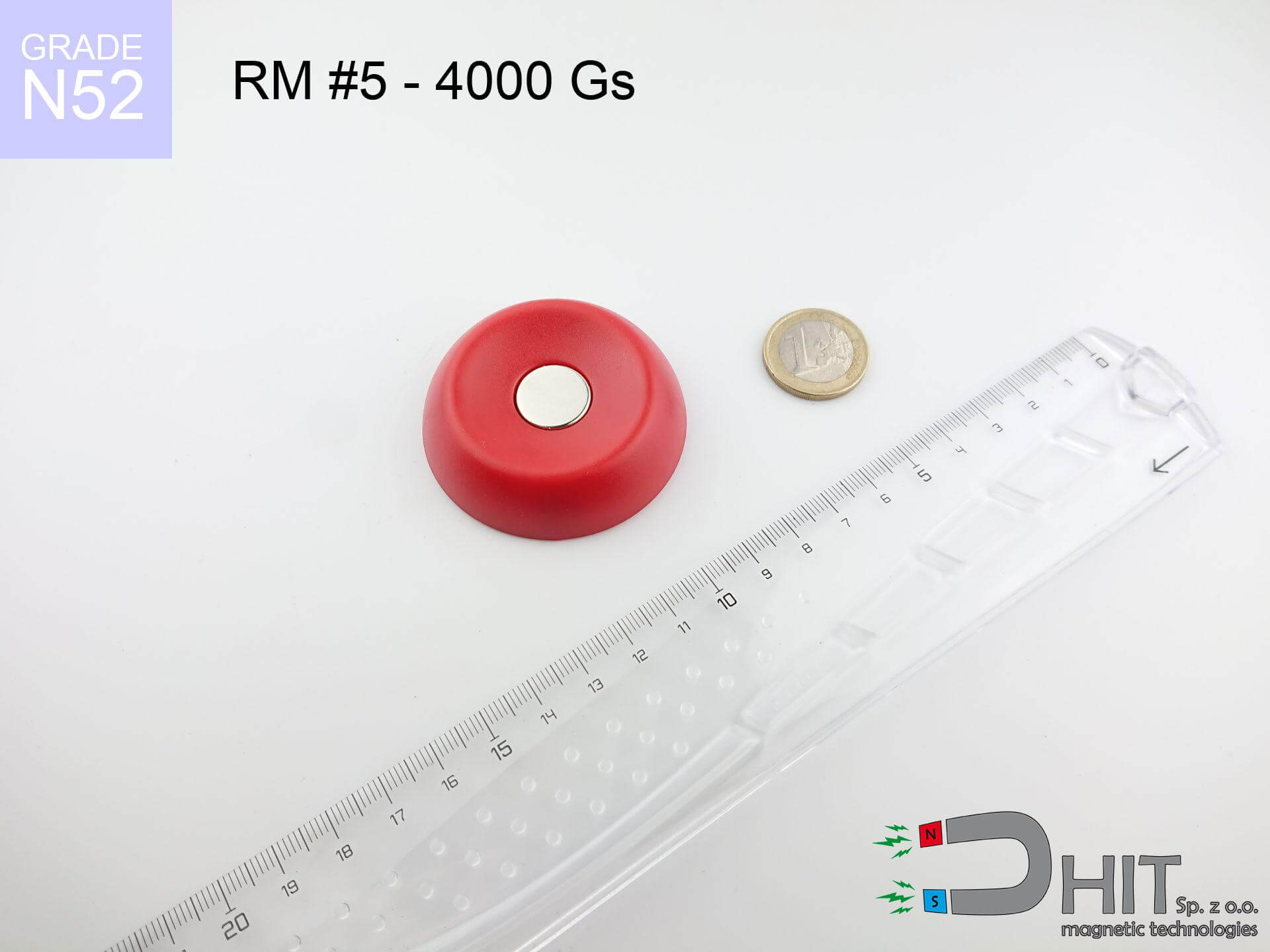

RM R5 - 4000 Gs / N52 - magnetic distributor

magnetic distributor

Catalog no 280255

GTIN/EAN: 5906301814467

Weight

47 g

Magnetization Direction

↑ axial

Coating

[NiCuNi] Nickel

66.42 ZŁ with VAT / pcs + price for transport

54.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

if you prefer send us a note via

our online form

the contact section.

Weight along with structure of a neodymium magnet can be analyzed using our

modular calculator.

Orders submitted before 14:00 will be dispatched today!

Physical properties - RM R5 - 4000 Gs / N52 - magnetic distributor

Specification / characteristics - RM R5 - 4000 Gs / N52 - magnetic distributor

| properties | values |

|---|---|

| Cat. no. | 280255 |

| GTIN/EAN | 5906301814467 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 47 g |

| Magnetization Direction | ↑ axial |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N52

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 14.2-14.7 | kGs |

| remenance Br [min. - max.] ? | 1420-1470 | mT |

| coercivity bHc ? | 10.8-12.5 | kOe |

| coercivity bHc ? | 860-995 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 48-53 | BH max MGOe |

| energy density [min. - max.] ? | 380-422 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other proposals

Pros as well as cons of neodymium magnets.

Pros

- They retain attractive force for nearly ten years – the drop is just ~1% (based on simulations),

- Neodymium magnets are highly resistant to demagnetization caused by external field sources,

- The use of an shiny coating of noble metals (nickel, gold, silver) causes the element to be more visually attractive,

- The surface of neodymium magnets generates a unique magnetic field – this is a key feature,

- Through (appropriate) combination of ingredients, they can achieve high thermal resistance, allowing for functioning at temperatures approaching 230°C and above...

- Considering the potential of free molding and adaptation to specialized needs, magnetic components can be created in a variety of geometric configurations, which increases their versatility,

- Fundamental importance in modern industrial fields – they are utilized in hard drives, electric drive systems, precision medical tools, as well as complex engineering applications.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Weaknesses

- To avoid cracks under impact, we recommend using special steel housings. Such a solution secures the magnet and simultaneously improves its durability.

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their force. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- We recommend a housing - magnetic holder, due to difficulties in realizing nuts inside the magnet and complicated shapes.

- Possible danger related to microscopic parts of magnets are risky, if swallowed, which becomes key in the aspect of protecting the youngest. Additionally, tiny parts of these magnets are able to complicate diagnosis medical when they are in the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Lifting parameters

Optimal lifting capacity of a neodymium magnet – what contributes to it?

- with the application of a sheet made of special test steel, guaranteeing maximum field concentration

- whose thickness is min. 10 mm

- with a surface free of scratches

- with total lack of distance (without impurities)

- for force acting at a right angle (pull-off, not shear)

- in temp. approx. 20°C

Key elements affecting lifting force

- Clearance – existence of foreign body (paint, tape, gap) interrupts the magnetic circuit, which reduces capacity rapidly (even by 50% at 0.5 mm).

- Angle of force application – highest force is available only during perpendicular pulling. The shear force of the magnet along the surface is usually many times smaller (approx. 1/5 of the lifting capacity).

- Wall thickness – thin material does not allow full use of the magnet. Magnetic flux passes through the material instead of generating force.

- Steel grade – the best choice is pure iron steel. Hardened steels may attract less.

- Plate texture – smooth surfaces ensure maximum contact, which improves force. Rough surfaces weaken the grip.

- Heat – NdFeB sinters have a sensitivity to temperature. At higher temperatures they are weaker, and in frost they can be stronger (up to a certain limit).

Lifting capacity testing was conducted on plates with a smooth surface of suitable thickness, under a perpendicular pulling force, whereas under shearing force the load capacity is reduced by as much as 5 times. Moreover, even a minimal clearance between the magnet and the plate decreases the load capacity.

H&S for magnets

Medical implants

Warning for patients: Strong magnetic fields disrupt medical devices. Maintain minimum 30 cm distance or ask another person to handle the magnets.

Caution required

Before starting, read the rules. Uncontrolled attraction can destroy the magnet or hurt your hand. Think ahead.

Shattering risk

Despite metallic appearance, the material is delicate and cannot withstand shocks. Avoid impacts, as the magnet may crumble into hazardous fragments.

Heat warning

Standard neodymium magnets (grade N) lose power when the temperature exceeds 80°C. Damage is permanent.

Cards and drives

Do not bring magnets close to a wallet, laptop, or screen. The magnetic field can permanently damage these devices and wipe information from cards.

Flammability

Machining of neodymium magnets poses a fire hazard. Magnetic powder oxidizes rapidly with oxygen and is hard to extinguish.

Warning for allergy sufferers

It is widely known that the nickel plating (standard magnet coating) is a common allergen. If you have an allergy, avoid direct skin contact and opt for versions in plastic housing.

Compass and GPS

Be aware: neodymium magnets generate a field that confuses sensitive sensors. Keep a separation from your phone, device, and GPS.

Crushing risk

Danger of trauma: The pulling power is so immense that it can cause hematomas, crushing, and even bone fractures. Use thick gloves.

Swallowing risk

Neodymium magnets are not toys. Swallowing several magnets can lead to them pinching intestinal walls, which poses a direct threat to life and requires urgent medical intervention.

![SM 25x175 [2xM8] / N52 - magnetic separator SM 25x175 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x175-2xm8-gif.jpg)