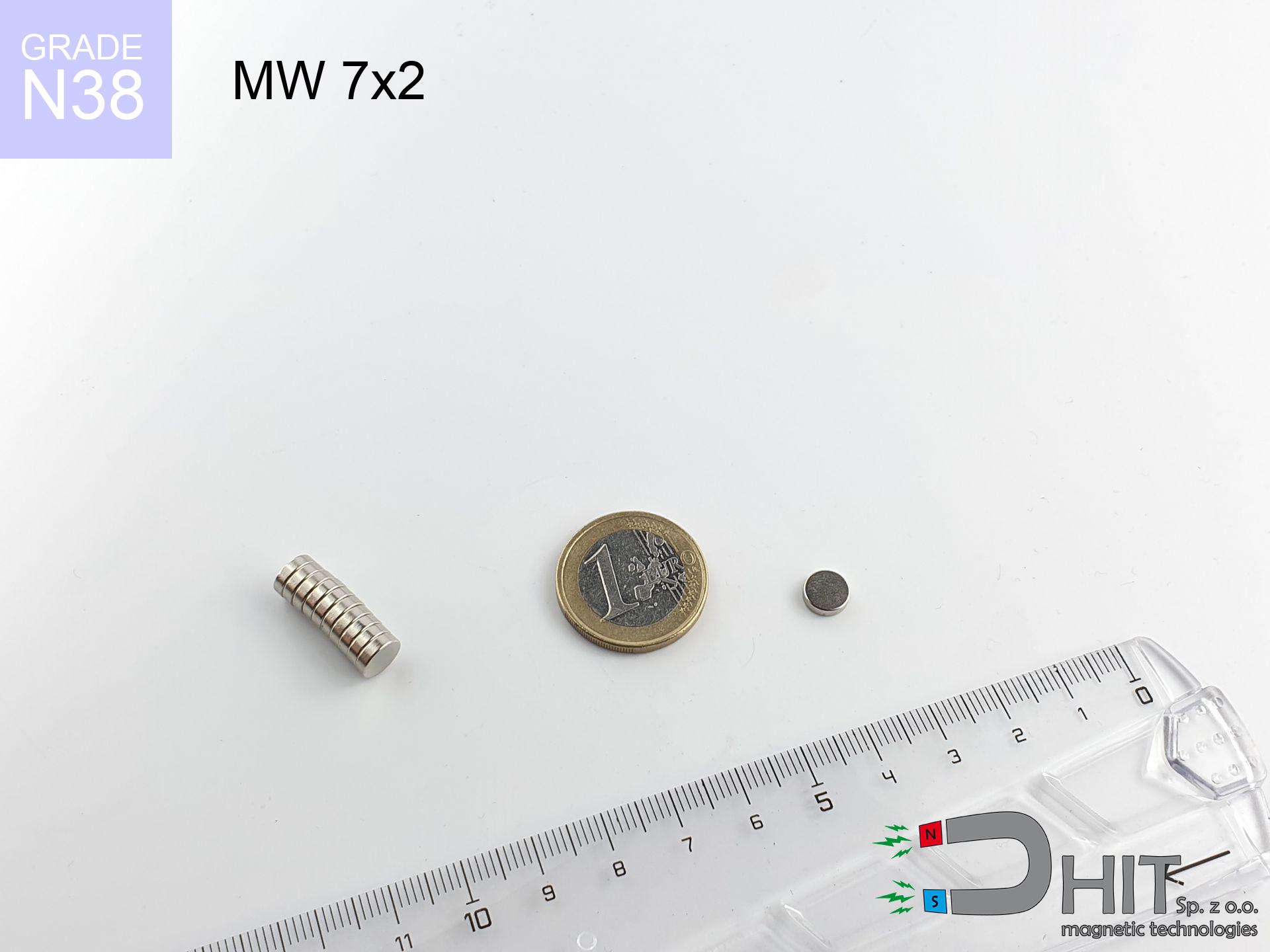

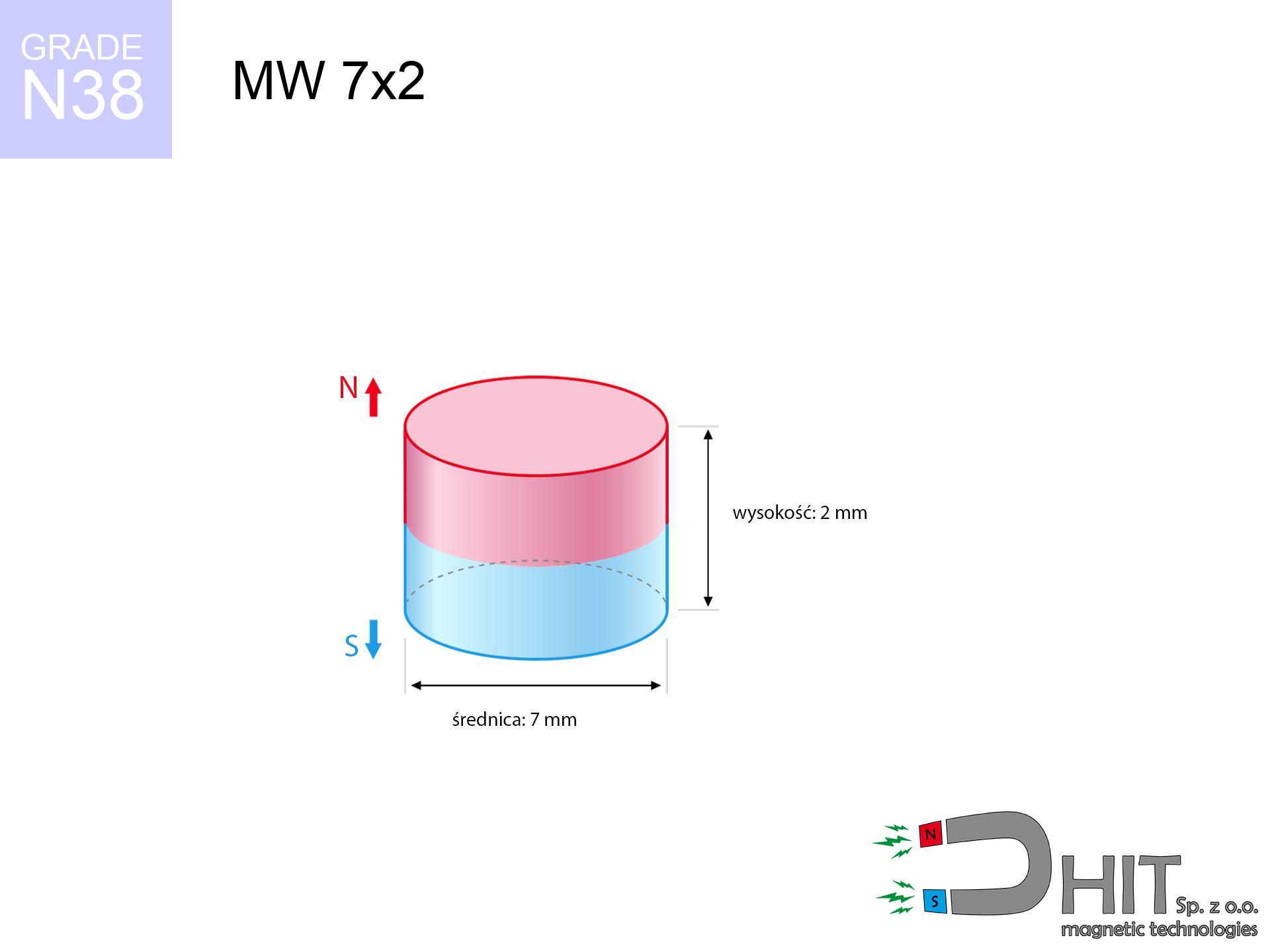

MW 7x2 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010099

GTIN/EAN: 5906301810988

Diameter Ø

7 mm [±0,1 mm]

Height

2 mm [±0,1 mm]

Weight

0.58 g

Magnetization Direction

↑ axial

Load capacity

0.99 kg / 9.76 N

Magnetic Induction

307.23 mT / 3072 Gs

Coating

[NiCuNi] Nickel

0.381 ZŁ with VAT / pcs + price for transport

0.310 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 888 99 98 98

alternatively let us know by means of

our online form

the contact page.

Weight as well as form of a magnet can be estimated using our

force calculator.

Same-day processing for orders placed before 14:00.

Technical - MW 7x2 / N38 - cylindrical magnet

Specification / characteristics - MW 7x2 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010099 |

| GTIN/EAN | 5906301810988 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 7 mm [±0,1 mm] |

| Height | 2 mm [±0,1 mm] |

| Weight | 0.58 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.99 kg / 9.76 N |

| Magnetic Induction ~ ? | 307.23 mT / 3072 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the magnet - technical parameters

Presented values are the result of a engineering calculation. Results were calculated on algorithms for the class Nd2Fe14B. Actual parameters might slightly differ from theoretical values. Treat these calculations as a preliminary roadmap during assembly planning.

Table 1: Static force (pull vs distance) - power drop

MW 7x2 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3070 Gs

307.0 mT

|

0.99 kg / 2.18 lbs

990.0 g / 9.7 N

|

weak grip |

| 1 mm |

2332 Gs

233.2 mT

|

0.57 kg / 1.26 lbs

571.1 g / 5.6 N

|

weak grip |

| 2 mm |

1590 Gs

159.0 mT

|

0.27 kg / 0.59 lbs

265.5 g / 2.6 N

|

weak grip |

| 3 mm |

1044 Gs

104.4 mT

|

0.11 kg / 0.25 lbs

114.6 g / 1.1 N

|

weak grip |

| 5 mm |

466 Gs

46.6 mT

|

0.02 kg / 0.05 lbs

22.8 g / 0.2 N

|

weak grip |

| 10 mm |

100 Gs

10.0 mT

|

0.00 kg / 0.00 lbs

1.1 g / 0.0 N

|

weak grip |

| 15 mm |

35 Gs

3.5 mT

|

0.00 kg / 0.00 lbs

0.1 g / 0.0 N

|

weak grip |

| 20 mm |

16 Gs

1.6 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

| 30 mm |

5 Gs

0.5 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

weak grip |

Table 2: Sliding hold (vertical surface)

MW 7x2 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.20 kg / 0.44 lbs

198.0 g / 1.9 N

|

| 1 mm | Stal (~0.2) |

0.11 kg / 0.25 lbs

114.0 g / 1.1 N

|

| 2 mm | Stal (~0.2) |

0.05 kg / 0.12 lbs

54.0 g / 0.5 N

|

| 3 mm | Stal (~0.2) |

0.02 kg / 0.05 lbs

22.0 g / 0.2 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.01 lbs

4.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 7x2 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.30 kg / 0.65 lbs

297.0 g / 2.9 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.20 kg / 0.44 lbs

198.0 g / 1.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.10 kg / 0.22 lbs

99.0 g / 1.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.50 kg / 1.09 lbs

495.0 g / 4.9 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 7x2 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.10 kg / 0.22 lbs

99.0 g / 1.0 N

|

| 1 mm |

|

0.25 kg / 0.55 lbs

247.5 g / 2.4 N

|

| 2 mm |

|

0.50 kg / 1.09 lbs

495.0 g / 4.9 N

|

| 3 mm |

|

0.74 kg / 1.64 lbs

742.5 g / 7.3 N

|

| 5 mm |

|

0.99 kg / 2.18 lbs

990.0 g / 9.7 N

|

| 10 mm |

|

0.99 kg / 2.18 lbs

990.0 g / 9.7 N

|

| 11 mm |

|

0.99 kg / 2.18 lbs

990.0 g / 9.7 N

|

| 12 mm |

|

0.99 kg / 2.18 lbs

990.0 g / 9.7 N

|

Table 5: Thermal stability (stability) - thermal limit

MW 7x2 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.99 kg / 2.18 lbs

990.0 g / 9.7 N

|

OK |

| 40 °C | -2.2% |

0.97 kg / 2.13 lbs

968.2 g / 9.5 N

|

OK |

| 60 °C | -4.4% |

0.95 kg / 2.09 lbs

946.4 g / 9.3 N

|

|

| 80 °C | -6.6% |

0.92 kg / 2.04 lbs

924.7 g / 9.1 N

|

|

| 100 °C | -28.8% |

0.70 kg / 1.55 lbs

704.9 g / 6.9 N

|

Table 6: Two magnets (repulsion) - field collision

MW 7x2 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

2.24 kg / 4.93 lbs

4 653 Gs

|

0.34 kg / 0.74 lbs

335 g / 3.3 N

|

N/A |

| 1 mm |

1.76 kg / 3.89 lbs

5 454 Gs

|

0.26 kg / 0.58 lbs

265 g / 2.6 N

|

1.59 kg / 3.50 lbs

~0 Gs

|

| 2 mm |

1.29 kg / 2.84 lbs

4 663 Gs

|

0.19 kg / 0.43 lbs

193 g / 1.9 N

|

1.16 kg / 2.56 lbs

~0 Gs

|

| 3 mm |

0.89 kg / 1.97 lbs

3 884 Gs

|

0.13 kg / 0.30 lbs

134 g / 1.3 N

|

0.81 kg / 1.77 lbs

~0 Gs

|

| 5 mm |

0.40 kg / 0.87 lbs

2 581 Gs

|

0.06 kg / 0.13 lbs

59 g / 0.6 N

|

0.36 kg / 0.78 lbs

~0 Gs

|

| 10 mm |

0.05 kg / 0.11 lbs

932 Gs

|

0.01 kg / 0.02 lbs

8 g / 0.1 N

|

0.05 kg / 0.10 lbs

~0 Gs

|

| 20 mm |

0.00 kg / 0.01 lbs

200 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 lbs

17 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 lbs

10 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 lbs

6 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 lbs

4 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 lbs

3 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 lbs

2 Gs

|

0.00 kg / 0.00 lbs

0 g / 0.0 N

|

0.00 kg / 0.00 lbs

~0 Gs

|

Table 7: Protective zones (implants) - precautionary measures

MW 7x2 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 2.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (kinetic energy) - warning

MW 7x2 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

41.69 km/h

(11.58 m/s)

|

0.04 J | |

| 30 mm |

72.17 km/h

(20.05 m/s)

|

0.12 J | |

| 50 mm |

93.17 km/h

(25.88 m/s)

|

0.19 J | |

| 100 mm |

131.76 km/h

(36.60 m/s)

|

0.39 J |

Table 9: Surface protection spec

MW 7x2 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 7x2 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 284 Mx | 12.8 µWb |

| Pc Coefficient | 0.39 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MW 7x2 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.99 kg | Standard |

| Water (riverbed) |

1.13 kg

(+0.14 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Caution: On a vertical wall, the magnet holds just ~20% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) severely limits the holding force.

3. Power loss vs temp

*For N38 grade, the max working temp is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.39

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also offers

Pros as well as cons of Nd2Fe14B magnets.

Advantages

- Their magnetic field remains stable, and after around 10 years it decreases only by ~1% (according to research),

- They have excellent resistance to magnetic field loss as a result of external magnetic sources,

- A magnet with a shiny nickel surface has better aesthetics,

- Magnetic induction on the top side of the magnet is impressive,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Considering the option of flexible forming and customization to individualized needs, NdFeB magnets can be modeled in a broad palette of forms and dimensions, which increases their versatility,

- Huge importance in modern technologies – they serve a role in HDD drives, electric drive systems, advanced medical instruments, and technologically advanced constructions.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Cons

- To avoid cracks under impact, we suggest using special steel holders. Such a solution secures the magnet and simultaneously increases its durability.

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of strength (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- They rust in a humid environment. For use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Due to limitations in realizing threads and complex forms in magnets, we recommend using casing - magnetic mechanism.

- Possible danger resulting from small fragments of magnets can be dangerous, in case of ingestion, which gains importance in the aspect of protecting the youngest. Additionally, small components of these magnets are able to disrupt the diagnostic process medical when they are in the body.

- With mass production the cost of neodymium magnets is economically unviable,

Holding force characteristics

Maximum holding power of the magnet – what it depends on?

- with the application of a yoke made of special test steel, guaranteeing maximum field concentration

- whose transverse dimension is min. 10 mm

- with a surface perfectly flat

- under conditions of ideal adhesion (surface-to-surface)

- under perpendicular application of breakaway force (90-degree angle)

- in temp. approx. 20°C

Lifting capacity in practice – influencing factors

- Air gap (between the magnet and the metal), as even a very small clearance (e.g. 0.5 mm) results in a drastic drop in lifting capacity by up to 50% (this also applies to paint, corrosion or dirt).

- Force direction – catalog parameter refers to detachment vertically. When attempting to slide, the magnet exhibits much less (often approx. 20-30% of maximum force).

- Metal thickness – thin material does not allow full use of the magnet. Part of the magnetic field passes through the material instead of generating force.

- Plate material – low-carbon steel gives the best results. Higher carbon content decrease magnetic properties and lifting capacity.

- Plate texture – ground elements guarantee perfect abutment, which improves field saturation. Rough surfaces reduce efficiency.

- Thermal conditions – neodymium magnets have a negative temperature coefficient. When it is hot they lose power, and at low temperatures they can be stronger (up to a certain limit).

Lifting capacity was measured by applying a smooth steel plate of suitable thickness (min. 20 mm), under vertically applied force, whereas under attempts to slide the magnet the lifting capacity is smaller. Moreover, even a small distance between the magnet and the plate lowers the load capacity.

Warnings

Medical implants

Warning for patients: Strong magnetic fields disrupt electronics. Keep minimum 30 cm distance or ask another person to work with the magnets.

Safe operation

Be careful. Rare earth magnets attract from a long distance and connect with massive power, often faster than you can move away.

Heat warning

Standard neodymium magnets (N-type) lose magnetization when the temperature exceeds 80°C. The loss of strength is permanent.

Metal Allergy

Nickel alert: The Ni-Cu-Ni coating consists of nickel. If redness occurs, immediately stop handling magnets and wear gloves.

Bone fractures

Watch your fingers. Two large magnets will join instantly with a force of several hundred kilograms, crushing everything in their path. Be careful!

Keep away from electronics

A powerful magnetic field negatively affects the functioning of compasses in phones and navigation systems. Maintain magnets near a smartphone to prevent breaking the sensors.

Product not for children

Absolutely store magnets away from children. Ingestion danger is high, and the effects of magnets clamping inside the body are very dangerous.

Dust is flammable

Fire hazard: Rare earth powder is explosive. Avoid machining magnets in home conditions as this risks ignition.

Protective goggles

Despite metallic appearance, the material is delicate and cannot withstand shocks. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Safe distance

Very strong magnetic fields can destroy records on credit cards, HDDs, and storage devices. Keep a distance of min. 10 cm.

![SM 18x300 [2xM5] / N42 - magnetic separator SM 18x300 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x300-2xm5-xad.jpg)