MW 18x1.5 / N38 - cylindrical magnet

cylindrical magnet

Catalog no 010037

GTIN/EAN: 5906301810360

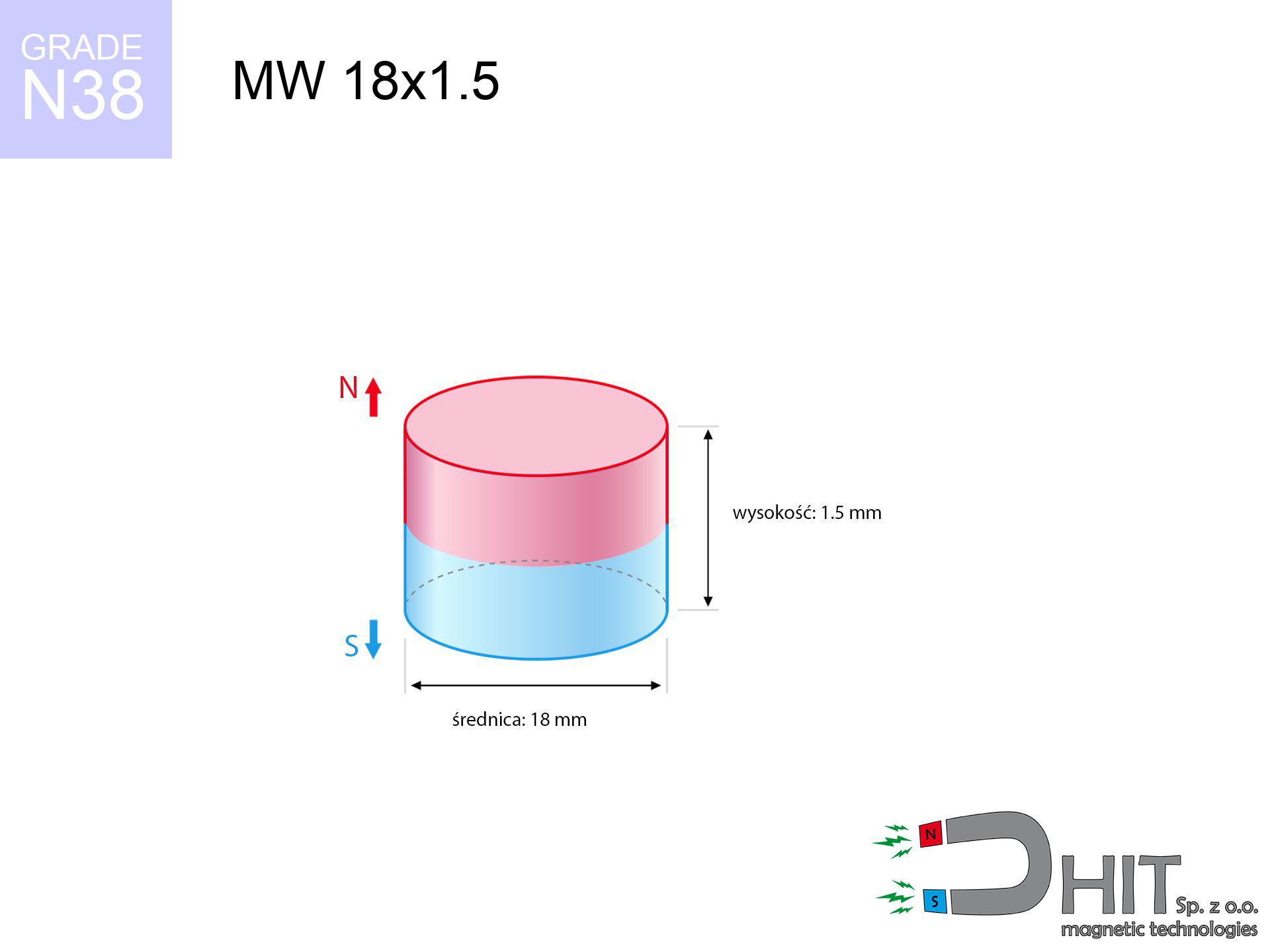

Diameter Ø

18 mm [±0,1 mm]

Height

1.5 mm [±0,1 mm]

Weight

2.86 g

Magnetization Direction

↑ axial

Load capacity

0.95 kg / 9.34 N

Magnetic Induction

101.91 mT / 1019 Gs

Coating

[NiCuNi] Nickel

1.353 ZŁ with VAT / pcs + price for transport

1.100 ZŁ net + 23% VAT / pcs

bulk discounts:

Need more?

Contact us by phone

+48 22 499 98 98

or send us a note via

request form

the contact section.

Weight as well as structure of neodymium magnets can be verified with our

force calculator.

Order by 14:00 and we’ll ship today!

Detailed specification - MW 18x1.5 / N38 - cylindrical magnet

Specification / characteristics - MW 18x1.5 / N38 - cylindrical magnet

| properties | values |

|---|---|

| Cat. no. | 010037 |

| GTIN/EAN | 5906301810360 |

| Production/Distribution | Dhit sp. z o.o. |

| Country of origin | Poland / China / Germany |

| Customs code | 85059029 |

| Diameter Ø | 18 mm [±0,1 mm] |

| Height | 1.5 mm [±0,1 mm] |

| Weight | 2.86 g |

| Magnetization Direction | ↑ axial |

| Load capacity ~ ? | 0.95 kg / 9.34 N |

| Magnetic Induction ~ ? | 101.91 mT / 1019 Gs |

| Coating | [NiCuNi] Nickel |

| Manufacturing Tolerance | ±0.1 mm |

Magnetic properties of material N38

| properties | values | units |

|---|---|---|

| remenance Br [min. - max.] ? | 12.2-12.6 | kGs |

| remenance Br [min. - max.] ? | 1220-1260 | mT |

| coercivity bHc ? | 10.8-11.5 | kOe |

| coercivity bHc ? | 860-915 | kA/m |

| actual internal force iHc | ≥ 12 | kOe |

| actual internal force iHc | ≥ 955 | kA/m |

| energy density [min. - max.] ? | 36-38 | BH max MGOe |

| energy density [min. - max.] ? | 287-303 | BH max KJ/m |

| max. temperature ? | ≤ 80 | °C |

Physical properties of sintered neodymium magnets Nd2Fe14B at 20°C

| properties | values | units |

|---|---|---|

| Vickers hardness | ≥550 | Hv |

| Density | ≥7.4 | g/cm3 |

| Curie Temperature TC | 312 - 380 | °C |

| Curie Temperature TF | 593 - 716 | °F |

| Specific resistance | 150 | μΩ⋅cm |

| Bending strength | 250 | MPa |

| Compressive strength | 1000~1100 | MPa |

| Thermal expansion parallel (∥) to orientation (M) | (3-4) x 10-6 | °C-1 |

| Thermal expansion perpendicular (⊥) to orientation (M) | -(1-3) x 10-6 | °C-1 |

| Young's modulus | 1.7 x 104 | kg/mm² |

Engineering simulation of the assembly - report

These data are the result of a engineering calculation. Values rely on models for the class Nd2Fe14B. Actual performance might slightly differ from theoretical values. Please consider these calculations as a supplementary guide for designers.

Table 1: Static force (force vs gap) - power drop

MW 18x1.5 / N38

| Distance (mm) | Induction (Gauss) / mT | Pull Force (kg/lbs/g/N) | Risk Status |

|---|---|---|---|

| 0 mm |

1019 Gs

101.9 mT

|

0.95 kg / 2.09 pounds

950.0 g / 9.3 N

|

low risk |

| 1 mm |

975 Gs

97.5 mT

|

0.87 kg / 1.92 pounds

869.2 g / 8.5 N

|

low risk |

| 2 mm |

902 Gs

90.2 mT

|

0.74 kg / 1.64 pounds

744.7 g / 7.3 N

|

low risk |

| 3 mm |

812 Gs

81.2 mT

|

0.60 kg / 1.33 pounds

603.4 g / 5.9 N

|

low risk |

| 5 mm |

619 Gs

61.9 mT

|

0.35 kg / 0.77 pounds

350.6 g / 3.4 N

|

low risk |

| 10 mm |

274 Gs

27.4 mT

|

0.07 kg / 0.15 pounds

68.7 g / 0.7 N

|

low risk |

| 15 mm |

126 Gs

12.6 mT

|

0.01 kg / 0.03 pounds

14.6 g / 0.1 N

|

low risk |

| 20 mm |

65 Gs

6.5 mT

|

0.00 kg / 0.01 pounds

3.9 g / 0.0 N

|

low risk |

| 30 mm |

23 Gs

2.3 mT

|

0.00 kg / 0.00 pounds

0.5 g / 0.0 N

|

low risk |

| 50 mm |

6 Gs

0.6 mT

|

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

low risk |

Table 2: Vertical force (vertical surface)

MW 18x1.5 / N38

| Distance (mm) | Friction coefficient | Pull Force (kg/lbs/g/N) |

|---|---|---|

| 0 mm | Stal (~0.2) |

0.19 kg / 0.42 pounds

190.0 g / 1.9 N

|

| 1 mm | Stal (~0.2) |

0.17 kg / 0.38 pounds

174.0 g / 1.7 N

|

| 2 mm | Stal (~0.2) |

0.15 kg / 0.33 pounds

148.0 g / 1.5 N

|

| 3 mm | Stal (~0.2) |

0.12 kg / 0.26 pounds

120.0 g / 1.2 N

|

| 5 mm | Stal (~0.2) |

0.07 kg / 0.15 pounds

70.0 g / 0.7 N

|

| 10 mm | Stal (~0.2) |

0.01 kg / 0.03 pounds

14.0 g / 0.1 N

|

| 15 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

2.0 g / 0.0 N

|

| 20 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 30 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

| 50 mm | Stal (~0.2) |

0.00 kg / 0.00 pounds

0.0 g / 0.0 N

|

Table 3: Wall mounting (shearing) - vertical pull

MW 18x1.5 / N38

| Surface type | Friction coefficient / % Mocy | Max load (kg/lbs/g/N) |

|---|---|---|

| Raw steel |

µ = 0.3

30% Nominalnej Siły

|

0.29 kg / 0.63 pounds

285.0 g / 2.8 N

|

| Painted steel (standard) |

µ = 0.2

20% Nominalnej Siły

|

0.19 kg / 0.42 pounds

190.0 g / 1.9 N

|

| Oily/slippery steel |

µ = 0.1

10% Nominalnej Siły

|

0.10 kg / 0.21 pounds

95.0 g / 0.9 N

|

| Magnet with anti-slip rubber |

µ = 0.5

50% Nominalnej Siły

|

0.48 kg / 1.05 pounds

475.0 g / 4.7 N

|

Table 4: Steel thickness (substrate influence) - sheet metal selection

MW 18x1.5 / N38

| Steel thickness (mm) | % power | Real pull force (kg/lbs/g/N) |

|---|---|---|

| 0.5 mm |

|

0.10 kg / 0.21 pounds

95.0 g / 0.9 N

|

| 1 mm |

|

0.24 kg / 0.52 pounds

237.5 g / 2.3 N

|

| 2 mm |

|

0.48 kg / 1.05 pounds

475.0 g / 4.7 N

|

| 3 mm |

|

0.71 kg / 1.57 pounds

712.5 g / 7.0 N

|

| 5 mm |

|

0.95 kg / 2.09 pounds

950.0 g / 9.3 N

|

| 10 mm |

|

0.95 kg / 2.09 pounds

950.0 g / 9.3 N

|

| 11 mm |

|

0.95 kg / 2.09 pounds

950.0 g / 9.3 N

|

| 12 mm |

|

0.95 kg / 2.09 pounds

950.0 g / 9.3 N

|

Table 5: Working in heat (material behavior) - resistance threshold

MW 18x1.5 / N38

| Ambient temp. (°C) | Power loss | Remaining pull (kg/lbs/g/N) | Status |

|---|---|---|---|

| 20 °C | 0.0% |

0.95 kg / 2.09 pounds

950.0 g / 9.3 N

|

OK |

| 40 °C | -2.2% |

0.93 kg / 2.05 pounds

929.1 g / 9.1 N

|

OK |

| 60 °C | -4.4% |

0.91 kg / 2.00 pounds

908.2 g / 8.9 N

|

|

| 80 °C | -6.6% |

0.89 kg / 1.96 pounds

887.3 g / 8.7 N

|

|

| 100 °C | -28.8% |

0.68 kg / 1.49 pounds

676.4 g / 6.6 N

|

Table 6: Two magnets (attraction) - field range

MW 18x1.5 / N38

| Gap (mm) | Attraction (kg/lbs) (N-S) | Sliding Force (kg/lbs/g/N) | Repulsion (kg/lbs) (N-N) |

|---|---|---|---|

| 0 mm |

1.63 kg / 3.59 pounds

1 960 Gs

|

0.24 kg / 0.54 pounds

244 g / 2.4 N

|

N/A |

| 1 mm |

1.57 kg / 3.47 pounds

2 002 Gs

|

0.24 kg / 0.52 pounds

236 g / 2.3 N

|

1.41 kg / 3.12 pounds

~0 Gs

|

| 2 mm |

1.49 kg / 3.29 pounds

1 949 Gs

|

0.22 kg / 0.49 pounds

224 g / 2.2 N

|

1.34 kg / 2.96 pounds

~0 Gs

|

| 3 mm |

1.39 kg / 3.06 pounds

1 883 Gs

|

0.21 kg / 0.46 pounds

209 g / 2.0 N

|

1.25 kg / 2.76 pounds

~0 Gs

|

| 5 mm |

1.16 kg / 2.55 pounds

1 717 Gs

|

0.17 kg / 0.38 pounds

174 g / 1.7 N

|

1.04 kg / 2.30 pounds

~0 Gs

|

| 10 mm |

0.60 kg / 1.33 pounds

1 238 Gs

|

0.09 kg / 0.20 pounds

90 g / 0.9 N

|

0.54 kg / 1.19 pounds

~0 Gs

|

| 20 mm |

0.12 kg / 0.26 pounds

548 Gs

|

0.02 kg / 0.04 pounds

18 g / 0.2 N

|

0.11 kg / 0.23 pounds

~0 Gs

|

| 50 mm |

0.00 kg / 0.00 pounds

74 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 60 mm |

0.00 kg / 0.00 pounds

46 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 70 mm |

0.00 kg / 0.00 pounds

30 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 80 mm |

0.00 kg / 0.00 pounds

21 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 90 mm |

0.00 kg / 0.00 pounds

15 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

| 100 mm |

0.00 kg / 0.00 pounds

11 Gs

|

0.00 kg / 0.00 pounds

0 g / 0.0 N

|

0.00 kg / 0.00 pounds

~0 Gs

|

Table 7: Safety (HSE) (electronics) - precautionary measures

MW 18x1.5 / N38

| Object / Device | Limit (Gauss) / mT | Safe distance |

|---|---|---|

| Pacemaker | 5 Gs (0.5 mT) | 5.5 cm |

| Hearing aid | 10 Gs (1.0 mT) | 4.5 cm |

| Mechanical watch | 20 Gs (2.0 mT) | 3.5 cm |

| Phone / Smartphone | 40 Gs (4.0 mT) | 2.5 cm |

| Remote | 50 Gs (5.0 mT) | 2.5 cm |

| Payment card | 400 Gs (40.0 mT) | 1.0 cm |

| HDD hard drive | 600 Gs (60.0 mT) | 1.0 cm |

Table 8: Impact energy (cracking risk) - collision effects

MW 18x1.5 / N38

| Start from (mm) | Speed (km/h) | Energy (J) | Predicted outcome |

|---|---|---|---|

| 10 mm |

19.19 km/h

(5.33 m/s)

|

0.04 J | |

| 30 mm |

31.85 km/h

(8.85 m/s)

|

0.11 J | |

| 50 mm |

41.10 km/h

(11.42 m/s)

|

0.19 J | |

| 100 mm |

58.12 km/h

(16.15 m/s)

|

0.37 J |

Table 9: Surface protection spec

MW 18x1.5 / N38

| Technical parameter | Value / Description |

|---|---|

| Coating type | [NiCuNi] Nickel |

| Layer structure | Nickel - Copper - Nickel |

| Layer thickness | 10-20 µm |

| Salt spray test (SST) ? | 24 h |

| Recommended environment | Indoors only (dry) |

Table 10: Electrical data (Flux)

MW 18x1.5 / N38

| Parameter | Value | SI Unit / Description |

|---|---|---|

| Magnetic Flux | 3 519 Mx | 35.2 µWb |

| Pc Coefficient | 0.13 | Low (Flat) |

Table 11: Physics of underwater searching

MW 18x1.5 / N38

| Environment | Effective steel pull | Effect |

|---|---|---|

| Air (land) | 0.95 kg | Standard |

| Water (riverbed) |

1.09 kg

(+0.14 kg buoyancy gain)

|

+14.5% |

1. Wall mount (shear)

*Note: On a vertical surface, the magnet holds only ~20% of its max power.

2. Steel thickness impact

*Thin steel (e.g. computer case) drastically limits the holding force.

3. Heat tolerance

*For N38 material, the critical limit is 80°C.

4. Demagnetization curve and operating point (B-H)

chart generated for the permeance coefficient Pc (Permeance Coefficient) = 0.13

This simulation demonstrates the magnetic stability of the selected magnet under specific geometric conditions. The solid red line represents the demagnetization curve (material potential), while the dashed blue line is the load line based on the magnet's geometry. The Pc (Permeance Coefficient), also known as the load line slope, is a dimensionless value that describes the relationship between the magnet's shape and its magnetic stability. The intersection of these two lines (the black dot) is the operating point — it determines the actual magnetic flux density generated by the magnet in this specific configuration. A higher Pc value means the magnet is more 'slender' (tall relative to its area), resulting in a higher operating point and better resistance to irreversible demagnetization caused by external fields or temperature. A value of 0.42 is relatively low (typical for flat magnets), meaning the operating point is closer to the 'knee' of the curve — caution is advised when operating at temperatures near the maximum limit to avoid strength loss.

Chemical composition

| iron (Fe) | 64% – 68% |

| neodymium (Nd) | 29% – 32% |

| boron (B) | 1.1% – 1.2% |

| dysprosium (Dy) | 0.5% – 2.0% |

| coating (Ni-Cu-Ni) | < 0.05% |

Sustainability

| recyclability (EoL) | 100% |

| recycled raw materials | ~10% (pre-cons) |

| carbon footprint | low / zredukowany |

| waste code (EWC) | 16 02 16 |

Check out also offers

Advantages as well as disadvantages of rare earth magnets.

Pros

- They retain magnetic properties for nearly ten years – the loss is just ~1% (in theory),

- They are noted for resistance to demagnetization induced by external disturbances,

- By using a lustrous layer of silver, the element gains an proper look,

- Neodymium magnets generate maximum magnetic induction on a contact point, which allows for strong attraction,

- Thanks to resistance to high temperature, they are capable of working (depending on the form) even at temperatures up to 230°C and higher...

- Possibility of exact modeling and adapting to concrete conditions,

- Wide application in modern industrial fields – they find application in mass storage devices, electric motors, medical devices, also modern systems.

- Relatively small size with high pulling force – neodymium magnets offer strong magnetic field in compact dimensions, which makes them useful in miniature devices

Cons

- Susceptibility to cracking is one of their disadvantages. Upon intense impact they can fracture. We advise keeping them in a strong case, which not only protects them against impacts but also increases their durability

- When exposed to high temperature, neodymium magnets suffer a drop in force. Often, when the temperature exceeds 80°C, their strength decreases (depending on the size and shape of the magnet). For those who need magnets for extreme conditions, we offer [AH] versions withstanding up to 230°C

- Due to the susceptibility of magnets to corrosion in a humid environment, we advise using waterproof magnets made of rubber, plastic or other material stable to moisture, when using outdoors

- Due to limitations in creating threads and complex shapes in magnets, we propose using casing - magnetic holder.

- Health risk resulting from small fragments of magnets can be dangerous, when accidentally swallowed, which is particularly important in the context of child health protection. It is also worth noting that tiny parts of these products can complicate diagnosis medical when they are in the body.

- With mass production the cost of neodymium magnets can be a barrier,

Holding force characteristics

Breakaway strength of the magnet in ideal conditions – what affects it?

- with the application of a yoke made of special test steel, ensuring full magnetic saturation

- whose transverse dimension reaches at least 10 mm

- with a surface free of scratches

- without the slightest insulating layer between the magnet and steel

- for force applied at a right angle (in the magnet axis)

- in stable room temperature

Lifting capacity in real conditions – factors

- Clearance – existence of foreign body (rust, dirt, gap) interrupts the magnetic circuit, which reduces power rapidly (even by 50% at 0.5 mm).

- Angle of force application – highest force is reached only during pulling at a 90° angle. The shear force of the magnet along the surface is standardly several times lower (approx. 1/5 of the lifting capacity).

- Element thickness – to utilize 100% power, the steel must be adequately massive. Paper-thin metal restricts the lifting capacity (the magnet "punches through" it).

- Chemical composition of the base – mild steel attracts best. Alloy admixtures decrease magnetic properties and lifting capacity.

- Plate texture – ground elements ensure maximum contact, which improves force. Uneven metal weaken the grip.

- Thermal factor – hot environment reduces magnetic field. Exceeding the limit temperature can permanently damage the magnet.

Lifting capacity testing was conducted on plates with a smooth surface of optimal thickness, under perpendicular forces, in contrast under parallel forces the lifting capacity is smaller. Moreover, even a slight gap between the magnet’s surface and the plate reduces the lifting capacity.

Safety rules for work with NdFeB magnets

Maximum temperature

Regular neodymium magnets (N-type) lose magnetization when the temperature goes above 80°C. Damage is permanent.

Shattering risk

Watch out for shards. Magnets can explode upon uncontrolled impact, launching shards into the air. We recommend safety glasses.

Magnetic media

Powerful magnetic fields can destroy records on payment cards, HDDs, and storage devices. Stay away of min. 10 cm.

Magnetic interference

Navigation devices and smartphones are extremely sensitive to magnetic fields. Close proximity with a strong magnet can permanently damage the sensors in your phone.

Do not drill into magnets

Dust produced during grinding of magnets is combustible. Avoid drilling into magnets unless you are an expert.

Crushing force

Danger of trauma: The pulling power is so great that it can cause hematomas, crushing, and even bone fractures. Protective gloves are recommended.

Handling rules

Use magnets consciously. Their powerful strength can shock even experienced users. Plan your moves and respect their force.

Product not for children

Product intended for adults. Small elements can be swallowed, causing intestinal necrosis. Store away from kids and pets.

Sensitization to coating

Allergy Notice: The Ni-Cu-Ni coating contains nickel. If redness appears, immediately stop working with magnets and use protective gear.

Medical interference

Individuals with a ICD have to maintain an safe separation from magnets. The magnetism can disrupt the operation of the implant.

![SM 25x275 [2xM8] / N52 - magnetic separator SM 25x275 [2xM8] / N52 - magnetic separator](https://cdn3.dhit.pl/graphics/products/sm-25x275-2xm8-vih.jpg)