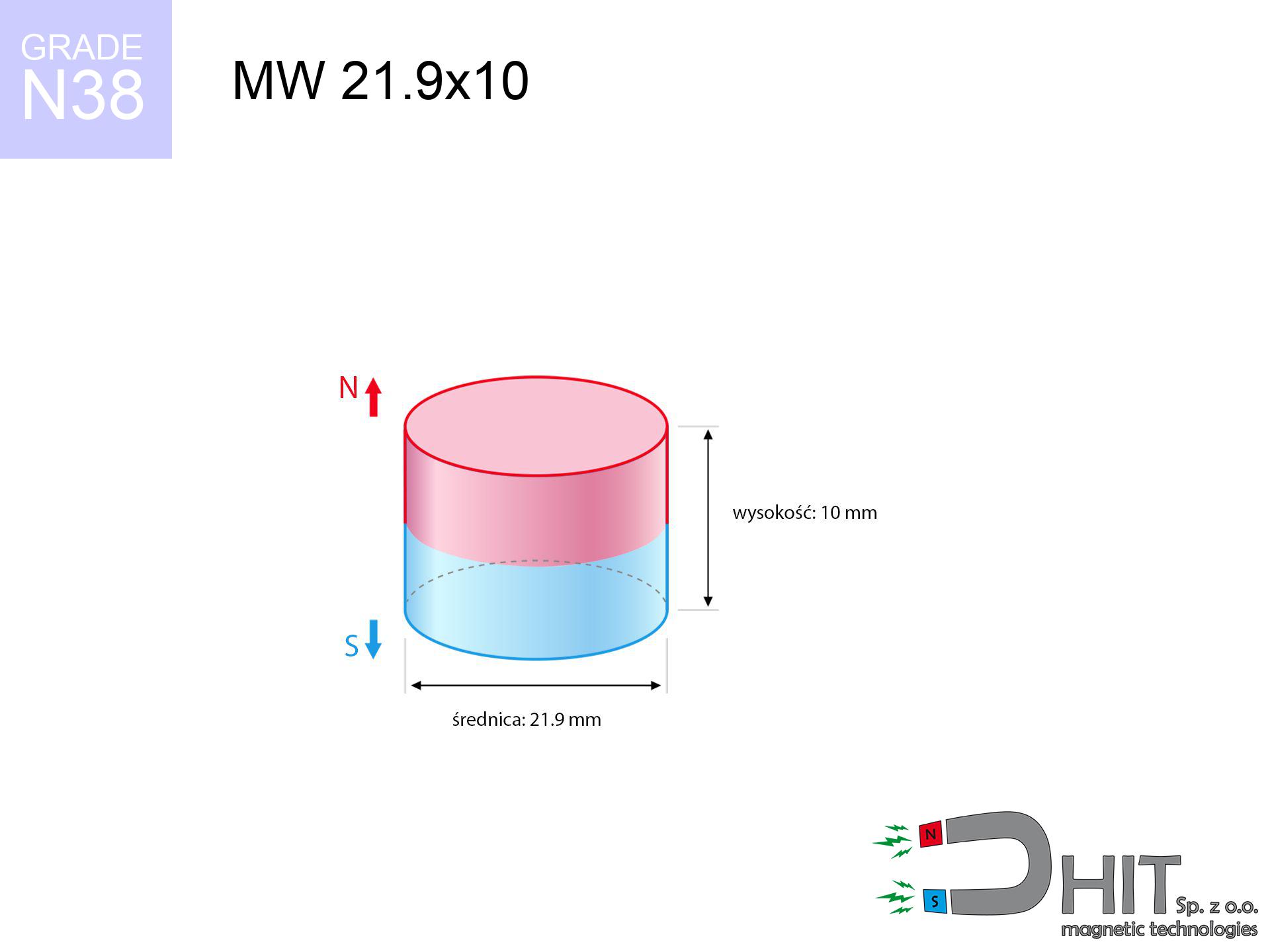

MW 21.9x10 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010045

GTIN/EAN: 5906301810445

Diameter Ø

21.9 mm [±0,1 mm]

Height

10 mm [±0,1 mm]

Weight

28.25 g

Magnetization Direction

→ diametrical

Load capacity

14.65 kg / 143.71 N

Magnetic Induction

417.89 mT / 4179 Gs

Coating

[NiCuNi] Nickel

15.50 ZŁ with VAT / pcs + price for transport

12.60 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Pick up the phone and ask

+48 22 499 98 98

otherwise send us a note using

form

the contact page.

Lifting power as well as shape of a magnet can be reviewed using our

magnetic calculator.

Same-day shipping for orders placed before 14:00.

Physical properties - MW 21.9x10 / N38 - cylindrical magnet

Specification / characteristics - MW 21.9x10 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010045 |

| GTIN/EAN | 5906301810445 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 21.9 mm [±0,1 mm] |

| Height | 10 mm [±0,1 mm] |

| Weight | 28.25 g |

| Magnetization Direction | → diametrical |

| Load capacity ~ ? | 14.65 kg / 143.71 N |

| Magnetic Induction ~ ? | 417.89 mT / 4179 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Physical simulation of the product - report

Presented values constitute the direct effect of a mathematical analysis. Results were calculated on models for the class Nd2Fe14B. Real-world performance may differ. Use these data as a reference point when designing systems.

Table 1: Static force (pull vs distance) - power drop

MW 21.9x10 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

4178 Gs

417.8 mT

|

14.65 kg / 32.30 LBS

14650.0 g / 143.7 N

|

crushing |

| 1 mm |

3830 Gs

383.0 mT

|

12.31 kg / 27.15 LBS

12314.7 g / 120.8 N

|

crushing |

| 2 mm |

3466 Gs

346.6 mT

|

10.08 kg / 22.23 LBS

10083.5 g / 98.9 N

|

crushing |

| 3 mm |

3104 Gs

310.4 mT

|

8.09 kg / 17.83 LBS

8086.3 g / 79.3 N

|

warning |

| 5 mm |

2432 Gs

243.2 mT

|

4.97 kg / 10.95 LBS

4966.5 g / 48.7 N

|

warning |

| 10 mm |

1257 Gs

125.7 mT

|

1.33 kg / 2.93 LBS

1327.0 g / 13.0 N

|

safe |

| 15 mm |

671 Gs

67.1 mT

|

0.38 kg / 0.83 LBS

378.5 g / 3.7 N

|

safe |

| 20 mm |

386 Gs

38.6 mT

|

0.13 kg / 0.28 LBS

125.0 g / 1.2 N

|

safe |

| 30 mm |

156 Gs

15.6 mT

|

0.02 kg / 0.04 LBS

20.4 g / 0.2 N

|

safe |

| 50 mm |

43 Gs

4.3 mT

|

0.00 kg / 0.00 LBS

1.5 g / 0.0 N

|

safe |

Table 2: Vertical force (vertical surface)

MW 21.9x10 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

2.93 kg / 6.46 LBS

2930.0 g / 28.7 N

|

| 1 mm | Stal (~0.2) |

2.46 kg / 5.43 LBS

2462.0 g / 24.2 N

|

| 2 mm | Stal (~0.2) |

2.02 kg / 4.44 LBS

2016.0 g / 19.8 N

|

| 3 mm | Stal (~0.2) |

1.62 kg / 3.57 LBS

1618.0 g / 15.9 N

|

| 5 mm | Stal (~0.2) |

0.99 kg / 2.19 LBS

994.0 g / 9.8 N

|

| 10 mm | Stal (~0.2) |

0.27 kg / 0.59 LBS

266.0 g / 2.6 N

|

| 15 mm | Stal (~0.2) |

0.08 kg / 0.17 LBS

76.0 g / 0.7 N

|

| 20 mm | Stal (~0.2) |

0.03 kg / 0.06 LBS

26.0 g / 0.3 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Vertical assembly (shearing) - vertical pull

MW 21.9x10 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

4.40 kg / 9.69 LBS

4395.0 g / 43.1 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

2.93 kg / 6.46 LBS

2930.0 g / 28.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

1.47 kg / 3.23 LBS

1465.0 g / 14.4 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

7.33 kg / 16.15 LBS

7325.0 g / 71.9 N

|

Table 4: Material efficiency (substrate influence) - sheet metal selection

MW 21.9x10 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.73 kg / 1.61 LBS

732.5 g / 7.2 N

|

| 1 mm |

|

1.83 kg / 4.04 LBS

1831.3 g / 18.0 N

|

| 2 mm |

|

3.66 kg / 8.07 LBS

3662.5 g / 35.9 N

|

| 3 mm |

|

5.49 kg / 12.11 LBS

5493.8 g / 53.9 N

|

| 5 mm |

|

9.16 kg / 20.19 LBS

9156.3 g / 89.8 N

|

| 10 mm |

|

14.65 kg / 32.30 LBS

14650.0 g / 143.7 N

|

| 11 mm |

|

14.65 kg / 32.30 LBS

14650.0 g / 143.7 N

|

| 12 mm |

|

14.65 kg / 32.30 LBS

14650.0 g / 143.7 N

|

Table 5: Working in heat (stability) - thermal limit

MW 21.9x10 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

14.65 kg / 32.30 LBS

14650.0 g / 143.7 N

|

OK |

| 40 °C | -2.2% |

14.33 kg / 31.59 LBS

14327.7 g / 140.6 N

|

OK |

| 60 °C | -4.4% |

14.01 kg / 30.88 LBS

14005.4 g / 137.4 N

|

|

| 80 °C | -6.6% |

13.68 kg / 30.17 LBS

13683.1 g / 134.2 N

|

|

| 100 °C | -28.8% |

10.43 kg / 23.00 LBS

10430.8 g / 102.3 N

|

Table 6: Magnet-Magnet interaction (attraction) - field range

MW 21.9x10 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Shear Strength (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

40.53 kg / 89.35 LBS

5 433 Gs

|

6.08 kg / 13.40 LBS

6079 g / 59.6 N

|

N/A |

| 1 mm |

37.31 kg / 82.26 LBS

8 017 Gs

|

5.60 kg / 12.34 LBS

5597 g / 54.9 N

|

33.58 kg / 74.03 LBS

~0 Gs

|

| 2 mm |

34.07 kg / 75.11 LBS

7 660 Gs

|

5.11 kg / 11.27 LBS

5110 g / 50.1 N

|

30.66 kg / 67.60 LBS

~0 Gs

|

| 3 mm |

30.92 kg / 68.16 LBS

7 297 Gs

|

4.64 kg / 10.22 LBS

4637 g / 45.5 N

|

27.82 kg / 61.34 LBS

~0 Gs

|

| 5 mm |

25.04 kg / 55.20 LBS

6 567 Gs

|

3.76 kg / 8.28 LBS

3756 g / 36.8 N

|

22.54 kg / 49.68 LBS

~0 Gs

|

| 10 mm |

13.74 kg / 30.29 LBS

4 865 Gs

|

2.06 kg / 4.54 LBS

2061 g / 20.2 N

|

12.37 kg / 27.26 LBS

~0 Gs

|

| 20 mm |

3.67 kg / 8.09 LBS

2 515 Gs

|

0.55 kg / 1.21 LBS

551 g / 5.4 N

|

3.30 kg / 7.28 LBS

~0 Gs

|

| 50 mm |

0.13 kg / 0.29 LBS

476 Gs

|

0.02 kg / 0.04 LBS

20 g / 0.2 N

|

0.12 kg / 0.26 LBS

~0 Gs

|

| 60 mm |

0.06 kg / 0.12 LBS

312 Gs

|

0.01 kg / 0.02 LBS

8 g / 0.1 N

|

0.05 kg / 0.11 LBS

~0 Gs

|

| 70 mm |

0.03 kg / 0.06 LBS

214 Gs

|

0.00 kg / 0.01 LBS

4 g / 0.0 N

|

0.02 kg / 0.05 LBS

~0 Gs

|

| 80 mm |

0.01 kg / 0.03 LBS

153 Gs

|

0.00 kg / 0.00 LBS

2 g / 0.0 N

|

0.01 kg / 0.03 LBS

~0 Gs

|

| 90 mm |

0.01 kg / 0.02 LBS

113 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.01 LBS

86 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (electronics) - warnings

MW 21.9x10 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 11.0 cm |

| Hearing aid | 10 Gs (1.0 mT) | 9.0 cm |

| Timepiece | 20 Gs (2.0 mT) | 7.0 cm |

| Mobile device | 40 Gs (4.0 mT) | 5.5 cm |

| Car key | 50 Gs (5.0 mT) | 5.0 cm |

| Payment card | 400 Gs (40.0 mT) | 2.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 2.0 cm |

Table 8: Collisions (kinetic energy) - warning

MW 21.9x10 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

24.23 km/h

(6.73 m/s)

|

0.64 J | |

| 30 mm |

39.81 km/h

(11.06 m/s)

|

1.73 J | |

| 50 mm |

51.36 km/h

(14.27 m/s)

|

2.87 J | |

| 100 mm |

72.63 km/h

(20.17 m/s)

|

5.75 J |

Table 9: Surface protection spec

MW 21.9x10 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Construction data (Pc)

MW 21.9x10 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 16 059 Mx | 160.6 µWb |

| Pc Coefficient | 0.55 | Low (Flat) |

Table 11: Hydrostatics and buoyancy

MW 21.9x10 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 14.65 kg | Standard |

| Water (riverbed) |

16.77 kg

(+2.12 kg buoyancy gain)

|

+14.5% |

1. Vertical hold

*Note: On a vertical wall, the magnet holds merely ~20% of its nominal pull.

2. Plate thickness effect

*Thin steel (e.g. 0.5mm PC case) severely reduces the holding force.

3. Power loss vs temp

*For N38 grade, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.55

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other deals

Advantages as well as disadvantages of Nd2Fe14B magnets.

Benefits

- They do not lose magnetism, even during approximately 10 years – the drop in strength is only ~1% (theoretically),

- Magnets effectively protect themselves against loss of magnetization caused by external fields,

- By applying a lustrous coating of nickel, the element presents an elegant look,

- They show high magnetic induction at the operating surface, which affects their effectiveness,

- Through (adequate) combination of ingredients, they can achieve high thermal strength, allowing for action at temperatures approaching 230°C and above...

- Possibility of custom shaping as well as adjusting to atypical needs,

- Huge importance in innovative solutions – they find application in data components, brushless drives, medical equipment, also modern systems.

- Thanks to concentrated force, small magnets offer high operating force, with minimal size,

Weaknesses

- They are fragile upon too strong impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only shields the magnet but also improves its resistance to damage

- NdFeB magnets lose strength when exposed to high temperatures. After reaching 80°C, many of them experience permanent weakening of power (a factor is the shape and dimensions of the magnet). We offer magnets specially adapted to work at temperatures up to 230°C marked [AH], which are extremely resistant to heat

- When exposed to humidity, magnets start to rust. For applications outside, it is recommended to use protective magnets, such as those in rubber or plastics, which prevent oxidation and corrosion.

- We suggest cover - magnetic mechanism, due to difficulties in creating nuts inside the magnet and complex forms.

- Health risk to health – tiny shards of magnets are risky, if swallowed, which is particularly important in the aspect of protecting the youngest. Furthermore, tiny parts of these devices can be problematic in diagnostics medical when they are in the body.

- High unit price – neodymium magnets have a higher price than other types of magnets (e.g. ferrite), which can limit application in large quantities

Holding force characteristics

Maximum lifting capacity of the magnet – what affects it?

- on a block made of mild steel, optimally conducting the magnetic field

- possessing a thickness of min. 10 mm to ensure full flux closure

- with an polished contact surface

- under conditions of gap-free contact (surface-to-surface)

- for force applied at a right angle (pull-off, not shear)

- at temperature room level

Determinants of practical lifting force of a magnet

- Gap (between the magnet and the plate), because even a very small distance (e.g. 0.5 mm) can cause a drastic drop in force by up to 50% (this also applies to varnish, corrosion or debris).

- Loading method – catalog parameter refers to pulling vertically. When applying parallel force, the magnet holds much less (often approx. 20-30% of maximum force).

- Base massiveness – too thin sheet does not close the flux, causing part of the flux to be lost into the air.

- Material type – ideal substrate is pure iron steel. Cast iron may have worse magnetic properties.

- Surface finish – full contact is possible only on smooth steel. Any scratches and bumps reduce the real contact area, reducing force.

- Thermal environment – temperature increase causes a temporary drop of force. Check the thermal limit for a given model.

Lifting capacity was determined by applying a polished steel plate of optimal thickness (min. 20 mm), under vertically applied force, however under shearing force the holding force is lower. Moreover, even a minimal clearance between the magnet’s surface and the plate lowers the lifting capacity.

Precautions when working with NdFeB magnets

Danger to pacemakers

For implant holders: Powerful magnets disrupt medical devices. Keep minimum 30 cm distance or request help to work with the magnets.

Magnet fragility

Despite metallic appearance, the material is delicate and not impact-resistant. Do not hit, as the magnet may crumble into sharp, dangerous pieces.

Magnetic media

Avoid bringing magnets close to a wallet, computer, or screen. The magnetic field can destroy these devices and erase data from cards.

Maximum temperature

Standard neodymium magnets (N-type) lose power when the temperature exceeds 80°C. Damage is permanent.

Do not underestimate power

Before starting, read the rules. Uncontrolled attraction can break the magnet or injure your hand. Think ahead.

Nickel coating and allergies

A percentage of the population suffer from a sensitization to nickel, which is the typical protective layer for NdFeB magnets. Prolonged contact may cause a rash. We suggest use protective gloves.

Keep away from children

NdFeB magnets are not suitable for play. Eating several magnets can lead to them pinching intestinal walls, which poses a severe health hazard and requires immediate surgery.

Machining danger

Powder created during grinding of magnets is flammable. Avoid drilling into magnets without proper cooling and knowledge.

Serious injuries

Large magnets can smash fingers in a fraction of a second. Never put your hand between two strong magnets.

Magnetic interference

GPS units and mobile phones are extremely susceptible to magnetic fields. Close proximity with a strong magnet can ruin the sensors in your phone.

![SM 32x475 [2xM8] / N52 - magnetic separator SM 32x475 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-32x475-2xm8-wef.jpg)