SM 25x200 [2xM8] / N42 - magnetic separator

magnetic separator

Catalog no 130291

GTIN/EAN: 5906301812845

Diameter Ø

25 mm [±1 mm]

Height

200 mm [±1 mm]

Weight

760 g

Magnetic Flux

~ 6 500 Gauss [±5%]

541.20 ZŁ with VAT / pcs + price for transport

440.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

alternatively get in touch by means of

our online form

through our site.

Force along with shape of a magnet can be estimated using our

modular calculator.

Orders placed before 14:00 will be shipped the same business day.

Detailed specification - SM 25x200 [2xM8] / N42 - magnetic separator

Specification / characteristics - SM 25x200 [2xM8] / N42 - magnetic separator

| properties | values |

|---|---|

| Cat. no. | 130291 |

| GTIN/EAN | 5906301812845 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

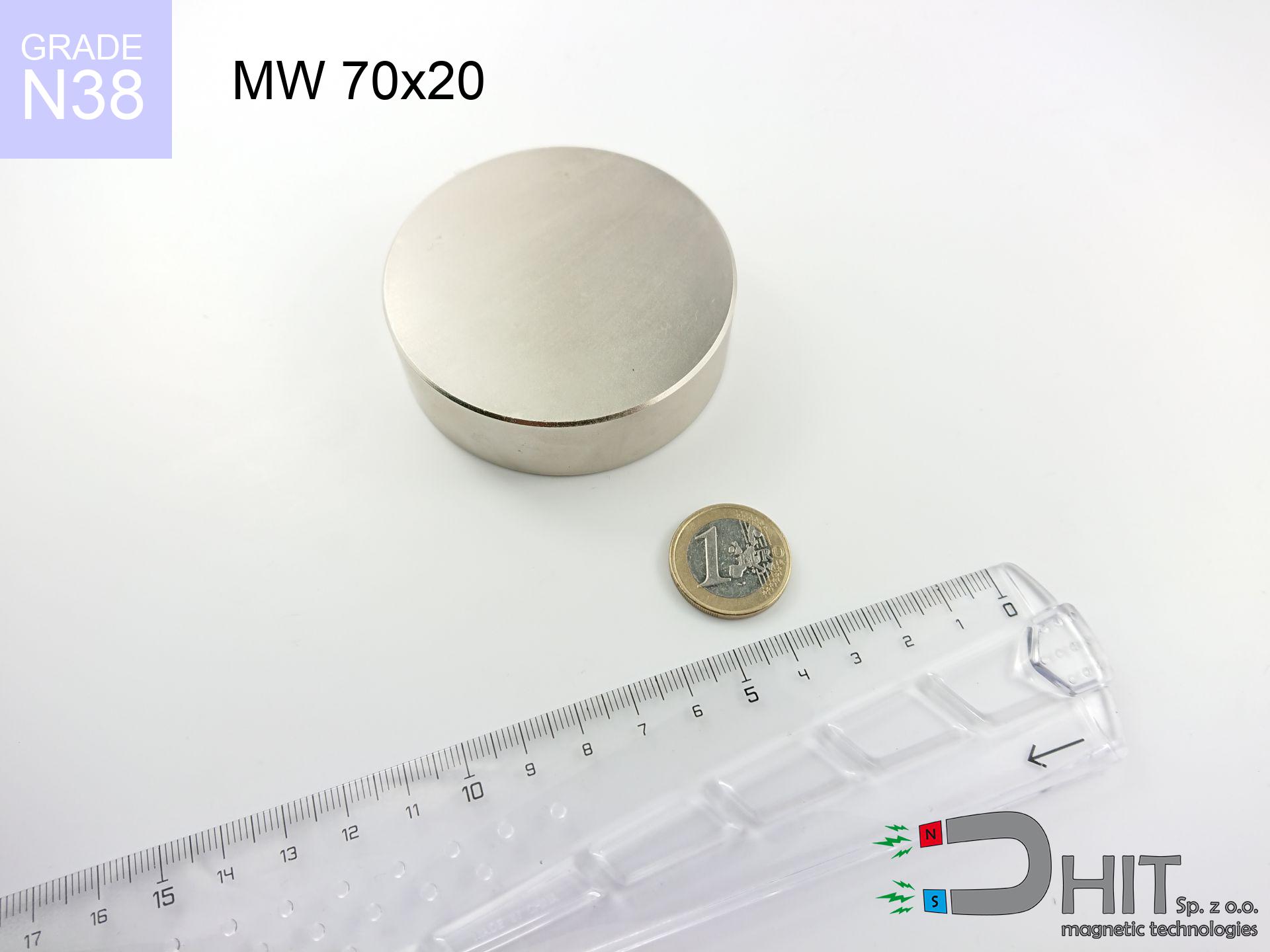

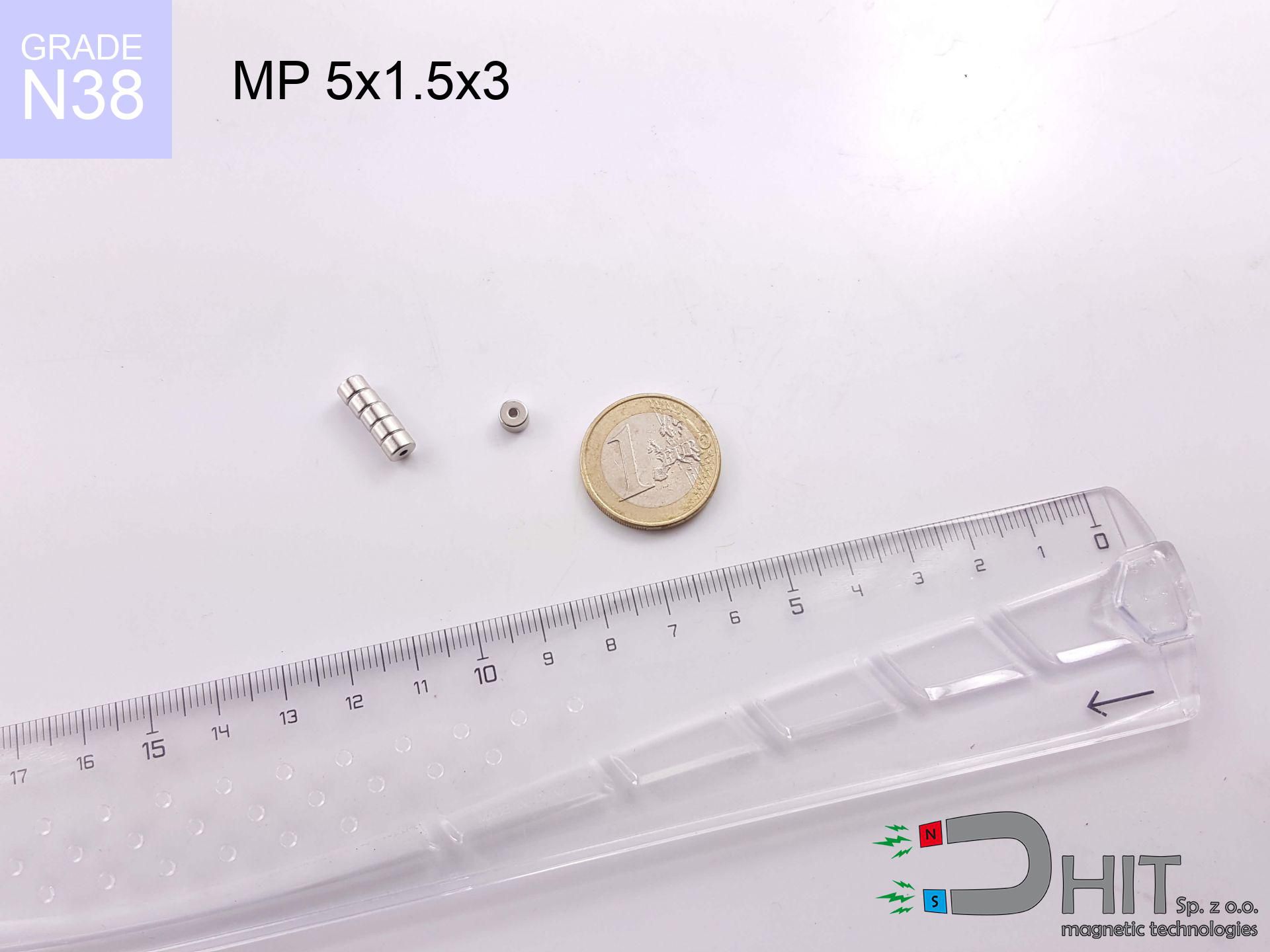

| Diameter Ø | 25 mm [±1 mm] |

| Height | 200 mm [±1 mm] |

| Weight | 760 g |

| Material Type | Stainless steel AISI 304 / A2 |

| Magnetic Flux | ~ 6 500 Gauss [±5%] |

| Size/Mount Quantity | 2xM8 |

| Polarity | circumferential - 7 poles |

| Casing Tube Thickness | 1 mm |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N42

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.9-13.2 | kGs |

| remenance Br [min. - max.] ? | 1290-1320 | mT |

| coercivity bHc ? | 10.8-12.0 | kOe |

| coercivity bHc ? | 860-955 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 40-42 | BH max MGOe |

| energy density [min. - max.] ? | 318-334 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Table 1: Rod construction

SM 25x200 [2xM8] / N42

| Parameter | Value | Description / Unit |

|---|---|---|

| Diameter (Ø) | 25 | mm |

| Total length | 200 | mm (L) |

| Active length | 164 | mm |

| Section count | 7 | modules |

| Dead zone | 36 | mm (2x 18mm starter) |

| Weight (est.) | ~746 | g |

| Active area | 129 | cm² (Area) |

| Housing material | AISI 304 | 1.4301 (Inox) |

| Surface finish | Ra < 0.8 µm | Polished |

| Temp. class | 80°C | Standard (N) |

| Force loss (at max °C) | -12.8% | Reversible loss (physics) |

| Force (calculated) | 10.6 | kg (theor.) |

| Induction (surface) | ~6 500 | Gauss (Max) |

Chart 2: Field profile (7 sections)

Chart 3: Temperature performance

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Ecology and recycling (GPSR)

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Advantages and disadvantages of rare earth magnets.

Strengths

- They retain full power for nearly 10 years – the drop is just ~1% (based on simulations),

- Neodymium magnets remain exceptionally resistant to magnetic field loss caused by magnetic disturbances,

- A magnet with a metallic nickel surface has an effective appearance,

- They show high magnetic induction at the operating surface, which improves attraction properties,

- Made from properly selected components, these magnets show impressive resistance to high heat, enabling them to function (depending on their shape) at temperatures up to 230°C and above...

- In view of the possibility of free forming and adaptation to individualized solutions, NdFeB magnets can be modeled in a variety of shapes and sizes, which amplifies use scope,

- Versatile presence in modern technologies – they are used in magnetic memories, electric motors, medical devices, and other advanced devices.

- Thanks to concentrated force, small magnets offer high operating force, in miniature format,

Cons

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution protects the magnet and simultaneously increases its durability.

- NdFeB magnets lose force when exposed to high temperatures. After reaching 80°C, many of them experience permanent drop of strength (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are very resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material resistant to moisture, in case of application outdoors

- Due to limitations in realizing nuts and complex forms in magnets, we propose using casing - magnetic mount.

- Possible danger related to microscopic parts of magnets can be dangerous, in case of ingestion, which becomes key in the aspect of protecting the youngest. Furthermore, small elements of these magnets can complicate diagnosis medical after entering the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which increases costs of application in large quantities

Lifting parameters

Detachment force of the magnet in optimal conditions – what it depends on?

- with the contact of a yoke made of low-carbon steel, ensuring maximum field concentration

- whose thickness is min. 10 mm

- with a plane free of scratches

- with total lack of distance (no paint)

- under axial force vector (90-degree angle)

- at ambient temperature approx. 20 degrees Celsius

Lifting capacity in practice – influencing factors

- Space between surfaces – every millimeter of distance (caused e.g. by varnish or dirt) significantly weakens the magnet efficiency, often by half at just 0.5 mm.

- Load vector – maximum parameter is obtained only during pulling at a 90° angle. The shear force of the magnet along the plate is usually several times smaller (approx. 1/5 of the lifting capacity).

- Substrate thickness – for full efficiency, the steel must be sufficiently thick. Thin sheet restricts the lifting capacity (the magnet "punches through" it).

- Plate material – low-carbon steel gives the best results. Alloy admixtures lower magnetic permeability and lifting capacity.

- Plate texture – smooth surfaces guarantee perfect abutment, which improves force. Uneven metal weaken the grip.

- Temperature influence – high temperature weakens pulling force. Too high temperature can permanently damage the magnet.

Holding force was checked on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, in contrast under shearing force the holding force is lower. In addition, even a minimal clearance between the magnet’s surface and the plate reduces the load capacity.

Safety rules for work with neodymium magnets

Beware of splinters

Despite the nickel coating, the material is brittle and not impact-resistant. Do not hit, as the magnet may shatter into hazardous fragments.

Adults only

Product intended for adults. Small elements pose a choking risk, leading to intestinal necrosis. Keep out of reach of children and animals.

Warning for allergy sufferers

Medical facts indicate that the nickel plating (the usual finish) is a potent allergen. If your skin reacts to metals, refrain from touching magnets with bare hands and opt for coated magnets.

Pinching danger

Large magnets can crush fingers instantly. Never put your hand between two strong magnets.

Thermal limits

Regular neodymium magnets (grade N) lose magnetization when the temperature surpasses 80°C. The loss of strength is permanent.

Caution required

Before use, read the rules. Uncontrolled attraction can break the magnet or hurt your hand. Think ahead.

Medical interference

People with a ICD should keep an absolute distance from magnets. The magnetism can interfere with the operation of the life-saving device.

Data carriers

Equipment safety: Strong magnets can damage payment cards and sensitive devices (heart implants, medical aids, mechanical watches).

GPS and phone interference

Be aware: rare earth magnets generate a field that disrupts precision electronics. Keep a safe distance from your mobile, device, and GPS.

Dust is flammable

Mechanical processing of neodymium magnets carries a risk of fire hazard. Neodymium dust reacts violently with oxygen and is hard to extinguish.

![Magnetic bar SM 25x200 [2xM8] / N42 Magnetic bar SM 25x200 [2xM8] / N42](https://cdn3.dhit.pl/graphics/banners/magnet.webp)

![SM 25x200 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x200-2xm8-dos.jpg)