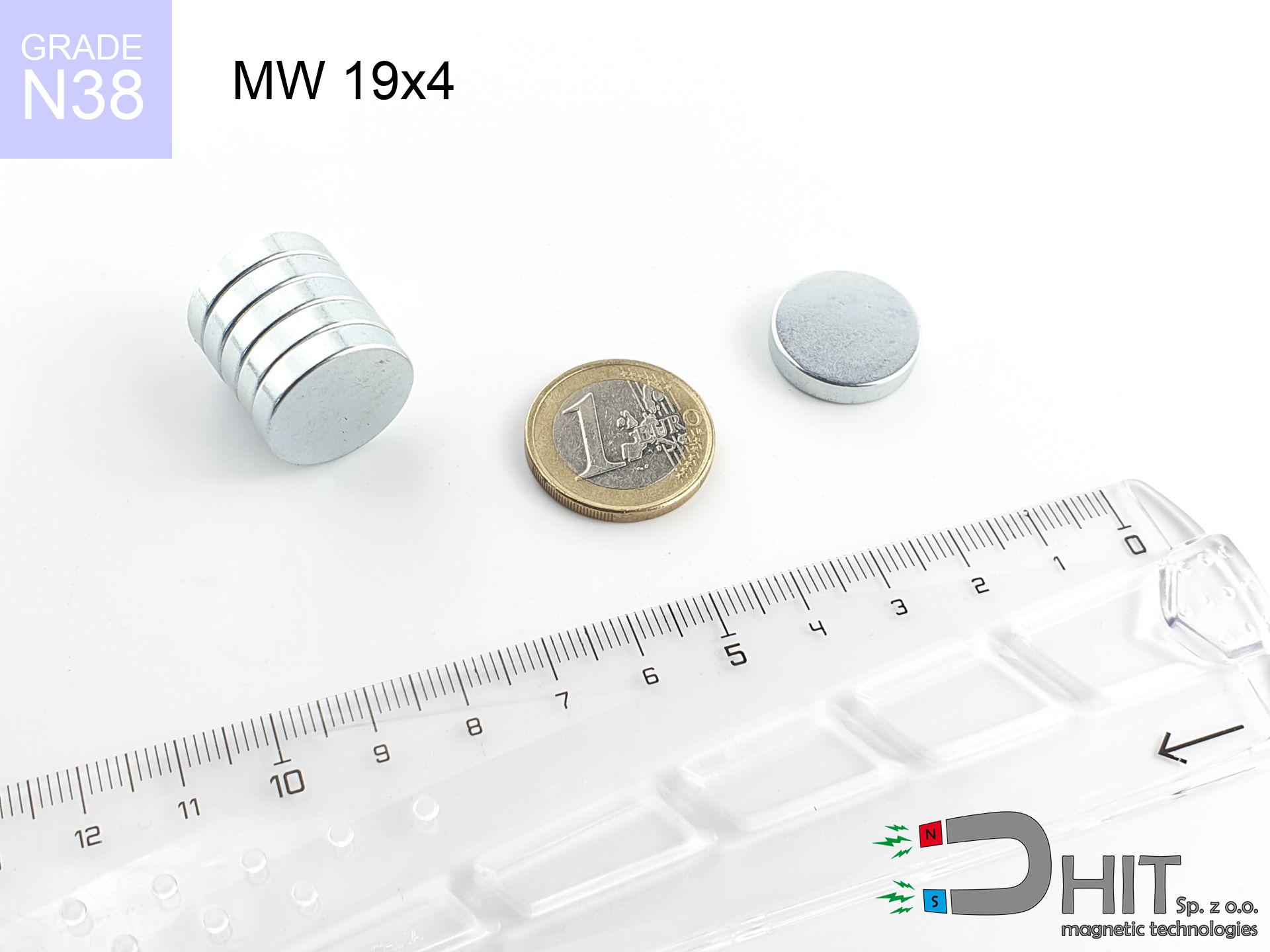

MW 19x4 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010038

GTIN/EAN: 5906301810377

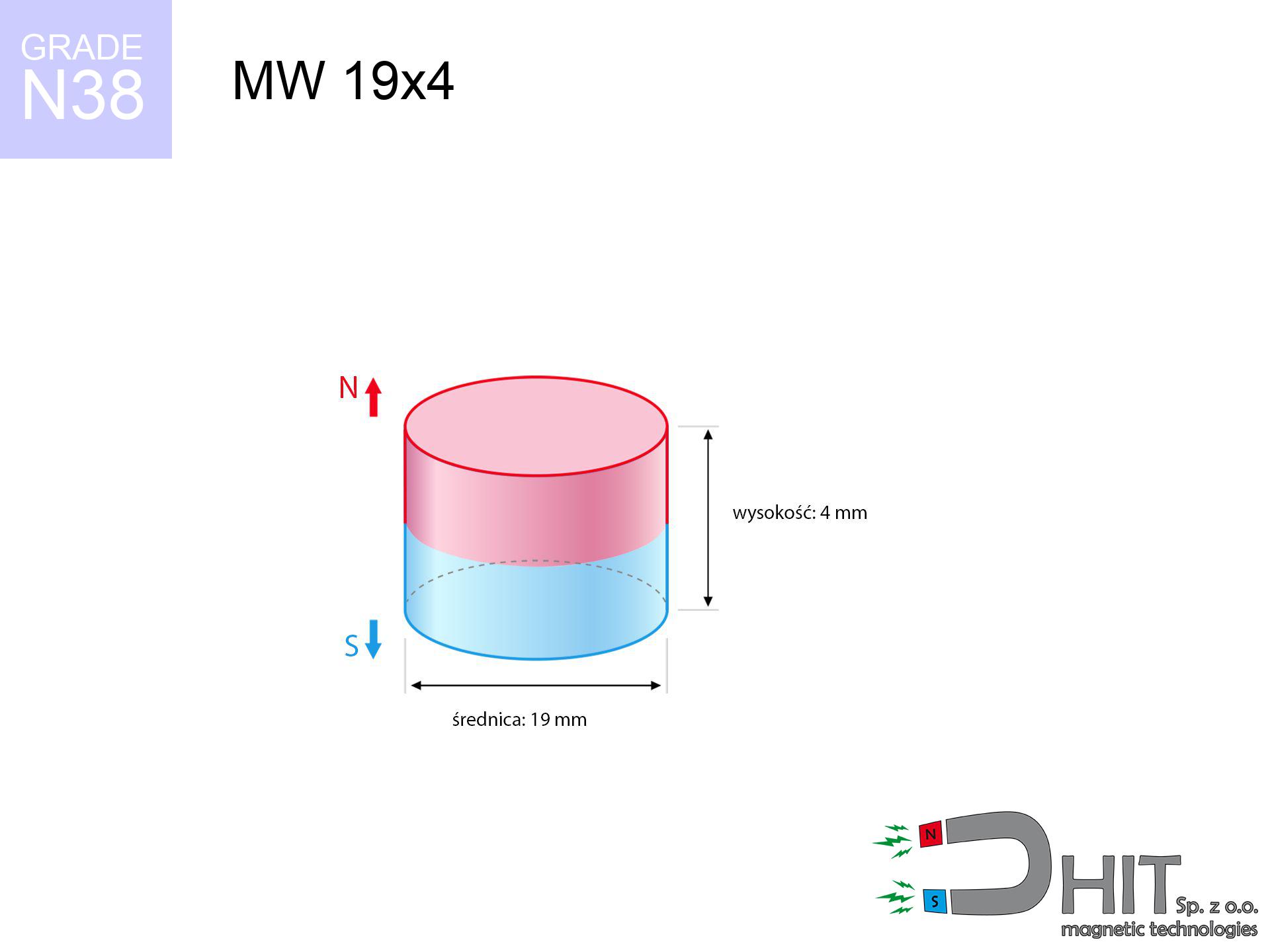

Diameter Ø

19 mm [±0,1 mm]

Height

4 mm [±0,1 mm]

Weight

8.51 g

Magnetization Direction

↑ axial

Load capacity

4.96 kg / 48.62 N

Magnetic Induction

240.51 mT / 2405 Gs

Coating

[Zn] Zinc

4.80 ZŁ with VAT / pcs + price for transport

3.90 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Call us

+48 888 99 98 98

if you prefer send us a note by means of

our online form

the contact section.

Lifting power and form of a neodymium magnet can be calculated using our

power calculator.

Orders placed before 14:00 will be shipped the same business day.

Technical data - MW 19x4 / N38 - cylindrical magnet

Specification / characteristics - MW 19x4 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010038 |

| GTIN/EAN | 5906301810377 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 19 mm [±0,1 mm] |

| Height | 4 mm [±0,1 mm] |

| Weight | 8.51 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 4.96 kg / 48.62 N |

| Magnetic Induction ~ ? | 240.51 mT / 2405 Gs |

| Coating | [Zn] Zinc |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering modeling of the assembly - report

Presented data constitute the result of a physical simulation. Values were calculated on algorithms for the class Nd2Fe14B. Real-world conditions may differ. Treat these calculations as a supplementary guide for designers.

Table 1: Static pull force (pull vs distance) - characteristics

MW 19x4 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

2405 Gs

240.5 mT

|

4.96 kg / 10.93 LBS

4960.0 g / 48.7 N

|

medium risk |

| 1 mm |

2239 Gs

223.9 mT

|

4.30 kg / 9.48 LBS

4299.0 g / 42.2 N

|

medium risk |

| 2 mm |

2033 Gs

203.3 mT

|

3.55 kg / 7.82 LBS

3547.4 g / 34.8 N

|

medium risk |

| 3 mm |

1811 Gs

181.1 mT

|

2.81 kg / 6.20 LBS

2813.0 g / 27.6 N

|

medium risk |

| 5 mm |

1376 Gs

137.6 mT

|

1.63 kg / 3.58 LBS

1625.2 g / 15.9 N

|

weak grip |

| 10 mm |

635 Gs

63.5 mT

|

0.35 kg / 0.76 LBS

346.3 g / 3.4 N

|

weak grip |

| 15 mm |

308 Gs

30.8 mT

|

0.08 kg / 0.18 LBS

81.2 g / 0.8 N

|

weak grip |

| 20 mm |

164 Gs

16.4 mT

|

0.02 kg / 0.05 LBS

23.2 g / 0.2 N

|

weak grip |

| 30 mm |

61 Gs

6.1 mT

|

0.00 kg / 0.01 LBS

3.1 g / 0.0 N

|

weak grip |

| 50 mm |

15 Gs

1.5 mT

|

0.00 kg / 0.00 LBS

0.2 g / 0.0 N

|

weak grip |

Table 2: Vertical force (wall)

MW 19x4 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.99 kg / 2.19 LBS

992.0 g / 9.7 N

|

| 1 mm | Stal (~0.2) |

0.86 kg / 1.90 LBS

860.0 g / 8.4 N

|

| 2 mm | Stal (~0.2) |

0.71 kg / 1.57 LBS

710.0 g / 7.0 N

|

| 3 mm | Stal (~0.2) |

0.56 kg / 1.24 LBS

562.0 g / 5.5 N

|

| 5 mm | Stal (~0.2) |

0.33 kg / 0.72 LBS

326.0 g / 3.2 N

|

| 10 mm | Stal (~0.2) |

0.07 kg / 0.15 LBS

70.0 g / 0.7 N

|

| 15 mm | Stal (~0.2) |

0.02 kg / 0.04 LBS

16.0 g / 0.2 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.01 LBS

4.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 LBS

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - behavior on slippery surfaces

MW 19x4 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

1.49 kg / 3.28 LBS

1488.0 g / 14.6 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.99 kg / 2.19 LBS

992.0 g / 9.7 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.50 kg / 1.09 LBS

496.0 g / 4.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

2.48 kg / 5.47 LBS

2480.0 g / 24.3 N

|

Table 4: Material efficiency (saturation) - sheet metal selection

MW 19x4 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.50 kg / 1.09 LBS

496.0 g / 4.9 N

|

| 1 mm |

|

1.24 kg / 2.73 LBS

1240.0 g / 12.2 N

|

| 2 mm |

|

2.48 kg / 5.47 LBS

2480.0 g / 24.3 N

|

| 3 mm |

|

3.72 kg / 8.20 LBS

3720.0 g / 36.5 N

|

| 5 mm |

|

4.96 kg / 10.93 LBS

4960.0 g / 48.7 N

|

| 10 mm |

|

4.96 kg / 10.93 LBS

4960.0 g / 48.7 N

|

| 11 mm |

|

4.96 kg / 10.93 LBS

4960.0 g / 48.7 N

|

| 12 mm |

|

4.96 kg / 10.93 LBS

4960.0 g / 48.7 N

|

Table 5: Working in heat (material behavior) - power drop

MW 19x4 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

4.96 kg / 10.93 LBS

4960.0 g / 48.7 N

|

OK |

| 40 °C | -2.2% |

4.85 kg / 10.69 LBS

4850.9 g / 47.6 N

|

OK |

| 60 °C | -4.4% |

4.74 kg / 10.45 LBS

4741.8 g / 46.5 N

|

|

| 80 °C | -6.6% |

4.63 kg / 10.21 LBS

4632.6 g / 45.4 N

|

|

| 100 °C | -28.8% |

3.53 kg / 7.79 LBS

3531.5 g / 34.6 N

|

Table 6: Magnet-Magnet interaction (repulsion) - forces in the system

MW 19x4 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Lateral Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

10.11 kg / 22.28 LBS

3 990 Gs

|

1.52 kg / 3.34 LBS

1516 g / 14.9 N

|

N/A |

| 1 mm |

9.48 kg / 20.89 LBS

4 657 Gs

|

1.42 kg / 3.13 LBS

1421 g / 13.9 N

|

8.53 kg / 18.80 LBS

~0 Gs

|

| 2 mm |

8.76 kg / 19.31 LBS

4 477 Gs

|

1.31 kg / 2.90 LBS

1314 g / 12.9 N

|

7.88 kg / 17.38 LBS

~0 Gs

|

| 3 mm |

8.00 kg / 17.64 LBS

4 279 Gs

|

1.20 kg / 2.65 LBS

1200 g / 11.8 N

|

7.20 kg / 15.88 LBS

~0 Gs

|

| 5 mm |

6.47 kg / 14.25 LBS

3 846 Gs

|

0.97 kg / 2.14 LBS

970 g / 9.5 N

|

5.82 kg / 12.83 LBS

~0 Gs

|

| 10 mm |

3.31 kg / 7.30 LBS

2 753 Gs

|

0.50 kg / 1.10 LBS

497 g / 4.9 N

|

2.98 kg / 6.57 LBS

~0 Gs

|

| 20 mm |

0.71 kg / 1.56 LBS

1 271 Gs

|

0.11 kg / 0.23 LBS

106 g / 1.0 N

|

0.64 kg / 1.40 LBS

~0 Gs

|

| 50 mm |

0.02 kg / 0.04 LBS

193 Gs

|

0.00 kg / 0.01 LBS

2 g / 0.0 N

|

0.01 kg / 0.03 LBS

~0 Gs

|

| 60 mm |

0.01 kg / 0.01 LBS

121 Gs

|

0.00 kg / 0.00 LBS

1 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 70 mm |

0.00 kg / 0.01 LBS

81 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 LBS

56 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 LBS

41 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 LBS

30 Gs

|

0.00 kg / 0.00 LBS

0 g / 0.0 N

|

0.00 kg / 0.00 LBS

~0 Gs

|

Table 7: Hazards (implants) - warnings

MW 19x4 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 7.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 6.0 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 5.0 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 4.0 cm |

| Car key | 50 Gs (5.0 mT) | 3.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.5 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.5 cm |

Table 8: Dynamics (kinetic energy) - warning

MW 19x4 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

25.39 km/h

(7.05 m/s)

|

0.21 J | |

| 30 mm |

42.19 km/h

(11.72 m/s)

|

0.58 J | |

| 50 mm |

54.44 km/h

(15.12 m/s)

|

0.97 J | |

| 100 mm |

76.99 km/h

(21.39 m/s)

|

1.95 J |

Table 9: Anti-corrosion coating durability

MW 19x4 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [Zn] Zinc |

| Layer structure | Zn (Zinc) |

| Layer thickness | 8-15 µm |

| Salt spray test (SST) ? | 48 h |

| Recommended environment | Indoors / Garage |

Table 10: Construction data (Flux)

MW 19x4 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 7 831 Mx | 78.3 µWb |

| Pc Coefficient | 0.30 | Low (Flat) |

Table 11: Physics of underwater searching

MW 19x4 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 4.96 kg | Standard |

| Water (riverbed) |

5.68 kg

(+0.72 kg buoyancy gain)

|

+14.5% |

1. Sliding resistance

*Caution: On a vertical surface, the magnet holds only a fraction of its nominal pull.

2. Steel saturation

*Thin metal sheet (e.g. 0.5mm PC case) significantly limits the holding force.

3. Temperature resistance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.30

The chart above illustrates the magnetic characteristics of the material within the second quadrant of the hysteresis loop. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Material specification

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Environmental data

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Other offers

Advantages as well as disadvantages of neodymium magnets.

Advantages

- They do not lose magnetism, even over nearly ten years – the drop in power is only ~1% (based on measurements),

- They feature excellent resistance to magnetic field loss when exposed to external fields,

- In other words, due to the glossy surface of gold, the element gains visual value,

- Magnets exhibit very high magnetic induction on the active area,

- Thanks to resistance to high temperature, they are capable of working (depending on the form) even at temperatures up to 230°C and higher...

- Possibility of accurate shaping and adjusting to complex applications,

- Wide application in innovative solutions – they are utilized in data components, electric motors, medical devices, and modern systems.

- Compactness – despite small sizes they provide effective action, making them ideal for precision applications

Disadvantages

- They are prone to damage upon heavy impacts. To avoid cracks, it is worth protecting magnets using a steel holder. Such protection not only protects the magnet but also improves its resistance to damage

- Neodymium magnets lose their force under the influence of heating. As soon as 80°C is exceeded, many of them start losing their power. Therefore, we recommend our special magnets marked [AH], which maintain stability even at temperatures up to 230°C

- Magnets exposed to a humid environment can rust. Therefore during using outdoors, we suggest using waterproof magnets made of rubber, plastic or other material protecting against moisture

- We recommend casing - magnetic mount, due to difficulties in producing nuts inside the magnet and complex shapes.

- Health risk to health – tiny shards of magnets can be dangerous, in case of ingestion, which is particularly important in the context of child health protection. Additionally, tiny parts of these magnets are able to be problematic in diagnostics medical when they are in the body.

- Higher cost of purchase is a significant factor to consider compared to ceramic magnets, especially in budget applications

Pull force analysis

Maximum lifting force for a neodymium magnet – what it depends on?

- on a plate made of structural steel, effectively closing the magnetic field

- with a thickness no less than 10 mm

- with an ground touching surface

- without the slightest insulating layer between the magnet and steel

- during pulling in a direction vertical to the mounting surface

- in neutral thermal conditions

Impact of factors on magnetic holding capacity in practice

- Distance (betwixt the magnet and the plate), because even a microscopic distance (e.g. 0.5 mm) can cause a reduction in force by up to 50% (this also applies to varnish, rust or debris).

- Pull-off angle – note that the magnet holds strongest perpendicularly. Under sliding down, the holding force drops significantly, often to levels of 20-30% of the nominal value.

- Plate thickness – too thin plate does not accept the full field, causing part of the flux to be lost to the other side.

- Metal type – not every steel reacts the same. High carbon content weaken the attraction effect.

- Surface finish – ideal contact is obtained only on polished steel. Any scratches and bumps create air cushions, reducing force.

- Temperature influence – high temperature reduces pulling force. Exceeding the limit temperature can permanently damage the magnet.

Holding force was measured on the plate surface of 20 mm thickness, when the force acted perpendicularly, however under attempts to slide the magnet the lifting capacity is smaller. Additionally, even a minimal clearance between the magnet and the plate reduces the load capacity.

Warnings

Bodily injuries

Danger of trauma: The attraction force is so great that it can cause hematomas, crushing, and broken bones. Use thick gloves.

Cards and drives

Equipment safety: Neodymium magnets can ruin data carriers and sensitive devices (pacemakers, hearing aids, timepieces).

Avoid contact if allergic

Allergy Notice: The nickel-copper-nickel coating contains nickel. If redness occurs, cease working with magnets and wear gloves.

Fragile material

Beware of splinters. Magnets can explode upon uncontrolled impact, ejecting sharp fragments into the air. Eye protection is mandatory.

Flammability

Powder produced during cutting of magnets is flammable. Avoid drilling into magnets unless you are an expert.

Caution required

Be careful. Rare earth magnets act from a distance and snap with huge force, often quicker than you can move away.

Phone sensors

GPS units and smartphones are highly sensitive to magnetic fields. Close proximity with a strong magnet can permanently damage the internal compass in your phone.

Warning for heart patients

Medical warning: Neodymium magnets can turn off pacemakers and defibrillators. Do not approach if you have electronic implants.

Swallowing risk

Absolutely store magnets away from children. Choking hazard is high, and the effects of magnets clamping inside the body are fatal.

Operating temperature

Regular neodymium magnets (N-type) lose power when the temperature goes above 80°C. This process is irreversible.