0 g / 22.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

1.51 kg / 3.34 pounds

1514.0 g / 14.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.76 kg / 1.67 pounds

757.0 g / 7.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

3.79 kg / 8.34 pounds

3785.0 g / 37.1 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MPL 50x30x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.76 kg / 1.67 pounds

757.0 g / 7.4 N

|

| 1 mm |

|

1.89 kg / 4.17 pounds

1892.5 g / 18.6 N

|

| 2 mm |

|

3.79 kg / 8.34 pounds

3785.0 g / 37.1 N

|

| 3 mm |

|

5.68 kg / 12.52 pounds

5677.5 g / 55.7 N

|

| 5 mm |

|

7.57 kg / 16.69 pounds

7570.0 g / 74.3 N

|

| 10 mm |

|

7.57 kg / 16.69 pounds

7570.0 g / 74.3 N

|

| 11 mm |

|

7.57 kg / 16.69 pounds

7570.0 g / 74.3 N

|

| 12 mm |

|

7.57 kg / 16.69 pounds

7570.0 g / 74.3 N

|

Table 5: Thermal stability (material behavior) - power drop

MPL 50x30x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

7.57 kg / 16.69 pounds

7570.0 g / 74.3 N

|

OK |

| 40 °C | -2.2% |

7.40 kg / 16.32 pounds

7403.5 g / 72.6 N

|

OK |

| 60 °C | -4.4% |

7.24 kg / 15.95 pounds

7236.9 g / 71.0 N

|

|

| 80 °C | -6.6% |

7.07 kg / 15.59 pounds

7070.4 g / 69.4 N

|

|

| 100 °C | -28.8% |

5.39 kg / 11.88 pounds

5389.8 g / 52.9 N

|

Table 6: Two magnets (repulsion) - field collision

MPL 50x30x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

13.32 kg / 29.37 pounds

2 260 Gs

|

2.00 kg / 4.41 pounds

1999 g / 19.6 N

|

N/A |

| 1 mm |

13.09 kg / 28.85 pounds

2 379 Gs

|

1.96 kg / 4.33 pounds

1963 g / 19.3 N

|

11.78 kg / 25.96 pounds

~0 Gs

|

| 2 mm |

12.80 kg / 28.21 pounds

2 353 Gs

|

1.92 kg / 4.23 pounds

1920 g / 18.8 N

|

11.52 kg / 25.39 pounds

~0 Gs

|

| 3 mm |

12.47 kg / 27.49 pounds

2 322 Gs

|

1.87 kg / 4.12 pounds

1870 g / 18.3 N

|

11.22 kg / 24.74 pounds

~0 Gs

|

| 5 mm |

11.71 kg / 25.82 pounds

2 251 Gs

|

1.76 kg / 3.87 pounds

1756 g / 17.2 N

|

10.54 kg / 23.23 pounds

~0 Gs

|

| 10 mm |

9.47 kg / 20.88 pounds

2 024 Gs

|

1.42 kg / 3.13 pounds

1421 g / 13.9 N

|

8.52 kg / 18.79 pounds

~0 Gs

|

| 20 mm |

5.26 kg / 11.60 pounds

1 509 Gs

|

0.79 kg / 1.74 pounds

789 g / 7.7 N

|

4.74 kg / 10.44 pounds

~0 Gs

|

| 50 mm |

0.66 kg / 1.45 pounds

534 Gs

|

0.10 kg / 0.22 pounds

99 g / 1.0 N

|

0.59 kg / 1.31 pounds

~0 Gs

|

| 60 mm |

0.34 kg / 0.76 pounds

386 Gs

|

0.05 kg / 0.11 pounds

52 g / 0.5 N

|

0.31 kg / 0.68 pounds

~0 Gs

|

| 70 mm |

0.19 kg / 0.41 pounds

285 Gs

|

0.03 kg / 0.06 pounds

28 g / 0.3 N

|

0.17 kg / 0.37 pounds

~0 Gs

|

| 80 mm |

0.11 kg / 0.23 pounds

214 Gs

|

0.02 kg / 0.03 pounds

16 g / 0.2 N

|

0.10 kg / 0.21 pounds

~0 Gs

|

| 90 mm |

0.06 kg / 0.14 pounds

164 Gs

|

0.01 kg / 0.02 pounds

9 g / 0.1 N

|

0.06 kg / 0.12 pounds

~0 Gs

|

| 100 mm |

0.04 kg / 0.08 pounds

128 Gs

|

0.01 kg / 0.01 pounds

6 g / 0.1 N

|

0.03 kg / 0.07 pounds

~0 Gs

|

Table 7: Protective zones (electronics) - precautionary measures

MPL 50x30x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 13.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 10.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 8.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 6.5 cm |

| Car key | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Impact energy (cracking risk) - warning

MPL 50x30x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

15.99 km/h

(4.44 m/s)

|

0.44 J | |

| 30 mm |

23.02 km/h

(6.39 m/s)

|

0.92 J | |

| 50 mm |

29.30 km/h

(8.14 m/s)

|

1.49 J | |

| 100 mm |

41.37 km/h

(11.49 m/s)

|

2.97 J |

Table 9: Corrosion resistance

MPL 50x30x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MPL 50x30x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 22 399 Mx | 224.0 µWb |

| Pc Coefficient | 0.14 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MPL 50x30x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 7.57 kg | Standard |

| Water (riverbed) |

8.67 kg

(+1.10 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Note: On a vertical surface, the magnet holds just a fraction of its perpendicular strength.

2. Steel thickness impact

*Thin steel (e.g. computer case) severely limits the holding force.

3. Power loss vs temp

*For N38 material, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.14

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also offers

Pros as well as cons of rare earth magnets.

Strengths

- They virtually do not lose strength, because even after 10 years the decline in efficiency is only ~1% (in laboratory conditions),

- They do not lose their magnetic properties even under close interference source,

- Thanks to the shiny finish, the plating of nickel, gold, or silver-plated gives an clean appearance,

- Magnetic induction on the working layer of the magnet is very high,

- Due to their durability and thermal resistance, neodymium magnets can operate (depending on the form) even at high temperatures reaching 230°C or more...

- In view of the ability of flexible shaping and adaptation to specialized needs, neodymium magnets can be manufactured in a wide range of geometric configurations, which increases their versatility,

- Huge importance in high-tech industry – they are used in magnetic memories, motor assemblies, advanced medical instruments, and technologically advanced constructions.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in tiny dimensions, which enables their usage in miniature devices

Disadvantages

- Brittleness is one of their disadvantages. Upon intense impact they can fracture. We recommend keeping them in a steel housing, which not only secures them against impacts but also raises their durability

- We warn that neodymium magnets can lose their strength at high temperatures. To prevent this, we advise our specialized [AH] magnets, which work effectively even at 230°C.

- They oxidize in a humid environment - during use outdoors we advise using waterproof magnets e.g. in rubber, plastic

- Limited possibility of producing nuts in the magnet and complex forms - preferred is casing - magnet mounting.

- Health risk to health – tiny shards of magnets can be dangerous, if swallowed, which gains importance in the context of child health protection. Furthermore, tiny parts of these magnets can be problematic in diagnostics medical after entering the body.

- Due to expensive raw materials, their price exceeds standard values,

Pull force analysis

Detachment force of the magnet in optimal conditions – what it depends on?

- using a base made of mild steel, functioning as a ideal flux conductor

- with a cross-section minimum 10 mm

- with a surface cleaned and smooth

- under conditions of no distance (surface-to-surface)

- for force applied at a right angle (in the magnet axis)

- at standard ambient temperature

Lifting capacity in practice – influencing factors

- Distance (betwixt the magnet and the metal), because even a very small distance (e.g. 0.5 mm) leads to a drastic drop in lifting capacity by up to 50% (this also applies to paint, corrosion or debris).

- Force direction – catalog parameter refers to detachment vertically. When slipping, the magnet exhibits much less (typically approx. 20-30% of maximum force).

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Thin sheet limits the attraction force (the magnet "punches through" it).

- Plate material – low-carbon steel gives the best results. Alloy steels decrease magnetic properties and lifting capacity.

- Plate texture – ground elements guarantee perfect abutment, which improves field saturation. Uneven metal reduce efficiency.

- Thermal environment – heating the magnet results in weakening of force. Check the maximum operating temperature for a given model.

Lifting capacity testing was performed on plates with a smooth surface of suitable thickness, under perpendicular forces, in contrast under shearing force the load capacity is reduced by as much as 5 times. Additionally, even a slight gap between the magnet and the plate reduces the load capacity.

Safe handling of NdFeB magnets

Bodily injuries

Danger of trauma: The attraction force is so great that it can result in blood blisters, pinching, and broken bones. Use thick gloves.

Electronic devices

Equipment safety: Strong magnets can ruin data carriers and sensitive devices (pacemakers, hearing aids, timepieces).

This is not a toy

Absolutely keep magnets out of reach of children. Choking hazard is high, and the consequences of magnets clamping inside the body are very dangerous.

Phone sensors

An intense magnetic field negatively affects the functioning of compasses in smartphones and navigation systems. Do not bring magnets close to a smartphone to prevent damaging the sensors.

Conscious usage

Exercise caution. Neodymium magnets act from a long distance and connect with massive power, often quicker than you can react.

Nickel coating and allergies

Allergy Notice: The nickel-copper-nickel coating contains nickel. If an allergic reaction occurs, immediately stop working with magnets and use protective gear.

Machining danger

Dust produced during machining of magnets is combustible. Avoid drilling into magnets unless you are an expert.

Risk of cracking

Beware of splinters. Magnets can fracture upon uncontrolled impact, ejecting sharp fragments into the air. We recommend safety glasses.

Warning for heart patients

Health Alert: Strong magnets can turn off heart devices and defibrillators. Do not approach if you have electronic implants.

Do not overheat magnets

Do not overheat. NdFeB magnets are sensitive to heat. If you need resistance above 80°C, ask us about special high-temperature series (H, SH, UH).

![SM 25x125 [2xM8] / N42 - magnetic separator SM 25x125 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x125-2xm8-duj.jpg)

![SM 32x375 [2xM8] / N52 - magnetic separator SM 32x375 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x375-2xm8-mif.jpg)

![MPL 40x15x5x2[7/3.5] / N38 - lamellar magnet MPL 40x15x5x2[7/3.5] / N38 - lamellar magnet](https://cdn3.dhit.pl/graphics/products/mpl-40x15x5x27-3.5-cas.jpg)