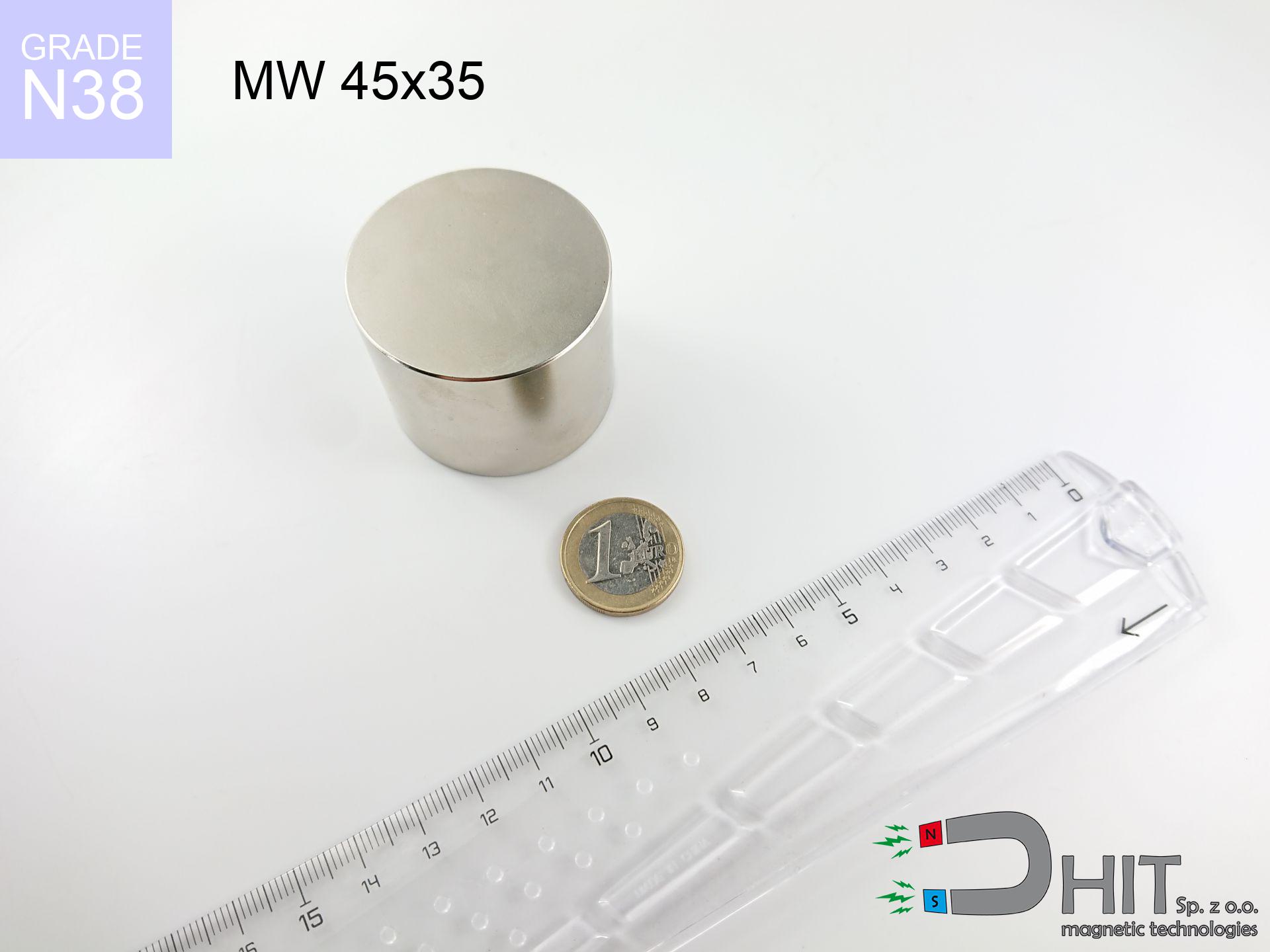

UMP 50x20 [M8] GW / N38 - search holder

search holder

Catalog no 210231

GTIN/EAN: 5906301813910

Diameter Ø

50 mm [±1 mm]

Height

20 mm [±1 mm]

Weight

0.6 g

Load capacity

130.00 kg / 1274.86 N

Coating

[NiCuNi] Nickel

77.00 ZŁ with VAT / pcs + price for transport

62.60 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 888 99 98 98

if you prefer get in touch via

our online form

through our site.

Lifting power and structure of a magnet can be checked using our

magnetic calculator.

Orders placed before 14:00 will be shipped the same business day.

💡 Guide: How to choose a decent magnet and not get ripped off?

Don't be fooled by amateur online tests – go for certified quality and specific parameters that guarantee success:

- 📏 Magnet thickness in the casing (min. 10mm) – This is what matters most! Thin magnets are weak. Thanks to the 1cm thickness of N52 neodymium, your magnet "sees" metal even through thick rust and mud.

- 🛡️ Armored protection (Black Epoxy) – Forget about rust. This coating doesn't chip when hitting rocks and protects the magnet in water much better than regular nickel, which fails quickly.

- 🧲 Eyelets that don't steal power – Made of special non-magnetic steel, so they don't stick to the magnet and don't block the force. Important: mount only one eyelet at a time! Using 3 at once is a mistake that weakens the magnet.

- 🧶 Certified rope (min. 8mm) – You gain the certainty that your gear won't stay at the bottom. It's thick and comfortable, so it doesn't cut your fingers when pulling out heavy scrap metal.

- 🚀 Our advantage: We are the only ones combining the strongest N52 neodymium (10mm thick) with non-magnetic eyelets. This is real power and durability you won't find anywhere else.

Invest in solid equipment and enjoy the results!

Technical specification - UMP 50x20 [M8] GW / N38 - search holder

Specification / characteristics - UMP 50x20 [M8] GW / N38 - search holder

| properties | values |

|---|---|

| Cat. no. | 210231 |

| GTIN/EAN | 5906301813910 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 50 mm [±1 mm] |

| Height | 20 mm [±1 mm] |

| Weight | 0.6 g |

| Load capacity ~ ? | 130.00 kg / 1274.86 N |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

See more products

Pros as well as cons of Nd2Fe14B magnets.

Pros

- They virtually do not lose strength, because even after ten years the decline in efficiency is only ~1% (according to literature),

- They are resistant to demagnetization induced by external field influence,

- In other words, due to the metallic surface of gold, the element gains visual value,

- Neodymium magnets create maximum magnetic induction on a small surface, which ensures high operational effectiveness,

- Due to their durability and thermal resistance, neodymium magnets are capable of operate (depending on the form) even at high temperatures reaching 230°C or more...

- Thanks to modularity in forming and the ability to modify to complex applications,

- Versatile presence in future technologies – they find application in computer drives, drive modules, advanced medical instruments, also modern systems.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in compact dimensions, which makes them useful in small systems

Weaknesses

- To avoid cracks under impact, we suggest using special steel holders. Such a solution protects the magnet and simultaneously improves its durability.

- NdFeB magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Magnets exposed to a humid environment can corrode. Therefore when using outdoors, we advise using waterproof magnets made of rubber, plastic or other material resistant to moisture

- Limited ability of producing nuts in the magnet and complicated shapes - recommended is cover - mounting mechanism.

- Health risk resulting from small fragments of magnets pose a threat, when accidentally swallowed, which is particularly important in the context of child safety. Furthermore, small elements of these products can complicate diagnosis medical when they are in the body.

- Due to complex production process, their price exceeds standard values,

Pull force analysis

Highest magnetic holding force – what it depends on?

- on a plate made of mild steel, effectively closing the magnetic flux

- whose thickness is min. 10 mm

- characterized by smoothness

- without the slightest clearance between the magnet and steel

- under vertical force direction (90-degree angle)

- in stable room temperature

Key elements affecting lifting force

- Gap between magnet and steel – every millimeter of distance (caused e.g. by varnish or unevenness) drastically reduces the magnet efficiency, often by half at just 0.5 mm.

- Angle of force application – maximum parameter is reached only during perpendicular pulling. The resistance to sliding of the magnet along the surface is typically several times smaller (approx. 1/5 of the lifting capacity).

- Base massiveness – insufficiently thick steel causes magnetic saturation, causing part of the power to be lost to the other side.

- Plate material – mild steel attracts best. Higher carbon content decrease magnetic permeability and holding force.

- Surface finish – ideal contact is obtained only on polished steel. Rough texture reduce the real contact area, reducing force.

- Temperature influence – high temperature reduces pulling force. Exceeding the limit temperature can permanently demagnetize the magnet.

Holding force was tested on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a small distance between the magnet and the plate lowers the holding force.

Precautions when working with neodymium magnets

Permanent damage

Regular neodymium magnets (N-type) lose magnetization when the temperature exceeds 80°C. The loss of strength is permanent.

This is not a toy

Adult use only. Small elements pose a choking risk, leading to severe trauma. Keep out of reach of children and animals.

Fire risk

Combustion risk: Rare earth powder is explosive. Avoid machining magnets without safety gear as this risks ignition.

Protective goggles

Despite the nickel coating, the material is brittle and not impact-resistant. Avoid impacts, as the magnet may shatter into hazardous fragments.

Allergic reactions

Studies show that the nickel plating (standard magnet coating) is a common allergen. If your skin reacts to metals, prevent direct skin contact and opt for encased magnets.

Phone sensors

Remember: rare earth magnets generate a field that disrupts sensitive sensors. Keep a safe distance from your mobile, device, and GPS.

Handling rules

Exercise caution. Neodymium magnets attract from a distance and snap with huge force, often quicker than you can react.

Danger to pacemakers

For implant holders: Strong magnetic fields disrupt medical devices. Maintain minimum 30 cm distance or ask another person to work with the magnets.

Serious injuries

Risk of injury: The pulling power is so immense that it can cause hematomas, crushing, and even bone fractures. Use thick gloves.

Protect data

Powerful magnetic fields can destroy records on credit cards, HDDs, and other magnetic media. Keep a distance of min. 10 cm.

![Search magnet UMP 50x20 [M8] GW / N38 - GOLD Series Search magnet UMP 50x20 [M8] GW / N38 - GOLD Series](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![UMP 50x20 [M8] GW / N38 - search holder](https://cdn3.dhit.pl/graphics/products/ump-50x20-m8-gw--xax.jpg)

![UMGW 16x13x5 [M4] GW / N38 - magnetic holder internal thread UMGW 16x13x5 [M4] GW / N38 - magnetic holder internal thread](https://cdn3.dhit.pl/graphics/products/um-16x13x5-m4-gw-fig.jpg)