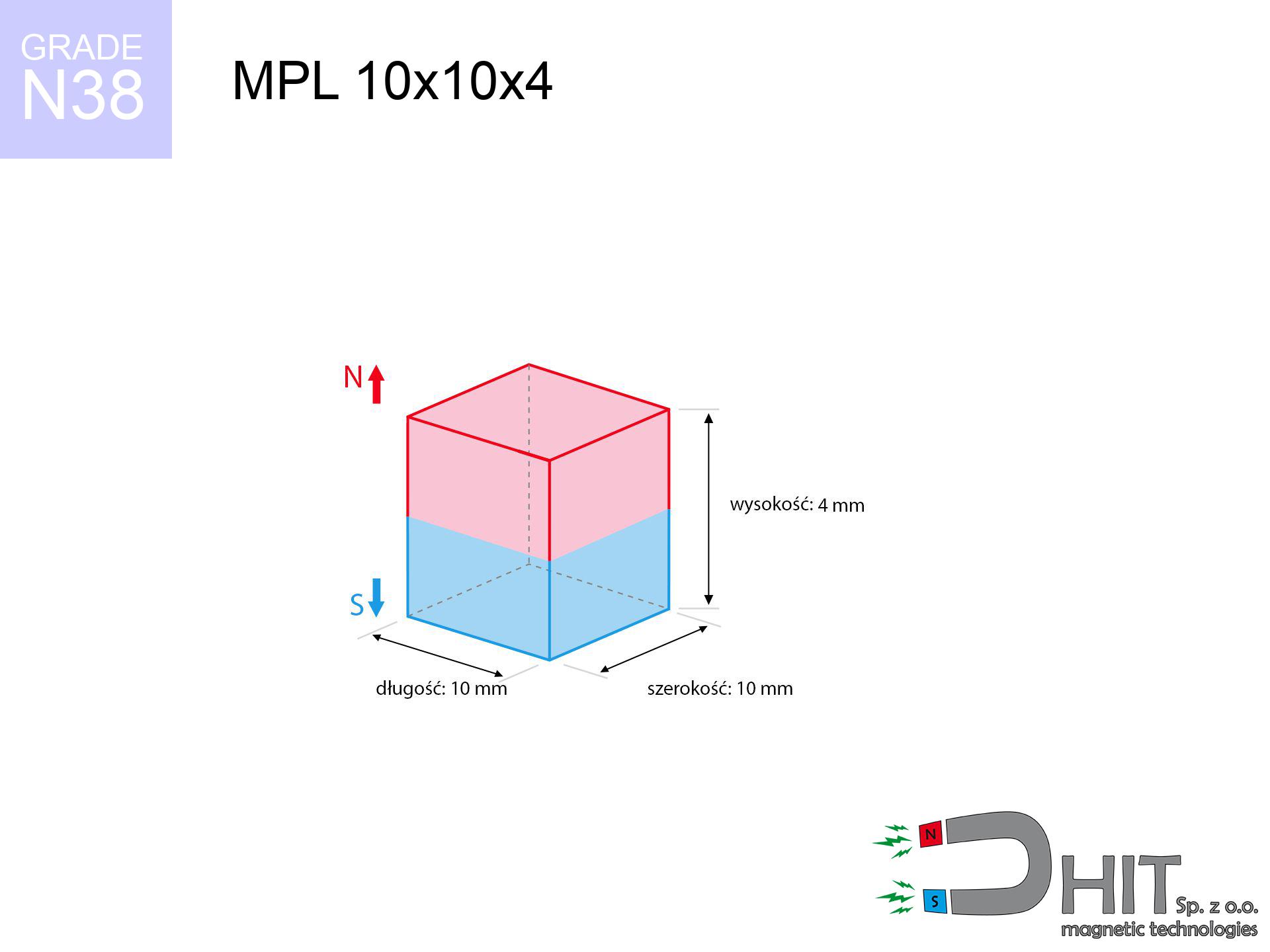

MPL 10x10x4 / N38 - lamellar magnet

lamellar magnet

Catalog no 020112

GTIN/EAN: 5906301811183

length

10 mm [±0,1 mm]

Width

10 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

3 g

Magnetization Direction

↑ axial

Load capacity

3.10 kg / 30.39 N

Magnetic Induction

360.85 mT / 3608 Gs

Coating

[NiCuNi] Nickel

1.538 ZŁ with VAT / pcs + price for transport

1.250 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

if you prefer get in touch by means of

contact form

through our site.

Parameters and form of neodymium magnets can be calculated with our

force calculator.

Same-day shipping for orders placed before 14:00.

Technical data - MPL 10x10x4 / N38 - lamellar magnet

Specification / characteristics - MPL 10x10x4 / N38 - lamellar magnet

| properties | values |

|---|---|

| Cat. no. | 020112 |

| GTIN/EAN | 5906301811183 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| length | 10 mm [±0,1 mm] |

| Width | 10 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 3 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 3.10 kg / 30.39 N |

| Magnetic Induction ~ ? | 360.85 mT / 3608 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the product - data

Presented values are the direct effect of a physical calculation. Values are based on models for the material Nd2Fe14B. Actual parameters may deviate from the simulation results. Treat these data as a preliminary roadmap during assembly planning.

Table 1: Static pull force (force vs gap) - characteristics

MPL 10x10x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3606 Gs

360.6 mT

|

3.10 kg / 6.83 pounds

3100.0 g / 30.4 N

|

strong |

| 1 mm |

3035 Gs

303.5 mT

|

2.20 kg / 4.84 pounds

2195.5 g / 21.5 N

|

strong |

| 2 mm |

2436 Gs

243.6 mT

|

1.41 kg / 3.12 pounds

1413.8 g / 13.9 N

|

safe |

| 3 mm |

1900 Gs

190.0 mT

|

0.86 kg / 1.90 pounds

860.8 g / 8.4 N

|

safe |

| 5 mm |

1127 Gs

112.7 mT

|

0.30 kg / 0.67 pounds

302.7 g / 3.0 N

|

safe |

| 10 mm |

347 Gs

34.7 mT

|

0.03 kg / 0.06 pounds

28.8 g / 0.3 N

|

safe |

| 15 mm |

140 Gs

14.0 mT

|

0.00 kg / 0.01 pounds

4.6 g / 0.0 N

|

safe |

| 20 mm |

68 Gs

6.8 mT

|

0.00 kg / 0.00 pounds

1.1 g / 0.0 N

|

safe |

| 30 mm |

23 Gs

2.3 mT

|

0.00 kg / 0.00 pounds

0.1 g / 0.0 N

|

safe |

| 50 mm |

6 Gs

0.6 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

safe |

Table 2: Slippage force (vertical surface)

MPL 10x10x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.62 kg / 1.37 pounds

620.0 g / 6.1 N

|

| 1 mm | Stal (~0.2) |

0.44 kg / 0.97 pounds

440.0 g / 4.3 N

|

| 2 mm | Stal (~0.2) |

0.28 kg / 0.62 pounds

282.0 g / 2.8 N

|

| 3 mm | Stal (~0.2) |

0.17 kg / 0.38 pounds

172.0 g / 1.7 N

|

| 5 mm | Stal (~0.2) |

0.06 kg / 0.13 pounds

60.0 g / 0.6 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.01 pounds

6.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MPL 10x10x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.93 kg / 2.05 pounds

930.0 g / 9.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.62 kg / 1.37 pounds

620.0 g / 6.1 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.31 kg / 0.68 pounds

310.0 g / 3.0 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

1.55 kg / 3.42 pounds

1550.0 g / 15.2 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MPL 10x10x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.31 kg / 0.68 pounds

310.0 g / 3.0 N

|

| 1 mm |

|

0.78 kg / 1.71 pounds

775.0 g / 7.6 N

|

| 2 mm |

|

1.55 kg / 3.42 pounds

1550.0 g / 15.2 N

|

| 3 mm |

|

2.33 kg / 5.13 pounds

2325.0 g / 22.8 N

|

| 5 mm |

|

3.10 kg / 6.83 pounds

3100.0 g / 30.4 N

|

| 10 mm |

|

3.10 kg / 6.83 pounds

3100.0 g / 30.4 N

|

| 11 mm |

|

3.10 kg / 6.83 pounds

3100.0 g / 30.4 N

|

| 12 mm |

|

3.10 kg / 6.83 pounds

3100.0 g / 30.4 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MPL 10x10x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

3.10 kg / 6.83 pounds

3100.0 g / 30.4 N

|

OK |

| 40 °C | -2.2% |

3.03 kg / 6.68 pounds

3031.8 g / 29.7 N

|

OK |

| 60 °C | -4.4% |

2.96 kg / 6.53 pounds

2963.6 g / 29.1 N

|

|

| 80 °C | -6.6% |

2.90 kg / 6.38 pounds

2895.4 g / 28.4 N

|

|

| 100 °C | -28.8% |

2.21 kg / 4.87 pounds

2207.2 g / 21.7 N

|

Table 6: Magnet-Magnet interaction (repulsion) - field range

MPL 10x10x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

8.02 kg / 17.68 pounds

5 067 Gs

|

1.20 kg / 2.65 pounds

1203 g / 11.8 N

|

N/A |

| 1 mm |

6.85 kg / 15.11 pounds

6 667 Gs

|

1.03 kg / 2.27 pounds

1028 g / 10.1 N

|

6.17 kg / 13.59 pounds

~0 Gs

|

| 2 mm |

5.68 kg / 12.52 pounds

6 070 Gs

|

0.85 kg / 1.88 pounds

852 g / 8.4 N

|

5.11 kg / 11.27 pounds

~0 Gs

|

| 3 mm |

4.60 kg / 10.14 pounds

5 463 Gs

|

0.69 kg / 1.52 pounds

690 g / 6.8 N

|

4.14 kg / 9.13 pounds

~0 Gs

|

| 5 mm |

2.87 kg / 6.32 pounds

4 313 Gs

|

0.43 kg / 0.95 pounds

430 g / 4.2 N

|

2.58 kg / 5.69 pounds

~0 Gs

|

| 10 mm |

0.78 kg / 1.73 pounds

2 254 Gs

|

0.12 kg / 0.26 pounds

117 g / 1.2 N

|

0.70 kg / 1.55 pounds

~0 Gs

|

| 20 mm |

0.07 kg / 0.16 pounds

695 Gs

|

0.01 kg / 0.02 pounds

11 g / 0.1 N

|

0.07 kg / 0.15 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

76 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

46 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

30 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

21 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

15 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

11 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MPL 10x10x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Timepiece | 20 Gs (2.0 mT) | 3.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 2.5 cm |

| Remote | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (kinetic energy) - collision effects

MPL 10x10x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

32.61 km/h

(9.06 m/s)

|

0.12 J | |

| 30 mm |

56.15 km/h

(15.60 m/s)

|

0.36 J | |

| 50 mm |

72.49 km/h

(20.14 m/s)

|

0.61 J | |

| 100 mm |

102.52 km/h

(28.48 m/s)

|

1.22 J |

Table 9: Surface protection spec

MPL 10x10x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MPL 10x10x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 760 Mx | 37.6 µWb |

| Pc Coefficient | 0.46 | Low (Flat) |

Table 11: Physics of underwater searching

MPL 10x10x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 3.10 kg | Standard |

| Water (riverbed) |

3.55 kg

(+0.45 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical wall, the magnet retains only approx. 20-30% of its perpendicular strength.

2. Steel thickness impact

*Thin metal sheet (e.g. 0.5mm PC case) severely limits the holding force.

3. Thermal stability

*For standard magnets, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.46

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Strengths as well as weaknesses of Nd2Fe14B magnets.

Advantages

- They virtually do not lose strength, because even after 10 years the performance loss is only ~1% (according to literature),

- They possess excellent resistance to magnetic field loss as a result of external fields,

- A magnet with a metallic silver surface has an effective appearance,

- The surface of neodymium magnets generates a intense magnetic field – this is a distinguishing feature,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the shape) even at high temperatures reaching 230°C or more...

- In view of the potential of accurate forming and adaptation to unique requirements, NdFeB magnets can be modeled in a wide range of geometric configurations, which makes them more universal,

- Wide application in advanced technology sectors – they serve a role in computer drives, drive modules, diagnostic systems, and complex engineering applications.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Limitations

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only shields the magnet but also improves its resistance to damage

- We warn that neodymium magnets can reduce their strength at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- They oxidize in a humid environment - during use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- We recommend a housing - magnetic mount, due to difficulties in realizing threads inside the magnet and complicated shapes.

- Potential hazard to health – tiny shards of magnets can be dangerous, when accidentally swallowed, which gains importance in the context of child safety. Additionally, small components of these products can complicate diagnosis medical when they are in the body.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Holding force characteristics

Detachment force of the magnet in optimal conditions – what it depends on?

- on a base made of structural steel, perfectly concentrating the magnetic flux

- with a cross-section of at least 10 mm

- with a surface free of scratches

- with zero gap (without paint)

- for force applied at a right angle (in the magnet axis)

- in temp. approx. 20°C

Determinants of practical lifting force of a magnet

- Gap (between the magnet and the metal), because even a tiny clearance (e.g. 0.5 mm) leads to a drastic drop in lifting capacity by up to 50% (this also applies to varnish, rust or dirt).

- Force direction – remember that the magnet has greatest strength perpendicularly. Under shear forces, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Plate thickness – too thin plate causes magnetic saturation, causing part of the power to be wasted to the other side.

- Plate material – mild steel gives the best results. Higher carbon content lower magnetic properties and holding force.

- Surface finish – full contact is obtained only on smooth steel. Rough texture create air cushions, reducing force.

- Thermal conditions – neodymium magnets have a sensitivity to temperature. When it is hot they lose power, and at low temperatures they can be stronger (up to a certain limit).

Lifting capacity testing was conducted on a smooth plate of suitable thickness, under a perpendicular pulling force, in contrast under attempts to slide the magnet the holding force is lower. In addition, even a slight gap between the magnet and the plate lowers the holding force.

Safety rules for work with neodymium magnets

Heat warning

Do not overheat. Neodymium magnets are sensitive to temperature. If you need resistance above 80°C, inquire about special high-temperature series (H, SH, UH).

Beware of splinters

Protect your eyes. Magnets can fracture upon uncontrolled impact, launching sharp fragments into the air. Eye protection is mandatory.

Sensitization to coating

Allergy Notice: The nickel-copper-nickel coating contains nickel. If redness appears, immediately stop handling magnets and wear gloves.

Respect the power

Before use, read the rules. Sudden snapping can break the magnet or injure your hand. Be predictive.

Fire warning

Mechanical processing of neodymium magnets carries a risk of fire risk. Neodymium dust reacts violently with oxygen and is difficult to extinguish.

Finger safety

Risk of injury: The attraction force is so immense that it can result in hematomas, crushing, and even bone fractures. Use thick gloves.

Warning for heart patients

Individuals with a ICD have to keep an large gap from magnets. The magnetic field can interfere with the functioning of the implant.

No play value

Adult use only. Small elements can be swallowed, causing intestinal necrosis. Store out of reach of kids and pets.

Threat to navigation

Navigation devices and mobile phones are highly sensitive to magnetic fields. Direct contact with a strong magnet can decalibrate the internal compass in your phone.

Protect data

Very strong magnetic fields can corrupt files on credit cards, HDDs, and storage devices. Maintain a gap of at least 10 cm.

![UMGGZ 88x8.5 [M8] GZ / N38 - rubber magnetic holder external thread UMGGZ 88x8.5 [M8] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-88x8.5-m8-gz-waf.jpg)

![SM 25x100 [2xM8] / N42 - magnetic separator SM 25x100 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-feg.jpg)

![UMH 42x9x46 [M6] / N38 - magnetic holder with hook UMH 42x9x46 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-42x9x46-m6-vat.jpg)