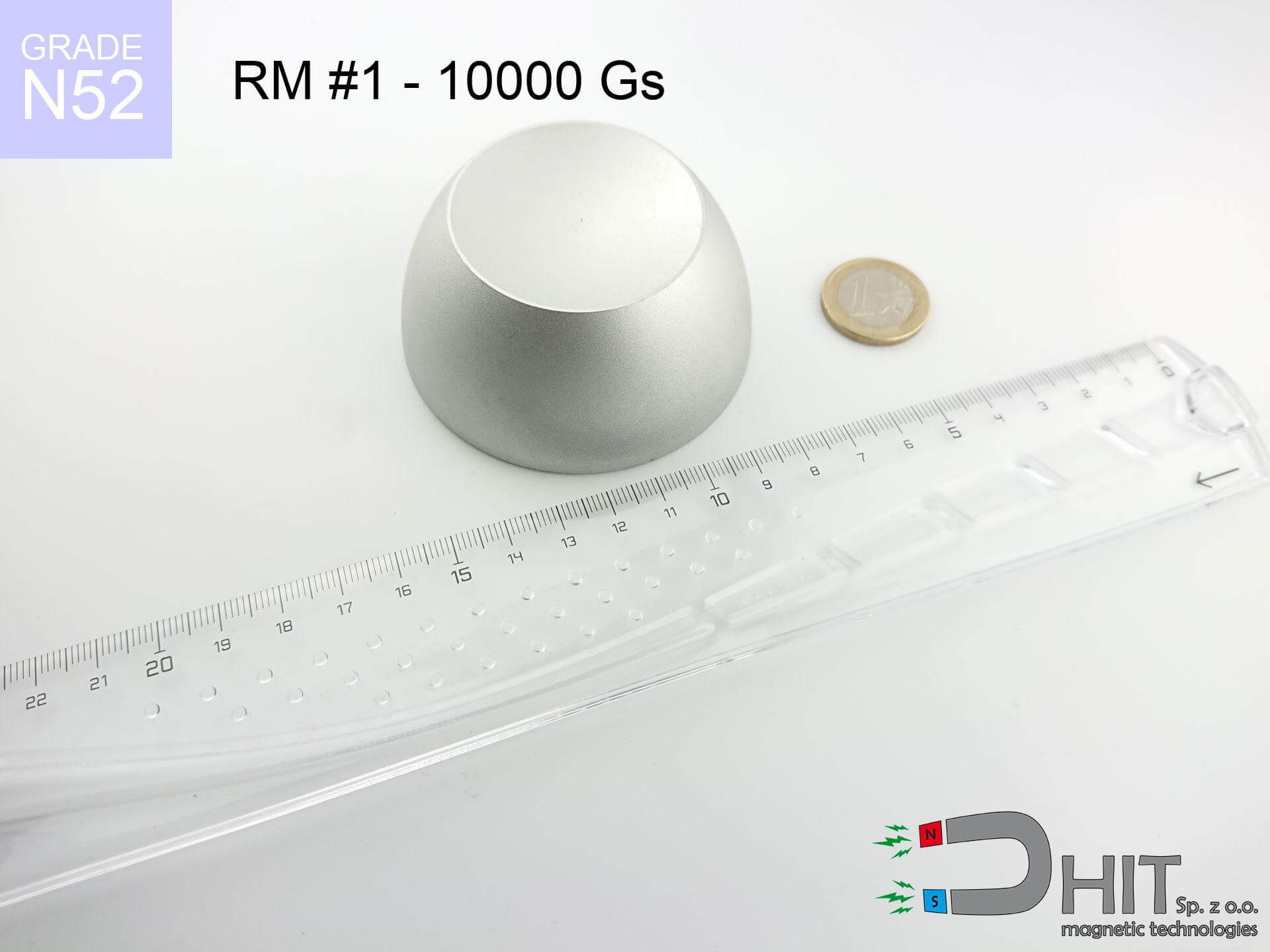

RM R1 - 10000 Gs / N52 - magnetic distributor

magnetic distributor

Catalog no 280251

GTIN/EAN: 5906301814429

Weight

0.01 g

Magnetization Direction

↑ axial

Coating

[NiCuNi] Nickel

141.45 ZŁ with VAT / pcs + price for transport

115.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

alternatively drop us a message through

form

the contact section.

Specifications along with form of a neodymium magnet can be calculated with our

force calculator.

Same-day processing for orders placed before 14:00.

Product card - RM R1 - 10000 Gs / N52 - magnetic distributor

Specification / characteristics - RM R1 - 10000 Gs / N52 - magnetic distributor

| properties | values |

|---|---|

| Cat. no. | 280251 |

| GTIN/EAN | 5906301814429 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Weight | 0.01 g |

| Magnetization Direction | ↑ axial |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±1 mm |

Magnetic properties of material N52

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 14.2-14.7 | kGs |

| remenance Br [min. - max.] ? | 1420-1470 | mT |

| coercivity bHc ? | 10.8-12.5 | kOe |

| coercivity bHc ? | 860-995 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 48-53 | BH max MGOe |

| energy density [min. - max.] ? | 380-422 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more products

Pros as well as cons of neodymium magnets.

Strengths

- They have constant strength, and over more than ten years their attraction force decreases symbolically – ~1% (according to theory),

- They do not lose their magnetic properties even under strong external field,

- Thanks to the shimmering finish, the coating of nickel, gold-plated, or silver gives an visually attractive appearance,

- Neodymium magnets ensure maximum magnetic induction on a small surface, which increases force concentration,

- Neodymium magnets are characterized by extremely high magnetic induction on the magnet surface and can work (depending on the form) even at a temperature of 230°C or more...

- Possibility of individual machining and adjusting to defined needs,

- Key role in high-tech industry – they find application in mass storage devices, drive modules, diagnostic systems, and other advanced devices.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Weaknesses

- At very strong impacts they can break, therefore we recommend placing them in steel cases. A metal housing provides additional protection against damage and increases the magnet's durability.

- We warn that neodymium magnets can lose their power at high temperatures. To prevent this, we suggest our specialized [AH] magnets, which work effectively even at 230°C.

- They rust in a humid environment - during use outdoors we recommend using waterproof magnets e.g. in rubber, plastic

- Due to limitations in creating nuts and complicated shapes in magnets, we recommend using a housing - magnetic mechanism.

- Health risk to health – tiny shards of magnets pose a threat, in case of ingestion, which gains importance in the aspect of protecting the youngest. It is also worth noting that small components of these magnets can complicate diagnosis medical in case of swallowing.

- With budget limitations the cost of neodymium magnets is a challenge,

Holding force characteristics

Highest magnetic holding force – what affects it?

- on a block made of structural steel, effectively closing the magnetic flux

- with a thickness no less than 10 mm

- characterized by smoothness

- with direct contact (no impurities)

- during detachment in a direction vertical to the mounting surface

- in neutral thermal conditions

Impact of factors on magnetic holding capacity in practice

- Air gap (between the magnet and the metal), because even a microscopic distance (e.g. 0.5 mm) can cause a reduction in force by up to 50% (this also applies to paint, rust or debris).

- Pull-off angle – remember that the magnet has greatest strength perpendicularly. Under shear forces, the holding force drops drastically, often to levels of 20-30% of the maximum value.

- Substrate thickness – to utilize 100% power, the steel must be adequately massive. Thin sheet restricts the attraction force (the magnet "punches through" it).

- Steel type – mild steel gives the best results. Alloy admixtures reduce magnetic properties and holding force.

- Surface finish – ideal contact is obtained only on polished steel. Any scratches and bumps create air cushions, reducing force.

- Temperature – heating the magnet causes a temporary drop of force. Check the maximum operating temperature for a given model.

Holding force was measured on a smooth steel plate of 20 mm thickness, when the force acted perpendicularly, in contrast under shearing force the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet’s surface and the plate reduces the lifting capacity.

Safety rules for work with neodymium magnets

Machining danger

Fire warning: Rare earth powder is highly flammable. Avoid machining magnets without safety gear as this may cause fire.

Heat sensitivity

Regular neodymium magnets (N-type) lose power when the temperature surpasses 80°C. The loss of strength is permanent.

Handling rules

Before use, check safety instructions. Sudden snapping can destroy the magnet or injure your hand. Think ahead.

Pacemakers

Warning for patients: Strong magnetic fields affect medical devices. Keep at least 30 cm distance or request help to work with the magnets.

Eye protection

Despite metallic appearance, the material is delicate and not impact-resistant. Do not hit, as the magnet may shatter into hazardous fragments.

Crushing risk

Large magnets can smash fingers instantly. Never place your hand between two attracting surfaces.

Precision electronics

Navigation devices and mobile phones are extremely susceptible to magnetism. Close proximity with a strong magnet can ruin the sensors in your phone.

Avoid contact if allergic

Certain individuals experience a sensitization to Ni, which is the typical protective layer for neodymium magnets. Extended handling might lead to dermatitis. We recommend use protective gloves.

Electronic devices

Equipment safety: Neodymium magnets can ruin data carriers and sensitive devices (heart implants, medical aids, mechanical watches).

Adults only

NdFeB magnets are not toys. Swallowing a few magnets may result in them pinching intestinal walls, which poses a severe health hazard and requires urgent medical intervention.