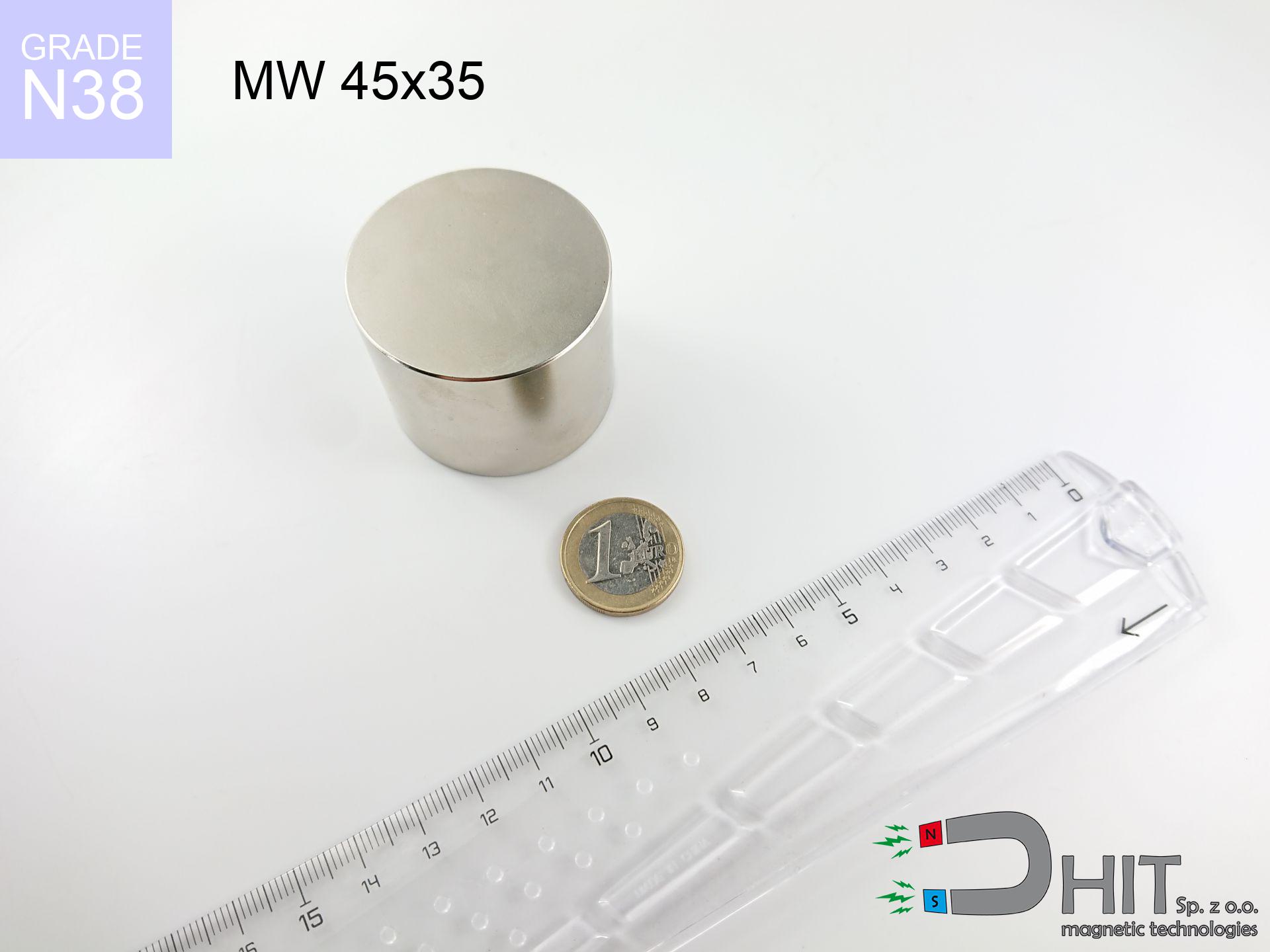

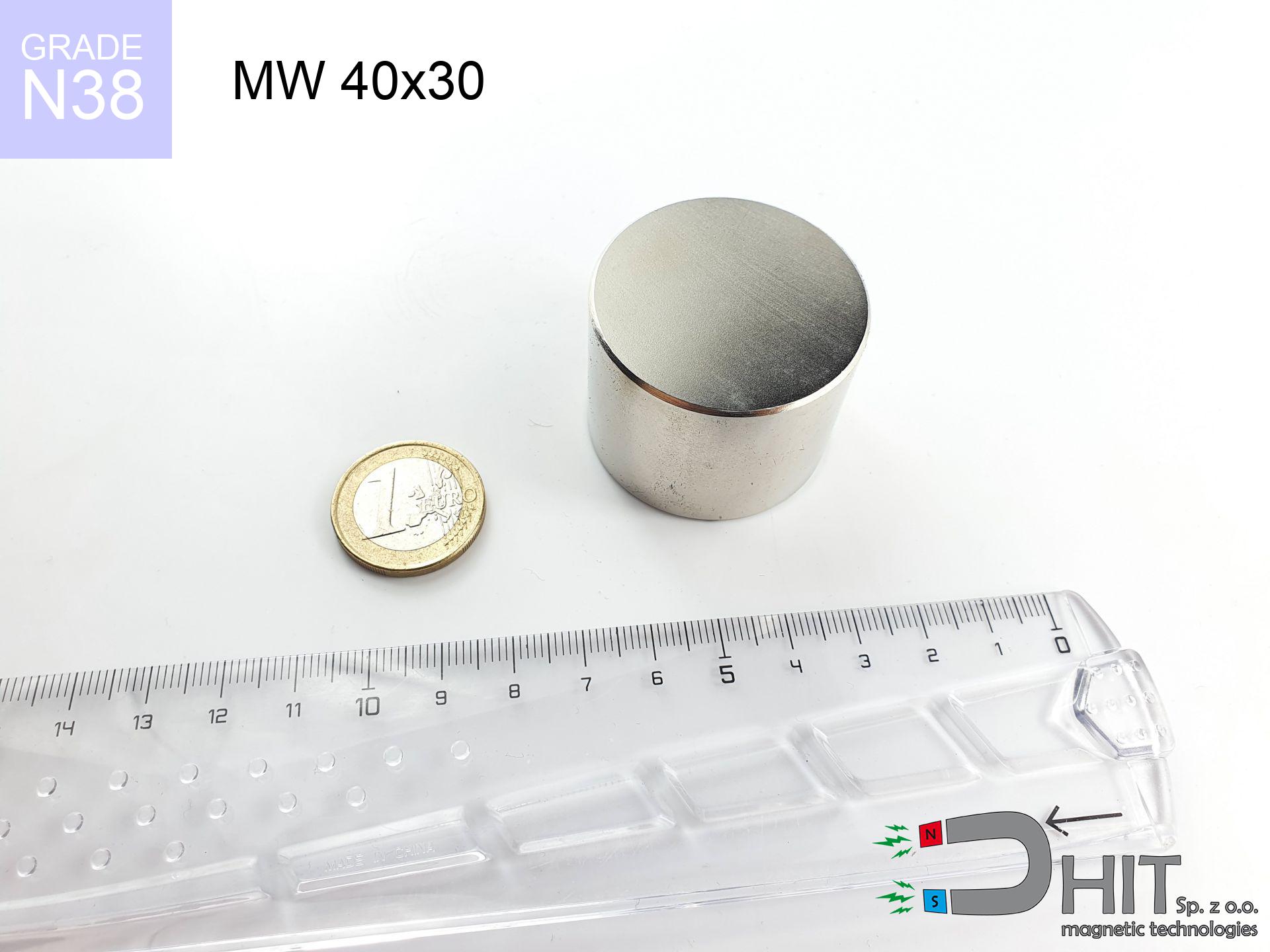

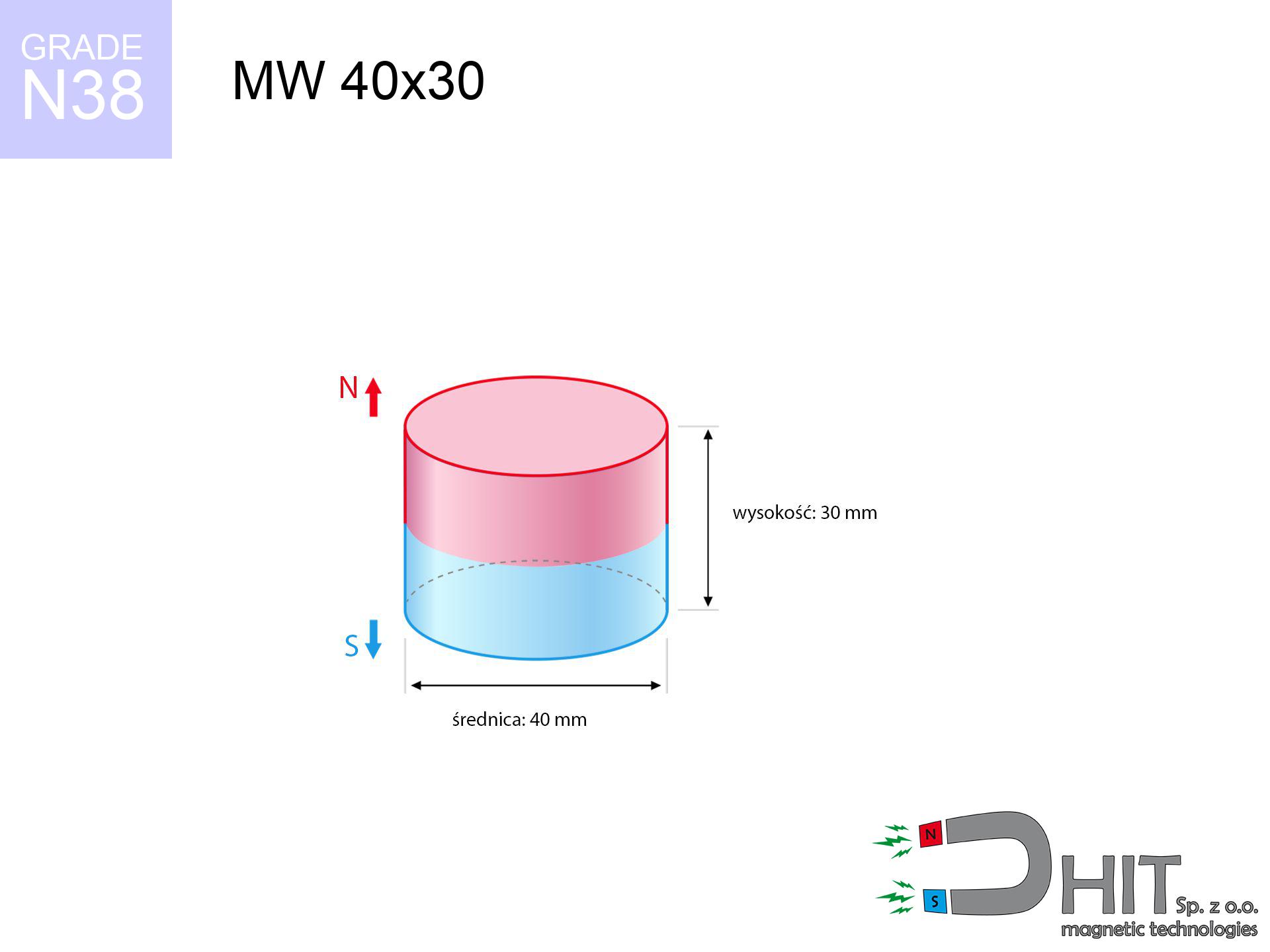

MW 40x30 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010068

GTIN/EAN: 5906301810674

Diameter Ø

40 mm [±0,1 mm]

Height

30 mm [±0,1 mm]

Weight

282.74 g

Magnetization Direction

→ diametrical

Load capacity

54.73 kg / 536.88 N

Magnetic Induction

515.71 mT / 5157 Gs

Coating

[NiCuNi] Nickel

104.80 ZŁ with VAT / pcs + price for transport

85.20 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 888 99 98 98

or send us a note using

form

the contact section.

Lifting power along with shape of neodymium magnets can be tested on our

force calculator.

Same-day processing for orders placed before 14:00.

Product card - MW 40x30 / N38 - cylindrical magnet

Specification / characteristics - MW 40x30 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010068 |

| GTIN/EAN | 5906301810674 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 40 mm [±0,1 mm] |

| Height | 30 mm [±0,1 mm] |

| Weight | 282.74 g |

| Magnetization Direction | → diametrical |

| Load capacity ~ ? | 54.73 kg / 536.88 N |

| Magnetic Induction ~ ? | 515.71 mT / 5157 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the product - technical parameters

The following data represent the outcome of a physical simulation. Values were calculated on models for the material Nd2Fe14B. Operational performance may differ from theoretical values. Treat these data as a supplementary guide when designing systems.

Table 1: Static pull force (force vs distance) - interaction chart

MW 40x30 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

5156 Gs

515.6 mT

|

54.73 kg / 120.66 LBS

54730.0 g / 536.9 N

|

critical level |

| 1 mm |

4900 Gs

490.0 mT

|

49.43 kg / 108.98 LBS

49432.0 g / 484.9 N

|

critical level |

| 2 mm |

4641 Gs

464.1 mT

|

44.33 kg / 97.74 LBS

44334.0 g / 434.9 N

|

critical level |

| 3 mm |

4383 Gs

438.3 mT

|

39.54 kg / 87.17 LBS

39538.7 g / 387.9 N

|

critical level |

| 5 mm |

3879 Gs

387.9 mT

|

30.98 kg / 68.30 LBS

30981.5 g / 303.9 N

|

critical level |

| 10 mm |

2773 Gs

277.3 mT

|

15.83 kg / 34.89 LBS

15826.7 g / 155.3 N

|

critical level |

| 15 mm |

1946 Gs

194.6 mT

|

7.79 kg / 17.18 LBS

7792.9 g / 76.4 N

|

medium risk |

| 20 mm |

1372 Gs

137.2 mT

|

3.88 kg / 8.55 LBS

3877.9 g / 38.0 N

|

medium risk |

| 30 mm |

723 Gs

72.3 mT

|

1.08 kg / 2.37 LBS

1076.5 g / 10.6 N

|

low risk |

| 50 mm |

258 Gs

25.8 mT

|

0.14 kg / 0.30 LBS

137.4 g / 1.3 N

|

low risk |

Table 2: Vertical hold (wall)

MW 40x30 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

10.95 kg / 24.13 LBS

10946.0 g / 107.4 N

|

| 1 mm | Stal (~0.2) |

9.89 kg / 21.79 LBS

9886.0 g / 97.0 N

|

| 2 mm | Stal (~0.2) |

8.87 kg / 19.55 LBS

8866.0 g / 87.0 N

|

| 3 mm | Stal (~0.2) |

7.91 kg / 17.43 LBS

7908.0 g / 77.6 N

|

| 5 mm | Stal (~0.2) |

6.20 kg / 13.66 LBS

6196.0 g / 60.8 N

|

| 10 mm | Stal (~0.2) |

3.17 kg / 6.98 LBS

3166.0 g / 31.1 N

|

| 15 mm | Stal (~0.2) |

1.56 kg / 3.43 LBS

1558.0 g / 15.3 N

|

| 20 mm | Stal (~0.2) |

0.78 kg / 1.71 LBS

776.0 g / 7.6 N

|

| 30 mm | Stal (~0.2) |

0.22 kg / 0.48 LBS

216.0 g / 2.1 N

|

| 50 mm | Stal (~0.2) |

0.03 kg / 0.06 LBS

28.0 g / 0.3 N

|

Table 3: Vertical assembly (sliding) - behavior on slippery surfaces

MW 40x30 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

16.42 kg / 36.20 LBS

16419.0 g / 161.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

10.95 kg / 24.13 LBS

10946.0 g / 107.4 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

5.47 kg / 12.07 LBS

5473.0 g / 53.7 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

27.37 kg / 60.33 LBS

27365.0 g / 268.5 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MW 40x30 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.82 kg / 4.02 LBS

1824.3 g / 17.9 N

|

| 1 mm |

|

4.56 kg / 10.05 LBS

4560.8 g / 44.7 N

|

| 2 mm |

|

9.12 kg / 20.11 LBS

9121.7 g / 89.5 N

|

| 3 mm |

|

13.68 kg / 30.16 LBS

13682.5 g / 134.2 N

|

| 5 mm |

|

22.80 kg / 50.27 LBS

22804.2 g / 223.7 N

|

| 10 mm |

|

45.61 kg / 100.55 LBS

45608.3 g / 447.4 N

|

| 11 mm |

|

50.17 kg / 110.60 LBS

50169.2 g / 492.2 N

|

| 12 mm |

|

54.73 kg / 120.66 LBS

54730.0 g / 536.9 N

|

Table 5: Thermal resistance (material behavior) - resistance threshold

MW 40x30 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

54.73 kg / 120.66 LBS

54730.0 g / 536.9 N

|

OK |

| 40 °C | -2.2% |

53.53 kg / 118.00 LBS

53525.9 g / 525.1 N

|

OK |

| 60 °C | -4.4% |

52.32 kg / 115.35 LBS

52321.9 g / 513.3 N

|

OK |

| 80 °C | -6.6% |

51.12 kg / 112.70 LBS

51117.8 g / 501.5 N

|

|

| 100 °C | -28.8% |

38.97 kg / 85.91 LBS

38967.8 g / 382.3 N

|

Table 6: Two magnets (attraction) - field collision

MW 40x30 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

205.97 kg / 454.08 LBS

5 879 Gs

|

30.89 kg / 68.11 LBS

30895 g / 303.1 N

|

N/A |

| 1 mm |

195.99 kg / 432.09 LBS

10 060 Gs

|

29.40 kg / 64.81 LBS

29399 g / 288.4 N

|

176.39 kg / 388.88 LBS

~0 Gs

|

| 2 mm |

186.03 kg / 410.12 LBS

9 800 Gs

|

27.90 kg / 61.52 LBS

27904 g / 273.7 N

|

167.42 kg / 369.11 LBS

~0 Gs

|

| 3 mm |

176.30 kg / 388.68 LBS

9 541 Gs

|

26.45 kg / 58.30 LBS

26445 g / 259.4 N

|

158.67 kg / 349.81 LBS

~0 Gs

|

| 5 mm |

157.67 kg / 347.60 LBS

9 023 Gs

|

23.65 kg / 52.14 LBS

23650 g / 232.0 N

|

141.90 kg / 312.84 LBS

~0 Gs

|

| 10 mm |

116.59 kg / 257.04 LBS

7 759 Gs

|

17.49 kg / 38.56 LBS

17489 g / 171.6 N

|

104.93 kg / 231.34 LBS

~0 Gs

|

| 20 mm |

59.56 kg / 131.31 LBS

5 545 Gs

|

8.93 kg / 19.70 LBS

8934 g / 87.6 N

|

53.60 kg / 118.18 LBS

~0 Gs

|

| 50 mm |

7.52 kg / 16.58 LBS

1 971 Gs

|

1.13 kg / 2.49 LBS

1128 g / 11.1 N

|

6.77 kg / 14.92 LBS

~0 Gs

|

| 60 mm |

4.05 kg / 8.93 LBS

1 446 Gs

|

0.61 kg / 1.34 LBS

608 g / 6.0 N

|

3.65 kg / 8.04 LBS

~0 Gs

|

| 70 mm |

2.28 kg / 5.03 LBS

1 085 Gs

|

0.34 kg / 0.75 LBS

342 g / 3.4 N

|

2.05 kg / 4.53 LBS

~0 Gs

|

| 80 mm |

1.34 kg / 2.96 LBS

832 Gs

|

0.20 kg / 0.44 LBS

201 g / 2.0 N

|

1.21 kg / 2.66 LBS

~0 Gs

|

| 90 mm |

0.82 kg / 1.80 LBS

650 Gs

|

0.12 kg / 0.27 LBS

123 g / 1.2 N

|

0.74 kg / 1.62 LBS

~0 Gs

|

| 100 mm |

0.52 kg / 1.14 LBS

517 Gs

|

0.08 kg / 0.17 LBS

78 g / 0.8 N

|

0.47 kg / 1.03 LBS

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 40x30 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 23.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 18.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 14.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 11.0 cm |

| Remote | 50 Gs (5.0 mT) | 10.0 cm |

| Payment card | 400 Gs (40.0 mT) | 4.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 3.5 cm |

Table 8: Dynamics (cracking risk) - collision effects

MW 40x30 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

16.37 km/h

(4.55 m/s)

|

2.92 J | |

| 30 mm |

24.60 km/h

(6.83 m/s)

|

6.60 J | |

| 50 mm |

31.42 km/h

(8.73 m/s)

|

10.77 J | |

| 100 mm |

44.37 km/h

(12.33 m/s)

|

21.48 J |

Table 9: Corrosion resistance

MW 40x30 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Pc)

MW 40x30 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 65 488 Mx | 654.9 µWb |

| Pc Coefficient | 0.76 | High (Stable) |

Table 11: Submerged application

MW 40x30 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 54.73 kg | Standard |

| Water (riverbed) |

62.67 kg

(+7.94 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical surface, the magnet holds merely ~20% of its perpendicular strength.

2. Steel thickness impact

*Thin steel (e.g. 0.5mm PC case) drastically reduces the holding force.

3. Thermal stability

*For standard magnets, the safety limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.76

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Elemental analysis

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View also offers

Advantages and disadvantages of Nd2Fe14B magnets.

Benefits

- They virtually do not lose power, because even after 10 years the decline in efficiency is only ~1% (based on calculations),

- They do not lose their magnetic properties even under strong external field,

- The use of an shiny coating of noble metals (nickel, gold, silver) causes the element to have aesthetics,

- Magnets are characterized by excellent magnetic induction on the working surface,

- Thanks to resistance to high temperature, they can operate (depending on the shape) even at temperatures up to 230°C and higher...

- Possibility of accurate shaping and adjusting to precise conditions,

- Wide application in modern industrial fields – they find application in computer drives, electromotive mechanisms, medical devices, as well as multitasking production systems.

- Thanks to their power density, small magnets offer high operating force, occupying minimum space,

Cons

- To avoid cracks upon strong impacts, we recommend using special steel housings. Such a solution secures the magnet and simultaneously increases its durability.

- Neodymium magnets demagnetize when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape as well as dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- Due to the susceptibility of magnets to corrosion in a humid environment, we recommend using waterproof magnets made of rubber, plastic or other material immune to moisture, in case of application outdoors

- We recommend a housing - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complex forms.

- Potential hazard resulting from small fragments of magnets can be dangerous, if swallowed, which gains importance in the aspect of protecting the youngest. Furthermore, small elements of these products can complicate diagnosis medical in case of swallowing.

- Due to expensive raw materials, their price is relatively high,

Lifting parameters

Maximum lifting capacity of the magnet – what it depends on?

- with the contact of a sheet made of low-carbon steel, guaranteeing maximum field concentration

- with a thickness minimum 10 mm

- with an polished contact surface

- without any air gap between the magnet and steel

- for force applied at a right angle (pull-off, not shear)

- in stable room temperature

Lifting capacity in practice – influencing factors

- Distance (betwixt the magnet and the plate), as even a very small distance (e.g. 0.5 mm) can cause a reduction in force by up to 50% (this also applies to paint, rust or debris).

- Loading method – declared lifting capacity refers to detachment vertically. When slipping, the magnet holds significantly lower power (often approx. 20-30% of maximum force).

- Plate thickness – insufficiently thick plate does not close the flux, causing part of the flux to be escaped to the other side.

- Plate material – mild steel gives the best results. Alloy admixtures reduce magnetic properties and lifting capacity.

- Base smoothness – the smoother and more polished the plate, the better the adhesion and higher the lifting capacity. Unevenness acts like micro-gaps.

- Thermal conditions – NdFeB sinters have a negative temperature coefficient. When it is hot they are weaker, and in frost gain strength (up to a certain limit).

Lifting capacity was determined with the use of a steel plate with a smooth surface of optimal thickness (min. 20 mm), under perpendicular pulling force, whereas under attempts to slide the magnet the holding force is lower. Moreover, even a small distance between the magnet’s surface and the plate decreases the holding force.

H&S for magnets

Swallowing risk

Only for adults. Small elements can be swallowed, leading to severe trauma. Store away from children and animals.

Skin irritation risks

Some people suffer from a contact allergy to Ni, which is the typical protective layer for neodymium magnets. Frequent touching might lead to skin redness. We suggest use protective gloves.

Beware of splinters

Beware of splinters. Magnets can explode upon violent connection, ejecting shards into the air. Wear goggles.

Serious injuries

Protect your hands. Two powerful magnets will join immediately with a force of several hundred kilograms, crushing everything in their path. Be careful!

Permanent damage

Watch the temperature. Exposing the magnet above 80 degrees Celsius will destroy its properties and pulling force.

Safe distance

Intense magnetic fields can corrupt files on credit cards, HDDs, and other magnetic media. Stay away of at least 10 cm.

Magnetic interference

A strong magnetic field interferes with the operation of magnetometers in smartphones and navigation systems. Do not bring magnets close to a device to avoid damaging the sensors.

Combustion hazard

Machining of neodymium magnets poses a fire risk. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Life threat

For implant holders: Powerful magnets affect electronics. Maintain at least 30 cm distance or request help to handle the magnets.

Conscious usage

Be careful. Rare earth magnets attract from a distance and connect with huge force, often faster than you can move away.

![SM 18x125 [2xM5] / N42 - magnetic separator SM 18x125 [2xM5] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-18x125-2xm5-cij.jpg)

![SM 32x250 [2xM8] / N42 - magnetic separator SM 32x250 [2xM8] / N42 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x250-2xm8-kex.jpg)