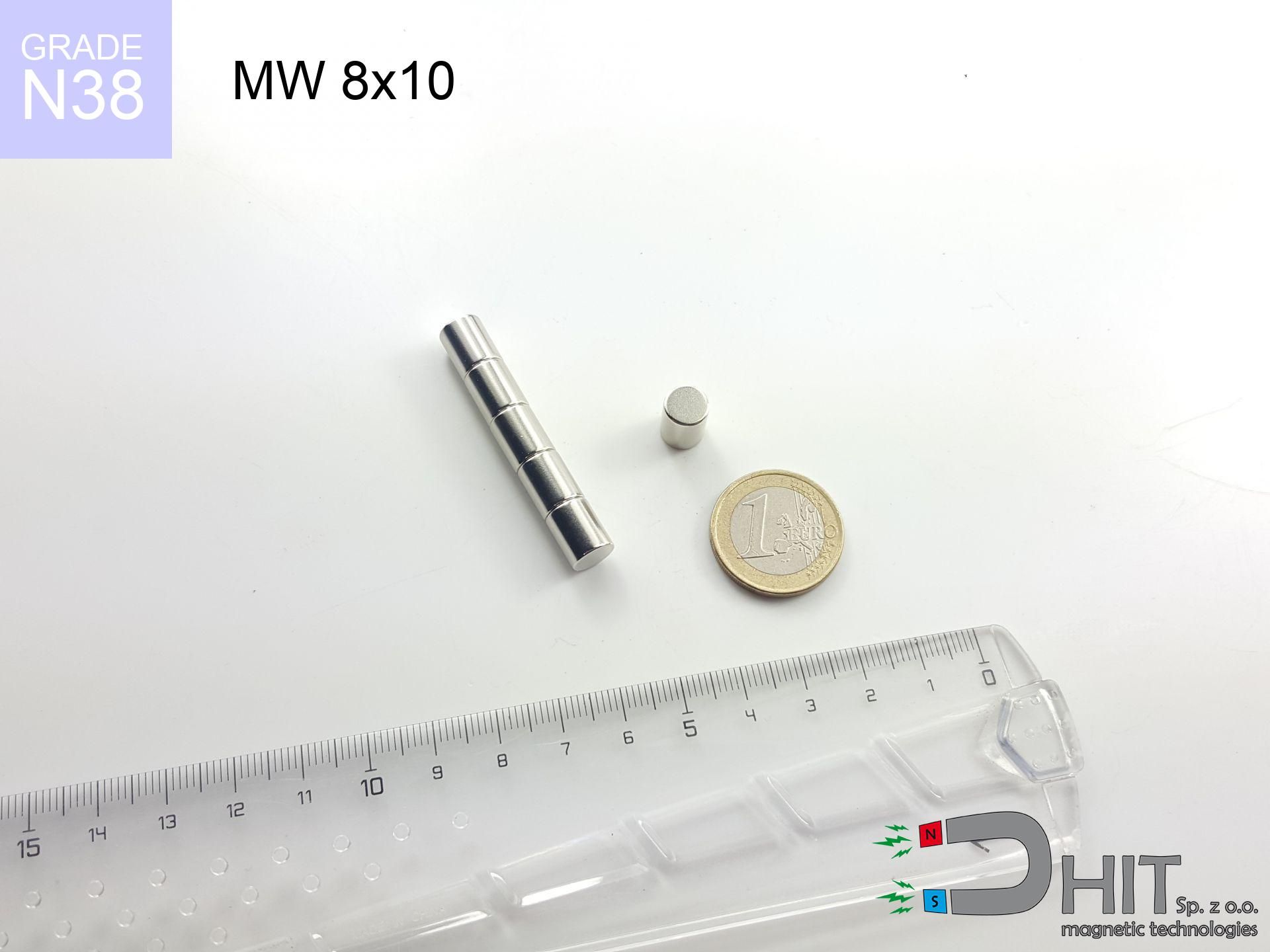

MW 8x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010504

GTIN/EAN: 5906301814993

Diameter Ø

8 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

3.77 g

Magnetization Direction

↑ axial

Load capacity

1.84 kg / 18.00 N

Magnetic Induction

574.74 mT / 5747 Gs

Coating

[NiCuNi] Nickel

1.501 ZŁ with VAT / pcs + price for transport

1.220 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

otherwise contact us by means of

inquiry form

our website.

Parameters along with appearance of magnetic components can be reviewed using our

magnetic calculator.

Orders submitted before 14:00 will be dispatched today!

Detailed specification - MW 8x10 / N38 - cylindrical magnet

Specification / characteristics - MW 8x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010504 |

| GTIN/EAN | 5906301814993 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 8 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 3.77 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 1.84 kg / 18.00 N |

| Magnetic Induction ~ ? | 574.74 mT / 5747 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical analysis of the magnet - technical parameters

Presented values are the result of a physical simulation. Values are based on models for the class Nd2Fe14B. Actual performance may differ from theoretical values. Use these data as a reference point when designing systems.

Table 1: Static force (force vs distance) - interaction chart

MW 8x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5742 Gs

574.2 mT

|

1.84 kg / 4.06 LBS

1840.0 g / 18.1 N

|

low risk |

| 1 mm |

4323 Gs

432.3 mT

|

1.04 kg / 2.30 LBS

1043.0 g / 10.2 N

|

low risk |

| 2 mm |

3109 Gs

310.9 mT

|

0.54 kg / 1.19 LBS

539.5 g / 5.3 N

|

low risk |

| 3 mm |

2206 Gs

220.6 mT

|

0.27 kg / 0.60 LBS

271.6 g / 2.7 N

|

low risk |

| 5 mm |

1149 Gs

114.9 mT

|

0.07 kg / 0.16 LBS

73.7 g / 0.7 N

|

low risk |

| 10 mm |

323 Gs

32.3 mT

|

0.01 kg / 0.01 LBS

5.8 g / 0.1 N

|

low risk |

| 15 mm |

131 Gs

13.1 mT

|

0.00 kg / 0.00 LBS

1.0 g / 0.0 N

|

low risk |

| 20 mm |

66 Gs

6.6 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

low risk |

| 30 mm |

24 Gs

2.4 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

| 50 mm |

6 Gs

0.6 mT

|

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

low risk |

Table 2: Sliding force (wall)

MW 8x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.37 kg / 0.81 LBS

368.0 g / 3.6 N

|

| 1 mm | Stal (~0.2) |

0.21 kg / 0.46 LBS

208.0 g / 2.0 N

|

| 2 mm | Stal (~0.2) |

0.11 kg / 0.24 LBS

108.0 g / 1.1 N

|

| 3 mm | Stal (~0.2) |

0.05 kg / 0.12 LBS

54.0 g / 0.5 N

|

| 5 mm | Stal (~0.2) |

0.01 kg / 0.03 LBS

14.0 g / 0.1 N

|

| 10 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

2.0 g / 0.0 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 8x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.55 kg / 1.22 LBS

552.0 g / 5.4 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.37 kg / 0.81 LBS

368.0 g / 3.6 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.18 kg / 0.41 LBS

184.0 g / 1.8 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.92 kg / 2.03 LBS

920.0 g / 9.0 N

|

Table 4: Steel thickness (substrate influence) - power losses

MW 8x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.18 kg / 0.41 LBS

184.0 g / 1.8 N

|

| 1 mm |

|

0.46 kg / 1.01 LBS

460.0 g / 4.5 N

|

| 2 mm |

|

0.92 kg / 2.03 LBS

920.0 g / 9.0 N

|

| 3 mm |

|

1.38 kg / 3.04 LBS

1380.0 g / 13.5 N

|

| 5 mm |

|

1.84 kg / 4.06 LBS

1840.0 g / 18.1 N

|

| 10 mm |

|

1.84 kg / 4.06 LBS

1840.0 g / 18.1 N

|

| 11 mm |

|

1.84 kg / 4.06 LBS

1840.0 g / 18.1 N

|

| 12 mm |

|

1.84 kg / 4.06 LBS

1840.0 g / 18.1 N

|

Table 5: Working in heat (material behavior) - power drop

MW 8x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

1.84 kg / 4.06 LBS

1840.0 g / 18.1 N

|

OK |

| 40 °C | -2.2% |

1.80 kg / 3.97 LBS

1799.5 g / 17.7 N

|

OK |

| 60 °C | -4.4% |

1.76 kg / 3.88 LBS

1759.0 g / 17.3 N

|

OK |

| 80 °C | -6.6% |

1.72 kg / 3.79 LBS

1718.6 g / 16.9 N

|

|

| 100 °C | -28.8% |

1.31 kg / 2.89 LBS

1310.1 g / 12.9 N

|

Table 6: Two magnets (attraction) - field range

MW 8x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

10.22 kg / 22.52 LBS

6 064 Gs

|

1.53 kg / 3.38 LBS

1532 g / 15.0 N

|

N/A |

| 1 mm |

7.82 kg / 17.25 LBS

10 050 Gs

|

1.17 kg / 2.59 LBS

1174 g / 11.5 N

|

7.04 kg / 15.52 LBS

~0 Gs

|

| 2 mm |

5.79 kg / 12.77 LBS

8 646 Gs

|

0.87 kg / 1.92 LBS

869 g / 8.5 N

|

5.21 kg / 11.49 LBS

~0 Gs

|

| 3 mm |

4.19 kg / 9.25 LBS

7 358 Gs

|

0.63 kg / 1.39 LBS

629 g / 6.2 N

|

3.77 kg / 8.32 LBS

~0 Gs

|

| 5 mm |

2.13 kg / 4.69 LBS

5 238 Gs

|

0.32 kg / 0.70 LBS

319 g / 3.1 N

|

1.91 kg / 4.22 LBS

~0 Gs

|

| 10 mm |

0.41 kg / 0.90 LBS

2 299 Gs

|

0.06 kg / 0.14 LBS

61 g / 0.6 N

|

0.37 kg / 0.81 LBS

~0 Gs

|

| 20 mm |

0.03 kg / 0.07 LBS

646 Gs

|

0.00 kg / 0.01 LBS

5 g / 0.0 N

|

0.03 kg / 0.06 LBS

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 LBS

76 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 LBS

47 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 LBS

31 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

22 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

16 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

12 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 8x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Car key | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Collisions (cracking risk) - collision effects

MW 8x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.32 km/h

(6.20 m/s)

|

0.07 J | |

| 30 mm |

38.59 km/h

(10.72 m/s)

|

0.22 J | |

| 50 mm |

49.82 km/h

(13.84 m/s)

|

0.36 J | |

| 100 mm |

70.46 km/h

(19.57 m/s)

|

0.72 J |

Table 9: Corrosion resistance

MW 8x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Flux)

MW 8x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 040 Mx | 30.4 µWb |

| Pc Coefficient | 1.00 | High (Stable) |

Table 11: Submerged application

MW 8x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 1.84 kg | Standard |

| Water (riverbed) |

2.11 kg

(+0.27 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Note: On a vertical wall, the magnet retains merely ~20% of its max power.

2. Efficiency vs thickness

*Thin steel (e.g. computer case) significantly limits the holding force.

3. Heat tolerance

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 1.00

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Advantages and disadvantages of Nd2Fe14B magnets.

Strengths

- They virtually do not lose strength, because even after ten years the decline in efficiency is only ~1% (according to literature),

- They show high resistance to demagnetization induced by external field influence,

- A magnet with a smooth gold surface has an effective appearance,

- Magnets are distinguished by huge magnetic induction on the active area,

- Thanks to resistance to high temperature, they are able to function (depending on the shape) even at temperatures up to 230°C and higher...

- Thanks to the potential of flexible molding and customization to custom needs, magnetic components can be modeled in a variety of geometric configurations, which makes them more universal,

- Versatile presence in advanced technology sectors – they find application in mass storage devices, electric drive systems, medical devices, also other advanced devices.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Cons

- To avoid cracks under impact, we suggest using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- They rust in a humid environment - during use outdoors we suggest using waterproof magnets e.g. in rubber, plastic

- Due to limitations in producing threads and complex forms in magnets, we recommend using a housing - magnetic holder.

- Potential hazard related to microscopic parts of magnets are risky, if swallowed, which is particularly important in the aspect of protecting the youngest. Additionally, small components of these products can be problematic in diagnostics medical in case of swallowing.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Lifting parameters

Maximum lifting force for a neodymium magnet – what affects it?

- using a sheet made of mild steel, acting as a magnetic yoke

- with a thickness no less than 10 mm

- with an ideally smooth contact surface

- under conditions of ideal adhesion (surface-to-surface)

- during pulling in a direction vertical to the plane

- at ambient temperature approx. 20 degrees Celsius

Impact of factors on magnetic holding capacity in practice

- Clearance – existence of foreign body (paint, dirt, gap) acts as an insulator, which lowers capacity steeply (even by 50% at 0.5 mm).

- Force direction – catalog parameter refers to pulling vertically. When applying parallel force, the magnet holds much less (often approx. 20-30% of maximum force).

- Wall thickness – the thinner the sheet, the weaker the hold. Magnetic flux passes through the material instead of generating force.

- Steel type – low-carbon steel attracts best. Higher carbon content reduce magnetic properties and lifting capacity.

- Surface finish – ideal contact is obtained only on smooth steel. Rough texture create air cushions, weakening the magnet.

- Temperature – temperature increase results in weakening of force. Check the maximum operating temperature for a given model.

Holding force was tested on a smooth steel plate of 20 mm thickness, when a perpendicular force was applied, whereas under attempts to slide the magnet the holding force is lower. In addition, even a minimal clearance between the magnet’s surface and the plate lowers the holding force.

Warnings

Warning for heart patients

Warning for patients: Strong magnetic fields affect electronics. Maintain minimum 30 cm distance or ask another person to work with the magnets.

Adults only

Neodymium magnets are not toys. Eating several magnets can lead to them pinching intestinal walls, which constitutes a severe health hazard and necessitates urgent medical intervention.

Handling rules

Handle magnets with awareness. Their powerful strength can surprise even experienced users. Be vigilant and do not underestimate their power.

Threat to navigation

Be aware: neodymium magnets produce a field that confuses sensitive sensors. Maintain a safe distance from your mobile, device, and navigation systems.

Data carriers

Equipment safety: Neodymium magnets can ruin data carriers and delicate electronics (heart implants, hearing aids, timepieces).

Magnet fragility

Watch out for shards. Magnets can explode upon uncontrolled impact, launching shards into the air. Wear goggles.

Warning for allergy sufferers

Nickel alert: The Ni-Cu-Ni coating consists of nickel. If an allergic reaction appears, cease working with magnets and wear gloves.

Machining danger

Powder created during grinding of magnets is self-igniting. Avoid drilling into magnets without proper cooling and knowledge.

Thermal limits

Standard neodymium magnets (grade N) undergo demagnetization when the temperature surpasses 80°C. Damage is permanent.

Bone fractures

Pinching hazard: The attraction force is so great that it can result in blood blisters, pinching, and even bone fractures. Use thick gloves.

![UMH 60x15x69 [M8] / N38 - magnetic holder with hook UMH 60x15x69 [M8] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-60x15x69-m8-nij.jpg)