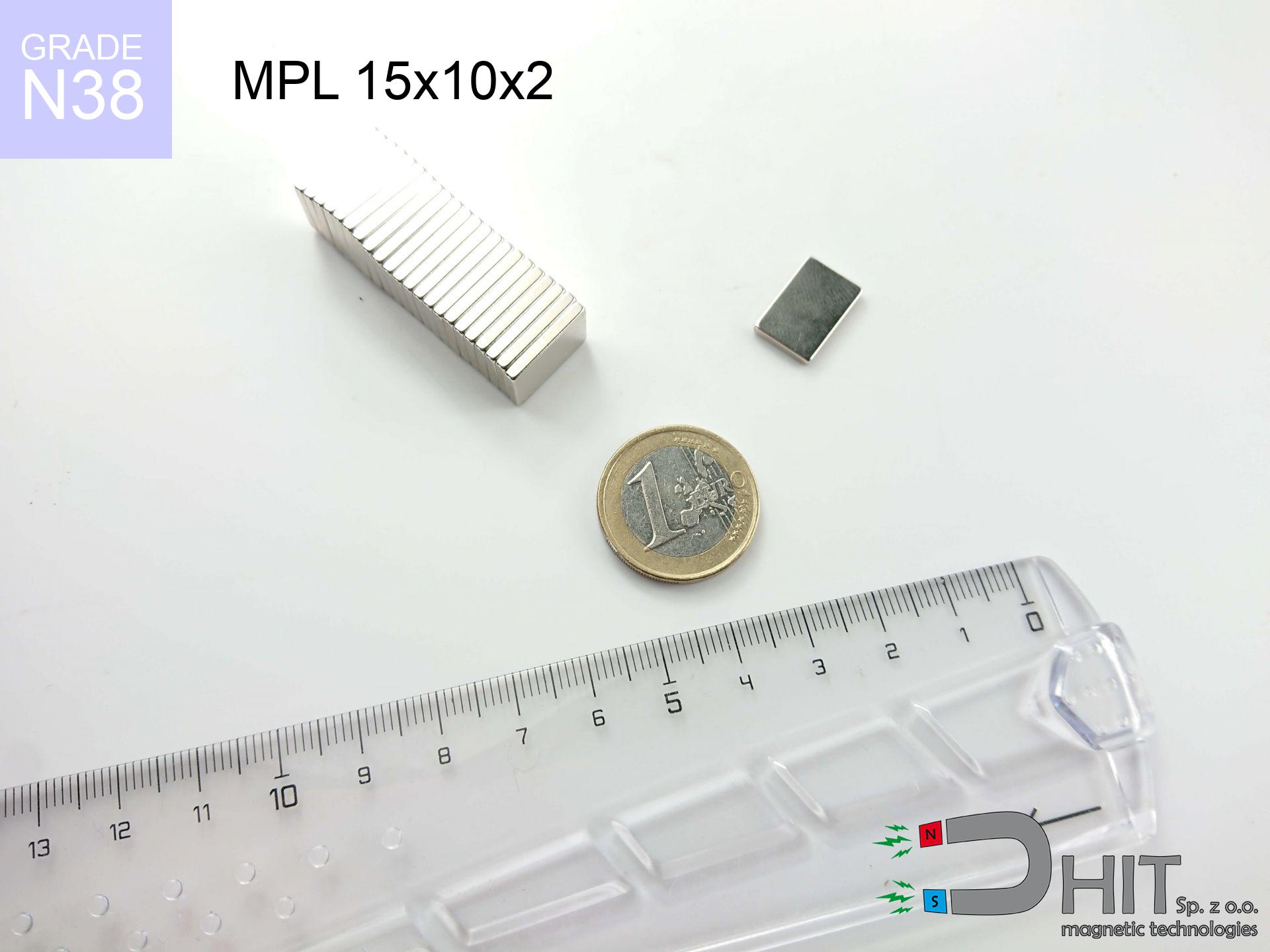

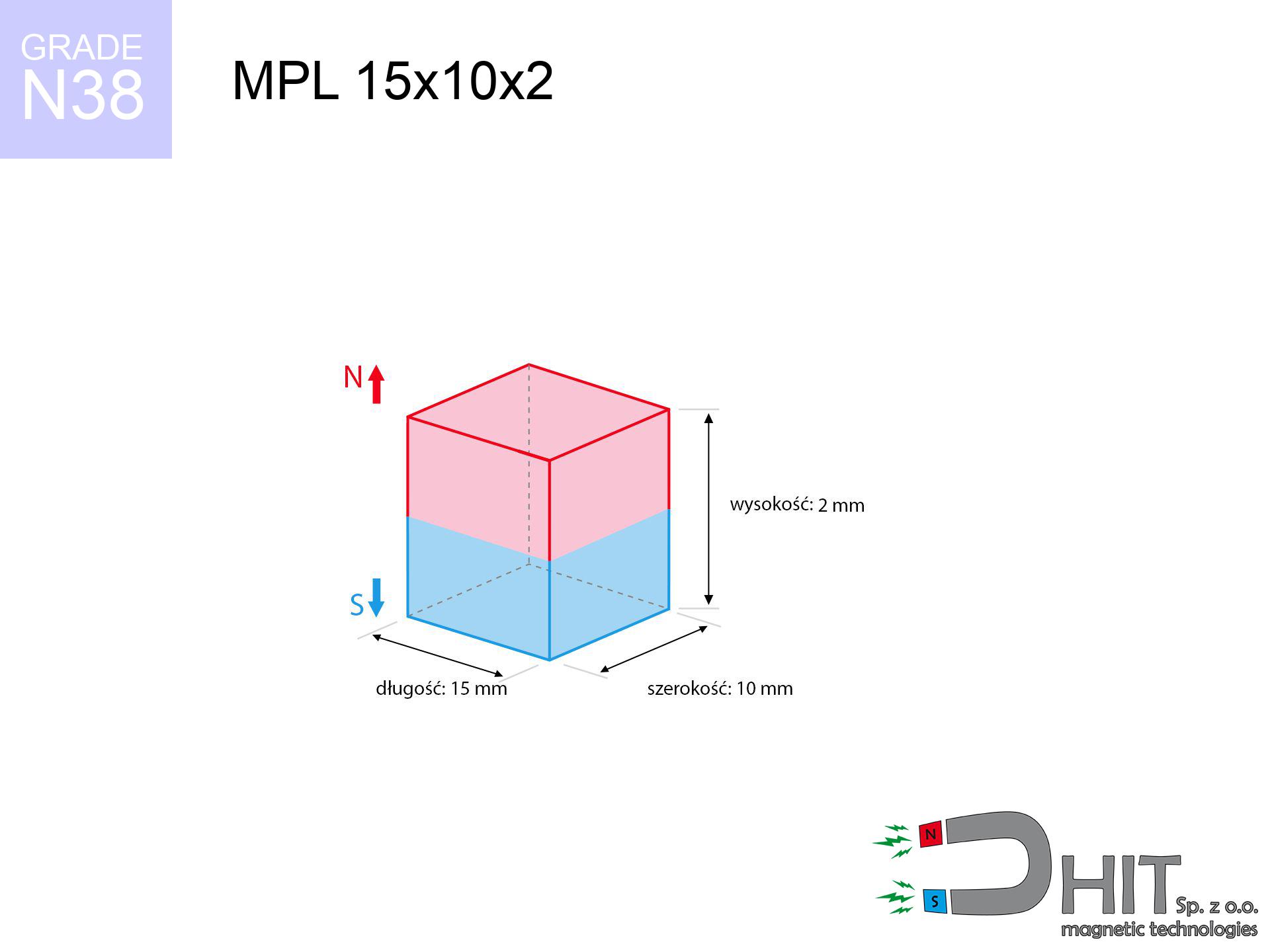

MPL 15x10x2 / N38 - lamellar magnet

lamellar magnet

Catalog no 020388

GTIN: 5906301811879

length [±0,1 mm]

15 mm

Width [±0,1 mm]

10 mm

Height [±0,1 mm]

2 mm

Weight

2.25 g

Magnetization Direction

↑ axial

Load capacity

1.93 kg / 18.93 N

Magnetic Induction

180.53 mT

Coating

[NiCuNi] nickel

1.316 ZŁ with VAT / pcs + price for transport

1.070 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Not sure about your choice?

Pick up the phone and ask

+48 22 499 98 98

if you prefer drop us a message by means of

form

through our site.

Lifting power along with shape of magnets can be estimated using our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Magnetic properties of material N38

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

Shopping tips

Advantages and disadvantages of NdFeB magnets.

Besides their magnetic performance, neodymium magnets are valued for these benefits:

- They have unchanged lifting capacity, and over more than ten years their performance decreases symbolically – ~1% (in testing),

- Neodymium magnets are characterized by extremely resistant to demagnetization caused by external magnetic fields,

- By using a shiny layer of silver, the element gains an proper look,

- Magnets exhibit impressive magnetic induction on the active area,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their form) at temperatures up to 230°C and above...

- Possibility of detailed forming as well as adapting to complex needs,

- Universal use in innovative solutions – they are used in hard drives, drive modules, advanced medical instruments, as well as industrial machines.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Disadvantages of NdFeB magnets:

- At strong impacts they can crack, therefore we recommend placing them in strong housings. A metal housing provides additional protection against damage, as well as increases the magnet's durability.

- When exposed to high temperature, neodymium magnets suffer a drop in strength. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material stable to moisture, in case of application outdoors

- We suggest casing - magnetic mechanism, due to difficulties in realizing nuts inside the magnet and complicated forms.

- Health risk to health – tiny shards of magnets can be dangerous, in case of ingestion, which gains importance in the context of child safety. Furthermore, small components of these magnets can complicate diagnosis medical when they are in the body.

- High unit price – neodymium magnets cost more than other types of magnets (e.g. ferrite), which can limit application in large quantities

Magnetic strength at its maximum – what contributes to it?

Magnet power is the result of a measurement for the most favorable conditions, assuming:

- with the use of a sheet made of special test steel, ensuring maximum field concentration

- whose transverse dimension reaches at least 10 mm

- with an ideally smooth contact surface

- without any clearance between the magnet and steel

- for force applied at a right angle (in the magnet axis)

- in temp. approx. 20°C

Practical aspects of lifting capacity – factors

Real force impacted by specific conditions, including (from most important):

- Gap (between the magnet and the plate), because even a microscopic clearance (e.g. 0.5 mm) leads to a drastic drop in force by up to 50% (this also applies to varnish, rust or debris).

- Direction of force – maximum parameter is obtained only during perpendicular pulling. The resistance to sliding of the magnet along the surface is usually several times smaller (approx. 1/5 of the lifting capacity).

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Paper-thin metal limits the attraction force (the magnet "punches through" it).

- Plate material – low-carbon steel attracts best. Alloy admixtures decrease magnetic properties and lifting capacity.

- Surface finish – ideal contact is obtained only on polished steel. Rough texture create air cushions, weakening the magnet.

- Temperature – temperature increase causes a temporary drop of induction. Check the maximum operating temperature for a given model.

* Lifting capacity testing was conducted on a smooth plate of suitable thickness, under a perpendicular pulling force, however under parallel forces the load capacity is reduced by as much as 5 times. Moreover, even a minimal clearance {between} the magnet and the plate decreases the load capacity.

H&S for magnets

Keep away from computers

Equipment safety: Strong magnets can ruin data carriers and delicate electronics (heart implants, hearing aids, mechanical watches).

Do not underestimate power

Exercise caution. Rare earth magnets act from a long distance and snap with massive power, often faster than you can move away.

Do not give to children

Strictly store magnets away from children. Choking hazard is significant, and the effects of magnets clamping inside the body are life-threatening.

Avoid contact if allergic

It is widely known that the nickel plating (the usual finish) is a strong allergen. For allergy sufferers, avoid direct skin contact and choose coated magnets.

Machining danger

Fire warning: Rare earth powder is explosive. Avoid machining magnets without safety gear as this may cause fire.

Maximum temperature

Control the heat. Heating the magnet to high heat will permanently weaken its properties and pulling force.

Hand protection

Large magnets can break fingers instantly. Do not put your hand between two attracting surfaces.

Magnet fragility

Neodymium magnets are ceramic materials, which means they are very brittle. Collision of two magnets will cause them breaking into shards.

Precision electronics

GPS units and smartphones are extremely sensitive to magnetism. Direct contact with a strong magnet can ruin the sensors in your phone.

Danger to pacemakers

Individuals with a pacemaker have to maintain an safe separation from magnets. The magnetic field can stop the operation of the implant.

Safety First!

Looking for details? Check our post: Why are neodymium magnets dangerous?

![UMGGW 34x8 [M4] GW / N38 - magnetic holder rubber internal thread UMGGW 34x8 [M4] GW / N38 - magnetic holder rubber internal thread](https://cdn3.dhit.pl/graphics/products/umg-34x8-m4-gw-kek.jpg)

![UMGGZ 88x8.5 [M8] GZ / N38 - rubber magnetic holder external thread UMGGZ 88x8.5 [M8] GZ / N38 - rubber magnetic holder external thread](https://cdn3.dhit.pl/graphics/products/umg-88x8.5-m8-gz-waf.jpg)