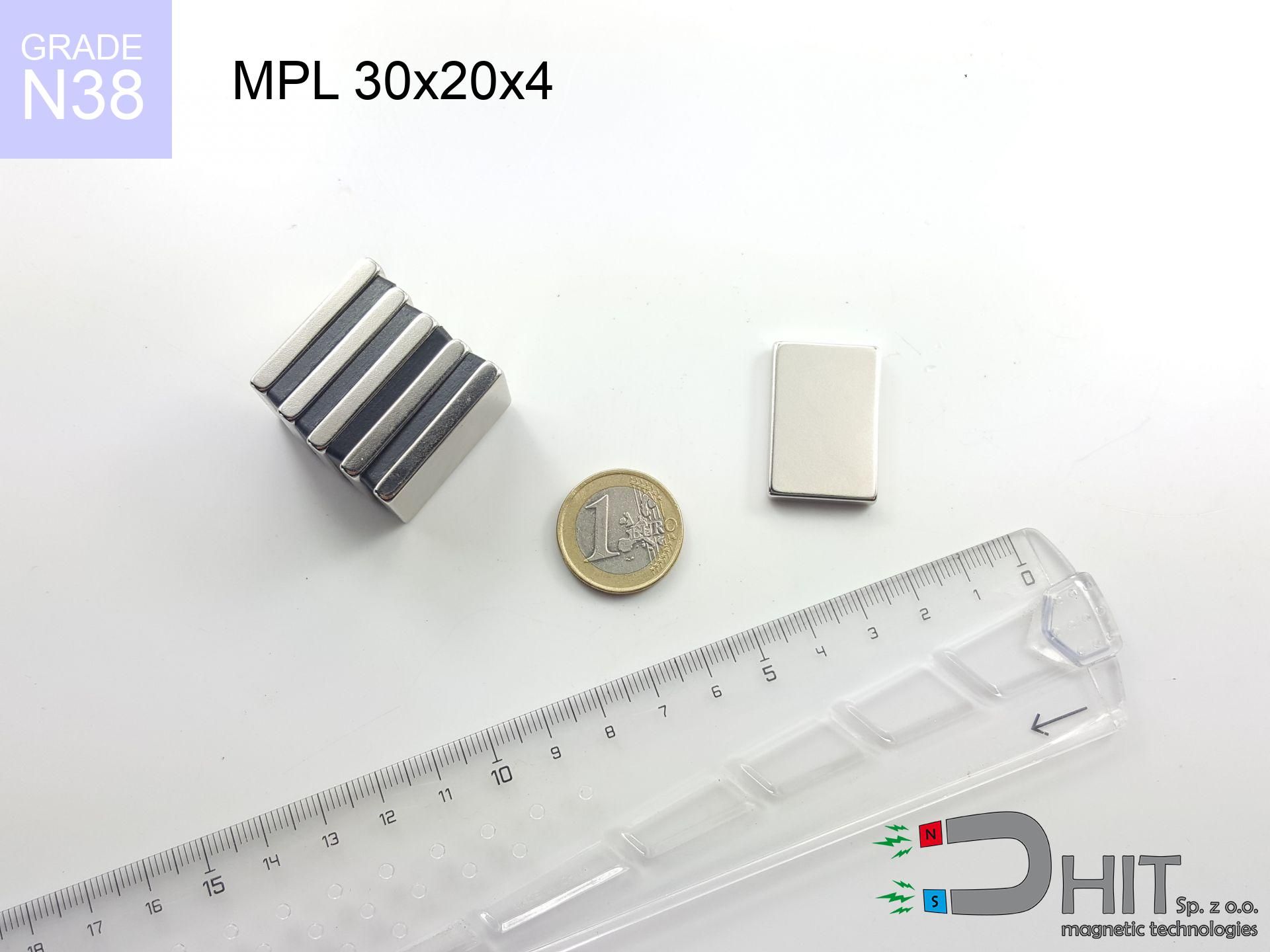

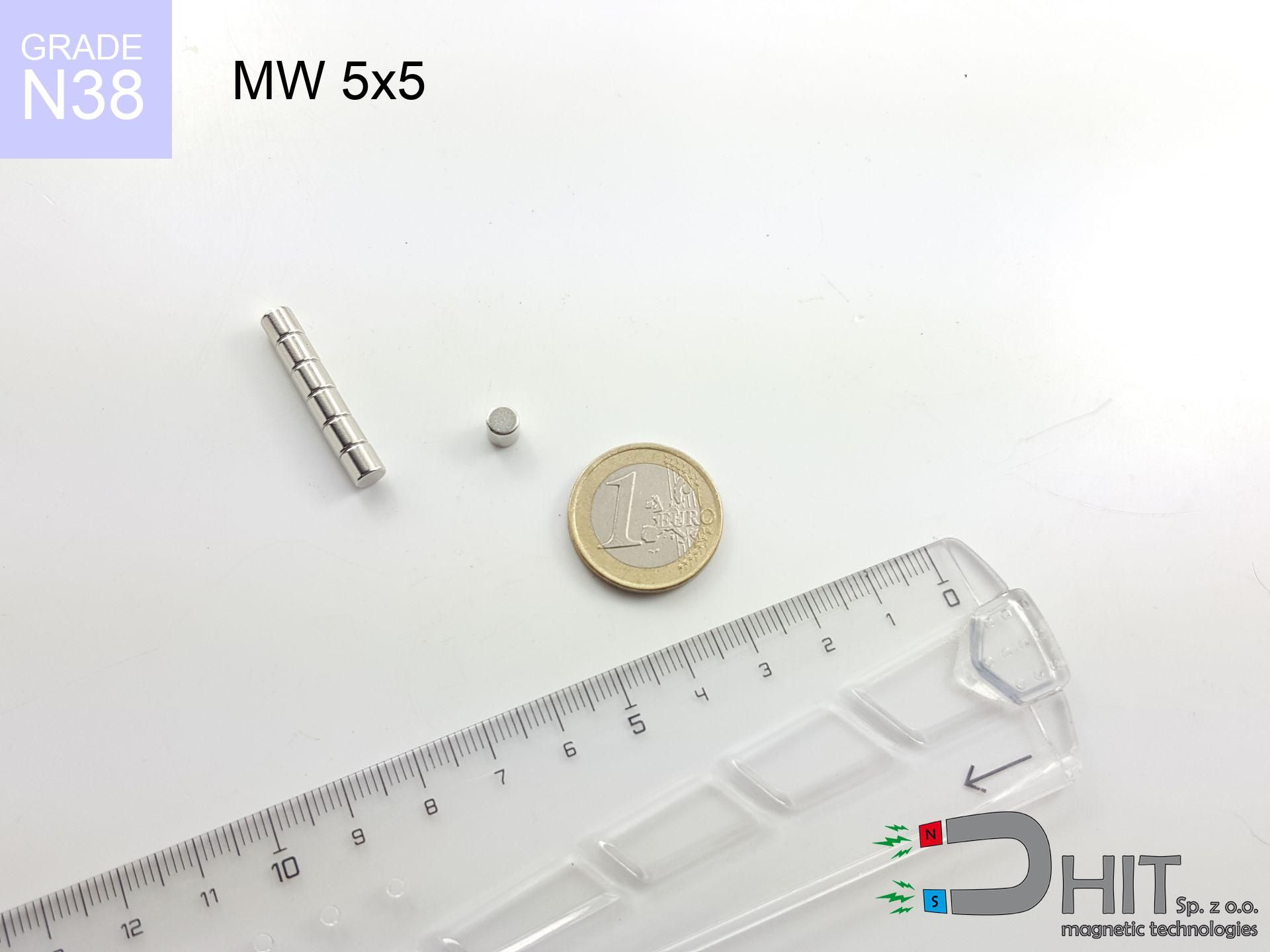

MW 5x5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010503

GTIN/EAN: 5906301814979

Diameter Ø

5 mm [±0,1 mm]

Height

5 mm [±0,1 mm]

Weight

0.74 g

Magnetization Direction

↑ axial

Load capacity

0.79 kg / 7.76 N

Magnetic Induction

553.14 mT / 5531 Gs

Coating

[NiCuNi] Nickel

0.394 ZŁ with VAT / pcs + price for transport

0.320 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer get in touch using

contact form

the contact form page.

Lifting power along with structure of magnetic components can be checked using our

our magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Technical of the product - MW 5x5 / N38 - cylindrical magnet

Specification / characteristics - MW 5x5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010503 |

| GTIN/EAN | 5906301814979 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 5 mm [±0,1 mm] |

| Height | 5 mm [±0,1 mm] |

| Weight | 0.74 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.79 kg / 7.76 N |

| Magnetic Induction ~ ? | 553.14 mT / 5531 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the assembly - data

The following information represent the outcome of a mathematical calculation. Values are based on algorithms for the class Nd2Fe14B. Real-world conditions might slightly differ. Please consider these data as a preliminary roadmap when designing systems.

Table 1: Static pull force (pull vs gap) - characteristics

MW 5x5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5523 Gs

552.3 mT

|

0.79 kg / 1.74 LBS

790.0 g / 7.7 N

|

low risk |

| 1 mm |

3420 Gs

342.0 mT

|

0.30 kg / 0.67 LBS

303.0 g / 3.0 N

|

low risk |

| 2 mm |

1966 Gs

196.6 mT

|

0.10 kg / 0.22 LBS

100.1 g / 1.0 N

|

low risk |

| 3 mm |

1155 Gs

115.5 mT

|

0.03 kg / 0.08 LBS

34.5 g / 0.3 N

|

low risk |

| 5 mm |

469 Gs

46.9 mT

|

0.01 kg / 0.01 LBS

5.7 g / 0.1 N

|

low risk |

| 10 mm |

101 Gs

10.1 mT

|

0.00 kg / 0.00 LBS

0.3 g / 0.0 N

|

low risk |

| 15 mm |

36 Gs

3.6 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 20 mm |

17 Gs

1.7 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 30 mm |

6 Gs

0.6 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 50 mm |

1 Gs

0.1 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Shear hold (wall)

MW 5x5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.16 kg / 0.35 LBS

158.0 g / 1.5 N

|

| 1 mm | Stal (~0.2) |

0.06 kg / 0.13 LBS

60.0 g / 0.6 N

|

| 2 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

20.0 g / 0.2 N

|

| 3 mm | Stal (~0.2) |

0.01 kg / 0.01 LBS

6.0 g / 0.1 N

|

| 5 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (sliding) - vertical pull

MW 5x5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.24 kg / 0.52 LBS

237.0 g / 2.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.16 kg / 0.35 LBS

158.0 g / 1.5 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.08 kg / 0.17 LBS

79.0 g / 0.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.40 kg / 0.87 LBS

395.0 g / 3.9 N

|

Table 4: Material efficiency (substrate influence) - power losses

MW 5x5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.08 kg / 0.17 LBS

79.0 g / 0.8 N

|

| 1 mm |

|

0.20 kg / 0.44 LBS

197.5 g / 1.9 N

|

| 2 mm |

|

0.40 kg / 0.87 LBS

395.0 g / 3.9 N

|

| 3 mm |

|

0.59 kg / 1.31 LBS

592.5 g / 5.8 N

|

| 5 mm |

|

0.79 kg / 1.74 LBS

790.0 g / 7.7 N

|

| 10 mm |

|

0.79 kg / 1.74 LBS

790.0 g / 7.7 N

|

| 11 mm |

|

0.79 kg / 1.74 LBS

790.0 g / 7.7 N

|

| 12 mm |

|

0.79 kg / 1.74 LBS

790.0 g / 7.7 N

|

Table 5: Thermal resistance (material behavior) - power drop

MW 5x5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.79 kg / 1.74 LBS

790.0 g / 7.7 N

|

OK |

| 40 °C | -2.2% |

0.77 kg / 1.70 LBS

772.6 g / 7.6 N

|

OK |

| 60 °C | -4.4% |

0.76 kg / 1.67 LBS

755.2 g / 7.4 N

|

OK |

| 80 °C | -6.6% |

0.74 kg / 1.63 LBS

737.9 g / 7.2 N

|

|

| 100 °C | -28.8% |

0.56 kg / 1.24 LBS

562.5 g / 5.5 N

|

Table 6: Two magnets (repulsion) - field collision

MW 5x5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

3.69 kg / 8.14 LBS

5 990 Gs

|

0.55 kg / 1.22 LBS

554 g / 5.4 N

|

N/A |

| 1 mm |

2.37 kg / 5.23 LBS

8 857 Gs

|

0.36 kg / 0.79 LBS

356 g / 3.5 N

|

2.14 kg / 4.71 LBS

~0 Gs

|

| 2 mm |

1.42 kg / 3.12 LBS

6 841 Gs

|

0.21 kg / 0.47 LBS

212 g / 2.1 N

|

1.27 kg / 2.81 LBS

~0 Gs

|

| 3 mm |

0.82 kg / 1.80 LBS

5 194 Gs

|

0.12 kg / 0.27 LBS

122 g / 1.2 N

|

0.73 kg / 1.62 LBS

~0 Gs

|

| 5 mm |

0.27 kg / 0.60 LBS

2 996 Gs

|

0.04 kg / 0.09 LBS

41 g / 0.4 N

|

0.24 kg / 0.54 LBS

~0 Gs

|

| 10 mm |

0.03 kg / 0.06 LBS

939 Gs

|

0.00 kg / 0.01 LBS

4 g / 0.0 N

|

0.02 kg / 0.05 LBS

~0 Gs

|

| 20 mm |

0.00 kg / 0.00 LBS

202 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

19 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

11 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

7 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

5 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

4 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

3 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 5x5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 3.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 2.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 2.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 1.5 cm |

| Car key | 50 Gs (5.0 mT) | 1.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 0.5 cm |

Table 8: Collisions (cracking risk) - warning

MW 5x5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

32.96 km/h

(9.16 m/s)

|

0.03 J | |

| 30 mm |

57.07 km/h

(15.85 m/s)

|

0.09 J | |

| 50 mm |

73.68 km/h

(20.47 m/s)

|

0.15 J | |

| 100 mm |

104.20 km/h

(28.95 m/s)

|

0.31 J |

Table 9: Surface protection spec

MW 5x5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 5x5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 1 120 Mx | 11.2 µWb |

| Pc Coefficient | 0.89 | High (Stable) |

Table 11: Underwater work (magnet fishing)

MW 5x5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.79 kg | Standard |

| Water (riverbed) |

0.90 kg

(+0.11 kg buoyancy gain)

|

+14.5% |

1. Shear force

*Warning: On a vertical wall, the magnet holds just a fraction of its nominal pull.

2. Steel thickness impact

*Thin metal sheet (e.g. computer case) drastically reduces the holding force.

3. Thermal stability

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.89

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See also proposals

Pros and cons of neodymium magnets.

Pros

- They do not lose strength, even after around ten years – the drop in power is only ~1% (according to tests),

- They are noted for resistance to demagnetization induced by presence of other magnetic fields,

- A magnet with a metallic silver surface looks better,

- They show high magnetic induction at the operating surface, making them more effective,

- Thanks to resistance to high temperature, they can operate (depending on the form) even at temperatures up to 230°C and higher...

- Thanks to freedom in constructing and the capacity to customize to client solutions,

- Wide application in future technologies – they are commonly used in data components, electric drive systems, diagnostic systems, also complex engineering applications.

- Thanks to efficiency per cm³, small magnets offer high operating force, occupying minimum space,

Cons

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can break. We advise keeping them in a special holder, which not only protects them against impacts but also raises their durability

- Neodymium magnets decrease their strength under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material immune to moisture, when using outdoors

- We suggest a housing - magnetic mount, due to difficulties in realizing threads inside the magnet and complex shapes.

- Health risk related to microscopic parts of magnets can be dangerous, in case of ingestion, which gains importance in the context of child health protection. It is also worth noting that tiny parts of these magnets can complicate diagnosis medical in case of swallowing.

- Due to expensive raw materials, their price is relatively high,

Lifting parameters

Maximum lifting force for a neodymium magnet – what affects it?

- with the use of a sheet made of low-carbon steel, ensuring maximum field concentration

- possessing a thickness of min. 10 mm to avoid saturation

- characterized by even structure

- with total lack of distance (without paint)

- for force applied at a right angle (in the magnet axis)

- at room temperature

What influences lifting capacity in practice

- Gap between surfaces – every millimeter of separation (caused e.g. by varnish or unevenness) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Angle of force application – maximum parameter is obtained only during perpendicular pulling. The force required to slide of the magnet along the surface is typically several times lower (approx. 1/5 of the lifting capacity).

- Steel thickness – too thin plate does not accept the full field, causing part of the power to be lost into the air.

- Chemical composition of the base – low-carbon steel gives the best results. Alloy steels reduce magnetic permeability and holding force.

- Base smoothness – the more even the surface, the larger the contact zone and stronger the hold. Unevenness creates an air distance.

- Thermal factor – high temperature reduces pulling force. Too high temperature can permanently demagnetize the magnet.

Holding force was measured on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, however under parallel forces the lifting capacity is smaller. Additionally, even a small distance between the magnet and the plate reduces the load capacity.

Safety rules for work with neodymium magnets

Power loss in heat

Keep cool. NdFeB magnets are susceptible to heat. If you need operation above 80°C, inquire about special high-temperature series (H, SH, UH).

Magnets are brittle

Protect your eyes. Magnets can fracture upon violent connection, ejecting shards into the air. Eye protection is mandatory.

Handling rules

Use magnets consciously. Their huge power can surprise even professionals. Be vigilant and do not underestimate their force.

Dust explosion hazard

Mechanical processing of NdFeB material poses a fire risk. Magnetic powder reacts violently with oxygen and is hard to extinguish.

Bodily injuries

Danger of trauma: The pulling power is so great that it can cause blood blisters, pinching, and broken bones. Use thick gloves.

Electronic devices

Avoid bringing magnets close to a purse, laptop, or TV. The magnetic field can permanently damage these devices and wipe information from cards.

GPS Danger

An intense magnetic field interferes with the operation of magnetometers in phones and navigation systems. Keep magnets near a device to avoid breaking the sensors.

Allergy Warning

Warning for allergy sufferers: The Ni-Cu-Ni coating contains nickel. If skin irritation happens, cease handling magnets and use protective gear.

Adults only

Always store magnets out of reach of children. Choking hazard is significant, and the consequences of magnets connecting inside the body are tragic.

Pacemakers

Medical warning: Neodymium magnets can turn off heart devices and defibrillators. Stay away if you have electronic implants.

![UMH 60x15x69 [M8] / N38 - magnetic holder with hook UMH 60x15x69 [M8] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-60x15x69-m8-nij.jpg)

![SM 32x175 [2xM8] / N42 - magnetic separator SM 32x175 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x175-2xm8-tej.jpg)