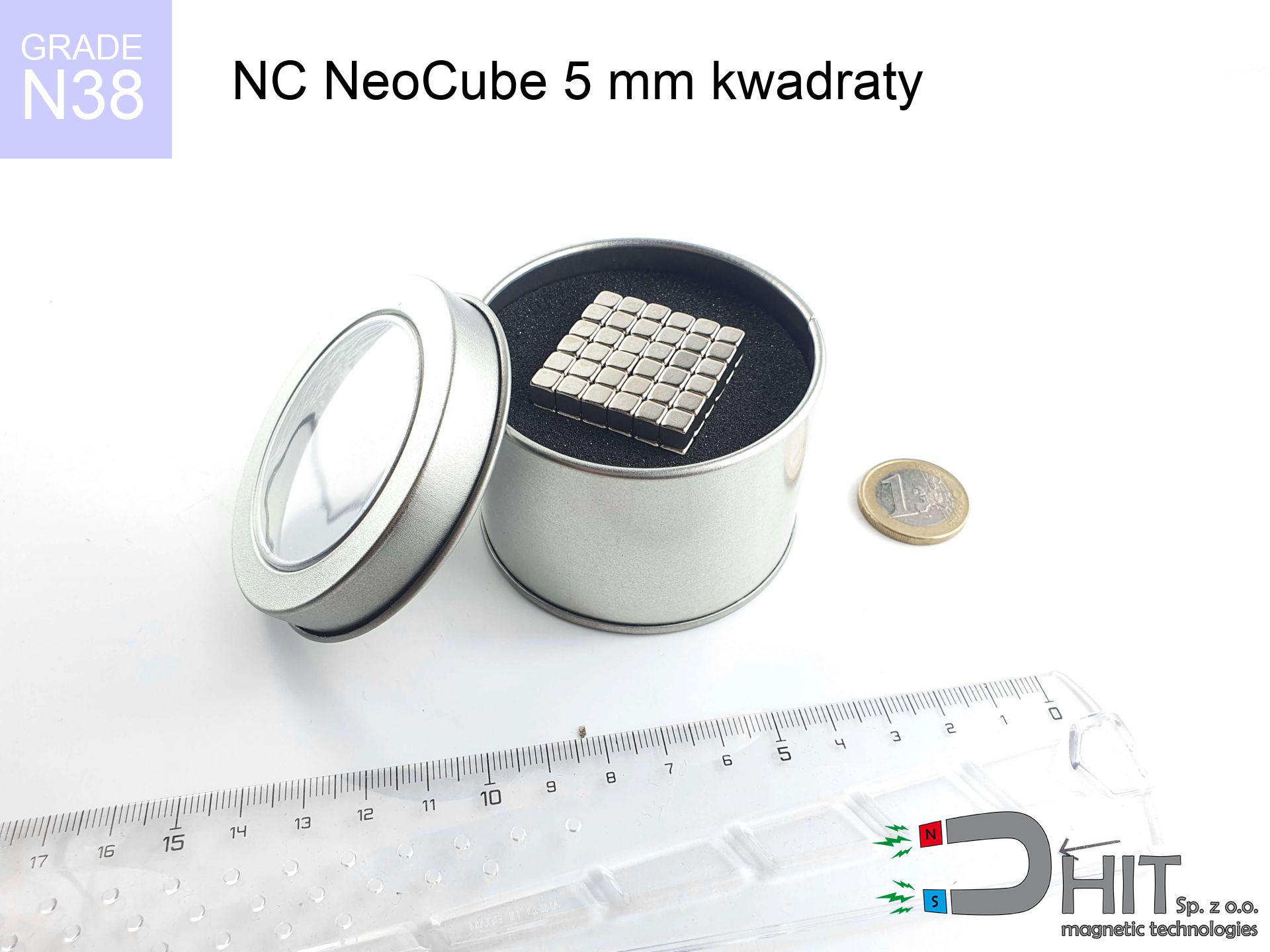

NC NeoCube 5 mm kwadraty / N38 - neocube

neocube

Catalog no 120227

GTIN: 5906301812661

Weight

216.5 g

Magnetization Direction

↑ axial

Coating

[NiCuNi] nickel

49.99 ZŁ with VAT / pcs + price for transport

40.64 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?Looking for a better price?

Pick up the phone and ask

+48 888 99 98 98

or get in touch by means of

inquiry form

our website.

Weight along with shape of magnets can be analyzed on our

magnetic mass calculator.

Orders submitted before 14:00 will be dispatched today!

Magnetic properties of material N38

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

Shopping tips

Strengths and weaknesses of rare earth magnets.

In addition to their long-term stability, neodymium magnets provide the following advantages:

- They do not lose power, even after approximately 10 years – the reduction in power is only ~1% (according to tests),

- They possess excellent resistance to magnetic field loss as a result of opposing magnetic fields,

- By using a smooth layer of gold, the element has an proper look,

- Magnetic induction on the surface of the magnet is exceptional,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, enabling operation at temperatures reaching 230°C and above...

- Due to the ability of accurate forming and adaptation to specialized needs, magnetic components can be created in a variety of geometric configurations, which amplifies use scope,

- Huge importance in high-tech industry – they find application in HDD drives, electromotive mechanisms, diagnostic systems, and industrial machines.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Disadvantages of neodymium magnets:

- Brittleness is one of their disadvantages. Upon intense impact they can break. We advise keeping them in a steel housing, which not only secures them against impacts but also raises their durability

- When exposed to high temperature, neodymium magnets experience a drop in power. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we suggest using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- We suggest a housing - magnetic mechanism, due to difficulties in realizing nuts inside the magnet and complicated shapes.

- Health risk related to microscopic parts of magnets are risky, in case of ingestion, which becomes key in the context of child health protection. Additionally, small elements of these magnets can be problematic in diagnostics medical when they are in the body.

- With mass production the cost of neodymium magnets can be a barrier,

Optimal lifting capacity of a neodymium magnet – what contributes to it?

Magnet power is the result of a measurement for ideal contact conditions, including:

- with the application of a yoke made of special test steel, ensuring full magnetic saturation

- with a cross-section no less than 10 mm

- characterized by lack of roughness

- without any insulating layer between the magnet and steel

- during detachment in a direction vertical to the mounting surface

- in stable room temperature

Determinants of lifting force in real conditions

It is worth knowing that the application force will differ depending on elements below, in order of importance:

- Space between surfaces – every millimeter of separation (caused e.g. by varnish or dirt) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Direction of force – highest force is available only during perpendicular pulling. The resistance to sliding of the magnet along the surface is typically many times lower (approx. 1/5 of the lifting capacity).

- Plate thickness – insufficiently thick steel causes magnetic saturation, causing part of the flux to be lost into the air.

- Steel grade – the best choice is pure iron steel. Cast iron may attract less.

- Surface finish – full contact is possible only on polished steel. Rough texture reduce the real contact area, reducing force.

- Thermal environment – heating the magnet causes a temporary drop of induction. It is worth remembering the maximum operating temperature for a given model.

* Lifting capacity was determined with the use of a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular pulling force, whereas under attempts to slide the magnet the load capacity is reduced by as much as 5 times. Moreover, even a slight gap {between} the magnet’s surface and the plate reduces the holding force.

H&S for magnets

Power loss in heat

Monitor thermal conditions. Exposing the magnet to high heat will permanently weaken its properties and pulling force.

Dust explosion hazard

Machining of NdFeB material carries a risk of fire risk. Magnetic powder oxidizes rapidly with oxygen and is difficult to extinguish.

Powerful field

Before use, check safety instructions. Sudden snapping can destroy the magnet or injure your hand. Think ahead.

Phone sensors

A powerful magnetic field negatively affects the functioning of magnetometers in phones and GPS navigation. Keep magnets close to a smartphone to prevent damaging the sensors.

Magnetic media

Do not bring magnets near a purse, computer, or TV. The magnetism can permanently damage these devices and erase data from cards.

Risk of cracking

Despite metallic appearance, the material is brittle and cannot withstand shocks. Do not hit, as the magnet may crumble into hazardous fragments.

Allergic reactions

Studies show that the nickel plating (standard magnet coating) is a common allergen. If you have an allergy, prevent touching magnets with bare hands or opt for coated magnets.

Serious injuries

Protect your hands. Two large magnets will snap together instantly with a force of several hundred kilograms, destroying anything in their path. Be careful!

Health Danger

For implant holders: Strong magnetic fields affect electronics. Maintain minimum 30 cm distance or request help to work with the magnets.

Adults only

Absolutely keep magnets away from children. Risk of swallowing is high, and the effects of magnets connecting inside the body are fatal.

Attention!

Looking for details? Read our article: Are neodymium magnets dangerous?

![HH 32x7.8 [M5] / N38 - through hole magnetic holder HH 32x7.8 [M5] / N38 - through hole magnetic holder](https://cdn3.dhit.pl/graphics/products/hh-32x7.8-m5-war.jpg)

![SM 32x325 [2xM8] / N42 - magnetic separator SM 32x325 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x325-2xm8-fog.jpg)