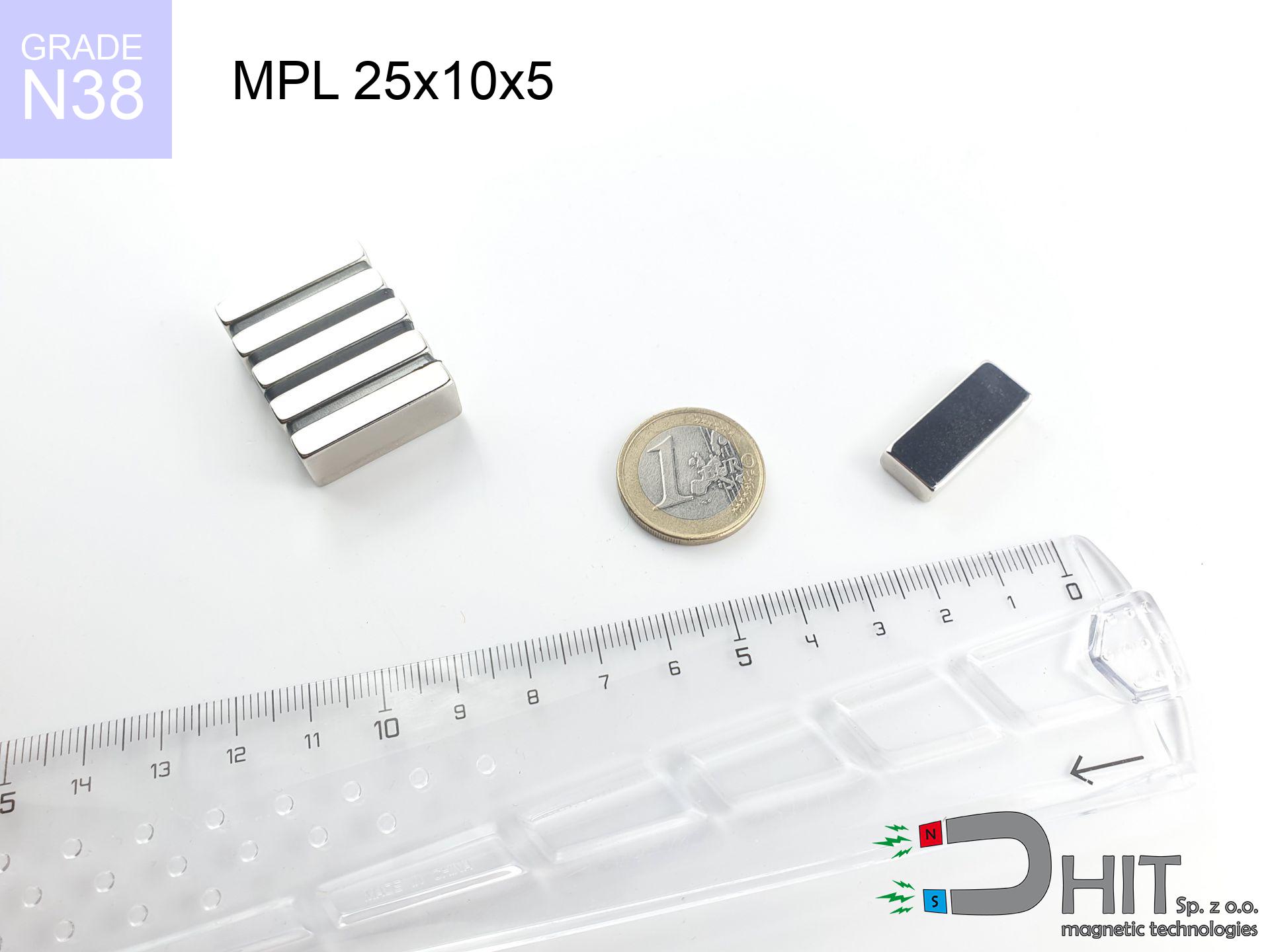

MPL 25x10x5 / N38 - lamellar magnet

lamellar magnet

Catalog no 020135

GTIN: 5906301811411

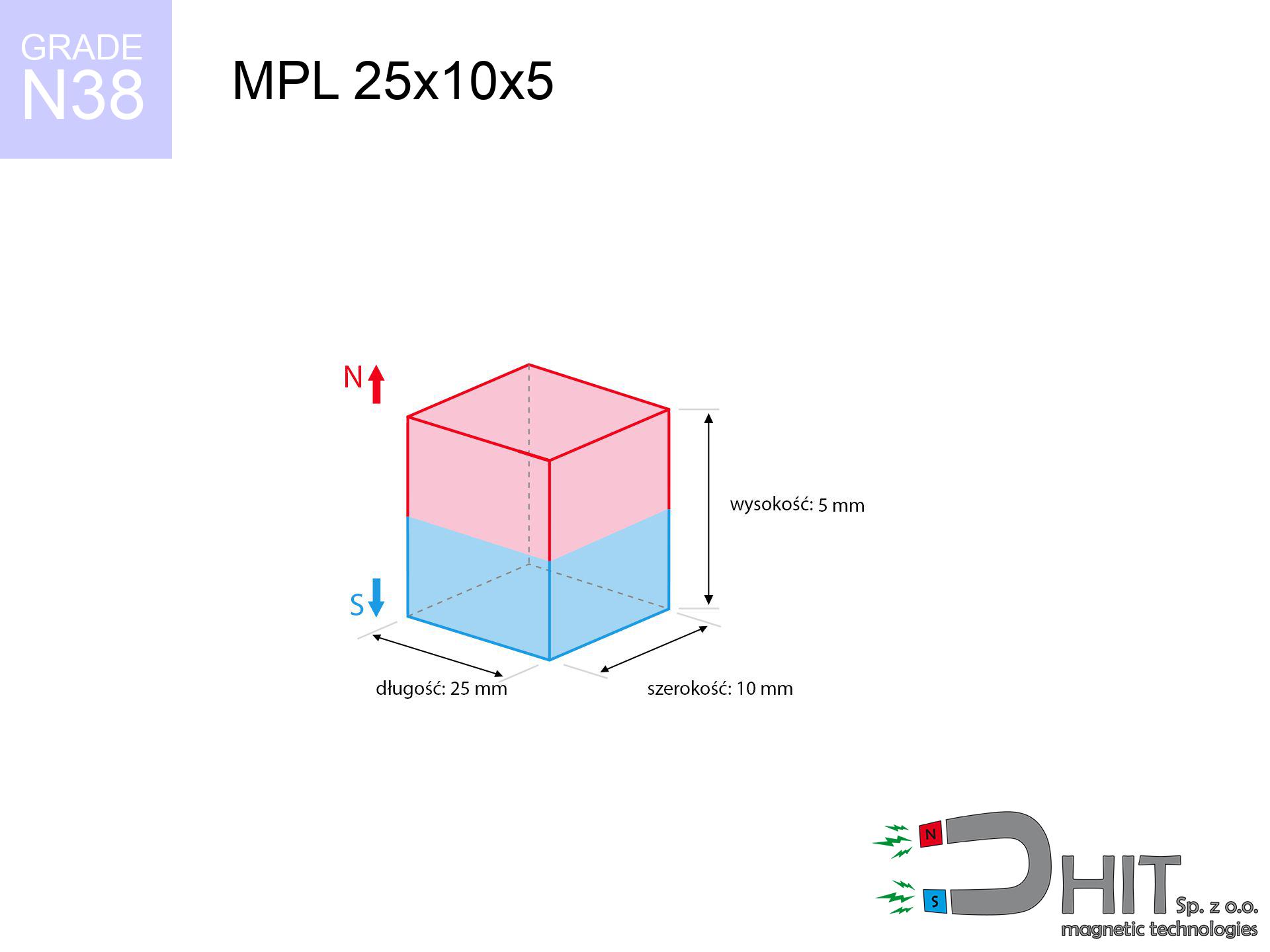

length [±0,1 mm]

25 mm

Width [±0,1 mm]

10 mm

Height [±0,1 mm]

5 mm

Weight

9.38 g

Magnetization Direction

↑ axial

Load capacity

6.24 kg / 61.19 N

Magnetic Induction

337.05 mT

Coating

[NiCuNi] nickel

4.66 ZŁ with VAT / pcs + price for transport

3.79 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Can't decide what to choose?

Call us

+48 22 499 98 98

alternatively get in touch through

contact form

the contact page.

Specifications along with shape of a magnet can be calculated with our

modular calculator.

Order by 14:00 and we’ll ship today!

Magnetic properties of material N38

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

Shopping tips

Strengths as well as weaknesses of rare earth magnets.

In addition to their magnetic efficiency, neodymium magnets provide the following advantages:

- They retain attractive force for around 10 years – the loss is just ~1% (in theory),

- Neodymium magnets are exceptionally resistant to magnetic field loss caused by external field sources,

- By applying a reflective coating of gold, the element acquires an proper look,

- They are known for high magnetic induction at the operating surface, which affects their effectiveness,

- Thanks to resistance to high temperature, they are able to function (depending on the form) even at temperatures up to 230°C and higher...

- Possibility of custom forming as well as adjusting to atypical applications,

- Wide application in advanced technology sectors – they are commonly used in hard drives, electric motors, advanced medical instruments, also technologically advanced constructions.

- Compactness – despite small sizes they offer powerful magnetic field, making them ideal for precision applications

Disadvantages of NdFeB magnets:

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets in special housings. Such protection not only shields the magnet but also improves its resistance to damage

- When exposed to high temperature, neodymium magnets experience a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore during using outdoors, we suggest using waterproof magnets made of rubber, plastic or other material protecting against moisture

- Due to limitations in creating nuts and complicated forms in magnets, we propose using cover - magnetic holder.

- Possible danger related to microscopic parts of magnets pose a threat, if swallowed, which gains importance in the context of child health protection. It is also worth noting that tiny parts of these products are able to disrupt the diagnostic process medical in case of swallowing.

- Higher cost of purchase is one of the disadvantages compared to ceramic magnets, especially in budget applications

Best holding force of the magnet in ideal parameters – what affects it?

The specified lifting capacity refers to the peak performance, recorded under ideal test conditions, meaning:

- using a plate made of mild steel, acting as a circuit closing element

- possessing a massiveness of at least 10 mm to avoid saturation

- with an polished contact surface

- with direct contact (without impurities)

- during detachment in a direction perpendicular to the plane

- at standard ambient temperature

Determinants of practical lifting force of a magnet

Please note that the magnet holding will differ influenced by elements below, in order of importance:

- Gap between magnet and steel – every millimeter of separation (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Force direction – note that the magnet has greatest strength perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Wall thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of converting into lifting capacity.

- Chemical composition of the base – low-carbon steel gives the best results. Alloy admixtures reduce magnetic permeability and holding force.

- Plate texture – smooth surfaces ensure maximum contact, which increases field saturation. Uneven metal reduce efficiency.

- Temperature – heating the magnet causes a temporary drop of force. Check the maximum operating temperature for a given model.

* Lifting capacity testing was performed on a smooth plate of suitable thickness, under a perpendicular pulling force, however under parallel forces the load capacity is reduced by as much as 75%. Moreover, even a small distance {between} the magnet and the plate reduces the holding force.

Safe handling of neodymium magnets

Keep away from electronics

Remember: rare earth magnets generate a field that disrupts precision electronics. Maintain a safe distance from your mobile, tablet, and GPS.

Combustion hazard

Dust generated during machining of magnets is combustible. Avoid drilling into magnets without proper cooling and knowledge.

Thermal limits

Regular neodymium magnets (N-type) lose magnetization when the temperature exceeds 80°C. The loss of strength is permanent.

Pinching danger

Danger of trauma: The pulling power is so great that it can cause hematomas, pinching, and broken bones. Use thick gloves.

Medical implants

Medical warning: Strong magnets can deactivate heart devices and defibrillators. Do not approach if you have electronic implants.

Cards and drives

Data protection: Strong magnets can damage payment cards and sensitive devices (heart implants, medical aids, mechanical watches).

Warning for allergy sufferers

A percentage of the population have a contact allergy to nickel, which is the standard coating for neodymium magnets. Extended handling can result in an allergic reaction. We suggest wear safety gloves.

Choking Hazard

Only for adults. Small elements can be swallowed, causing severe trauma. Store away from children and animals.

Shattering risk

Protect your eyes. Magnets can fracture upon uncontrolled impact, ejecting shards into the air. We recommend safety glasses.

Caution required

Use magnets consciously. Their huge power can surprise even professionals. Stay alert and respect their force.

Security!

Want to know more? Check our post: Why are neodymium magnets dangerous?

![SM 25x100 [2xM8] / N52 - magnetic separator SM 25x100 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x100-2xm8-fin.jpg)