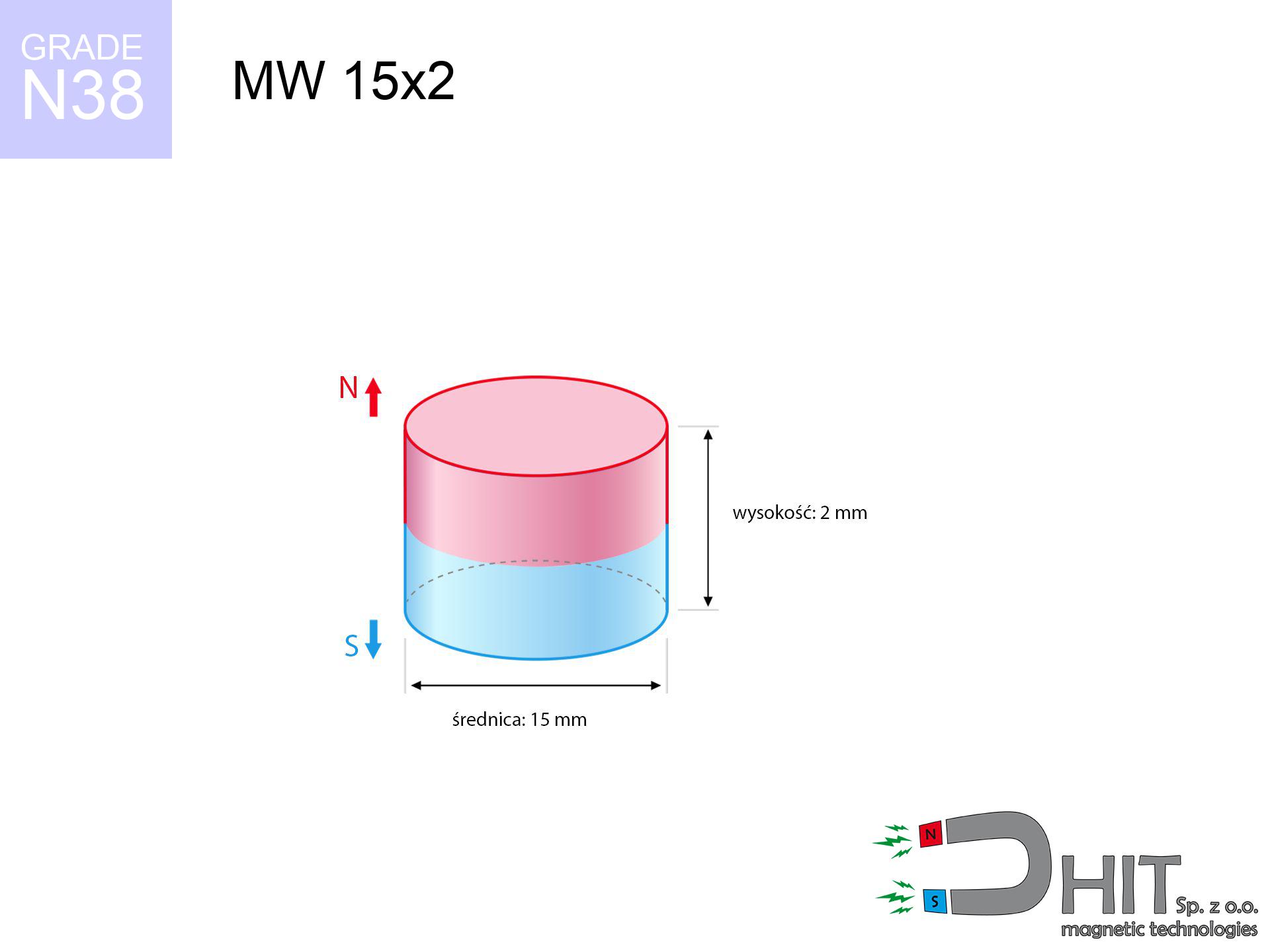

MW 15x2 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010028

GTIN: 5906301810278

Diameter Ø [±0,1 mm]

15 mm

Height [±0,1 mm]

2 mm

Weight

2.65 g

Magnetization Direction

↑ axial

Load capacity

1.66 kg / 16.28 N

Magnetic Induction

159.70 mT

Coating

[NiCuNi] nickel

1.218 ZŁ with VAT / pcs + price for transport

0.990 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Not sure which magnet to buy?

Contact us by phone

+48 22 499 98 98

if you prefer let us know through

form

through our site.

Weight as well as shape of a magnet can be reviewed on our

online calculation tool.

Orders placed before 14:00 will be shipped the same business day.

Magnetic properties of material N38

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

Shopping tips

Advantages and disadvantages of rare earth magnets.

Besides their magnetic performance, neodymium magnets are valued for these benefits:

- They virtually do not lose strength, because even after ten years the performance loss is only ~1% (based on calculations),

- Neodymium magnets are highly resistant to demagnetization caused by magnetic disturbances,

- A magnet with a metallic gold surface has an effective appearance,

- The surface of neodymium magnets generates a maximum magnetic field – this is a key feature,

- Thanks to resistance to high temperature, they are able to function (depending on the form) even at temperatures up to 230°C and higher...

- Possibility of custom forming as well as optimizing to concrete requirements,

- Universal use in electronics industry – they serve a role in HDD drives, electromotive mechanisms, advanced medical instruments, as well as multitasking production systems.

- Relatively small size with high pulling force – neodymium magnets offer impressive pulling force in small dimensions, which enables their usage in small systems

Disadvantages of NdFeB magnets:

- At very strong impacts they can crack, therefore we advise placing them in strong housings. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- Neodymium magnets lose power when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- When exposed to humidity, magnets start to rust. To use them in conditions outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation as well as corrosion.

- Due to limitations in creating threads and complicated shapes in magnets, we propose using cover - magnetic mount.

- Potential hazard related to microscopic parts of magnets are risky, if swallowed, which becomes key in the aspect of protecting the youngest. Additionally, small elements of these products are able to disrupt the diagnostic process medical when they are in the body.

- With budget limitations the cost of neodymium magnets is a challenge,

Maximum magnetic pulling force – what contributes to it?

Magnet power was determined for ideal contact conditions, including:

- with the use of a sheet made of special test steel, ensuring maximum field concentration

- whose thickness equals approx. 10 mm

- with a plane cleaned and smooth

- without any air gap between the magnet and steel

- during pulling in a direction vertical to the plane

- in stable room temperature

Magnet lifting force in use – key factors

During everyday use, the actual lifting capacity results from many variables, ranked from the most important:

- Space between magnet and steel – even a fraction of a millimeter of distance (caused e.g. by veneer or dirt) diminishes the pulling force, often by half at just 0.5 mm.

- Force direction – catalog parameter refers to detachment vertically. When attempting to slide, the magnet holds significantly lower power (typically approx. 20-30% of nominal force).

- Steel thickness – too thin sheet causes magnetic saturation, causing part of the power to be escaped into the air.

- Chemical composition of the base – mild steel gives the best results. Alloy admixtures decrease magnetic properties and holding force.

- Surface condition – ground elements guarantee perfect abutment, which improves force. Rough surfaces weaken the grip.

- Operating temperature – neodymium magnets have a sensitivity to temperature. At higher temperatures they are weaker, and at low temperatures gain strength (up to a certain limit).

* Holding force was tested on the plate surface of 20 mm thickness, when a perpendicular force was applied, in contrast under attempts to slide the magnet the holding force is lower. In addition, even a minimal clearance {between} the magnet’s surface and the plate decreases the load capacity.

Safety rules for work with neodymium magnets

Pinching danger

Danger of trauma: The pulling power is so immense that it can cause blood blisters, pinching, and broken bones. Protective gloves are recommended.

Heat warning

Regular neodymium magnets (grade N) lose power when the temperature goes above 80°C. The loss of strength is permanent.

Flammability

Dust generated during grinding of magnets is self-igniting. Avoid drilling into magnets unless you are an expert.

This is not a toy

Absolutely store magnets away from children. Risk of swallowing is significant, and the consequences of magnets clamping inside the body are fatal.

Keep away from electronics

GPS units and smartphones are highly susceptible to magnetism. Close proximity with a strong magnet can decalibrate the internal compass in your phone.

Shattering risk

Neodymium magnets are sintered ceramics, which means they are very brittle. Clashing of two magnets will cause them shattering into small pieces.

Life threat

Individuals with a pacemaker must keep an safe separation from magnets. The magnetism can stop the operation of the life-saving device.

Cards and drives

Avoid bringing magnets near a wallet, computer, or TV. The magnetic field can irreversibly ruin these devices and wipe information from cards.

Conscious usage

Handle magnets with awareness. Their immense force can shock even experienced users. Plan your moves and respect their power.

Nickel allergy

It is widely known that nickel (standard magnet coating) is a common allergen. If your skin reacts to metals, prevent touching magnets with bare hands and opt for coated magnets.

Safety First!

Want to know more? Read our article: Are neodymium magnets dangerous?

![UMP 75x25 [M10x3] GW F200 GOLD Lina / N42 - search holder UMP 75x25 [M10x3] GW F200 GOLD Lina / N42 - search holder](https://cdn3.dhit.pl/graphics/products/ump-75x25-m10x3-gw-f200-gold-lina-buh.jpg)

![HH 32x7.8 [M5] / N38 - through hole magnetic holder HH 32x7.8 [M5] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-32x7.8-m5-war.jpg)