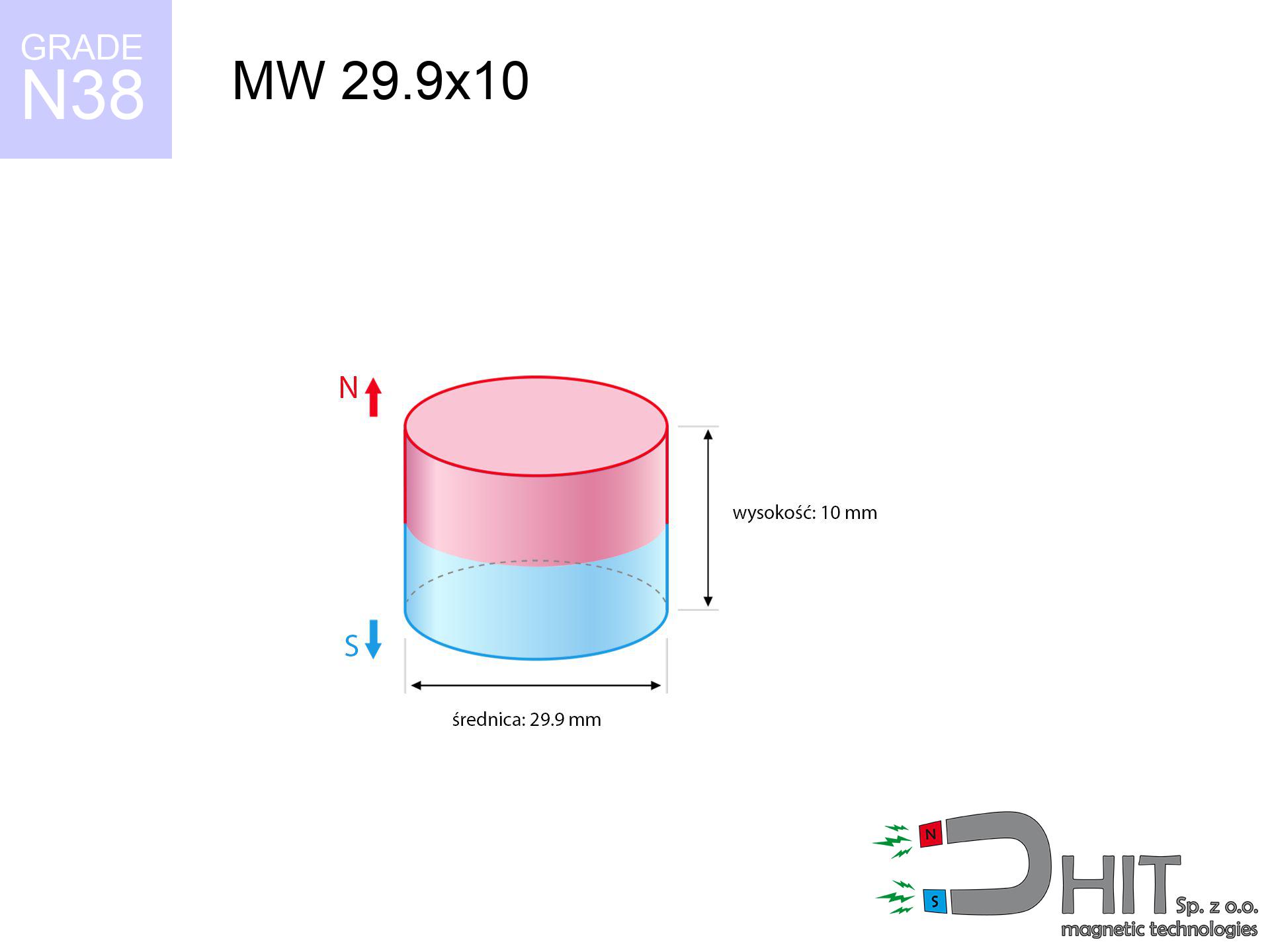

MW 29.9x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010052

GTIN/EAN: 5906301810513

Diameter Ø

29.9 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

52.66 g

Magnetization Direction

→ diametrical

Load capacity

21.50 kg / 210.90 N

Magnetic Induction

344.60 mT / 3446 Gs

Coating

[NiCuNi] Nickel

24.60 ZŁ with VAT / pcs + price for transport

20.00 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us now

+48 22 499 98 98

otherwise send us a note via

inquiry form

through our site.

Lifting power and appearance of a neodymium magnet can be estimated with our

power calculator.

Order by 14:00 and we’ll ship today!

Technical of the product - MW 29.9x10 / N38 - cylindrical magnet

Specification / characteristics - MW 29.9x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010052 |

| GTIN/EAN | 5906301810513 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 29.9 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 52.66 g |

| Magnetization Direction | → diametrical |

| Load capacity ~ ? | 21.50 kg / 210.90 N |

| Magnetic Induction ~ ? | 344.60 mT / 3446 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Technical analysis of the magnet - technical parameters

Presented values are the direct effect of a mathematical simulation. Values are based on models for the class Nd2Fe14B. Operational performance might slightly differ. Treat these calculations as a reference point during assembly planning.

Table 1: Static pull force (force vs distance) - power drop

MW 29.9x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

3445 Gs

344.5 mT

|

21.50 kg / 47.40 lbs

21500.0 g / 210.9 N

|

crushing |

| 1 mm |

3261 Gs

326.1 mT

|

19.26 kg / 42.45 lbs

19256.6 g / 188.9 N

|

crushing |

| 2 mm |

3059 Gs

305.9 mT

|

16.95 kg / 37.36 lbs

16947.4 g / 166.3 N

|

crushing |

| 3 mm |

2848 Gs

284.8 mT

|

14.70 kg / 32.40 lbs

14696.2 g / 144.2 N

|

crushing |

| 5 mm |

2425 Gs

242.5 mT

|

10.65 kg / 23.48 lbs

10650.1 g / 104.5 N

|

crushing |

| 10 mm |

1519 Gs

151.9 mT

|

4.18 kg / 9.21 lbs

4178.4 g / 41.0 N

|

medium risk |

| 15 mm |

930 Gs

93.0 mT

|

1.57 kg / 3.45 lbs

1565.8 g / 15.4 N

|

safe |

| 20 mm |

583 Gs

58.3 mT

|

0.62 kg / 1.36 lbs

616.0 g / 6.0 N

|

safe |

| 30 mm |

258 Gs

25.8 mT

|

0.12 kg / 0.27 lbs

121.0 g / 1.2 N

|

safe |

| 50 mm |

76 Gs

7.6 mT

|

0.01 kg / 0.02 lbs

10.4 g / 0.1 N

|

safe |

Table 2: Sliding hold (vertical surface)

MW 29.9x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

4.30 kg / 9.48 lbs

4300.0 g / 42.2 N

|

| 1 mm | Stal (~0.2) |

3.85 kg / 8.49 lbs

3852.0 g / 37.8 N

|

| 2 mm | Stal (~0.2) |

3.39 kg / 7.47 lbs

3390.0 g / 33.3 N

|

| 3 mm | Stal (~0.2) |

2.94 kg / 6.48 lbs

2940.0 g / 28.8 N

|

| 5 mm | Stal (~0.2) |

2.13 kg / 4.70 lbs

2130.0 g / 20.9 N

|

| 10 mm | Stal (~0.2) |

0.84 kg / 1.84 lbs

836.0 g / 8.2 N

|

| 15 mm | Stal (~0.2) |

0.31 kg / 0.69 lbs

314.0 g / 3.1 N

|

| 20 mm | Stal (~0.2) |

0.12 kg / 0.27 lbs

124.0 g / 1.2 N

|

| 30 mm | Stal (~0.2) |

0.02 kg / 0.05 lbs

24.0 g / 0.2 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 lbs

2.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - behavior on slippery surfaces

MW 29.9x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

6.45 kg / 14.22 lbs

6450.0 g / 63.3 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

4.30 kg / 9.48 lbs

4300.0 g / 42.2 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

2.15 kg / 4.74 lbs

2150.0 g / 21.1 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

10.75 kg / 23.70 lbs

10750.0 g / 105.5 N

|

Table 4: Steel thickness (saturation) - sheet metal selection

MW 29.9x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

1.08 kg / 2.37 lbs

1075.0 g / 10.5 N

|

| 1 mm |

|

2.69 kg / 5.92 lbs

2687.5 g / 26.4 N

|

| 2 mm |

|

5.38 kg / 11.85 lbs

5375.0 g / 52.7 N

|

| 3 mm |

|

8.06 kg / 17.77 lbs

8062.5 g / 79.1 N

|

| 5 mm |

|

13.44 kg / 29.62 lbs

13437.5 g / 131.8 N

|

| 10 mm |

|

21.50 kg / 47.40 lbs

21500.0 g / 210.9 N

|

| 11 mm |

|

21.50 kg / 47.40 lbs

21500.0 g / 210.9 N

|

| 12 mm |

|

21.50 kg / 47.40 lbs

21500.0 g / 210.9 N

|

Table 5: Thermal stability (material behavior) - resistance threshold

MW 29.9x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

21.50 kg / 47.40 lbs

21500.0 g / 210.9 N

|

OK |

| 40 °C | -2.2% |

21.03 kg / 46.36 lbs

21027.0 g / 206.3 N

|

OK |

| 60 °C | -4.4% |

20.55 kg / 45.31 lbs

20554.0 g / 201.6 N

|

|

| 80 °C | -6.6% |

20.08 kg / 44.27 lbs

20081.0 g / 197.0 N

|

|

| 100 °C | -28.8% |

15.31 kg / 33.75 lbs

15308.0 g / 150.2 N

|

Table 6: Magnet-Magnet interaction (attraction) - field collision

MW 29.9x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

51.38 kg / 113.28 lbs

4 963 Gs

|

7.71 kg / 16.99 lbs

7708 g / 75.6 N

|

N/A |

| 1 mm |

48.76 kg / 107.50 lbs

6 712 Gs

|

7.31 kg / 16.12 lbs

7314 g / 71.7 N

|

43.88 kg / 96.75 lbs

~0 Gs

|

| 2 mm |

46.02 kg / 101.46 lbs

6 521 Gs

|

6.90 kg / 15.22 lbs

6903 g / 67.7 N

|

41.42 kg / 91.32 lbs

~0 Gs

|

| 3 mm |

43.26 kg / 95.37 lbs

6 322 Gs

|

6.49 kg / 14.31 lbs

6489 g / 63.7 N

|

38.93 kg / 85.83 lbs

~0 Gs

|

| 5 mm |

37.78 kg / 83.30 lbs

5 909 Gs

|

5.67 kg / 12.49 lbs

5667 g / 55.6 N

|

34.00 kg / 74.97 lbs

~0 Gs

|

| 10 mm |

25.45 kg / 56.11 lbs

4 850 Gs

|

3.82 kg / 8.42 lbs

3818 g / 37.5 N

|

22.91 kg / 50.50 lbs

~0 Gs

|

| 20 mm |

9.99 kg / 22.02 lbs

3 038 Gs

|

1.50 kg / 3.30 lbs

1498 g / 14.7 N

|

8.99 kg / 19.81 lbs

~0 Gs

|

| 50 mm |

0.63 kg / 1.38 lbs

761 Gs

|

0.09 kg / 0.21 lbs

94 g / 0.9 N

|

0.56 kg / 1.24 lbs

~0 Gs

|

| 60 mm |

0.29 kg / 0.64 lbs

517 Gs

|

0.04 kg / 0.10 lbs

43 g / 0.4 N

|

0.26 kg / 0.57 lbs

~0 Gs

|

| 70 mm |

0.14 kg / 0.32 lbs

364 Gs

|

0.02 kg / 0.05 lbs

22 g / 0.2 N

|

0.13 kg / 0.28 lbs

~0 Gs

|

| 80 mm |

0.08 kg / 0.17 lbs

265 Gs

|

0.01 kg / 0.03 lbs

11 g / 0.1 N

|

0.07 kg / 0.15 lbs

~0 Gs

|

| 90 mm |

0.04 kg / 0.09 lbs

198 Gs

|

0.01 kg / 0.01 lbs

6 g / 0.1 N

|

0.04 kg / 0.08 lbs

~0 Gs

|

| 100 mm |

0.02 kg / 0.05 lbs

152 Gs

|

0.00 kg / 0.01 lbs

4 g / 0.0 N

|

0.02 kg / 0.05 lbs

~0 Gs

|

Table 7: Safety (HSE) (electronics) - warnings

MW 29.9x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 13.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 11.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 8.5 cm |

| Mobile device | 40 Gs (4.0 mT) | 6.5 cm |

| Remote | 50 Gs (5.0 mT) | 6.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Impact energy (kinetic energy) - warning

MW 29.9x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

22.72 km/h

(6.31 m/s)

|

1.05 J | |

| 30 mm |

35.42 km/h

(9.84 m/s)

|

2.55 J | |

| 50 mm |

45.58 km/h

(12.66 m/s)

|

4.22 J | |

| 100 mm |

64.44 km/h

(17.90 m/s)

|

8.44 J |

Table 9: Coating parameters (durability)

MW 29.9x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 29.9x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 25 588 Mx | 255.9 µWb |

| Pc Coefficient | 0.44 | Low (Flat) |

Table 11: Underwater work (magnet fishing)

MW 29.9x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 21.50 kg | Standard |

| Water (riverbed) |

24.62 kg

(+3.12 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Warning: On a vertical wall, the magnet holds merely ~20% of its perpendicular strength.

2. Steel thickness impact

*Thin steel (e.g. computer case) significantly limits the holding force.

3. Thermal stability

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.44

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

View more deals

Advantages and disadvantages of Nd2Fe14B magnets.

Strengths

- They have stable power, and over around 10 years their attraction force decreases symbolically – ~1% (according to theory),

- They have excellent resistance to magnetism drop as a result of opposing magnetic fields,

- The use of an shiny layer of noble metals (nickel, gold, silver) causes the element to present itself better,

- They feature high magnetic induction at the operating surface, making them more effective,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, allowing for functioning at temperatures approaching 230°C and above...

- Possibility of precise machining and optimizing to precise needs,

- Key role in advanced technology sectors – they are used in magnetic memories, electric motors, diagnostic systems, and modern systems.

- Thanks to concentrated force, small magnets offer high operating force, occupying minimum space,

Disadvantages

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets in a protective case. Such protection not only shields the magnet but also increases its resistance to damage

- When exposed to high temperature, neodymium magnets suffer a drop in power. Often, when the temperature exceeds 80°C, their power decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Magnets exposed to a humid environment can corrode. Therefore while using outdoors, we suggest using water-impermeable magnets made of rubber, plastic or other material protecting against moisture

- We recommend casing - magnetic mount, due to difficulties in creating nuts inside the magnet and complicated forms.

- Potential hazard related to microscopic parts of magnets are risky, if swallowed, which becomes key in the context of child safety. Furthermore, small elements of these devices can complicate diagnosis medical in case of swallowing.

- With budget limitations the cost of neodymium magnets is a challenge,

Holding force characteristics

Optimal lifting capacity of a neodymium magnet – what contributes to it?

- with the use of a yoke made of special test steel, guaranteeing full magnetic saturation

- possessing a massiveness of min. 10 mm to ensure full flux closure

- characterized by smoothness

- with direct contact (without coatings)

- under perpendicular force vector (90-degree angle)

- at temperature approx. 20 degrees Celsius

Determinants of practical lifting force of a magnet

- Gap between magnet and steel – every millimeter of distance (caused e.g. by varnish or unevenness) diminishes the magnet efficiency, often by half at just 0.5 mm.

- Force direction – catalog parameter refers to detachment vertically. When slipping, the magnet holds significantly lower power (typically approx. 20-30% of maximum force).

- Metal thickness – thin material does not allow full use of the magnet. Magnetic flux penetrates through instead of generating force.

- Material type – the best choice is pure iron steel. Cast iron may attract less.

- Surface condition – ground elements guarantee perfect abutment, which increases force. Uneven metal reduce efficiency.

- Thermal factor – hot environment weakens pulling force. Too high temperature can permanently damage the magnet.

Lifting capacity was measured using a polished steel plate of suitable thickness (min. 20 mm), under perpendicular pulling force, however under shearing force the load capacity is reduced by as much as fivefold. Additionally, even a slight gap between the magnet and the plate reduces the load capacity.

Safety rules for work with neodymium magnets

Allergy Warning

Studies show that nickel (standard magnet coating) is a strong allergen. If you have an allergy, prevent touching magnets with bare hands or opt for versions in plastic housing.

Conscious usage

Before use, read the rules. Uncontrolled attraction can break the magnet or injure your hand. Think ahead.

Keep away from children

Strictly keep magnets away from children. Ingestion danger is high, and the consequences of magnets connecting inside the body are fatal.

Health Danger

Individuals with a pacemaker have to maintain an safe separation from magnets. The magnetic field can stop the functioning of the implant.

Magnets are brittle

Despite the nickel coating, the material is delicate and not impact-resistant. Avoid impacts, as the magnet may crumble into hazardous fragments.

Bone fractures

Large magnets can break fingers instantly. Never place your hand betwixt two strong magnets.

Keep away from computers

Do not bring magnets near a wallet, computer, or screen. The magnetism can irreversibly ruin these devices and erase data from cards.

Thermal limits

Keep cool. Neodymium magnets are sensitive to heat. If you need resistance above 80°C, ask us about special high-temperature series (H, SH, UH).

Do not drill into magnets

Mechanical processing of NdFeB material carries a risk of fire risk. Neodymium dust reacts violently with oxygen and is hard to extinguish.

Magnetic interference

A strong magnetic field disrupts the functioning of compasses in phones and GPS navigation. Maintain magnets near a device to prevent breaking the sensors.

![BM 380x180x70 [4x M8] - magnetic beam BM 380x180x70 [4x M8] - magnetic beam](https://cdn3.dhit.pl/graphics/products/bm-380x180x70-4x-m8-wex.jpg)

![UMH 32x8x46 [M6] / N38 - magnetic holder with hook UMH 32x8x46 [M6] / N38 - magnetic holder with hook](https://cdn3.dhit.pl/graphics/products/umh-32x8x46-m6-xov.jpg)