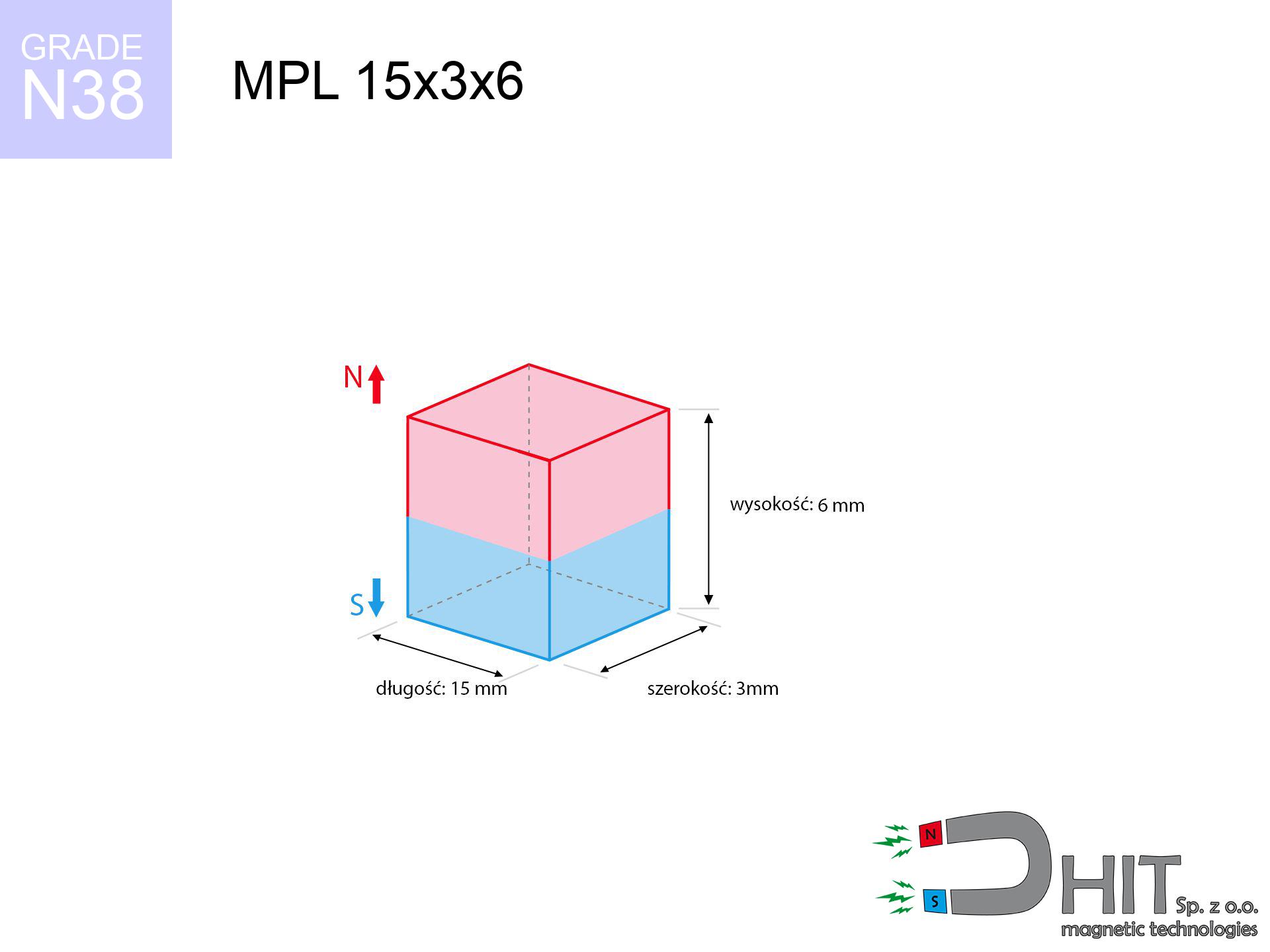

MPL 15x3x6 / N38 - lamellar magnet

lamellar magnet

Catalog no 020122

GTIN: 5906301811282

length [±0,1 mm]

15 mm

Width [±0,1 mm]

3 mm

Height [±0,1 mm]

6 mm

Weight

2.03 g

Magnetization Direction

↑ axial

Load capacity

3.18 kg / 31.19 N

Magnetic Induction

543.23 mT

Coating

[NiCuNi] nickel

0.73 ZŁ with VAT / pcs + price for transport

0.59 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Want to negotiate the price?

Call us +48 22 499 98 98 or write via form on the contact page. Test the magnet's power with our power calculator.

Orders placed by 14:00 are shipped the same day.

MPL 15x3x6 / N38 - lamellar magnet

Magnetic properties of material N38

Physical properties of NdFeB

Shopping tips

Thanks to their high strength, flat magnets are frequently used in structures that need strong holding power.

The standard temperature resistance of these magnets is 80 °C, but depending on the dimensions, this value grows.

Moreover, flat magnets often have special coatings applied to their surfaces, e.g. nickel, gold, or chrome, to improve their durability.

The magnet with the designation MPL 15x3x6 / N38 and a lifting capacity of 3.18 kg with a weight of only 2.03 grams, making it the perfect choice for projects needing a flat magnet.

Contact surface: Due to their flat shape, flat magnets guarantee a larger contact surface with adjacent parts, which can be beneficial in applications needing a stronger magnetic connection.

Technology applications: They are often utilized in many devices, e.g. sensors, stepper motors, or speakers, where the thin and wide shape is necessary for their operation.

Mounting: This form's flat shape makes it easier mounting, especially when it is necessary to attach the magnet to another surface.

Design flexibility: The flat shape of the magnets permits designers greater flexibility in placing them in devices, which is more difficult with magnets of other shapes.

Stability: In certain applications, the flat base of the flat magnet may offer better stability, reducing the risk of sliding or rotating. However, one should remember that the optimal shape of the magnet is dependent on the specific application and requirements. In some cases, other shapes, such as cylindrical or spherical, may be more appropriate.

Magnets have two poles: north (N) and south (S), which interact with each other when they are different. Poles of the same kind, e.g. two north poles, repel each other.

Thanks to this principle of operation, magnets are regularly used in electrical devices, e.g. motors, speakers, sensors, or magnetic locks. Neodymium magnets stand out with the greatest strength of attraction, making them indispensable for applications requiring strong magnetic fields. Additionally, the strength of a magnet depends on its dimensions and the material it is made of.

It should be noted that extremely high temperatures, above the Curie point, cause a loss of magnetic properties in the magnet. The Curie temperature is specific to each type of magnet, meaning that under such conditions, the magnet stops being magnetic. Interestingly, strong magnets can interfere with the operation of devices, such as navigational instruments, magnetic stripe cards or electronic devices sensitive to magnetic fields. Therefore, it is important to avoid placing magnets near such devices.

Advantages as well as disadvantages of neodymium magnets NdFeB.

In addition to immense strength, neodymium magnets have the following advantages:

- They do not lose strength over time - after about 10 years, their strength decreases by only ~1% (theoretically),

- They are highly resistant to demagnetization by external magnetic field,

- In other words, thanks to the shiny nickel, gold, or silver finish, the element gains an aesthetic appearance,

- They have very high magnetic induction on the surface of the magnet,

- Magnetic neodymium magnets are characterized by very high magnetic induction on the surface of the magnet and can operate (depending on the shape) even at temperatures of 230°C or higher...

- Due to the option of accurate forming and adaptation to individual needs – neodymium magnets can be produced in a wide range of shapes and sizes, which enhances their versatility in applications.

- Significant importance in modern technologies – are used in hard drives, electric motors, medical devices and other advanced devices.

Disadvantages of neodymium magnets:

- They are prone to breaking as they are extremely fragile when subjected to a powerful impact. If the magnets are exposed to impacts, it is suggested using magnets in a metal holder. The steel housing in the form of a holder protects the magnet from impacts and also increases its overall strength,

- Magnets lose their strength due to exposure to high temperatures. In most cases, when the temperature exceeds 80°C, these magnets experience permanent reduction in strength (although it is worth noting that this is dependent on the form and size of the magnet). To avoid this problem, we offer special magnets marked with the [AH] symbol, which exhibit high temperature resistance. They can operate even at temperatures as high as 230°C or more,

- Due to their susceptibility to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic, or other moisture-resistant materials when using them outdoors,

- The use of a cover - a magnetic holder is recommended due to the limited production capabilities of creating threads or complex shapes in the magnet

- Health risk arising from small pieces of magnets can be dangerous, in case of ingestion, which is particularly important in the aspect of protecting young children. It's also worth noting that tiny parts of these devices have the potential to be problematic in medical diagnosis when they are in the body.

Be Cautious with Neodymium Magnets

Neodymium magnets should not be near people with pacemakers.

In the case of neodymium magnets, there is a strong magnetic field. As a result, it interferes with the operation of a heart pacemaker. However, if the magnetic field does not affect the device, it can damage its components or deactivate the device when it is in a magnetic field.

Neodymium magnets can become demagnetized at high temperatures.

Despite the fact that magnets have been observed to maintain their efficacy up to temperatures of 80°C or 175°F, it's essential to consider that this threshold may fluctuate depending on the magnet's type, configuration, and intended usage.

It is crucial not to allow the magnets to pinch together uncontrollably or place your fingers in their path as they attract to each other.

If joining of neodymium magnets is not under control, then they may crumble and crack. You can't move them to each other. At a distance less than 10 cm you should hold them extremely firmly.

The magnet coating is made of nickel, so be cautious if you have an allergy.

Studies clearly indicate a small percentage of people who suffer from metal allergies such as nickel. An allergic reaction often manifests as skin redness and rash. If you have a nickel allergy, try wearing gloves or avoid direct contact with nickel-plated neodymium magnets.

Make sure not to bring neodymium magnets close to the TV, wallet, and computer HDD.

Strong fields generated by neodymium magnets can damage magnetic storage media such as floppy disks, credit cards, magnetic ID cards, cassette tapes, video tapes, or other similar devices. In addition, they can damage televisions, VCRs, computer monitors, and CRT displays. You should especially avoid placing neodymium magnets near electronic devices.

Magnets are not toys, youngest should not play with them.

Neodymium magnets are not toys. Do not allow children to play with them. In the case of swallowing multiple magnets simultaneously, they can attract to each other through the intestinal walls. In the worst case scenario, this can lead to death.

Neodymium magnets are the most powerful magnets ever invented. Their power can surprise you.

Please review the information on how to handle neodymium magnets and avoid significant harm to your body, as well as prevent unintentional damage to the magnets.

Neodymium magnetic are highly susceptible to damage, resulting in shattering.

Neodymium magnets are characterized by considerable fragility. Neodymium magnets are made of metal and coated with a shiny nickel surface, but they are not as hard as steel. At the moment of collision between the magnets, sharp metal fragments can be dispersed in different directions.

Do not bring neodymium magnets close to GPS and smartphones.

Magnetic fields generated by neodymium magnets interfere with compasses and magnetometers used in navigation, as well as internal compasses of smartphones and GPS devices.

Dust and powder from neodymium magnets are flammable.

Avoid drilling or mechanical processing of neodymium magnets. Once crushed into fine powder or dust, this material becomes highly flammable.

In order for you to know how strong neodymium magnets are and why they are so dangerous, read the article - Dangerous very strong neodymium magnets.

![UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 22x6 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-22x6-m4-gw-jek.jpg)